4Copyright © 2004 - 2015 Airmar Technology Corp. All rights reserved.

1. The O-rings must be intact and well lubricated to make a

watertight seal. On the blanking plug, inspect the O-rings

(replace if necessary) and lubricate them with the silicone

lubricant supplied or petroleum jelly (Vaseline®) (see Figure 4).

2. Remove the insert from the housing by removing the safety wire

from the cap nut. Unscrew the cap nut to lift the insert (see

Figure 2). Remove the insert with a slow pulling motion.

3. Slide the blanking plug into the housing. Screw the cap nut

several turns until the threads are engaged. Rotate the blanking

plug until the key fits into the notch in the housing. Continue to

tighten the cap nut. Hand tighten only. Do not over tighten.

4. Reattach the safety wire to prevent the blanking plug from

backing out in the unlikely event that the cap nut fails or is

screwed on incorrectly.

Winterizing

After the boat has been hauled for winter storage, remove the

blanking plug to let the water drain away before reinserting it. This

will prevent any water from freezing around the blanking plug and

possibly cracking it.

Servicing the Insert

Aquatic growth can impede or freeze the paddlewheel’s rotation and

must be removed. Clean the surface using a Scotch-Brite®scour pad

and mild household detergent. If fouling is severe, push out the shaft

using a spare shaft or a 4D finish nail with a flattened point. Then,

lightly wet sand the surface with fine grade wet/dry paper.

The water lubricated paddlewheel bearings have a life of up to 5

years on low-speed boats [less than 10kn (11 MPH)] and 1 year

on high-speed vessels. Paddlewheels can fracture and shafts can

bend due to impact with water borne objects. O-rings must be free

of abrasions and cuts to ensure a watertight seal. Order a

replacement Paddlewheel, Shaft & O-ring Kit, 33-499-01.

