Planning the Installation

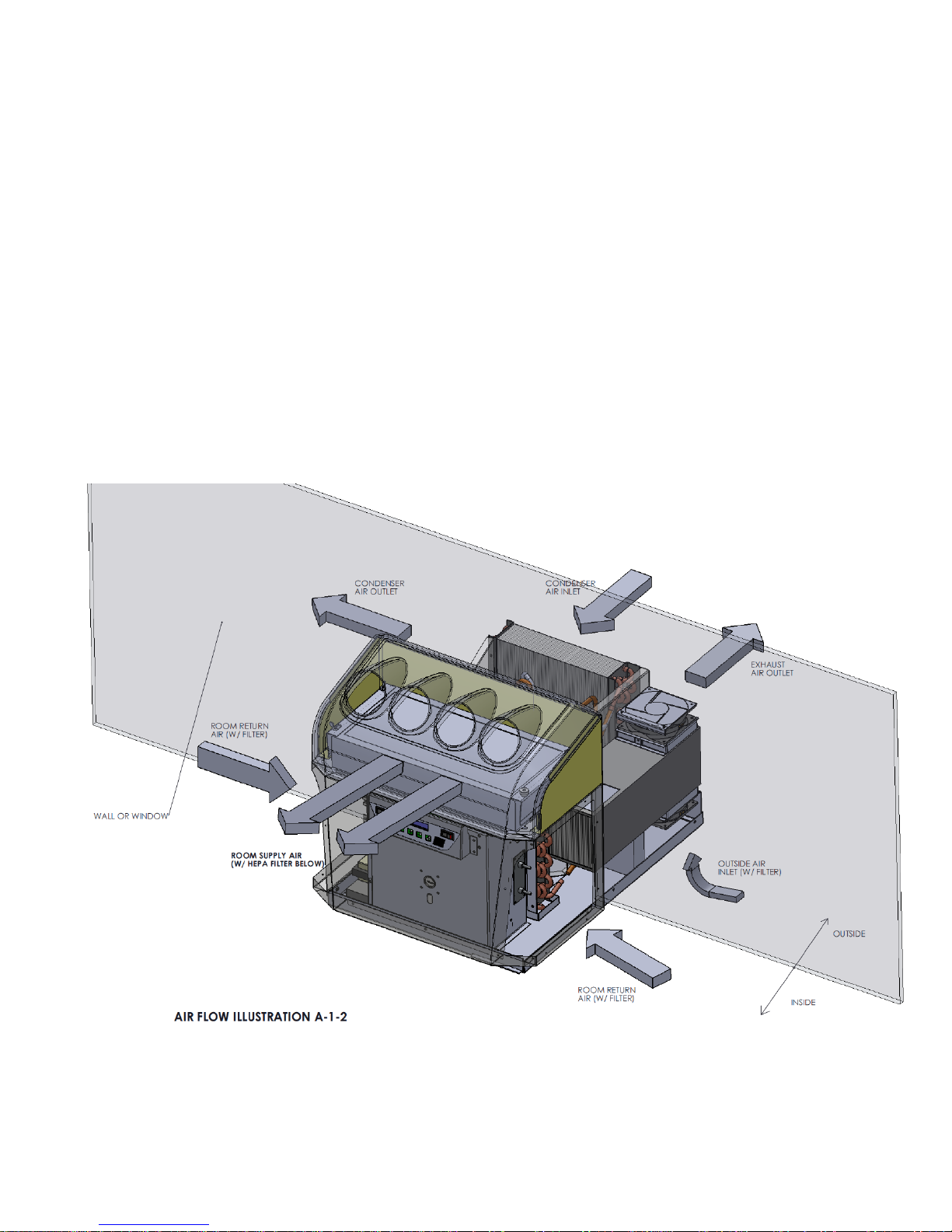

The HEPAirX units have been designed for single room applications. Although the units will

work in any room, they have been primarily designed for the bedroom where the occupants

spend much of their time with reduced activity. In order for the units to be most effective, it is

recommended that the door to the room be sealed with gasketing and floor sweeps to reduce the

infiltration of particulates from adjacent spaces. Also, the door to the room should be kept closed

most of the time but especially when there are other activities going on in other rooms, such as

cooking, cleaning or vacuuming. Any floor, ceiling or wall registers from a central heating or

air conditioning system should be closed and sealed off to prevent contaminating the room

from other spaces. Radiators or baseboard heating units may continue to operate normally.

