UNPACKING PRECAUTIONS

NOTE:When unpacking, assistance may be required when removing the LiftCart from the box. Ensure

the box is on a sturdy surface when unpacking.

CAUTION! When removing the LiftCart from its packaging box, be sure to grip the main frame. Do not just

grip the tabletop by the edges. Do not use excessive force if using a sharp, cutting blade when

unpacking. There are wires that can be damaged by a sharp, cutting instrument.

IMPORTANT SAFETY INSTRUCTIONS –PLEASE REVIEW

•Do not exceed the stated lift capacity for of your LiftCart model.

•Use only on flat, level, and hard surface capable of supporting the LiftCart and any item(s) placed on the table.

Evenly distribute load on the table to avoid tipping especially when using the LiftCart with caster wheels.

•Use as intended only. Do not use LiftCart to lift or transport animals, pets, or people.

•Assemble only according to these instructions. Improper assembly can create hazards.

•Follow all instructions specified in this manual.

•When using, keep work area clean and well lit. Ensure flooring is free of obstructions and debris when moving

the LiftCart using the included caster wheels.

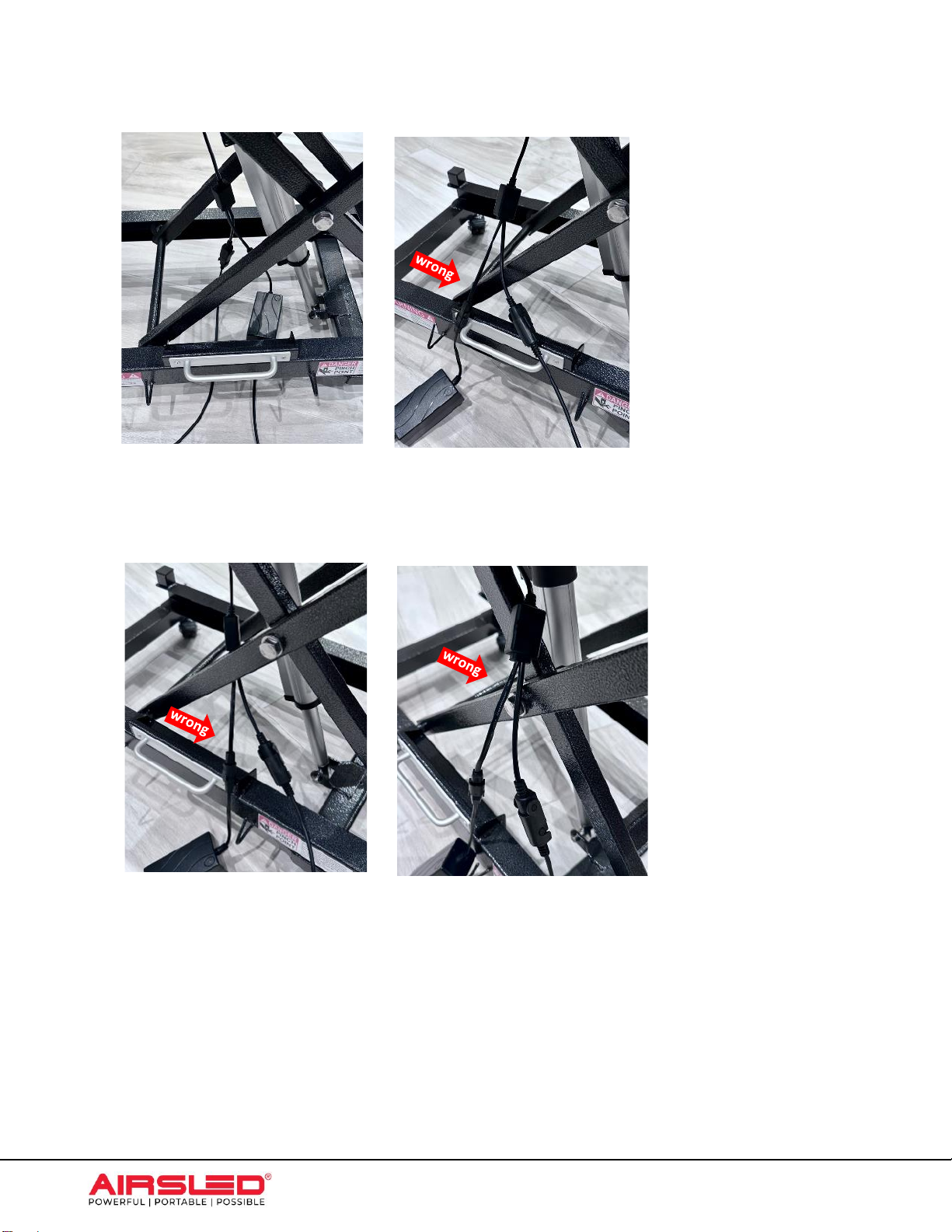

•Ensure are wires and the power box are located UNDER the frame when using.

•This product is not a toy. Do not allow children to play with or near this item.

•Inspect before every use; do not use if parts are loose or damaged.

•Maintain product labels and nameplates. These carry important safety information. If unreadable or missing,

contact Airsled for a replacement.

•Use extreme caution when moving things when the LiftCart is in the fully open position, as a higher center of

gravity can lead to risk of tipping. Airsled recommends to only move loads using the LiftCart when the LiftCart

is in the fully closed position.

•Keep this product away from water or damp environments to prevent risk of electric shock.

ASSEMBLY INSTRUCTIONS

•The LiftCart comes fully assembled. However, you may wish to install the included caster wheels to the frame.