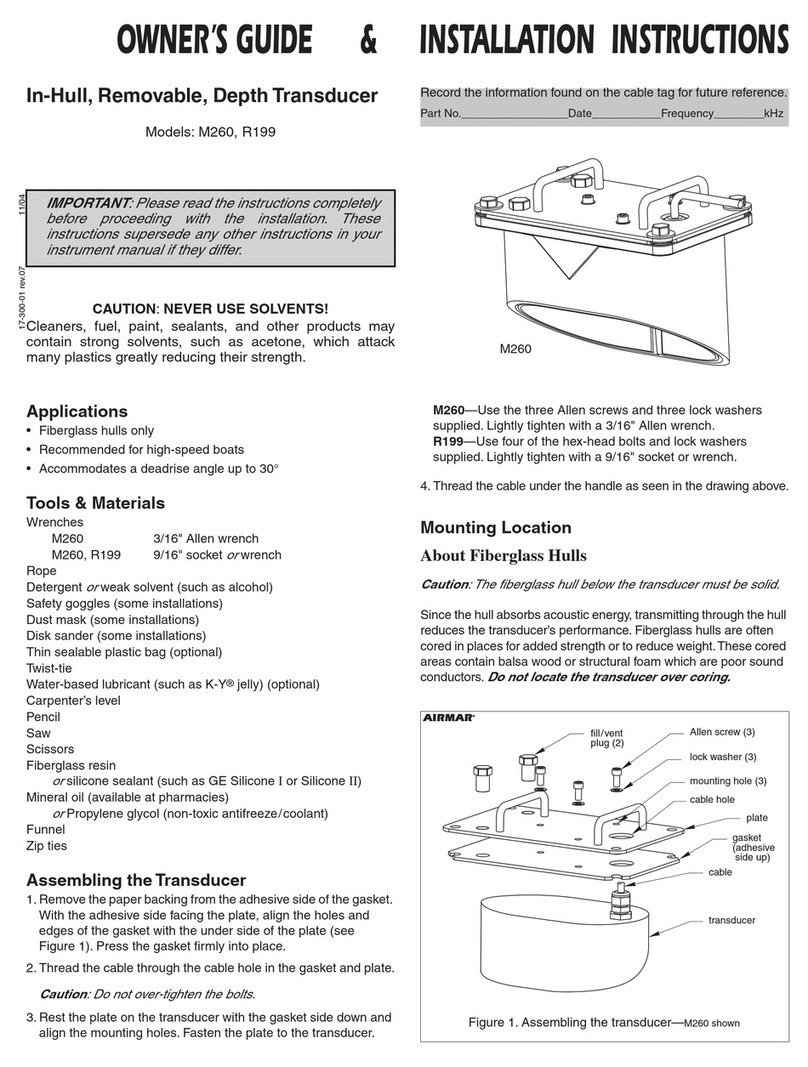

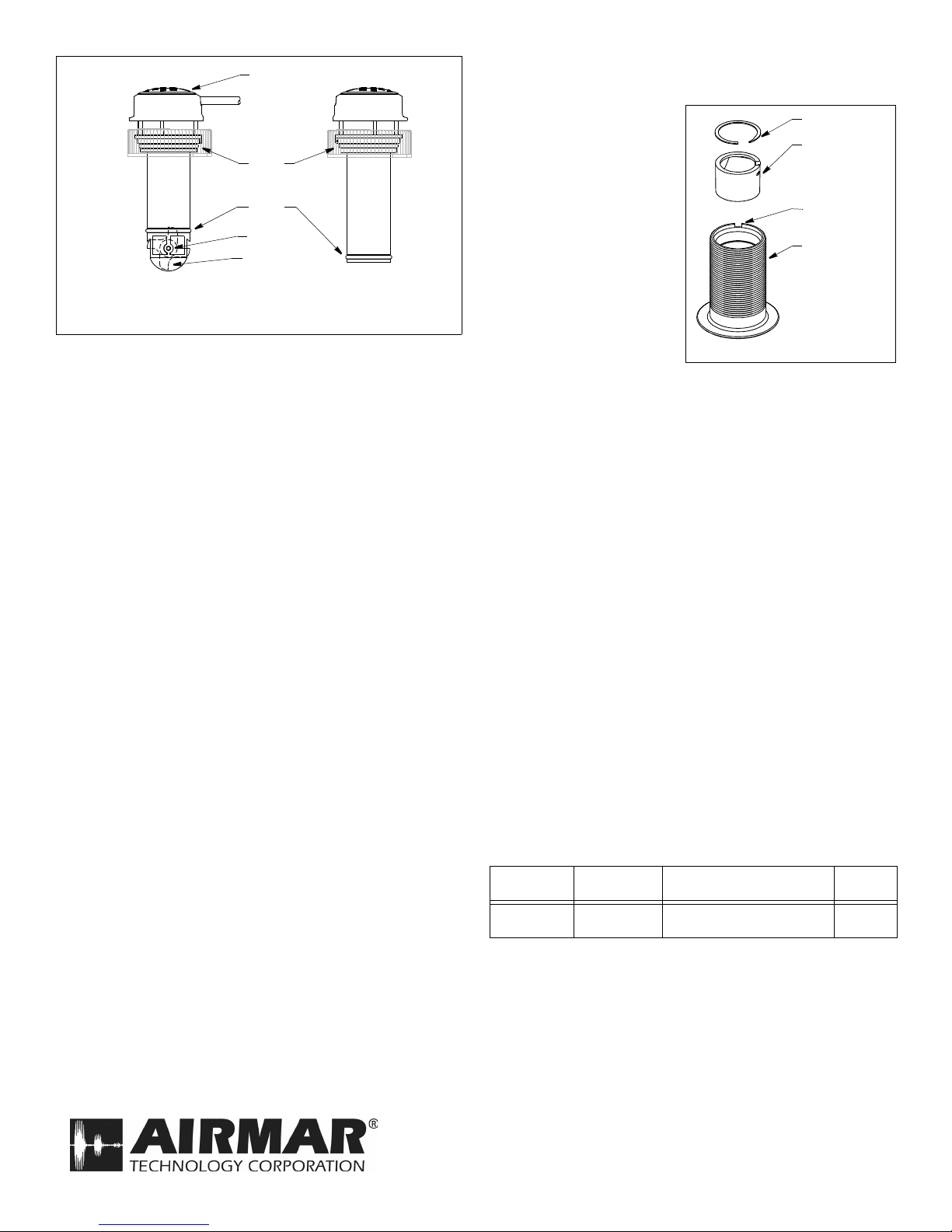

1. Using the new shaft, push the old shaft out about 6mm (1/4"). With

pliers, remove the old shaft (see Figure 4).

2. Place the new paddlewheel in the cavity with the flat side of the blade

facing the same direction as the arrow on the insert top.

