Alamo Schulte SRW 1400 Troubleshooting guide

SRW 1400

PIVOTING ROCK WINDROWER

Published 03/03 Effective S/N R20000256301 - Current Part No. R200-03-1

OPERATOR’S MANUAL

with PARTS LISTING

Schulte Industries Ltd.

P.O. Box 70

Englefeld Saskatchewan

Canada S0K 1N0

Tel. (306) 287-3715

Fax. (306) 287-3355

Parts Fax. (306) 287-4066

To The Owner/Operator/Dealer

This manual hasbeen compiled to assistyou in operating and servicing your new SCHULTERock

Windrower. READ and UNDERSTAND this manual BEFORE operating the rock windrower. Pay

special attention to the safety instructions.

In addition to the design and configuration of equipment, hazard control and accident prevention

aredependent upon the awareness, concern, prudenceand proper training ofpersonnel involved

in the operation, transport, maintenance and storage of equipment.

WARRANTY INFORMATION:

Read and understand the completeWarranty Statementfound at the back of this Manual. Fill out

the Warranty Validation Form in full and return it within thirty (30) days of the date of purchase.

Make certain the Serial Number and ModelNumberis recordedon theallthree copiesof theform.

The use of non-genuine SCHULTE replacement parts could result in voiding of warranty.

