8

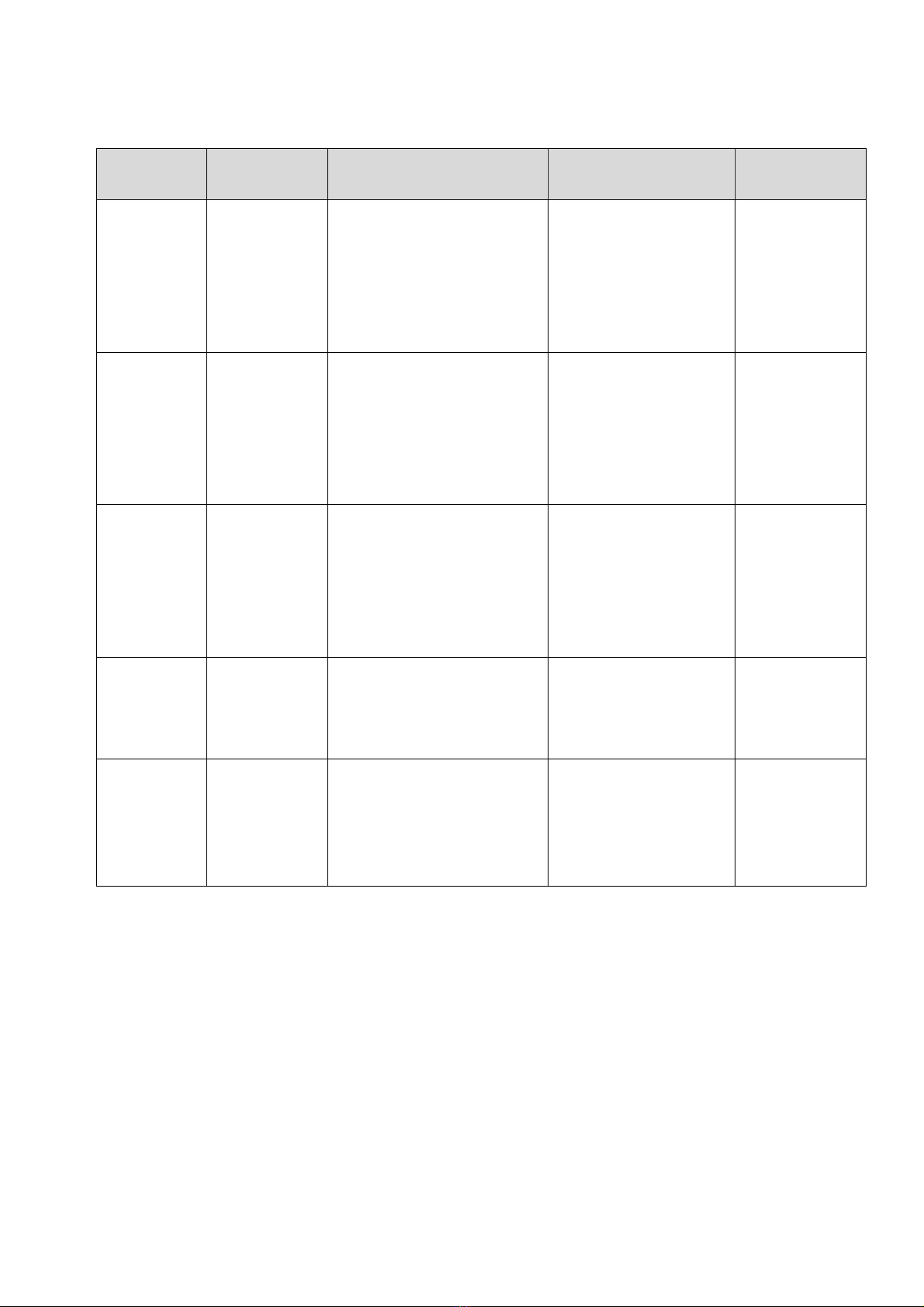

7.2 Accident during operation and the solutions

Accident Potential Hazard Solutions

Sudden power failure

Product, room and

operator will be in danger

Immediately stop the operation, fully close the

sliding sash and evacuate.

If harmful gas was continuously emitted from the

product, seal the product first simply and quickly,

then fully close sliding sash and evacuate. After

power restoration, personnel in PPE come in to

perform the disinfection for room and the cabinet.

Air supply fan failure

Product will be in danger

Immediately stop the operation, keep the exhaust

fan running (if present), on the UV light, fully close

the sliding sash and evacuate.

After the fan recovered, personnel in PPE come in

to take out the product, disinfect the room &etc.

Exhaust fan failure operator will be in danger

Immediately stop the operation, seal the product

first simply and quickly, on the UV light, fully close

the sliding sash and evacuate.

After the fan recovered, personnel in PPE come in

to take out the product, disinfect the room &etc.

Note: B2 type cabinet will stop the air supply fan

automatically.

Sliding Sash broken Product, room and

operator will be in danger

Seal the product first simply and quickly. Shut down

the cabinet, disinfect the room

Note: for B2 type cabinet, immediately stop the air

supply fan, and keep the exhaust fan running.

Emergency, such as

fire, earthquake, flood

Operator and the cabinet

will be in danger, the

cabinet broken.

Immediately stop the operation, fully close the

sliding sash and evacuate.

Turn off the power supply.

Disinfect the cabinet and room before re-start.

8. Product reception, installation and validation

Reminder: Please read this section carefully before moving and installing the cabinet.

(for installation personnel)

Reminder: The operator should kno about the contents in this section ell.

8.1 Product Reception

8.1.1 Upon receipt of your cabinet, inspect the crate whether there is any damage occurred in transit.

8.1.2 Please verify the cabinet type and model for which is exactly you ordered.