Doc. No.# AW70-105-01, Copy Right 2005, AirWild Hobbies, Inc. page 6of 6

If you decide to purchase the AirWild h

ardware package, it should leave you with just components are that are

mostly a matter of personal preference to purchase. These may be things such as servo choices, scheme of radio

installation and possibly other appearance related items. Feel free to consult the following list as it reflects what we

used to complete many of our prototype airplanes.

Description Qty.

Comment

AirWild Twist'd Servo Extensions, 36" 2

For elevator servos (use 36” + 12” to build up a 48” length, may vary)

AirWild Twist'd Servo Extensions, 12" 4

For elevator, aileron servos

AirWild Twist'd Servo Y-Connect, 10" 3

For aileron 2X, rudder servos 1X

AirWild Twist'd Servo Extensions, 6" 2

For aileron connections, from Rx

Cermark DSC Switches 3

2 for receiver batteries, 1 for ignition battery

AirWild 35% Pilot Figure 1

Optional

Smart-Fly Optical Kill Switch 1

Ignition Kill (STRONGLY RECOMMENDED FOR SAFETY)

Smart-Fly BatShare 1

Allows you to use two batteries to drive one Rx w/o concern for bat.

Failure

2X battery capacity + redundancy

Cermark NiMH 6V/1650mA 2

For Rx

Cermark NiMH 6V/2700mA 1

For Ignition

CF Nomex Panel, 12"x12" 1

Optional. Used to build floor board for mounting of Rx etc.

AirWild Nova Extra Spinner, 5" 1

Hitec 5945 Hi-Torque Digital Servo 8

Aileron x 4, elevator x 2, rudder x 2

Hitec 5245 Digital Mini Servo 1

Throttle

AirWild MLP Servo Arm, 2.5" 2

For rudder pull-pull use (ganged servos, series configuration)

Hanger 9 Pro Links 4

For rudder pull-pull use (length may vary depending on your placement)

Hanger 9 1/4 HD Double Ball Link 2

For rudder pull-pull use (approximately 2”~2.5” length)

Dubro 1/4 HD Ball Link 2

For rudder pull-pull use (ganged servos, series configuration)

Dynamite Pro Filter 1

Fuel Filter

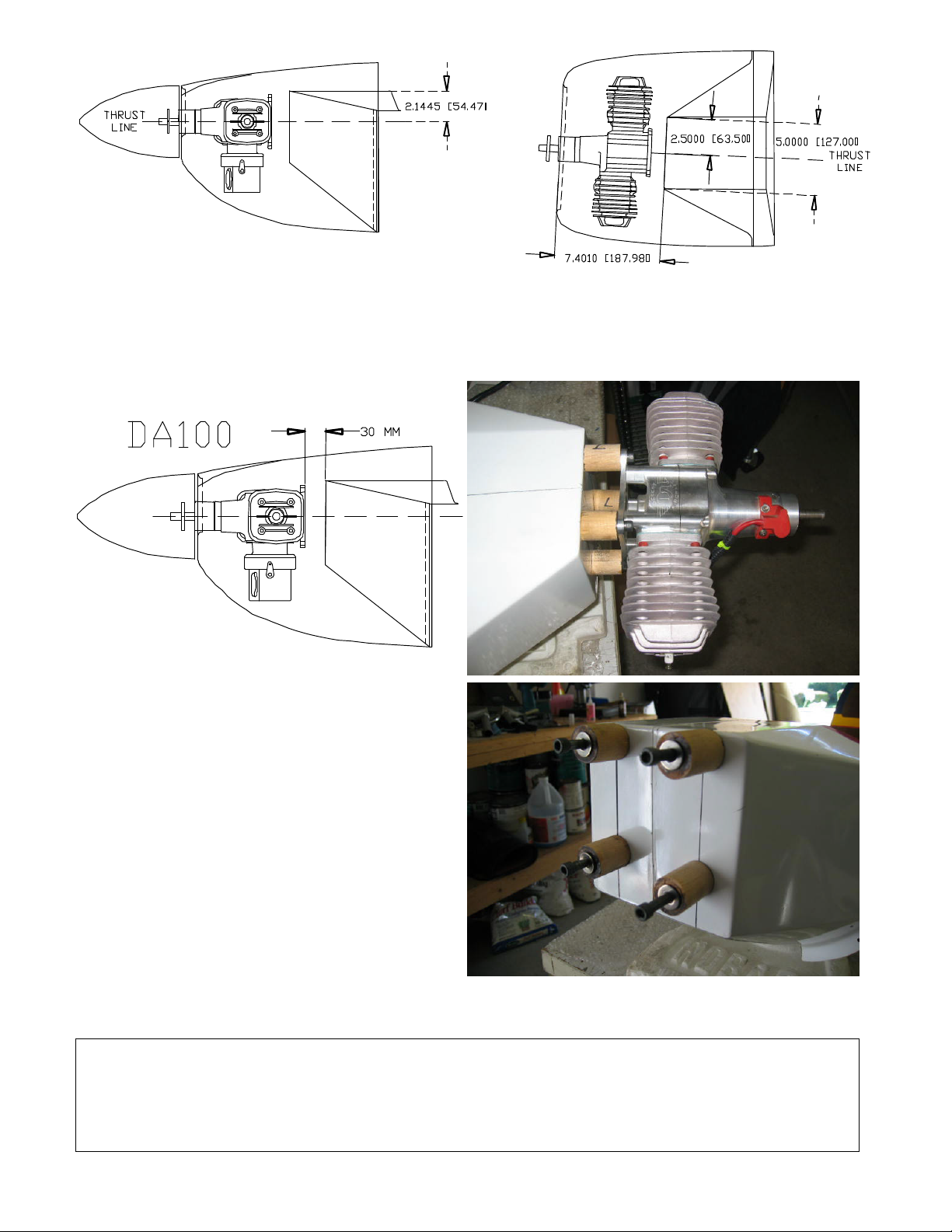

Engine, 100cc, Gasoline1

DA100, 3W106 etc.

Propeller 1

NX 27x10 2-blade, NX 28x10 2-blade, NX 26x12 3-blade (check w/

engine guide)

AirWild WingPAK Pro-Series 1

Optional, for 35% size

Again we want to emphasize that this list reflects our particular requirements only. Make changes in accordance to

your specific considerations.