Schulte SRW 1400 March, 2003

DEALER'S PREDELIVERY SERVICE GUIDE ..................................... i

SAFETY SECTION ........................................................ 1-1

Decals ........................................................... 1-10

INTRODUCTION SECTION ................................................. 2-1

General Data ....................................................... 2-3

ASSEMBLY SECTION ..................................................... 3-1

Before Operation .................................................... 3-2

Connection to Tractor ................................................ 3-2

Leveling the Windrower ............................................... 3-3

Wheel Lock Pins .................................................... 3-4

Driveline Shield Chains ............................................... 3-4

Light Kit ...........................................................3-5

OPERATION SECTION .................................................... 4-1

Transport to Working Position .......................................... 4-2

Working to Transport Position .......................................... 4-3

Transport Pin ....................................................... 4-4

Setting Working Depth ................................................ 4-4

Field Operation ..................................................... 4-4

Transportation ...................................................... 4-4

Troubleshooting ..................................................... 4-6

MAINTENANCE SECTION .................................................. 5-1

Nuts And Bolts ...................................................... 5-2

Drive Chain ........................................................ 5-2

Windrower Teeth .................................................... 5-2

Hubs And Spindles ..................................................5-3

Tires ............................................................. 5-4

Shear Bolt ......................................................... 5-4

Hydraulics ......................................................... 5-5

Slip Clutch ......................................................... 5-5

LUBRICATION ..................................................... 5-6

Gearbox ..................................................... 5-6

Grease Schedule .............................................. 5-7

Universal Joint Assemblies ...................................... 5-7

Windrower Frame ............................................. 5-7

Wheel Hubs ..................................................5-7

Drive Chain .................................................. 5-8

STORAGE ......................................................... 5-8

TABLE OF CONTENTS

Schulte SRW 1400 March, 2003

PARTS SECTION ......................................................... 6-9

Main Frame ....................................................... 6-10

Drum Frame ...................................................... 6-12

Hitch Pole ........................................................ 6-14

Wheel Standard, Pivoting ............................................ 6-16

Wheel Standard, Transport ........................................... 6-18

Hub, Axle, Tire (H517) ............................................... 6-20

Hub, Axle, Tire (H511) ............................................... 6-22

Chain Case Components ............................................. 6-24

Hydraulic Components .............................................. 6-26

Hydraulic Cylinder, 3 x 8 Monarch (100-3121) ............................. 6-28

Slip Clutch, 800 Nm, BP FF1 (341-4030) ................................ 6-29

Tractor Universal Joint, BP Size 4 (340-450) .............................. 6-30

Universal Joint, BP Size 4 (340-453) .................................... 6-31

Universal Joint, BP Size 6 (340-627) .................................... 6-32

Gearbox, BP#S2100230004 (330-550) .................................. 6-34

Screw Jack, Side Wind (232-600) ...................................... 6-36

Transport Kits ..................................................... 6-37

Safety Chain (S000-010) ....................................... 6-37

Light Kit (S000-065) ........................................... 6-37

Parts Index ....................................................... 6-38

iSchulte SRW 1400 March, 2003

DEALER'S PREDELIVERY SERVICE GUIDE

for Model SRW 1400 PIVOTING ROCK WINDROWER

DETAILS OF ITEMS LISTED BELOW ARE COVERED IN THIS OPERATOR'S MANUAL

____ Shipping damage corrected

____ Set up machine as outlined in the Assembly Instructions and Operator’s Manual.

____ Check that all safety decals are in good condition, replace if necessary.

____ IMPORTANT: Gearboxes are shipped dry, fill with gear oil.

____ Lubricate all grease fittings.

DEALER'S DELIVERY GUIDE

for Model SRW 1400 PIVOTING ROCK WINDROWER

____ Mounting and removal from tractor

____ Operation

____ Adjustments

____ Lubrication

____ Maintenance

____ Storage

____ Operator's safety precautions

____ User's responsibility and warranty

____ Operator's manual delivered to owner

____ Operator instructed on contents of owner's manual

PREDELIVERY SERVICE IS REQUIRED BY DEALER OR END USER

iiSchulte SRW 1400 March, 2003

1-1Schulte SRW 1400 March, 2003

SAFETY

SECTION

1-2Schulte SRW 1400 March, 2003

CAUTION!

WARNING!

DANGER!

Asafe and careful operator is the best operator. Safety is of primary importance to the

manufacturerandshouldbetotheowner/operator. Mostaccidentscanbeavoidedbybeingaware

of your equipment, your surroundings, and observing certainprecautions. The first section of this

Manual includes a list of Safety Messages that, if followed, will help protect the operator and

bystandersfrominjuryordeath. ReadandunderstandtheseSafetyMessagesbeforeassembling,

operatingor servicing this Windrower. This equipment should onlybe operated by those persons

who have read the Manual, who are responsible and trained, and who know how to do so safely

and responsibly.

The Safety Alert Symbol combined with a Signal Word, as seen below, is used throughout this

Manual and on decals which are attached to the equipment. The Safety Alert Symbol means:

“ATTENTION! BECOMEALERT! YOURSAFETY IS INVOLVED!” TheSymbolandSignalWord

are intended to warn the owner/operator of impending hazards and the degree of possible injury

faced when operating this equipment.

The lowest level of Safety Message; warns of possible injury. Decals located on the

Equipment with this Signal Word are Black and Yellow.

Serious injury or possible death! Decals are Black and Orange.

Imminent death/critical injury. Decals are Red and White. (SG-1)

SAFETY

Practice all usual and customary safe working precautions and

above all---remember safety is up to YOU. Only YOU can prevent

serious injury or death from unsafe practices.

1-3Schulte SRW 1400 March, 2003

PELIGRO!

¡LEA EL

INSTRUCTIVO!

DANGER!

WARNING!

WARNING!

WARNING!

WARNING!

DANGER!

READ,UNDERSTAND,andFOLLOWthefollowingSafetyMessages.

Serious injury or death may occur unless care is taken to follow the

warnings and instructions stated in the Safety Messages. Always

use good common sense to avoid hazards. (SG-2)

Si no lee Ingles, pida ayuda a alguien que si lo lea para

que le traduzca las medidas de seguridad. (SG-3)

NeveroperatetheTractororImplementuntil youhaveread and completely

understand this Manual, the Tractor Operator's Manual, and each of the

Safety Messages found in the Manual or on the Tractor and Implement.

