BH1AOZ2000A 3

Rev. 012919

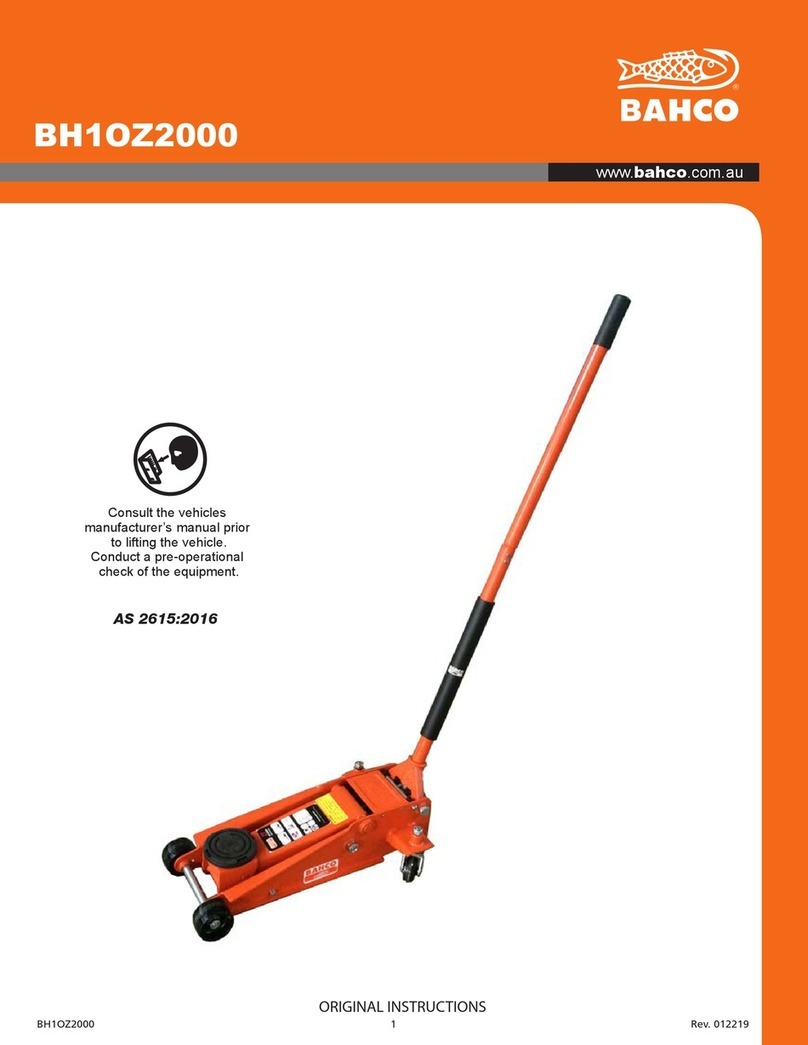

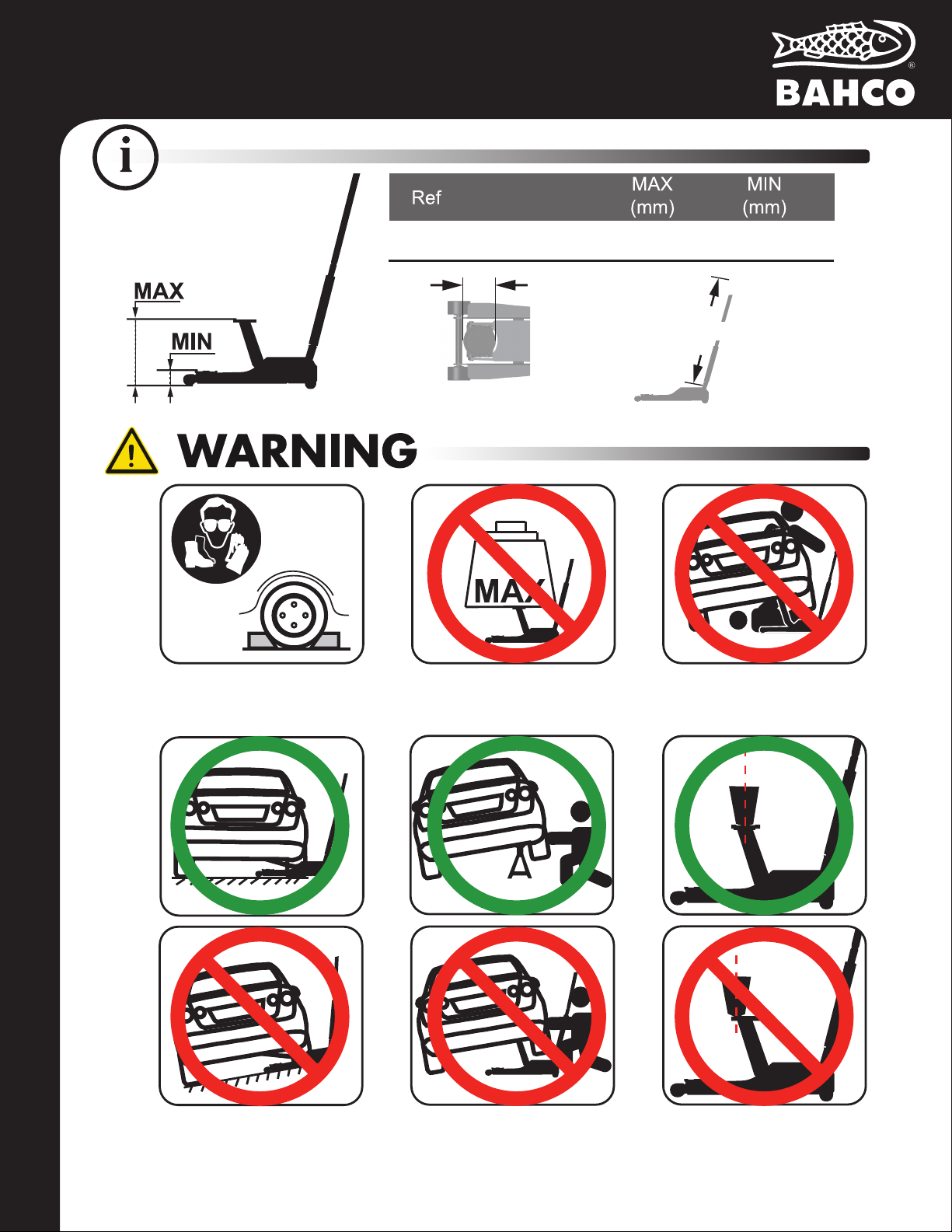

• Consult the vehicle manufacturer’s manual prior to the lifting of the vehicle.

• Conduct a pre-operational check of the equipment.

• Use the hydraulic trolley jack for lifting and lowering only; the raised vehicle should be supported on suitably rated vehicle

support stands.

• Use the hydraulic trolley jack on a hard level surface and ensure it is free to roll during lifting and lowering.

• No person should remain in a vehicle that is being lifted.

• Chock the unlifted wheels of the vehicle.

• Centrally locate the load on the head cap.

• Support the vehicle on suitably rated vehicle support stands and remove the hydraulic trolley jack prior to

commencement of work on the vehicle.

• No person should get bodily under a vehicle that is supported only by a hydraulic trolley jack.

• Modicationsmustnotbecarriedoutoraccessoriesadded.

PREVENTATIVE MAINTENANCE

Obey all instructions to avoid possible injury or death.

1. Always store the jack in a well protected area where it will not be exposed to inclement weather, corrosive vapors,

abrasive dust, or any other harmful elements. The jack must be cleaned of water, snow, sand, grit, oil, grease or other

foreign matter before using.

2. The jack must be lubricated periodically in order to prevent premature wearing of parts. A general purpose grease

must be applied to all zerk grease fittings, caster wheels, front axle, elevator arm, handle base pivot bolts, release

mechanism and all other bearing surfaces. Worn parts resulting from inadequate or no lubrication are not eligible for

warranty consideration.

