Aktobis AG, Borsigstr. 20, D-63110 Rodgau / Germany

www.AKTOBIS.de

Email: Info@Aktobis.de

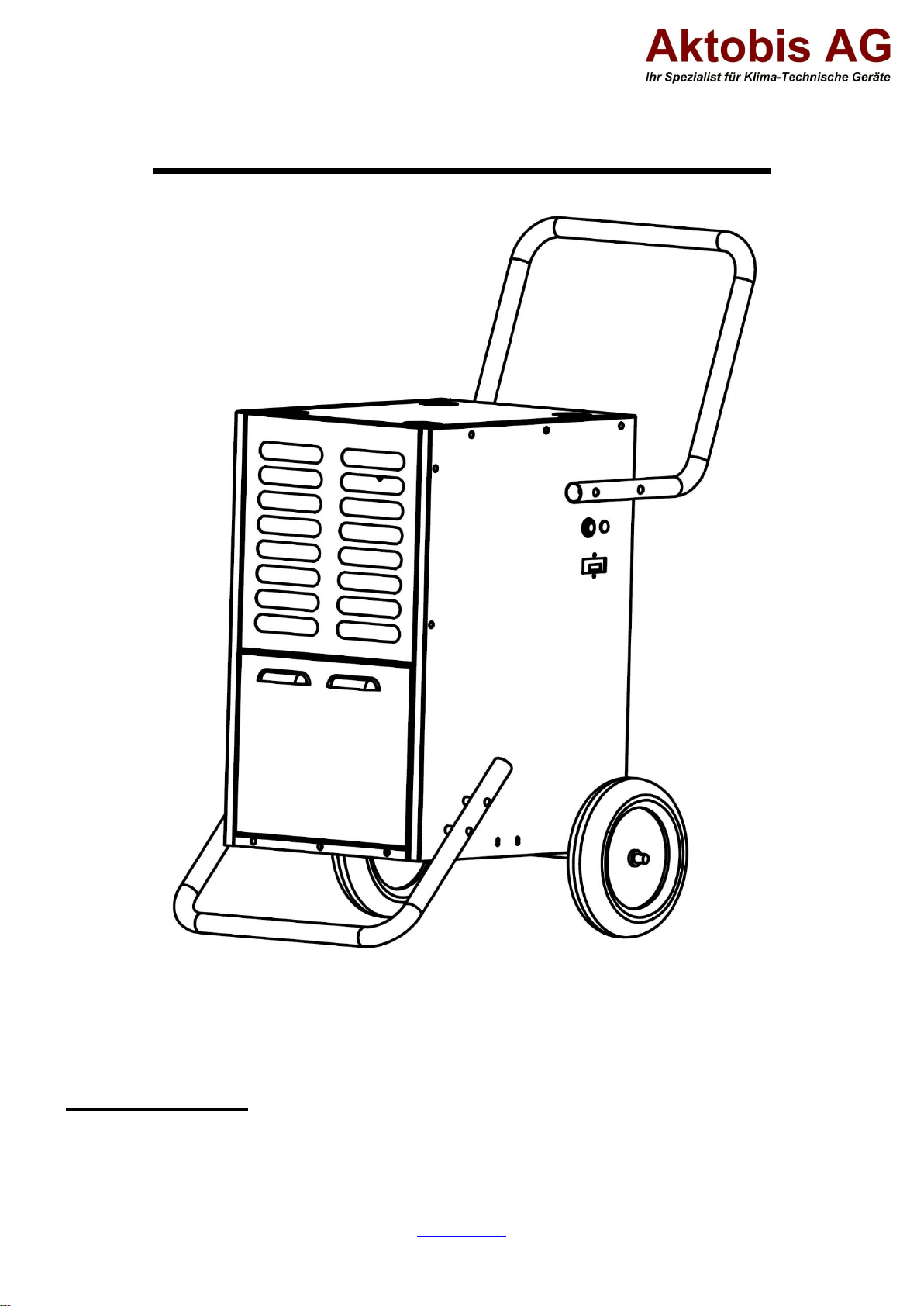

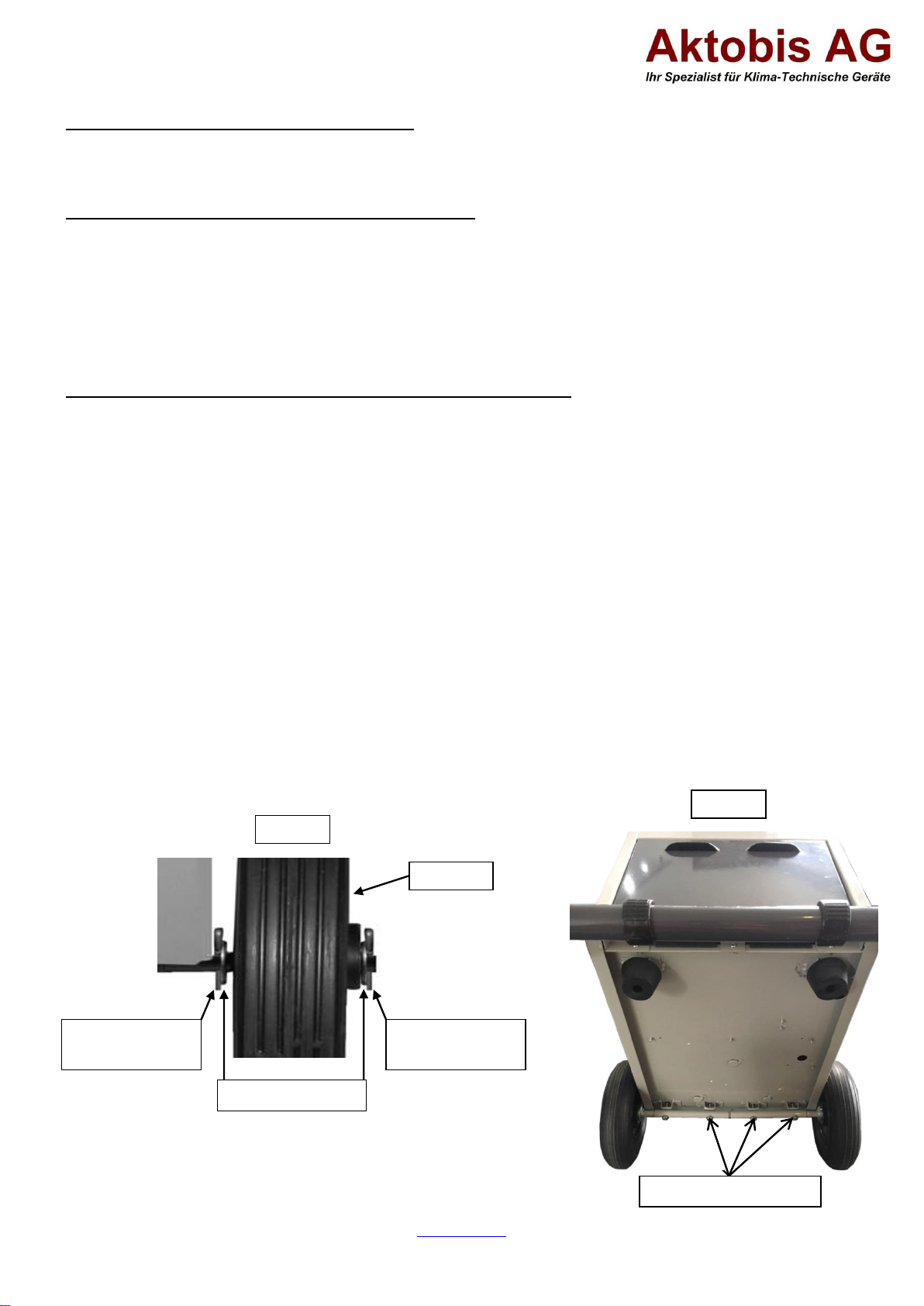

After transport or assembly:

As the unit works with cooling liquid, we ask you to let it stand upright for at least 1 hour before using it for the first

time or after mounting the castors and the transport handle, so that the cooling liquid can settle properly in the unit

again.