Learn how to stop the Tractor engine suddenly in an emergency. Never

allow inexperienced or untrained personnel too operate the Tractor and

Implementwithout supervision. Make sure the operator has fully read and

understood the Manuals prior to operation. (SG-4)

Always maintain the safety decals in good readable condition. If the decals are missing,

damaged, or unreadable, obtain and install replacement decals immediately. (SG-5)

Make certain that the "Slow Moving Vehicle"(SMV) signis installed in such

away as to be clearly visible and legible.When transporting the Equipment

use the Tractorflashingwarning lights and follow all local traffic regulations.

(SG-6)

roll-over-protectivesystem(ROPS).Alwayswearseatbelts.Seriousinjury

or even death could result from falling off the Tractor--particularly during

a turnover when the operator could be pinned under the ROPS. (SG-7)

Do not modify or alter this Implement. Do not permit anyone to modify or alter this Implement,

any of its components or any Implement function. (SG-8)

BEFORE leaving the Tractor seat,always engage the brake and/or set the

Tractor transmission in parking gear, disengage the PTO, stop the engine,

remove the key,and waitforallmoving parts to stop. Place the Tractor shift

lever into a low range or parking gear to prevent the Tractor from rolling.

Neverdismount a Tractor that is moving or while the engine is running.

Operate the Tractor controls from the Tractor seat only. (SG-9)

SAFETY

1-4Schulte SRW 1400 March, 2003

DANGER!

DANGER!

WARNING!

DANGER!

DANGER!

DANGER!

Never allow children or other persons to ride on the Tractor or Implement.

Falling off can result in serious injury or death. (SG-10)

Never allow children to operate or ride on the Tractor or Implement.

(SG-11)

Donotmount the Tractorwhile the Tractoris moving. MounttheTractor only

when the Tractor and all moving parts are completely stopped. (SG-12)

Start Tractoronly when properly seated in the Tractor seat.Starting a Tractor

in gear can result in injury or death. Read the Tractor Operators Manual for

proper starting instructions. (SG-13)

