Testing on the Water

1. Become familiar with your echosounder’s performance at a

speed of 4kn (5MPH).

2. Gradually increase the boat speed and observe the gradual

decline in performance due to turbulent water flowing over the

transducer’s active surface.

3. If the decline in performance is sudden (not gradual), identify

the boat speed at which the onset occurred. Return the boat to

this speed, then gradually increase speed while making

moderate turns in both directions.

4. If the performance improves while turning to the side on which

the sensor is installed, the transducer’s position probably needs

adjustment. It is probably in aerated water.

To improve performance, try the following one at a time in the

order given.

a. Increase the sensor’s angle in the water. Review “Plastic

Shims” and see Figure 10.

b. Move the sensor deeper into the water in increments of 3mm

(1/8") (see Figure 11).

c. Move the sensor closer to the centerline of the boat.

Fill unused screw holes with marine sealant.

High-speed operation [above 35kn (40MPH)] may require less

projection in the water to improve performance and reduce the

chance that water pressure will cause the bracket to release.

5. Calibration—To match the speed shown on the display to the

actual speed of the boat, you may need to calibrate the

instrument. Refer to your instrument owner’s manual.

Cable Routing

CAUTION: Do not remove the connector to ease cable routing. If the cable

must be cut and spliced, use Airmar’s splash-proof Junction Box No. 33-035

and follow the instructions provided. Removing the waterproof connector or

cutting the cable, except when using a water-tight junction box, will void the

sensor warranty.

Route the sensor cable over the transom, through a drain hole, or through

a new hole drilled in the transom above the waterline.

1. If a hole must be drilled through the transom, choose a location well

above the waterline (see Figure 11). Check for obstructions such as

trim tabs, pumps, or wiring inside the hull. Mark the location with a pencil.

Drill a hole using the appropriate size bit to accommodate the connector.

2. Route the cable over or through the transom.

3. On the outside of the hull, secure the cable against the transom using

the cable clamps. Position one cable clamp 50mm (2") above the

bracket and mark the mounting hole with a pencil.

4. Position the second cable clamp halfway between the first clamp and

the cable hole. Mark this mounting hole.

5. If a hole has been drilled in the transom, open the appropriate slot in the

cable cover. Position the cover over the cable where it enters the hull.

Mark the two mounting holes.

6. At each of the marked locations, use a 3mm or 1/8" bit to drill a hole

10mm (3/8") deep. To prevent drilling too deeply, wrap masking tape

around the bit 10mm (3/8") from the point.

7. Apply marine sealant to the threads of the #6 x 1/2" self-tapping screws

to prevent water from seeping into the transom. If you have drilled a

hole through the transom, apply marine sealant to the space around the

cable where it passes through the transom.

8. Position the two cable clamps and fasten them in place. If used, push

the cable cover over the cable and screw it in place.

9. Route the cable to the instrument being careful not to tear the cable jacket

when passing it through the bulkhead(s) and other parts of the boat. Use

grommets where appropriate. To reduce electrical interference, separate

the sensor cable from other electrical wiring and the engine(s). Coil any

excess cable and secure it in place with cable ties to prevent damage.

10.Refer to your echosounder owner’s manual to connect the sensor to

the instrument.