3. Tap the new shaft into place until the ends are flush with the insert.

4. Install a large O-ring near the top and a small O-ring near the

paddlewheel.

5. Place the two remaining O-rings in similar positions on the blanking plug.

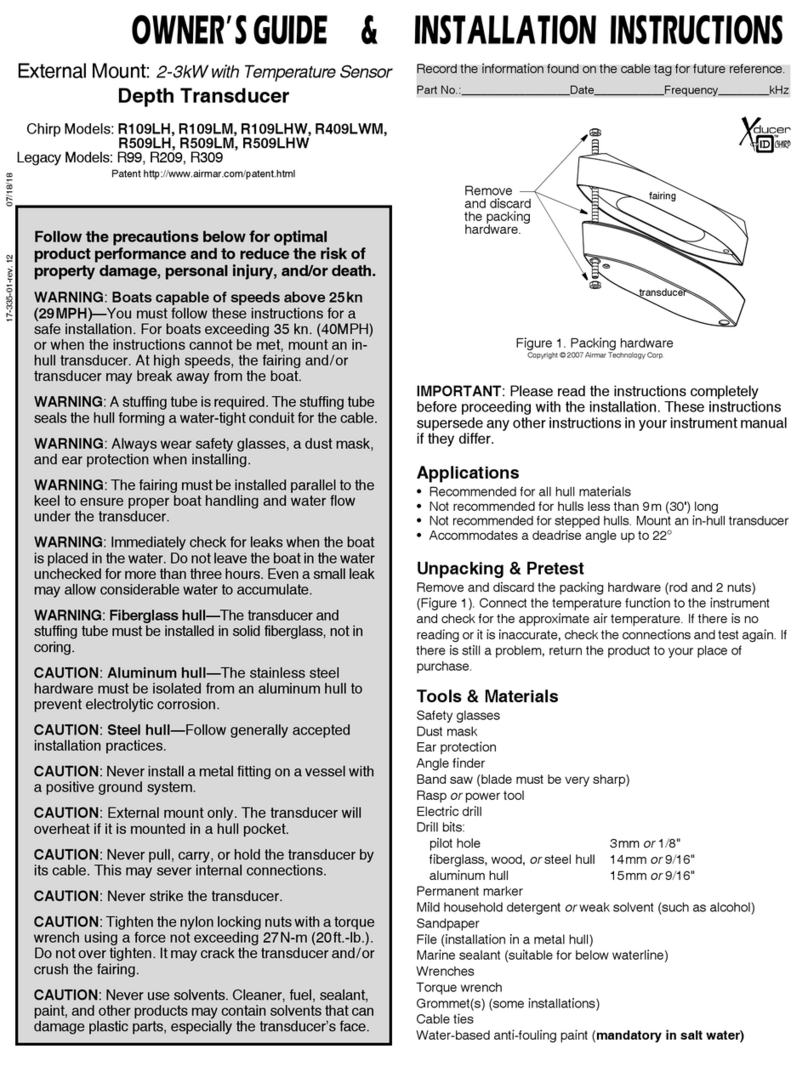

Servicing the Valve Assembly

Should the valve fail, remove it for servicing.

