Subject to technical modications | Valid from August 2019 9

1.10. PROPER USE

Use in accordance with the intended purpose also includes observing the installation and operating guide as well compliance

with the inspection and maintenance conditions. Any other use requires the written approval of the manufacturer. Improper use

can endanger persons and result in damage to the system. The unit is operated via a control element that may only be used after

reading and understanding the documentation. Furthermore, liability and warranty claims are excluded in case of non-compliance

with proper use. The unit must be operated under the operating conditions described in the user’s manual.

I

It is mandatory for all the manufacturer’s specications to be complied with. Among others, these specications are the

ambient temperature, quality of the installation environment as well as the connections that are to be used.

HINWEIS

• The cooling circuit and refrigeration system of the unit must not be damaged. This can lead to an unintentional

exothermic reaction of the ignitable gas/air mix.

• The ventilation openings of the cladding of the unit (including accessories) must not be blocked or covered.

In the event of a leak in the refrigeration system, this can lead to an unintentional exothermic reaction of the

ignitable gas/air mix.

• The ventilation openings on the front and back side of the appliance must be kept free. The minimum distances to

other units must be complied with. Make sure that the air circulation is unobstructed. In the event of a leak in the

refrigeration system, a blockage of the air circulation can lead to an unintentional exothermic reaction of the ignitable

gas/air mix.

• According to the standard DIN EN 378-1, the refrigerant propane is combustible and explosive (refrigerant group A3).

• The refrigerant propane (R290) can create an ignitable gas/air mix, which can trigger an exothermic reaction in a

critical mixing ratio with air and in connection with the respective ignition energy (ignition source).

1.11. TARGET GROUP AND PRIOR KNOWLEDGE

This documentation is intended for operating personnel in the area of gastronomy (e.g.: hotel chains, restaurants, catering) as well

for the installation personnel. The unit may only be operated by trained personnel who are to be dened by the operator.

Make sure that personnel intended to operate the unit have the following prerequisites:

• Operators may not be visually impaired, because they must be able to easily read the safety instructions on the unit and

the information in the documentation.

• Reading and understanding this documentation is a requirement, and the currently applicable regulations regarding

occupational safety and accident prevention must be complied with.

• Only instructed personnel may operate and clean the appliance. Only qualied personnel who have been

authorised by the manufacturer may perform mainte-nance and repair work

• Make sure without fail to observe the locally applicable safety regulations and regulations as mandated

by trade law.

To acquire the knowledge that is required to operate the unit, the following measures must be carried out by the operator

• product training

• regular safety instruction

This unit may be used by children as of 8 years old and moreover also by anyone with reduced physical, sensory or mental capa-

bilities or a lack of experience and knowledge if they are supervised or have been instructed in connection with safe use of the unit

and the danger resulting from it. Children are not allowed to play with the unit. Cleaning and maintenance must not be carried out

by children without supervision.

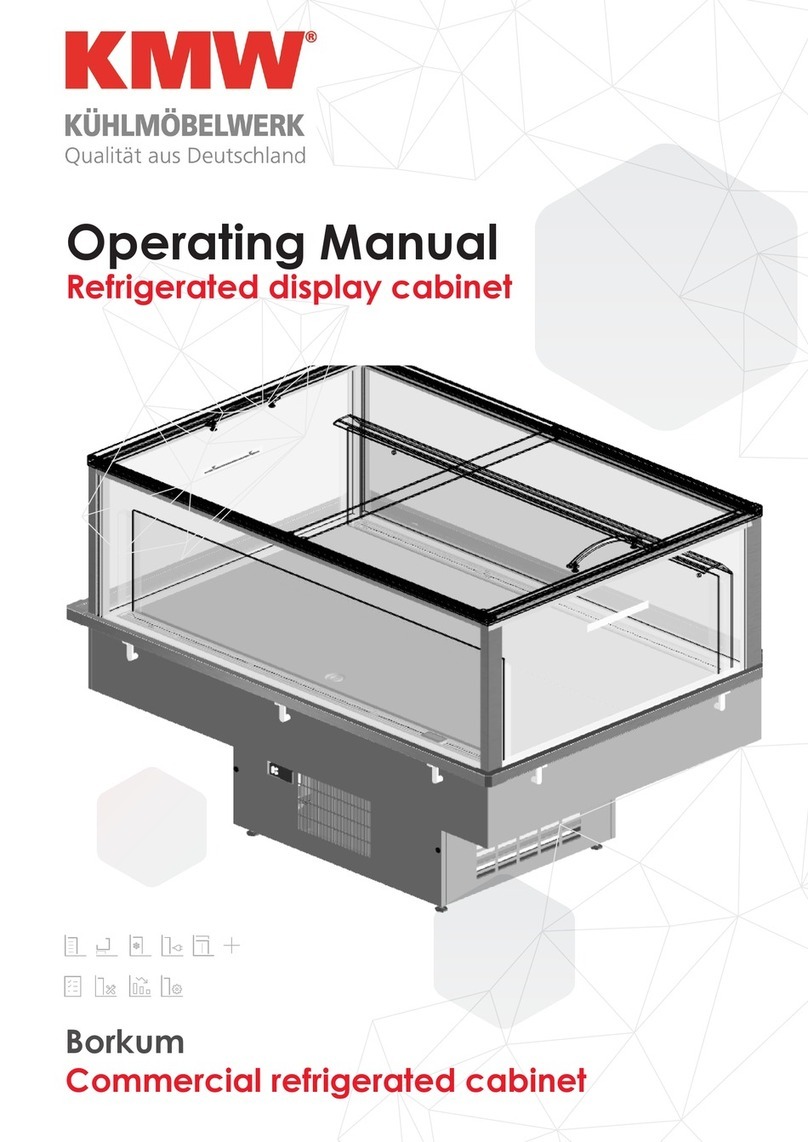

The units are intended specically for installation in food and dispensing counters. They are suitable for keeping food products and

beverages cold and presenting them at controllable temperatures (see catalogue and homepage). The units only serve to keep

food cold, but not to cool it down. The units must be operated in perfect condition. All existing covers and doors must be mounted

and closed during operation. The covers and doors may only be opened briey for stocking and removing products. The given

units are designed for climate class 3 according DIN EN ISO 23953. To save energy, we recommend switching o the units when

they are not in use outside of business hours. Before stocking the units, wait until the desired temperature is reached.