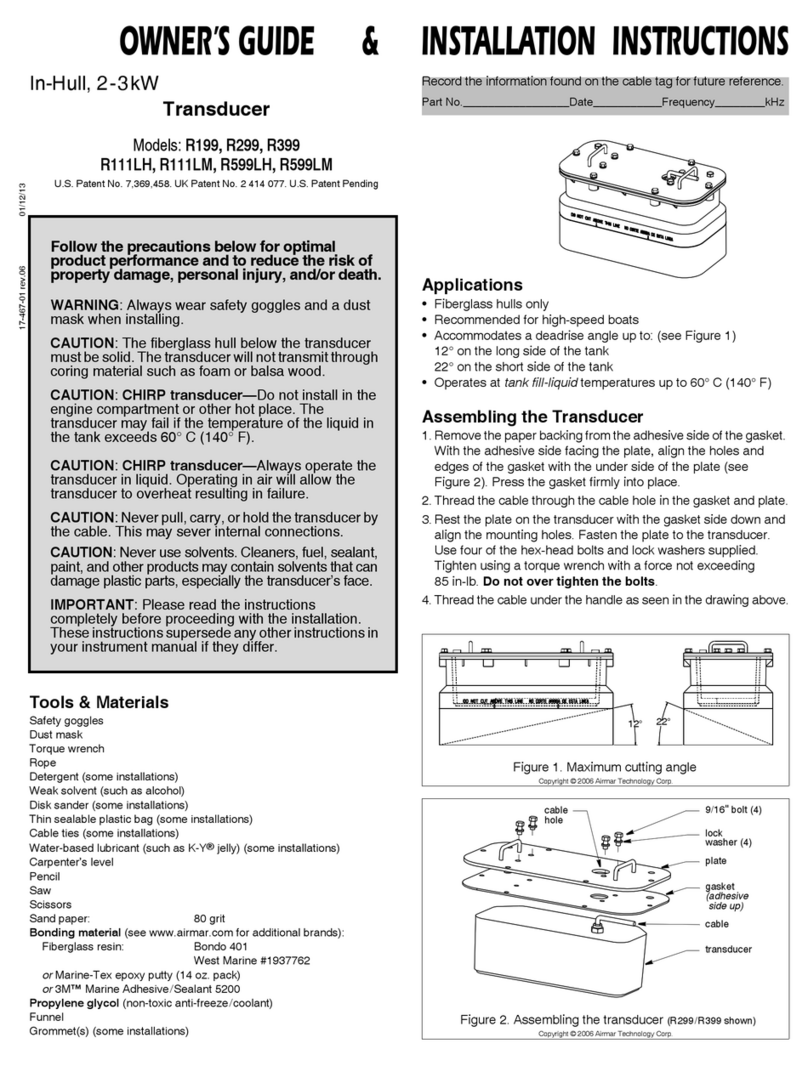

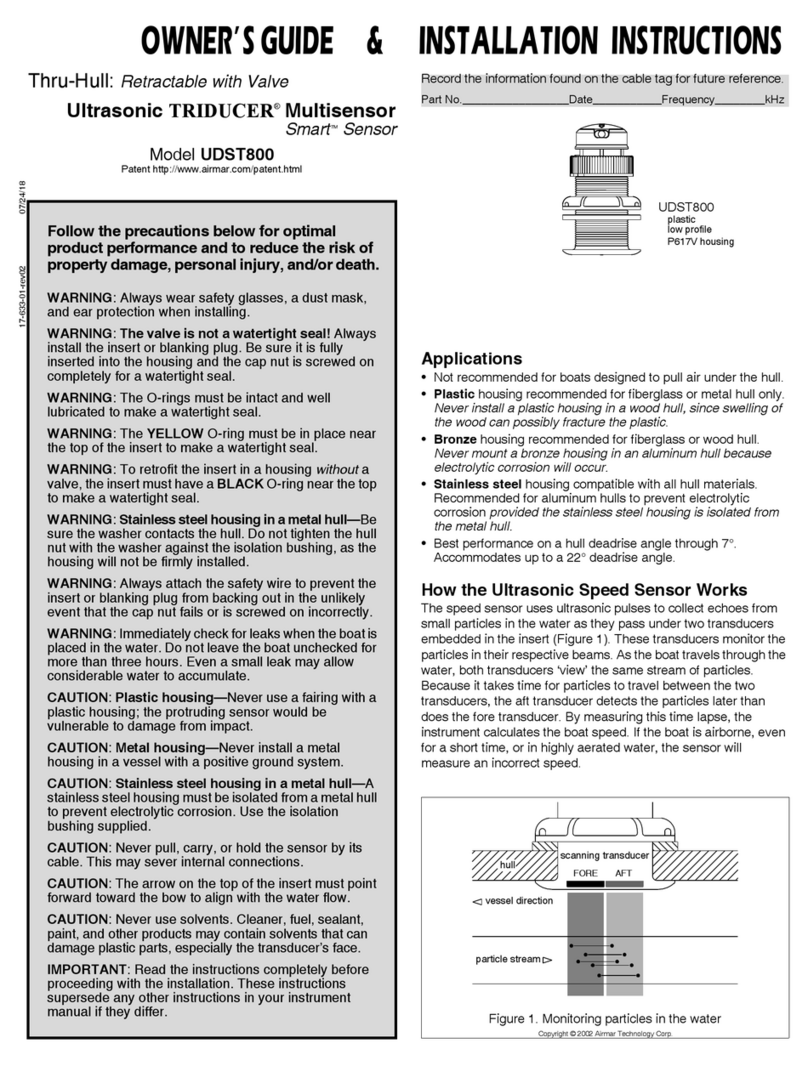

Figure 13. Servicing the speed sensor

side view

shaft

short side

of blade

insert shaft

4

BOW

through

hole B in

B

retaining

bar (2)

speed

sensor

housing

Checking for Leaks

WARNING: Do not leave the boat in the water unchecked for

several days. When the boat is placed in the water, immediately

check for leaks around the screws and any holes drilled in the

hull. Note that very small leaks may not be readily observed.

Anti-fouling Paint

Aquatic growth can accumulate rapidly on the sensor’s surface reducing

performance within weeks. Surfaces exposed to salt water that do not

interlock, must be coated with anti-fouling paint. Use water-based anti-

fouling paint only. Never use ketone based paint, since ketones can attack

many types of plastic possibly causing damage to the transducer. Apply

paint every 6 months or at the beginning of each boating season.

Maintenance,Repair & Parts

Clean the transducer’s surface with a Scotch-Brite® scour pad and mild

household detergent taking care to avoid making scratches. If the fouling

is severe, lightly wet sand with fine grade wet/dry paper.

Servicing the Speed Sensor

If the paddlewheel becomes fouled or inoperable, remove it for cleaning.

Remove the two screws from the speed sensor (see Figure 13). Slide it

upward to remove it from the transducer housing. Grasp the two retaining

bars and pull to access the shaft.