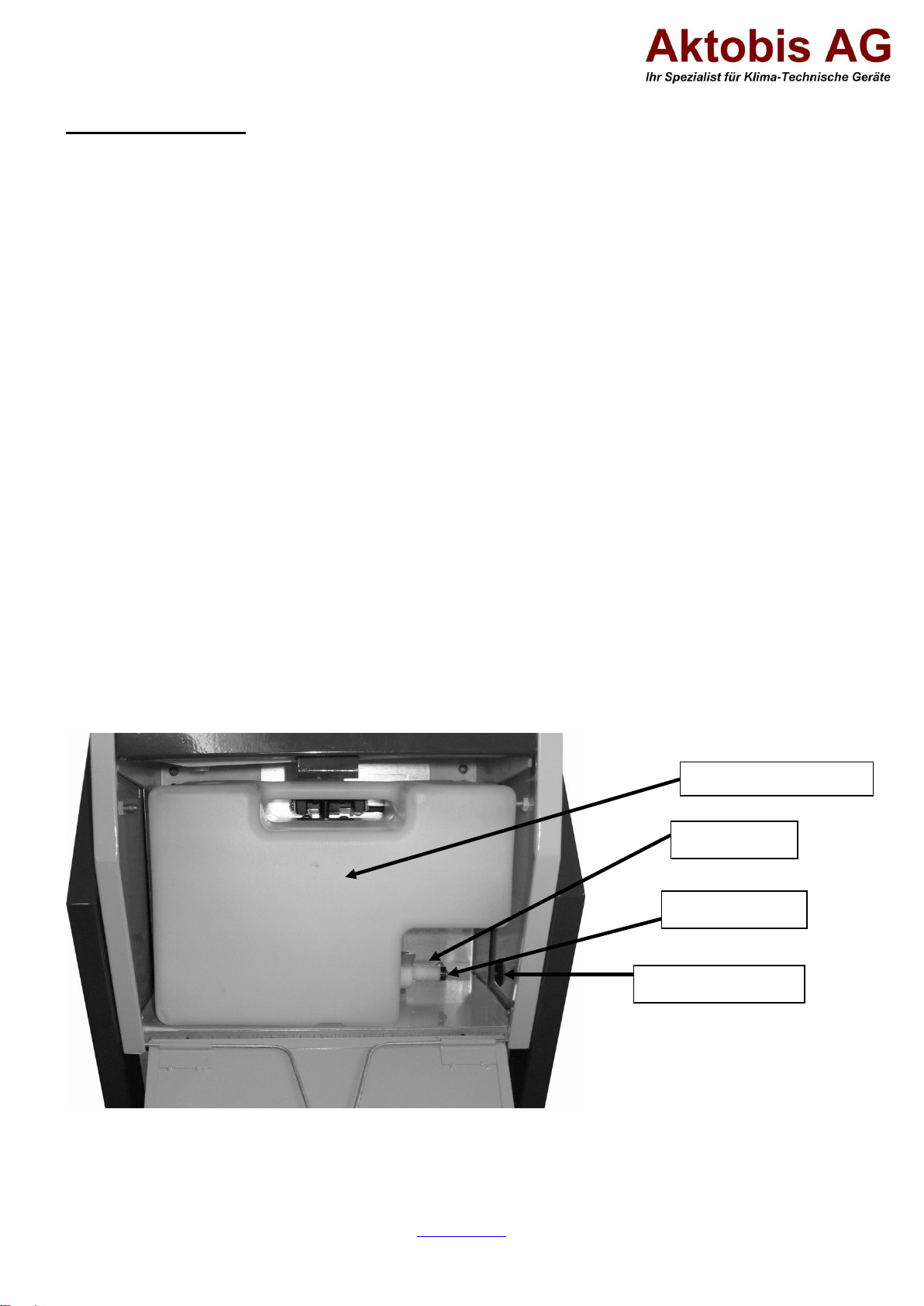

During first operation / hose connection:

If you want to use a hose connection for draining the condensate, make sure that the hose connection is properly

seated and that the condensate (water) can always drain off unhindered! If this is not observed, the water

condensed by the building dryer (up to 50 litres per day) can cause damage to the room!

Room humidity and dehumidification performance:

If you want to check the room humidity and the associated dehumidification performance with your own humidity

meter (hygrometer), please avoid attaching this humidity meter to a wall, as this will falsify the true humidity content

of the room air. See also the explanations under Troubleshooting !!!

Important safety instructions:

- Supervise the building dryer when children are near the unit !

- Watch out for electricity - never walk into or insert objects into the appliance !

- Do not place any objects on the construction dryer !