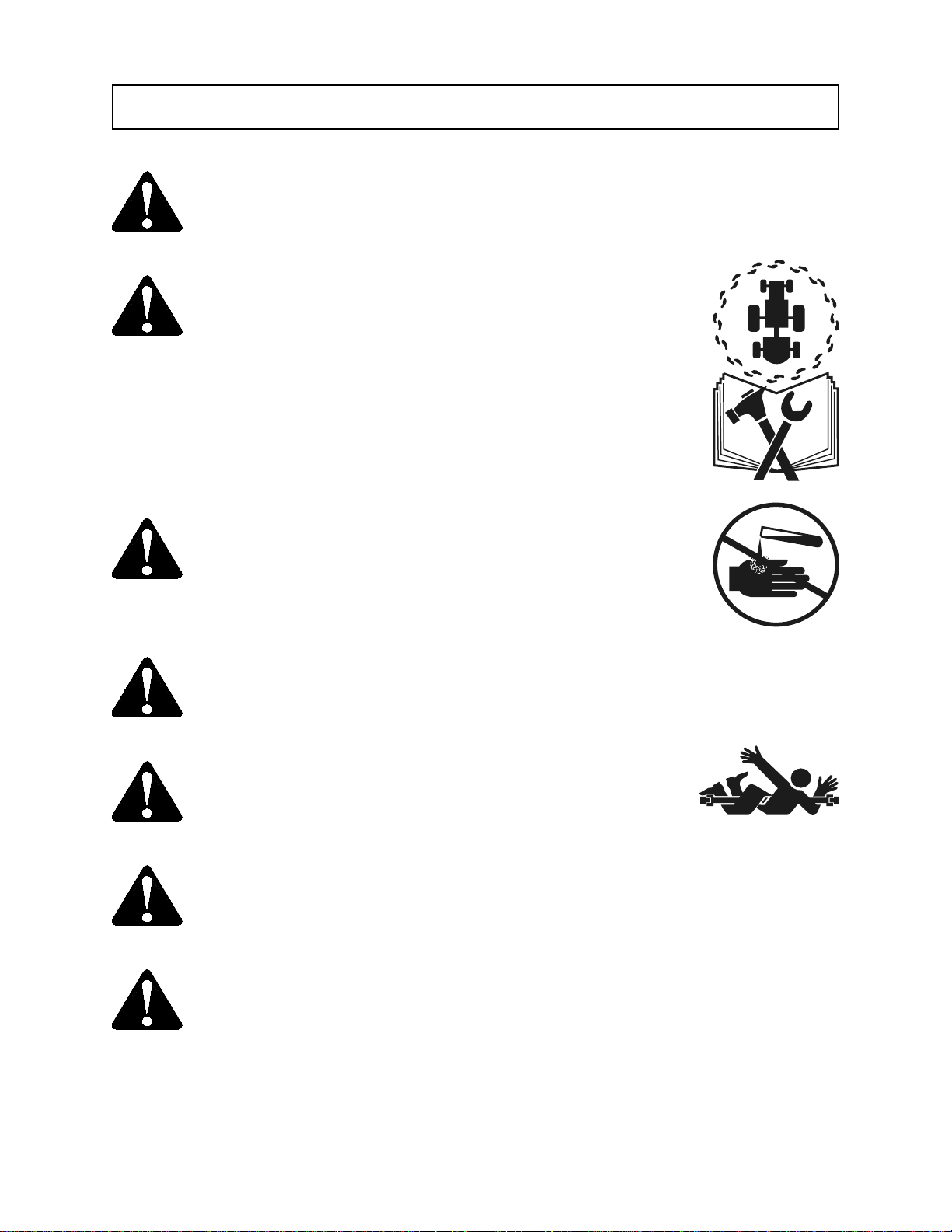

Never work under the Implement, the framework, orany lifted componentunlessthe Implement

is securely supported or blocked up to prevent sudden or inadvertent falling which could cause

serious injury or even death. (SG-14)

Do not operate this Equipment with hydraulic oil leaking. Oil is expensive

and its presence could present a hazard. Do not check for leaks with your

hand! Use a piece of heavy paper or cardboard. High-pressure oil streams

from breaks in the line could penetrate the skin and cause tissue damage

including gangrene. If oil does penetrate the skin, have the injury treated

immediately by a physician knowledgeable and skilled in this procedure.

(SG-15)

SAFETY

1-5Schulte SRW 1400 March, 2003

WARNING!

CAUTION!

WARNING!