3. It should not be necessary to refill or top off the reservoir with hydraulic fluid unless there is an external leak.

An external leak requires immediate repair which must be performed in a dirt-free environment by an authorized

service center.

IMPORTANT: In order to prevent seal damage and jack failure, never use alcohol, hydraulic brake fluid or transmission

oil in the jack.

Use Chevron Hydraulic Oil AW ISO 32 or its equivalent Unocal Unax AW 150.

4. Every jack owner is responsible for keeping the jack labels clean and readable. Use a mild soap solution to wash

external surfaces of the jack but not any moving hydraulic components.

5. Inspect the jack before each use. Do not use the jack if any component is cracked, broken, bent, shows sign of

damage or leaks hydraulic fluid. Do not use the jack if it has loose or missing hardware or components, or is modified

in any way. Take corrective action before using the jack again.

6. Any hydraulic repairs within the warranty period must be performed by an authorized service center.

IMPORTANT: Service jacks are designed for lifting purposes only; always support raised load with jack stands.

REGULAR MAINTENANCE

MONTHLY or as necessary (depending on usage)

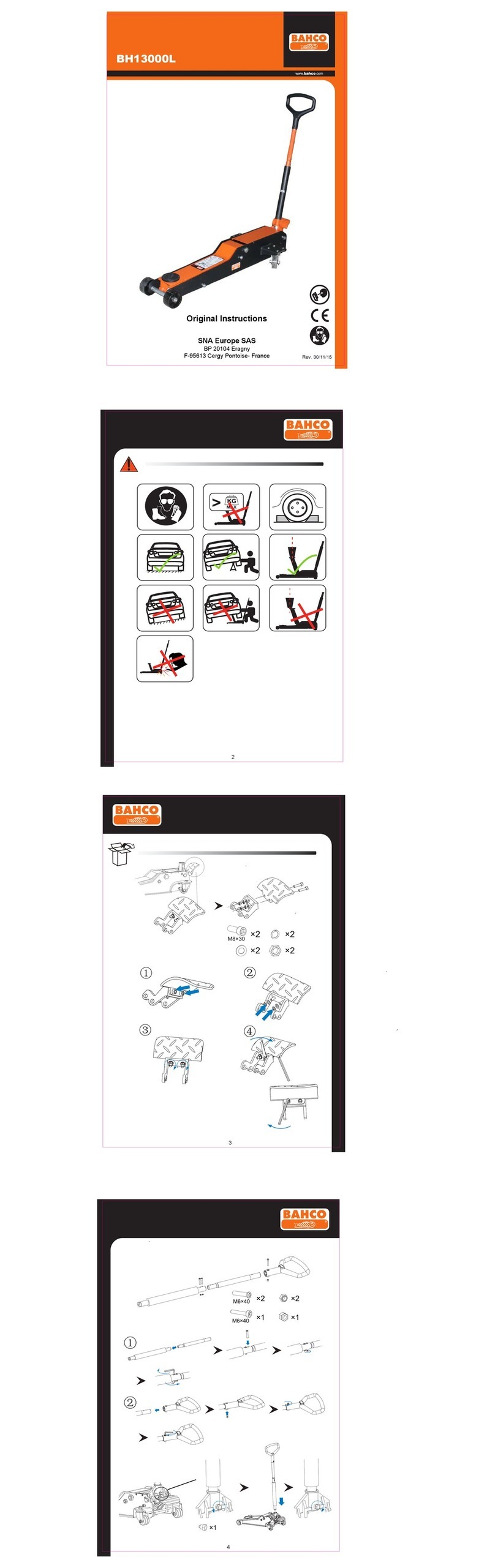

1. Using a grease gun, add grease to grease fitting in the lift arm pivot shaft.

(Use a multi-purpose NLGI type grease only.)

2. Lubricate all linkages and pivot points. (Use white lithium spray grease only.)

3. Remove handle; lubricate handle receptacle and handle end. (Use white lithium spray grease only.)

4. Lubricate both rear casters, bearing and both front wheels. (Use white lithium spray grease only.)

5. Tighten all accessible hardware.