After cleaning, slide the paddlewheel onto the shaft. Orient the short side

of the paddlewheel blade as shown on the side view. It must be oriented

correctly to measure the boat’s speed. Fit the shaft into the holes marked

“B” in the retaining bars. Note: There is a left retaining bar marked with an

L and a right retaining bar marked with an R. Slide the assembly into the

speed sensor housing. Note: The interior of the housing is marked with a

corresponding L and R. Re-attach the speed sensor.

Sensor Replacement & Parts

The information needed to order a replacement sensor is printed on the

cable tag. Do not remove this tag. When ordering, specify the part

number, date, and frequency in kHz. For convenient reference, record this

information on the top of page one.

Replace broken or worn parts immediately. The water-lubricated

paddlewheel bearings have a life of up to 5 years on low-speed boats

[less than 10kn (11MPH)] and 2 years on high-speed vessels. Some

depth/temperature units can be upgraded by adding a speed sensor.

Part Part Number

Paddlewheel Kit 33-473-01

Bracket and Wedge Kit 33-479-01

Speed Sensor Kit 33-346-03

Obtain parts from your instrument manufacturer or marine dealer.

Gemeco Tel: 843.210.7000

(USA) Fax: 843.210.7170

Airmar EMEA Tel: +33.(0)2.23.52.06.48

(Europe, Middle East, Africa) Fax: +33.(0)2.23.52.06.49

Copyright © 2000, 2010 Airmar Technology Corp. All rights reserved.

Copyright © 2003 Airmar Technology Corp.