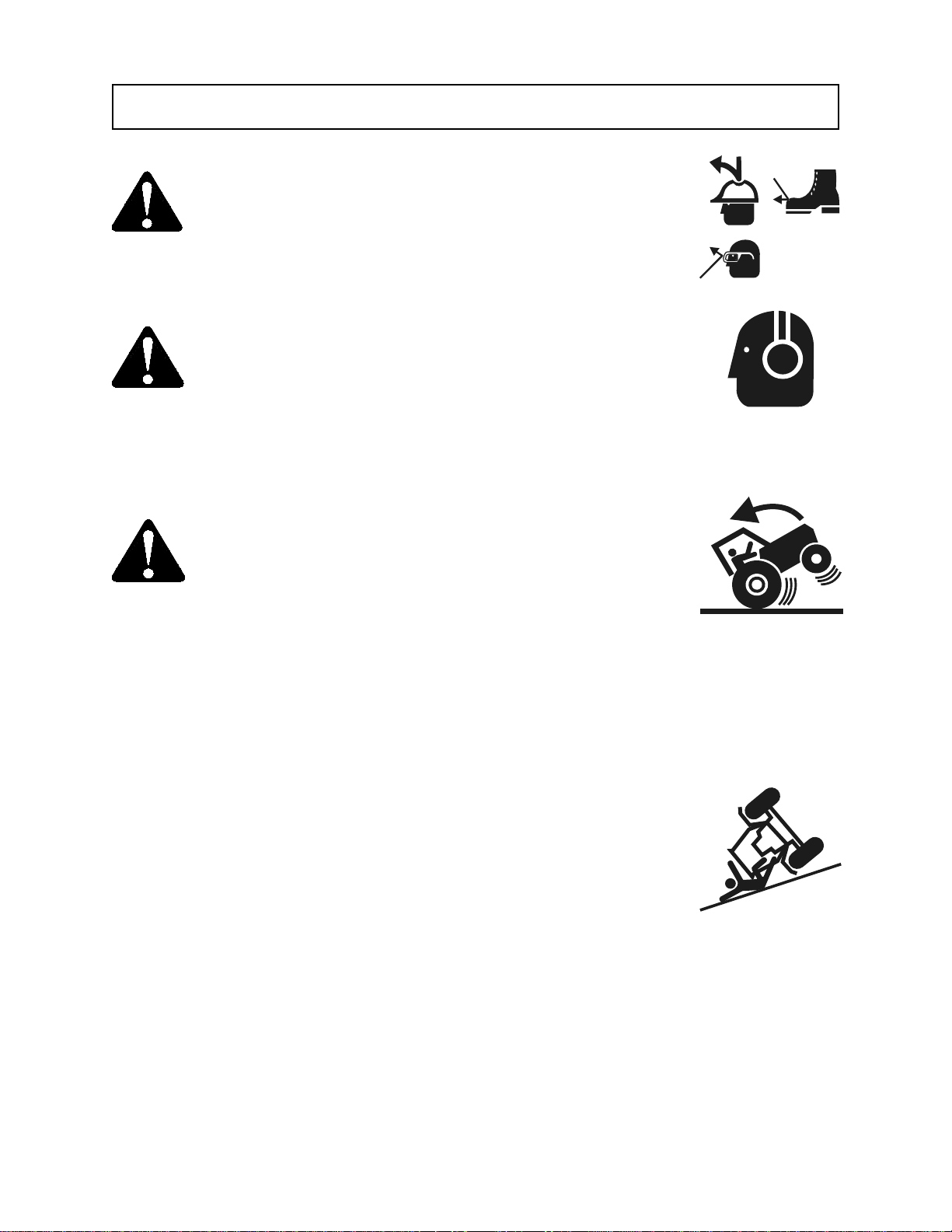

Theoperator and all support personnel should wear hard hats, safety

shoes, safety glasses, and proper hearing protection at all timesfor

protectionfrom injuryincludinginjury fromitems thrownbytheEquipment.

(SG-16)

PROLONGED EXPOSURE TO LOUD NOISE MAY CAUSE PERMANENT

HEARING LOSS! Tractors with or without an Implement attached can often

be noisy enough to cause permanent hearing loss. We recommend that you

alwayswear hearing protection if the noise in the Operator's position exceeds

80db. Noise over 85db over an extended period of time will cause severe

hearing loss. Noise over 90db adjacent to the Operator over an extended

period of time will cause permanent or total hearing loss. Note: Hearing loss

from loud noise [from Tractors, chainsaws, radios, and other such sources

closeto the ear] is cumulative over a lifetime without hopeof naturalrecovery.

(SG-I7)

Transport only at safe speeds. Serious accidents and injuries can result

from operating this Equipment at unsafe speeds. Understand the Tractor

and Implement and how it handles before transporting on streets and

highways. Make sure the Tractor steering and brakes are in good

condition and operate properly.

Before transporting the Tractor and Implement, determine the safe

transportspeedsforyou and theEquipment. Makesureyouabideby

the following rules:

1. Test the Tractorat a slow speed and increase the speed slowly. Apply

the Brakes smoothly to determine the stopping characteristics of the

Tractor and Implement.

Asyou increase the speedofthe Tractorthe stoppingdistance increases.

Determinethe maximumsafetransportspeedforyou andthis Equipment.

2. Test the Equipment at a slow speed in turns. Increase the speed

through the turn only after you determine that it is safe to operate at a

higher speed. Use extreme care and reduce your speed when turning

sharply to prevent the Tractor and Implement from turning over.

Determine the maximum safe turning speed for you and this Equipment

before operating on roads or uneven ground.

3. Only transport the Tractorand Implement atthe speedsthat you have

determined are safe and which allow you to properly control the

Equipment.

