Shenzhen Aituo Automation Device Co.,Ltd

3

(2)How to adjust when the number of rubber core in the feeding pathway is very

little ?········································································································

·······························14

(3)How to adjust when the knife can’t cut the wire on the cutting

workstation? ································································································

·····························15

(4)How to adjust when stripping will harm to the copper wire or can’t strip the outer skin

completely?··································································································

·····························16

(5)How to adjust when the wire be pulled broken on the pulling

workstation?·································································································

·····························16

(6)How to adjust when soldering the inner rubber can not add the solder

wire?··········································································································

·······························16

(7)How to adjust when the dislocation between bottom grippers and top

gripers?·······································································································

······························19

(8)How to adjust when connector stuck at feeding pathway or push material

parts?·········································································································

································20

(9)How to adjust the temperature of the soldering iron

head? ·········································································································

······························21

6、Adjusted accessories and the

methods················································································22

7、Attention

matters········································································································

········22

8、FAQ

summary·····································································································

··············23

9、Cleaning and attention

matters··························································································23

10 、Training

steps···········································································································

·······24

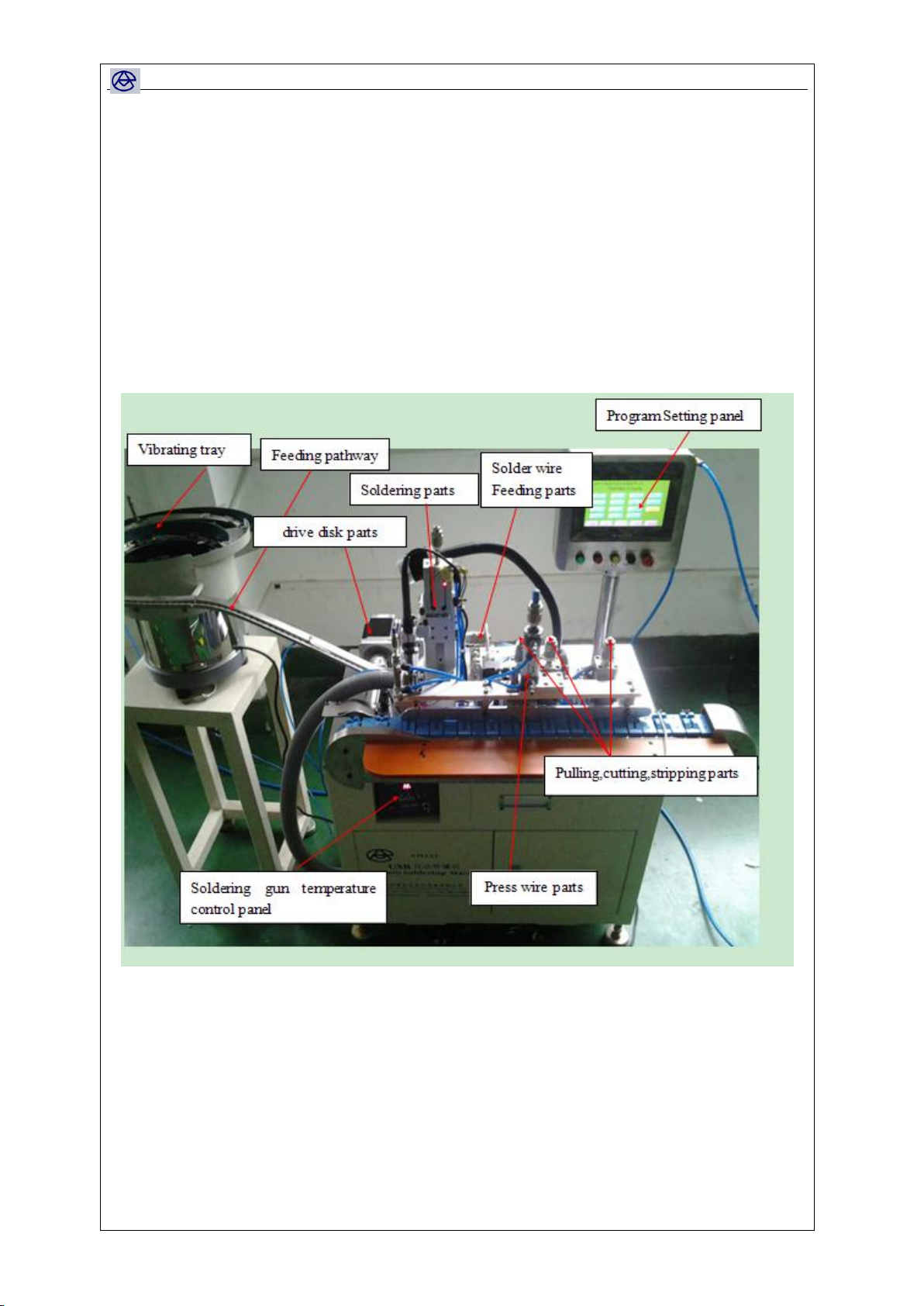

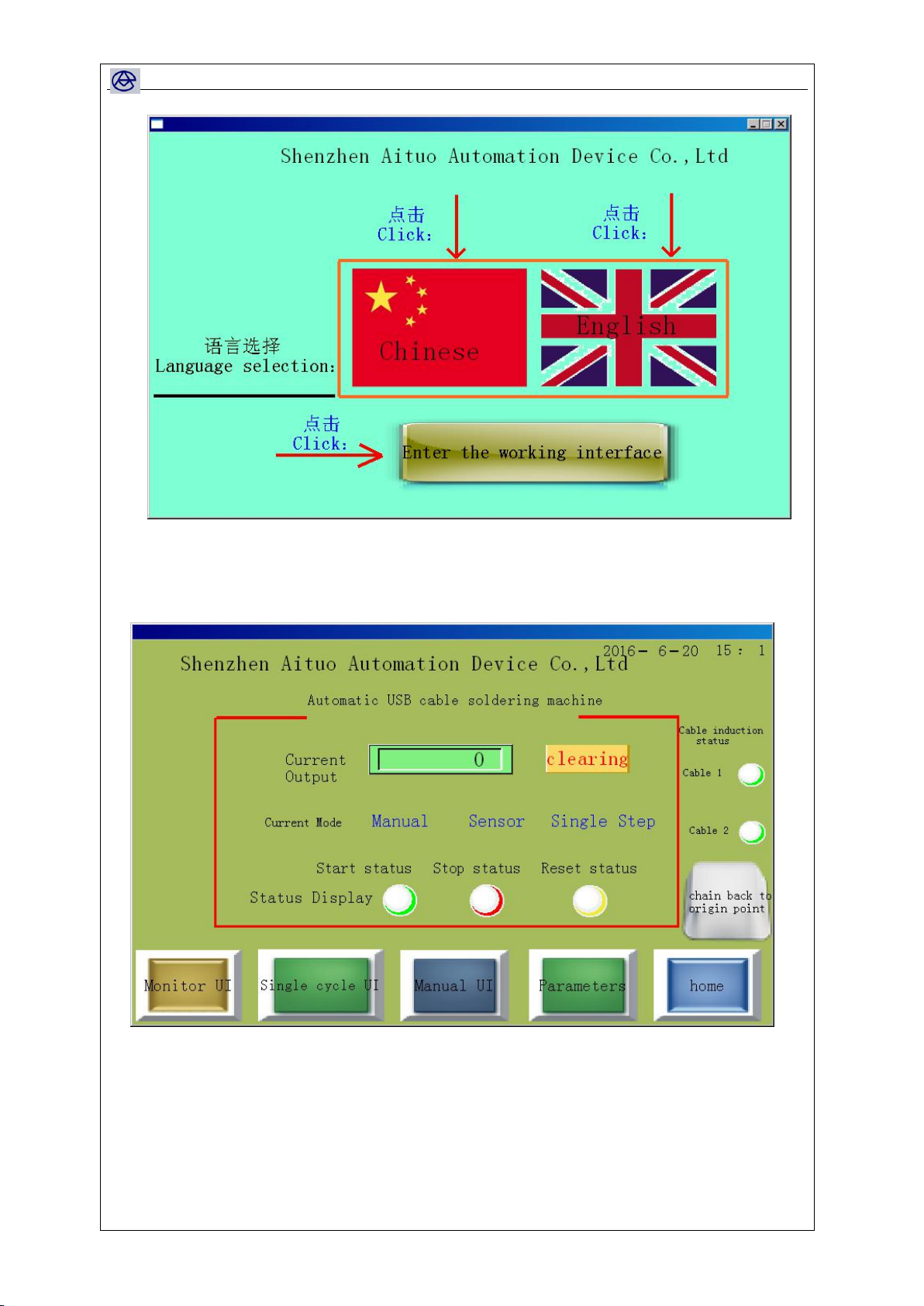

Automatic USB Soldering Machine