1. The O-rings must be intact and

well lubricated to make a

watertight seal. On the

blanking plug, inspect the

O-rings (replace if necessary)

and lubricate them with

silicone lubricant or petroleum

jelly (Vaseline®).

2. Remove the insert/blanking

plug from the housing.

3. Remove the snap ring from

the valve assembly using a

screw-driver to pry the end of

the ring free (see Figure 5).

4. Slide the valve assembly

upward and out of the housing

slowly.

NOTE: The flap valve retainer

pin is a loose slip-fit and may

fall out when the assembly is removed.

5. Push the blanking plug into the housing. Screw the cap nut several

turns until the threads are engaged. Rotate the blanking plug until the

key fits into the notch in the housing. Continue to tighten the cap nut.

Hand tighten only. Do not over tighten. Reattach the safety wire (see

Figure 2).

6. Clean, repair, or replace the valve assembly so the flap valve moves

freely and seats against the valve housing.

7. To reinstall the valve assembly, first reassemble the flap valve in the

valve housing with the retainer pin and spring in place (see Figure 5).

8. Remove the blanking plug. Slide the valve assembly into the housing

with the flap valve pointing downward. Install the snap ring being certain

that it LOCKS INTO THE GROOVE in the housing wall.

9. Slide the insert (or the blanking plug) into the housing with the arrow on

the top pointing forward toward the bow. Screw the cap nut several

turns until the threads are engaged. Rotate the insert (or the blanking

plug) until the key engages the notch in the housing.Be sure the arrow

on the top is facing forward toward the bow. Continue to tighten the cap

nut. Hand tighten only. Do not over tighten.

10.Reattach the safety wire to prevent the insert/blanking plug from

backing out in the unlikely event that the cap nut fails or is screwed on

incorrectly (see Figure 2).