Be aware of the operating conditions. Do not operate the Tractor with

weak or faulty brakes. When operating down a hill or on wet or rain slick

roads,the braking distance increases: use extreme care and reduce your

speed.WhenoperatingintrafficalwaysusetheTractor's flashingwarning

lights and reduce your speed. Be aware of traffic around you and watch

out for the other guy. (SG-19)

SAFETY

1-6Schulte SRW 1400 March, 2003

WARNING!

WARNING!

WARNING!

DANGER!

DANGER!

DANGER!

WARNING!

Never attempt to lubricate, adjust, or remove material from the Implement while it is in motion

or while Tractor engine is running. Make sure the Tractor engine is off before working on the

Implement. (SG-20)

Periodically inspect all moving parts for wear and replace when necessary

with authorized service parts. Look for loose fasteners, worn or broken

parts, and leaky or loose fittings. Make sure all pins have cotter pins and

washers. Serious injury may occur from not maintaining this machine in

good working order (SG-21)

Always read carefully and comply fully with the manufacturers instructions

when handlingoil, solvents,cleansers, and any other chemical agent.(SG-22)

Never run the Tractor engine in a closed building or without adequate ventilation. The exhaust

fumes can be hazardous to your health. (SG-23)

KEEP AWAY FROM ROTATING ELEMENTS to prevent entanglement

and possible serious injury or death. (SG-24)

Never allow children to play on or around Tractor or Implement. Children can slip or fall off the

Equipment and be injured or killed. Children can cause the Implement to shift or fall crushing

themselves or others. (SG-25)

Do not exceed the rated PTO speed for the Implement. Excessive PTO speeds can cause

Implement driveline or blade failures resulting in serious injury or death. (SG-26)

SAFETY

1-7Schulte SRW 1400 March, 2003

DANGER!

DANGER!

DANGER!

WARNING!

WARNING!

DANGER!

WARNING!

