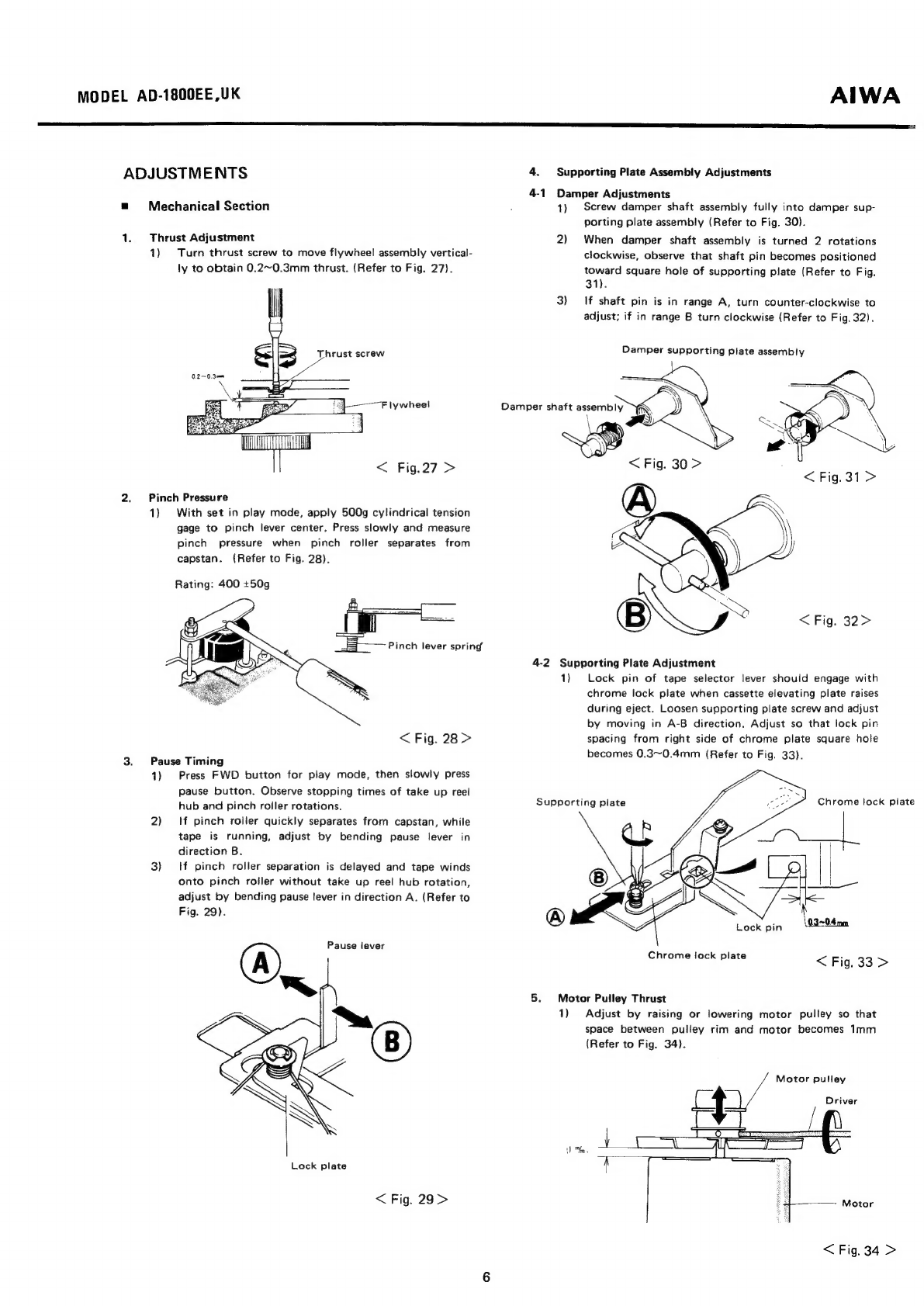

Aiwa AD-1800 User manual

Other Aiwa Stereo Receiver manuals

Aiwa

Aiwa CX-ZL800 User manual

Aiwa

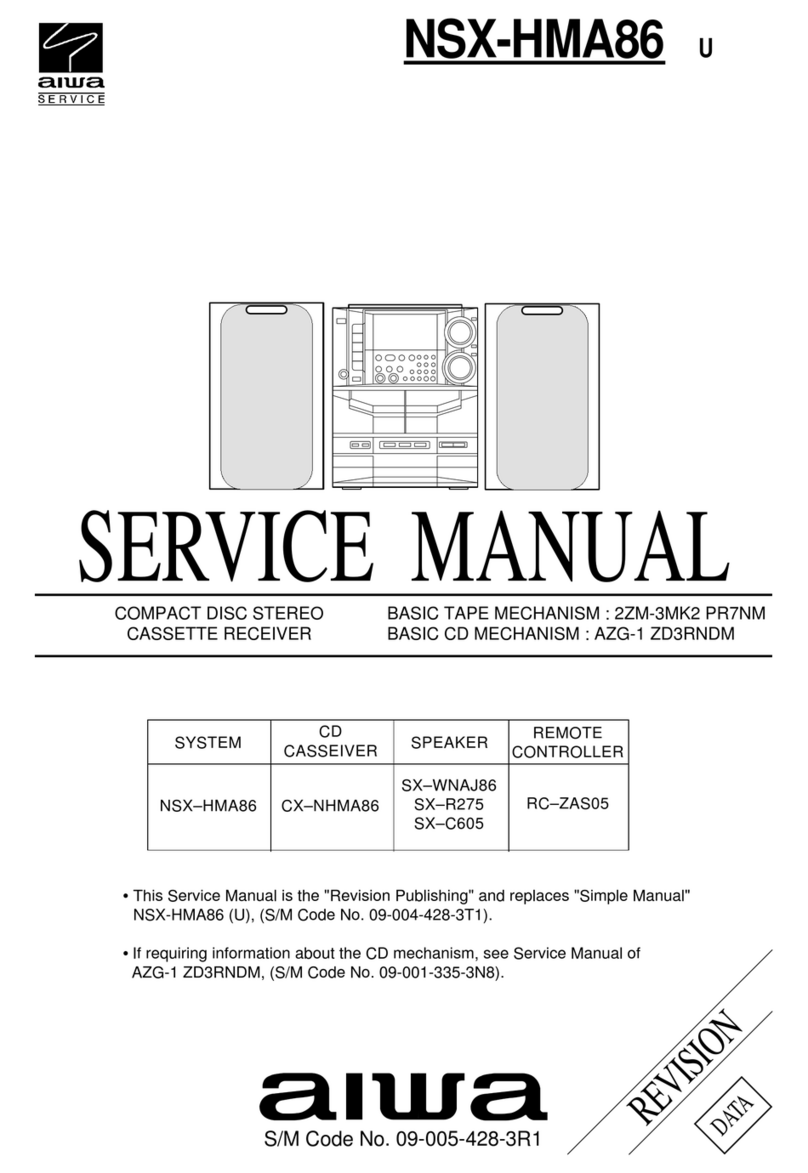

Aiwa NSX-HMA86 User manual

Aiwa

Aiwa NSX-AV240 Specification sheet

Aiwa

Aiwa AV-X100 User manual

Aiwa

Aiwa CR-LA30 User manual

Aiwa

Aiwa NSX-T99 LH User manual

Aiwa

Aiwa NSX-SZ80 User manual

Aiwa

Aiwa AV-D58 User manual

Aiwa

Aiwa AV-DV75 HC User manual

Aiwa