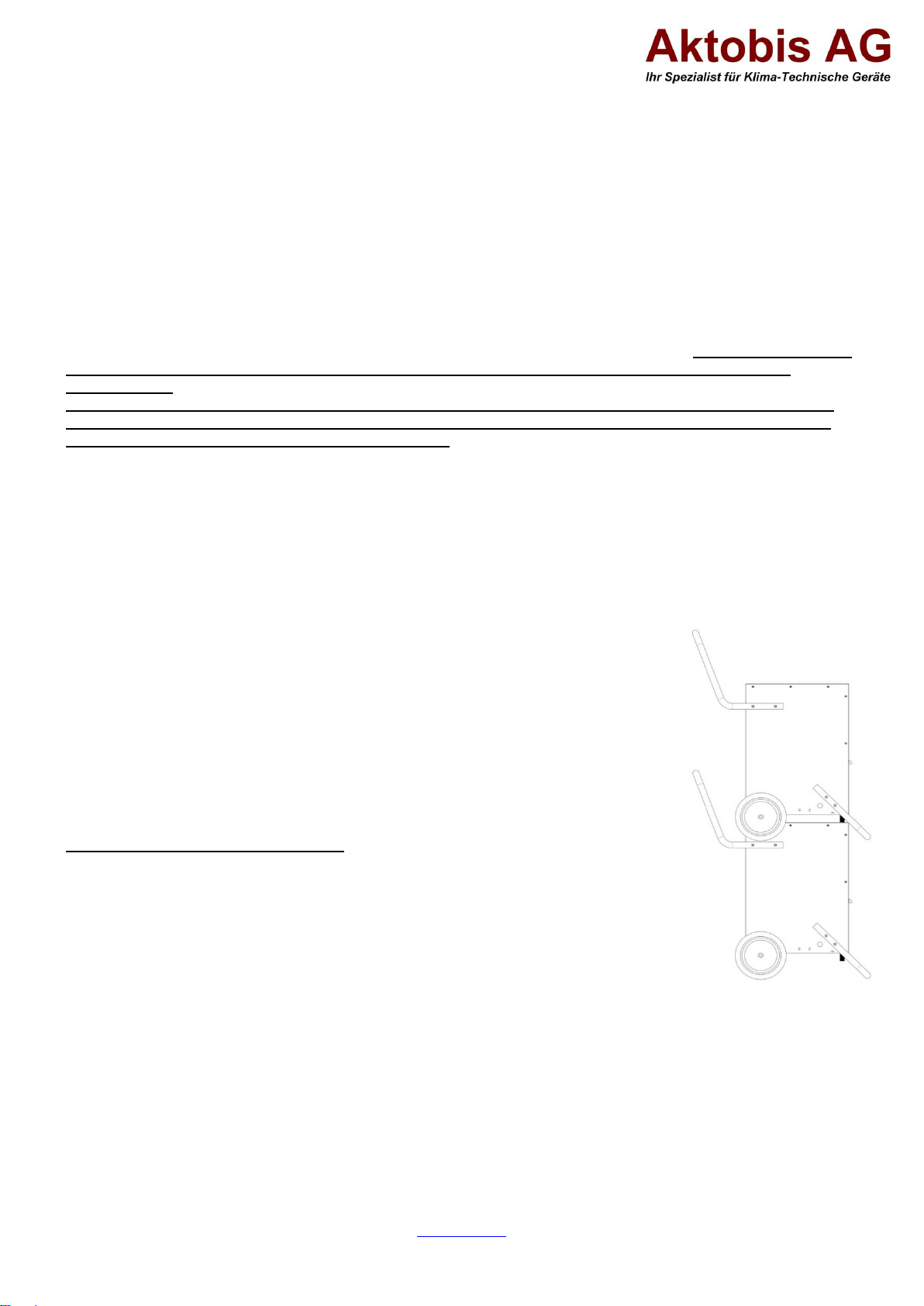

- Do not block the exhaust and intake louvres of the unit and please ensure sufficient space/clearance at and

around the fan !

- Make sure that there is sufficient air supply to the unit, otherwise it can lead to a reduction in performance and,

in the worst case, to overheating and/or fire ! Please always keep a distance of approx. 20 cm to the wall to

avoid possible overheating of the unit ! Do not use in airtight rooms !

- Only qualified personnel or electricians are allowed to open the unit or carry out repairs !

- Make sure that no moisture gets into or onto the unit !

- Use only the recommended voltage (220V-240V / 50Hz) to operate the appliance !

- Make sure that the power cable is unfolded (untied) before connecting it to the socket !

- Make sure that the plug is cleanly and properly connected to the socket before using the appliance !

- Do not use multiple sockets to operate the building dryer !

- Make sure that highly flammable substances (e.g. gases/oils etc.) are never in the vicinity of the unit !

- Do not use any insect, oil or paint spray etc. near the building dryer. This may cause damage to the unit or

even fire !

- If you are not going to use the unit for a long time, switch it off and disconnect the mains plug !

- Do not disconnect the mains plug by pulling on the power cable !

- Please keep the unit away from heat sources and avoid direct sunlight !

- Always hold and transport the unit in its proper position ! Never place the unit on its side or even upside down !

- Make sure that the unit is properly earthed via the earthed plug supplied !

Please switch off the unit immediately and disconnect it from the mains/power supply if anything

seems to be wrong !!! In this case, please contact a specialist and do not attempt to repair the

unit yourself !!!

Examples: Fan does not run during operation, fuse has blown, there is a funny smell or the compressor rattles

loudly.