4Copyright © 2005 - 2022 Airmar Technology Corp. All rights reserved.

4. Push the uncolored section of each threaded rod through the

fairing, the hull and the backing block until the washer rests inside

the recess in the fairing (Figure 6). With a person stationed inside

the vessel, secure each rod with a washer (bedded side against

the backing block) and double stainless steel nuts. Use a wrench

to hold the lower nut while tightening the top nut against it.

Aluminum hull—The top of the isolation sleeve must be below

the top of the backing block to prevent the sleeving from

interfering with tightening the nuts.

Wood hull—Allow the wood to swell before tightening the nuts.

Transducer: Bedding & Installing

1. Apply a 2mm (1/16") thick layer of marine sealant to the surface

of the transducer that will contact the fairing including the

recesses for the washers and nuts (Figure 8).

2. Thread the transducer cable through the stuffing tube.

3. Slide the transducer onto the threaded rods, being sure the

rounded bottom is facing forward toward the bow and the

temperature sensor is aft. Seat the transducer firmly within the

recess in the fairing. Secure the transducer in place by applying

a washer and a nylon locking nut to each threaded rod.

Tighten each nut with a torque wrench using a force not

exceeding 12N-m (10ft.-lb.). Then tighten each nut again using

a force not exceeding 27N-m (20ft.-lb.). Do not over tighten as it

may crack the transducer and/or crush the fairing. Be sure the

rods extend a minimum of 3 threads beyond the nut after

being tightened.

4. Plug the mounting holes to minimize turbulence on the surface

of the transducer. Be sure there is marine sealant on the

exposed threads of the rods. Cut the white foam plugs to length

so that when installed, each plug is recessed 5mm (3/16")

below the surface of the transducer. Push the foam plugs into

the holes. Use marine sealant to fill the remaining recess flush

with the transducer’s surface.

5. Remove excess marine sealant on the outside of the hull to

ensure smooth water flow under the transducer.

Sealing & Routing the Cable

To form a watertight seal inside the stuffing tube, follow the

installation instructions that came with your stuffing tube. The

completed installation will look like Figure 9.

1. Route the cable to the echosounder, being careful not to tear the

cable jacket when passing it through the bulkhead and other

parts of the boat. Use grommet(s) to prevent chafing. To reduce

electrical interference, separate the transducer cable from other

electrical wiring and the engine. Coil any excess cable and

secure it in place with cable ties to prevent damage.

2. Refer to your echosounder owners manual to connect the cable

to the instrument.

Checking for Leaks

When the boat is placed in the water, immediately check around

the threaded rods and the stuffing tube for leaks. Note that very

small leaks may not be readily observed. It is best not to leave the

boat in the water unattended for more than 3 hours before

rechecking. If there is a small leak, there may be considerable

bilge water accumulation after 24 hours. If a leak is observed,

repeat the bedding and installing procedures beginning on page 3

immediately.

Maintenance, Repair & Replacement

Antifouling Coating

Surfaces exposed to saltwater must be covered with an anti-

fouling coating. Use a water-based anti-fouling coating made for

transducers only. Never use ketone-based paint, since ketones

can attack many plastics possibly damaging the transducer. Brush

on anti-fouling coating every 6 months or at the beginning of each

boating season.

Cleaning

Aquatic growth can accumulate rapidly on the transducer’s

surface reducing its performance within weeks. Clean it using a

Scotch-Brite® scour pad and mild household detergent, being

careful to avoid making scratches. In severe cases, lightly wet

sand the surface with fine grade wet/dry paper.

Replacement Transducer & Parts

The information needed to order a replacement transducer is printed

on the cable tag. Do not remove this tag. When ordering, specify the

part number, serial number, date and frequency in kHz. For

convenient reference, record this information on the top of page 1.

Lost, broken and worn parts should be replaced immediately.

Obtain parts from your instrument manufacturer or marine dealer.