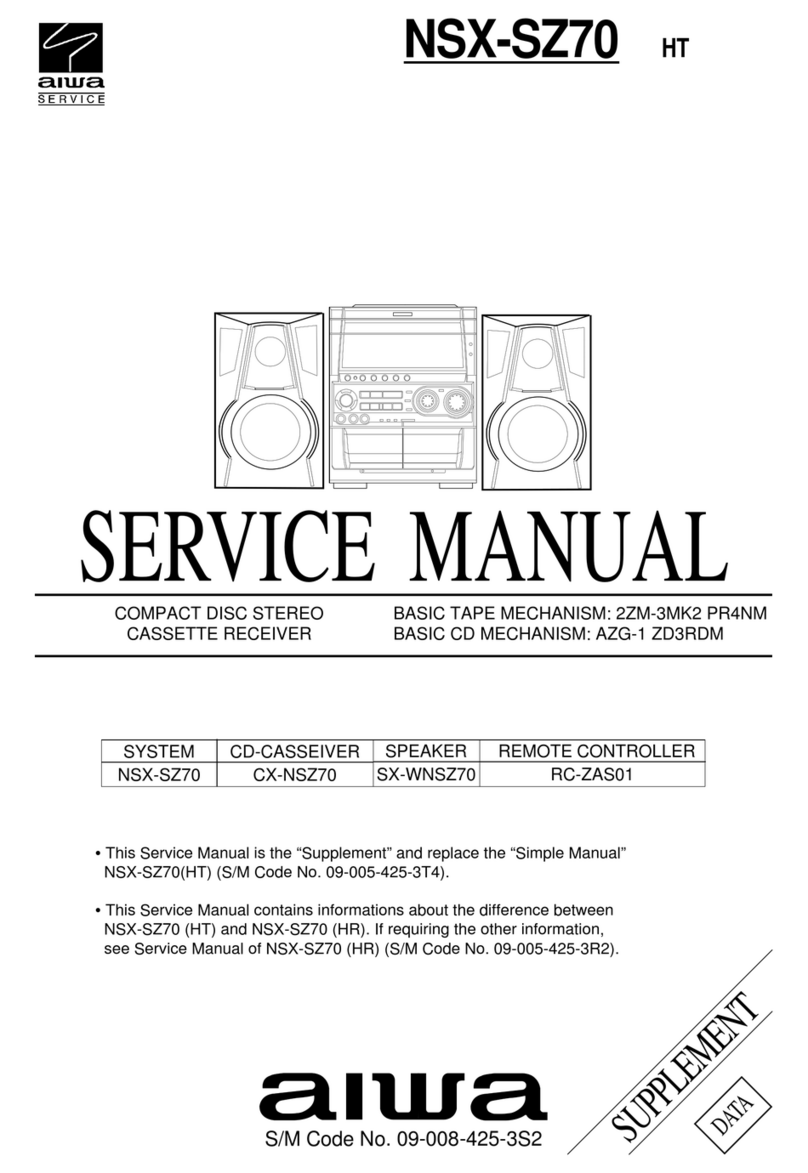

Aiwa NSX-SZ70HT User manual

Popular Stereo Receiver manuals by other brands

Pioneer

Pioneer SX-1000TA operating instructions

Yamaha

Yamaha MusicCast TSR-5B3D owner's manual

Sony

Sony STR-DE335 - Fm Stereo/fm-am Receiver operating instructions

Sony

Sony STR-DG500 - Multi Channel Av Receiver Service manual

Panasonic

Panasonic AJSD955B - DVCPRO50 STUDIO DECK Brochure & specs

Pioneer

Pioneer SX-838 Service manual