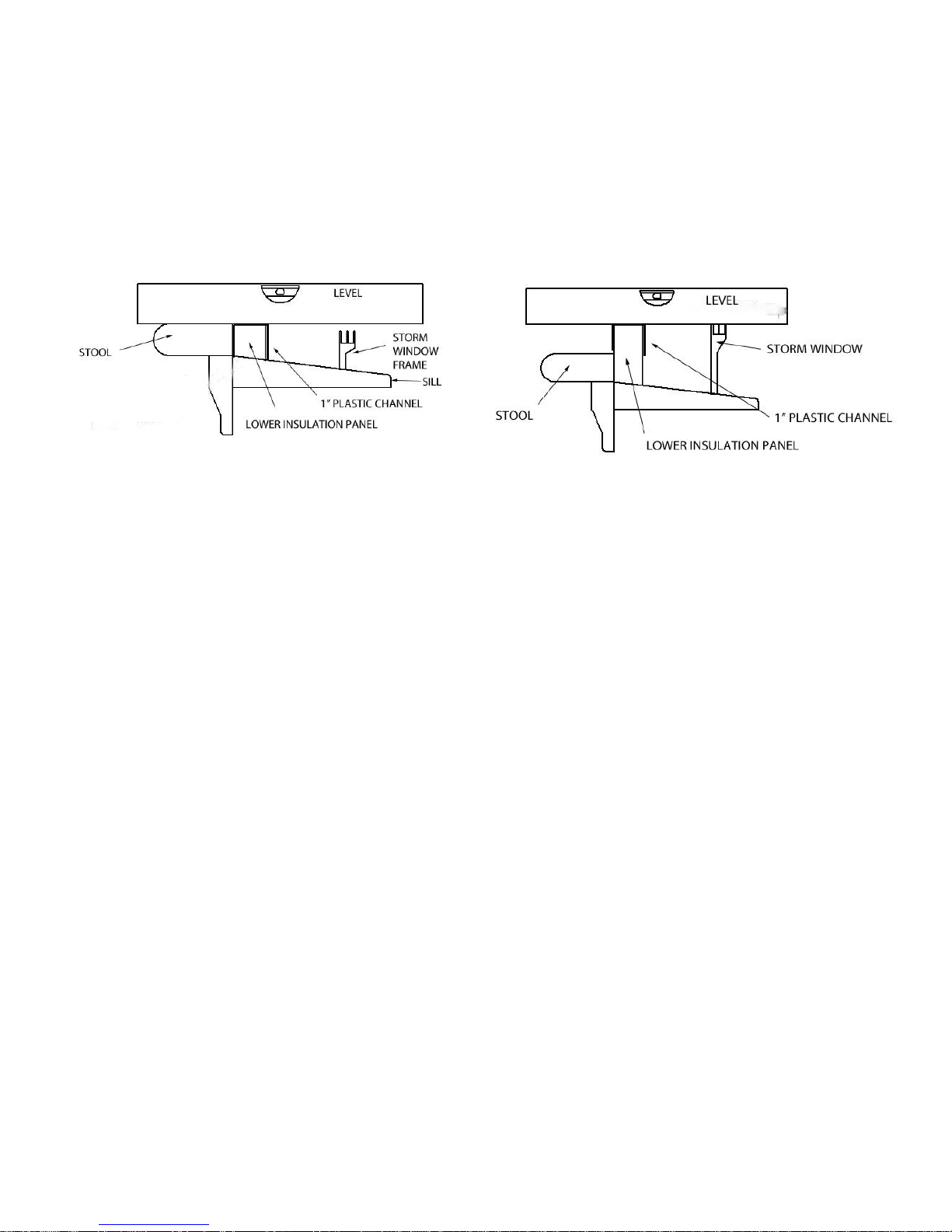

The HEPAirX unit needs to be installed in a window to the outside. Double hung-type windows

are the easiest to adapt to. Sliders and casement windows are also possible but require a more

complex installation procedure. It is possible to install the HEPAirX “through- the-wall,” but this

requires a carpenter to properly frame out the opening and seal around the unit. A standard 115-

volt, 3-prong electrical outlet is required (115v AC, 1 phase, 60 cycle). This outlet should be

dedicated only to HEPAirX operation. DO NOT overload circuits by plugging in multiple items.

If the outlet is more than 6 feet from the location of the unit, a UL-approved three-prong,

14-gauge extension cord should be used.

Pre-Installation

Immediately upon delivery, inspect the HEPAirX and any accessories for loose parts or

visible damage to the equipment or containers. Report any damage to the freight carrier

immediately. Do not proceed if there is visible damage to the box or unit.

Decide on the best window location for the unit, preferably in the center of a wall and in

a window where the sound of the unit and the dripping of the condensation will not

bother a neighbor. One that is also near an electrical power outlet.

NOTE: at minimum, the clear opening of the window must be at least 19.5” wide and

13.5” high. Add 2” to the minimum width if the window sleeve assembly will be used.

We recommend leaving the unit on the skid until ready to install. Materials to install the

window sleeve have been packed on top.

Unpack the unit and set it on the floor or a sturdy table.

CAUTION

The HEPAirX unit is heavy, weighing 118 lbs., and

should not be handled by one person alone.

The fins on the coil in the back of the unit are very sharp. Do not touch

or run your fingers down the coil surface.

Check the electrical power outlet by plugging in the unit. The light on the electronic user

interface panel should come on indicating the unit has power. Avoid exposing the power

or extension cord to wear or abuse, or being stepped on or tripped over.

Turn on the unit by pressing the ON/OFF button on the user interface on the front of the

unit.