Gemeco USA

Tel: 803-693-0777

Airmar EMEA Europe, Middle East, Africa

Tel: +33.(0)2.23.52.06.48

Email: sales@airmar-emea.com

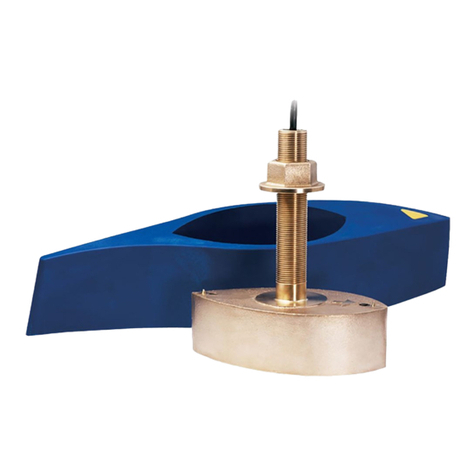

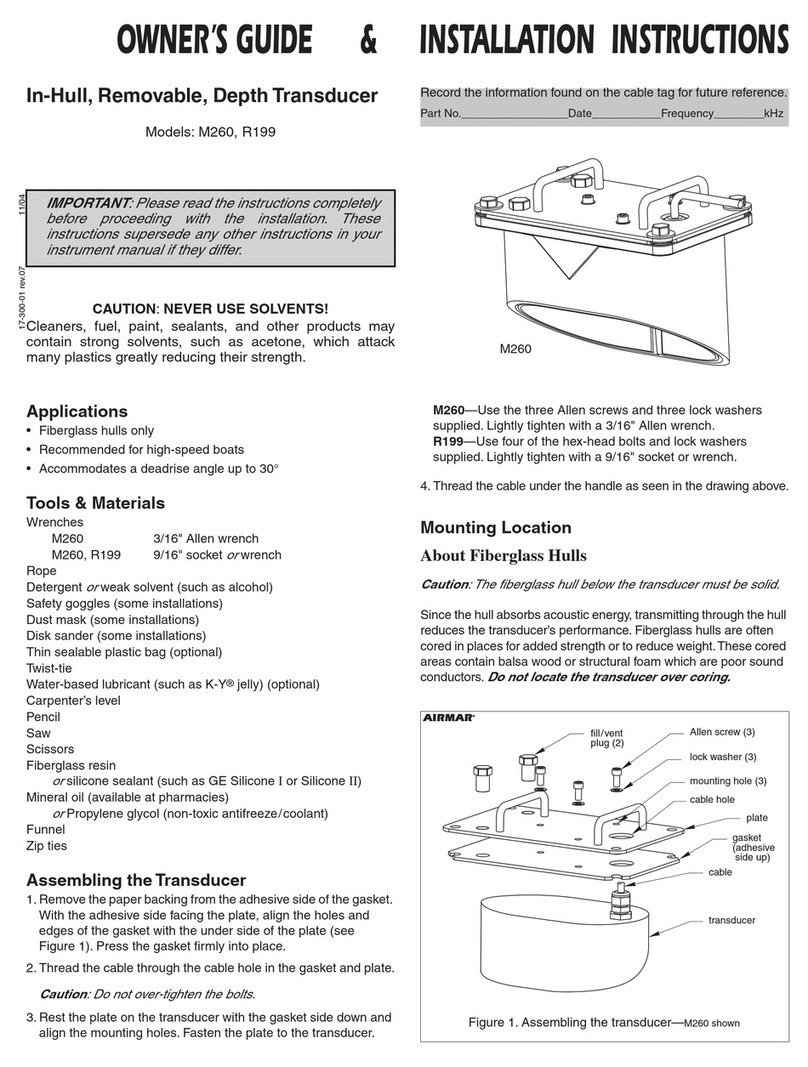

cable

backing block

fairing

hull

stuffing tube

transducer

Figure 9. Completed installation (non-metal hull shown)

Copyright © 2005 Airmar Technology Corp.

aft view

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA

www.airmar.com