Installation/Operation

Pressure Relief Procedure

WARNING

INJECTION

HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally

. Fluid

under high pressure can be injected through the

skin and cause serious injury

. T

o reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the

Pressure Relief Procedure

whenever you:

are instructed to relieve the pressure,

stop spraying,

check or service any of the system equipment,

or install or clean the spray tips.

1.

Lock the gun trigger safety

.

2.

Shut of

f the power supply to the pump. Close any

bleed-type master air valves.

3.

Unlock the gun trigger safety

.

4.

Hold a metal part of the gun firmly to the side of a

grounded metal pail, and trigger the gun to relieve

pressure.

5.

Lock the gun trigger safety

.

6.

Open the drain valve (required in your system),

having a container ready to catch the drainage.

7.

Leave the drain valve open until you are ready to

spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above,

very slowly

loosen the

tip guard retaining nut or hose end coupling and relieve

pressure gradually

, then loosen completely

. Now clear

the tip or hose.

System Requirements

WARNING

Be sure your system has a bleed-type master air

valve (pneumatic pumps only) and a pressure drain

valve. These accessories help reduce the risk of

serious bodily injury

, including fluid injection,

splashing in the eyes or on the skin, or injury from

moving parts, if you are adjusting or repairing the

pump or gun.

1.

The bleed-type master air valve

(air-powered

pumps only) relieves air trapped between this

valve and the pump after the air regulator is shut

off. T

rapped air can cause the pump to cycle

unexpectedly.

2.

The pressure drain valve

assists in relieving fluid

pressure in the displacement pump, hose and gun:

triggering the gun to relieve pressure may not be

sufficient.

3.

Strain the fluid you are spraying if it contains

particles which could clog the spray tip.

How to Use the Gun Trigger Safety

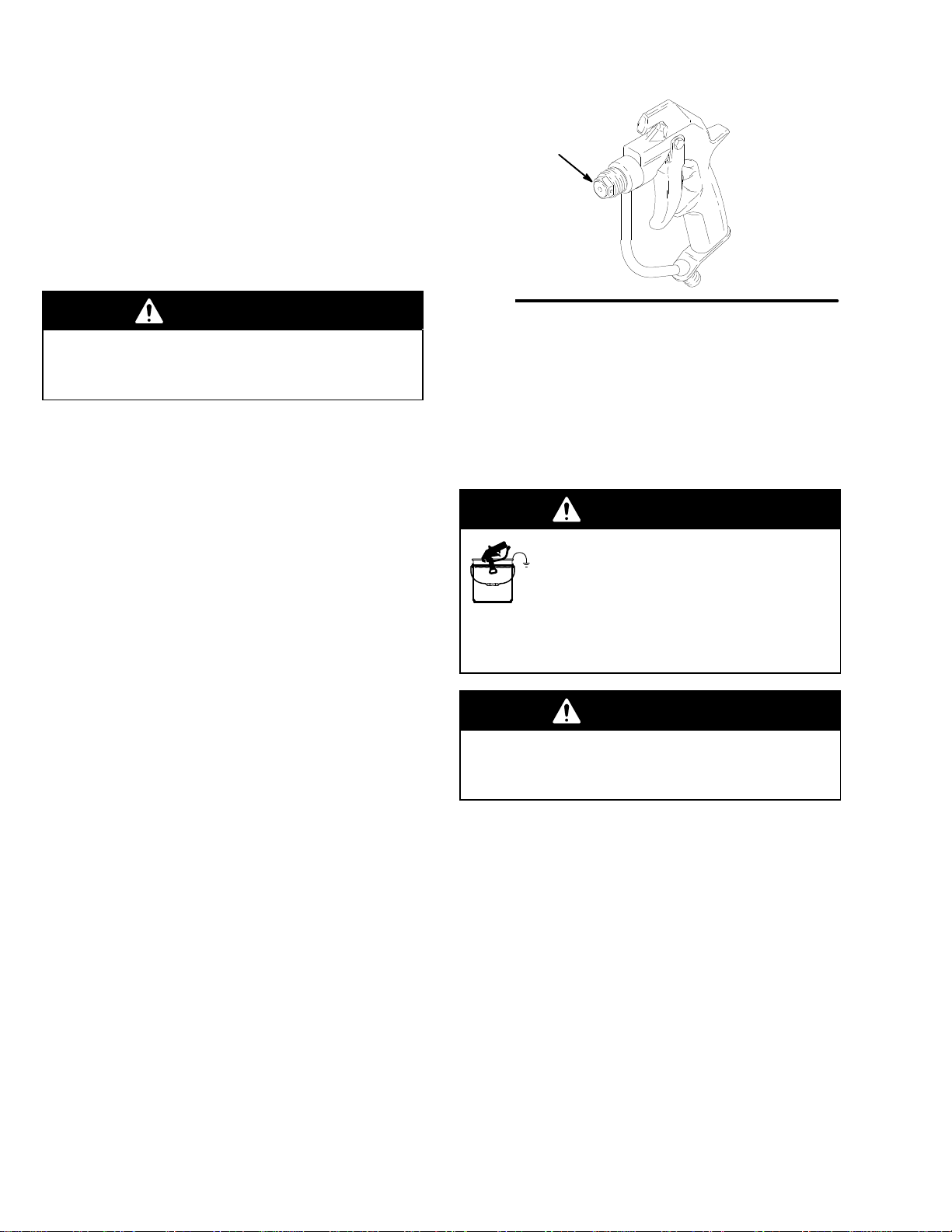

1. To

lock the gun trigger safety

, turn the latch to a

right angle with the gun body

. See Fig. 1.

2. T

o unlock the gun trigger safety

, push the latch out

and turn it parallel with the gun body

.

Fig. 1

The

trigger safety is shown

in

the locked position.

The

trigger safety is shown

in

the unlocked position.

5