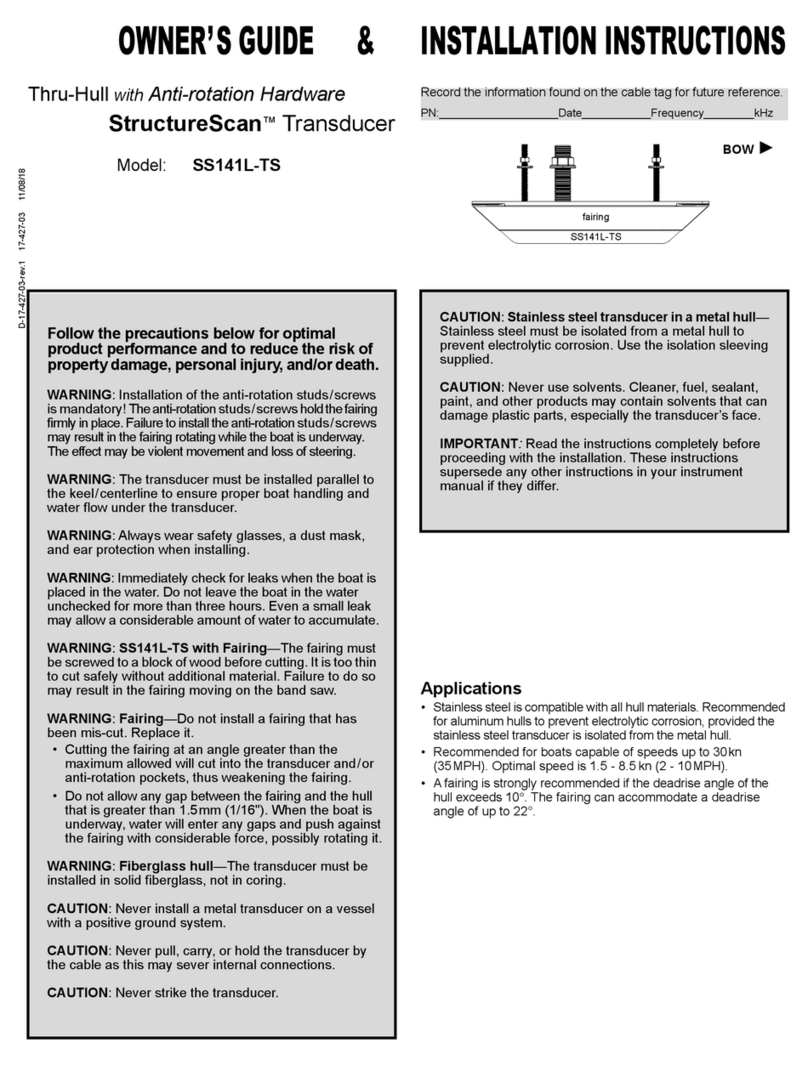

Replacement Sensor & Parts

The information needed to order a replacement sensor is printed on the cable

tag. Do not remove this tag. When ordering, specify the part number and date.

For convenient reference, record this information on the top of page one.

Lost, broken, and worn parts should be replace immediately. If you have

purchased a plastic housing and have a wood hull or desire greater

strength, purchase a bronze housing.

Paddlewheel, Shaft & O-ring Kit 33-499-01

Obtain parts from your instrument manufacturer or marine dealer.

Gemeco (USA) Tel: 803.693.0777

Fax: 803.693.0477

Airmar EMEA Tel: +33.(0)2.23.52.06.48

(Europe, Middle East, Africa) Fax: +33.(0)2.23.52.06.49

Blanking Plug Hull Nut Housing, Hull Nut & Washer Paddlewheel

& Valve Kit

33-481-01 04-004 (plastic)

02-030 (bronze)

33-340-02 (plastic, P120)

33-340-01 (bronze, B120) 33-493-01

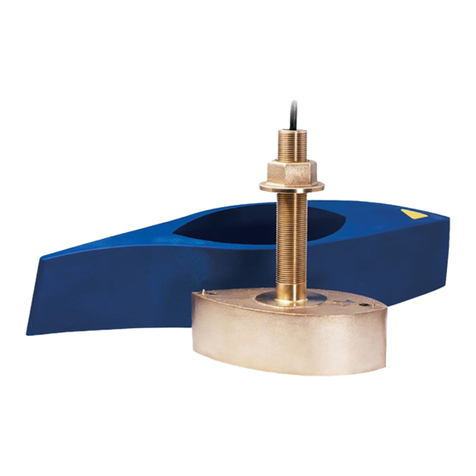

Figure 4. Replacing the paddlewheel and O-rings

arrow

flat side

of blade

shaft

faces bow

large

O-ring

small

O-ring

Copyright © 2006 Airmar Technology Corp.

paddlewheel

insert

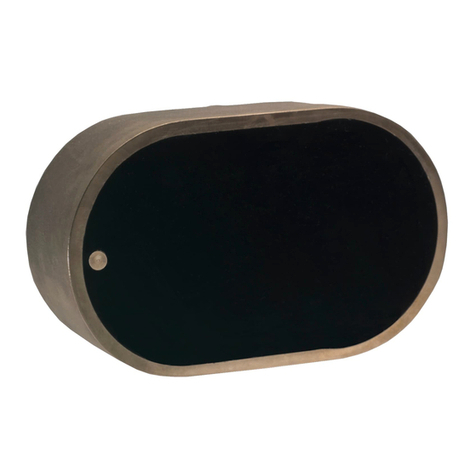

blanking

plug snap ring

valve assembly

flap valve

spring

retainer pin

housing

notch

Figure 5. Servicing

the valve assembly

Copyright © 2006 Airmar Technology Corp.

BOW ►

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA

•www.airmar.com