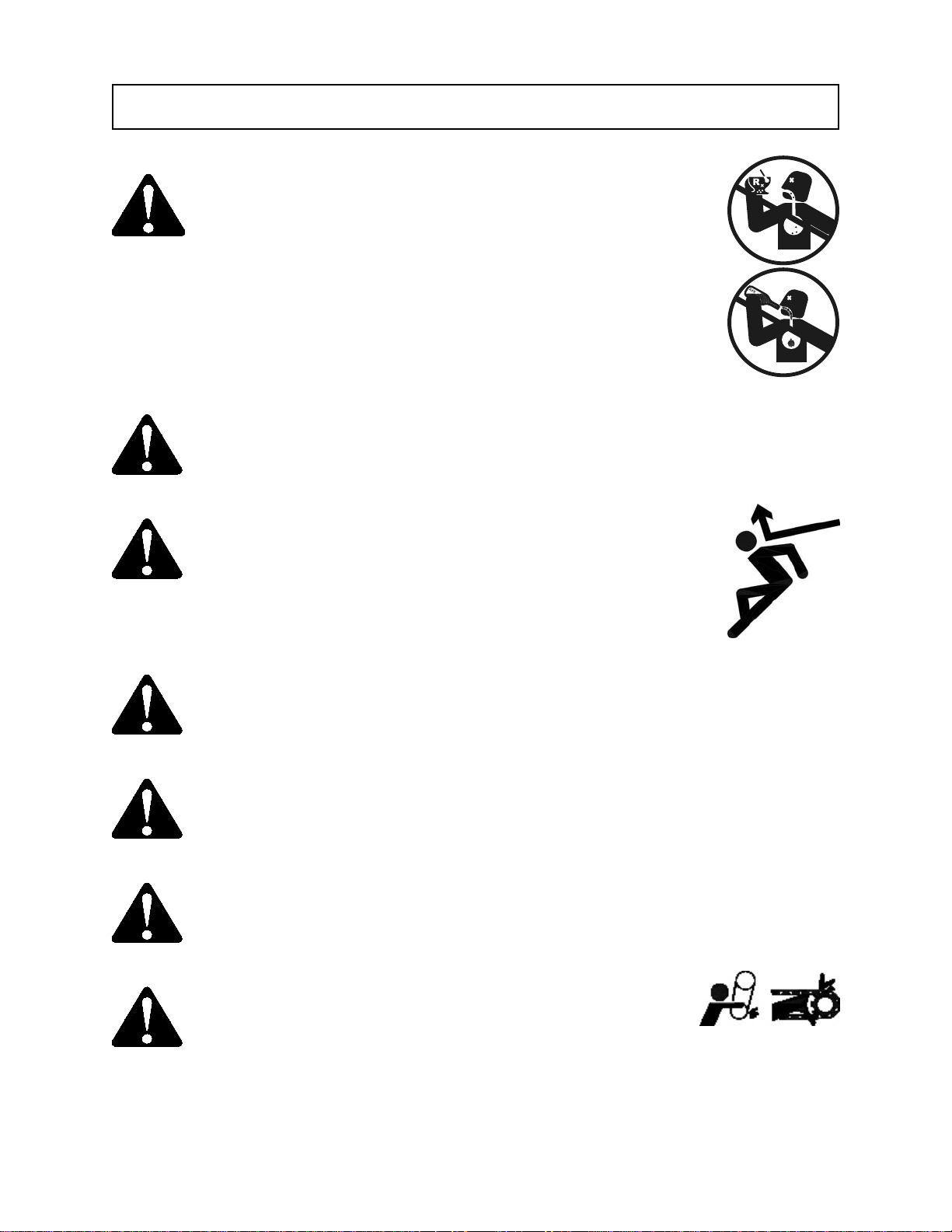

NEVER usedrugsoralcoholimmediatelybeforeorwhileoperatingtheTractor

and Implement. Drugs and alcohol will affect an operator's alertness and

coordination and therefore affect the operator's ability to operate the

Equipmentsafely. Before operating the Tractor or Implement, an operator on

prescription or over-the-counter medication must consult a medical

professional regarding any side effects of the medication that would hinder

their ability to operate the Equipment safely. NEVERknowingly allow anyone

to operate this Equipment when their alertness or coordination is impaired.

Serious injury or death to the operator or others could result if the operator is

under the influence of drugs or alcohol. (SG-27)

Operate the Tractor and/orImplementcontrols onlywhile properly seated in theTractorseatwith

the seat belt securely fastened around you. Inadvertentmovement of the Tractor or Implement

may cause serious injury or death. (SG-29)

There are obvious and hidden potential hazards in the operation of this

Implement. REMEMBER! This machine isoften operated inareas with heavy

rocks and the teeth of this Implement can throw objects. Serious injury or

evendeath may occurunlesscare is taken to insurethe safety of the operator,

bystanders,or passerby inthe area. Do not operate this machine with anyone

in the area. (SGR-1)

Many varied objects, such as wire, cable, rope, orchainscan become entangled in the rotating

Drum. These items could then spin at greater velocities then the Drum. Such a situation is

extremely hazardous and could result in serious injury or even death. Inspect area for such

objects before windrowing. Remove any like object from the site. (SGR-2)

Operate at the speed that you can safely operate and control the Tractor and Implement. Safe

operating speed depends on terrain condition, rock density, rock size, and working depth.

Normal ground speed range is from 0 to 5 mph. Use slow speeds when operating on or near

steepslopes,drop-offs,overhead obstructions, power lines, or when debris and foreign objects

are to be avoided. (SGR-3)

Always disconnect the main PTO Driveline from the tractor before performing service on the

Implement. Never work on the Implement with the Tractor PTO Driveline connected and

running. Rotating Parts, Drivelines, or the Drum could turn without warning and cause

immediate entanglement, injury or death. (SGR-4)

Keep hands, feet,hairand clothing away from moving parts. Contact with

movingparts can result in serious injury oreven death. Stay away until all

motion has stopped. (SGR-5)

SAFETY

1-8Schulte SRW 1400 March, 2003

WARNING!

WARNING!

DANGER!

WARNING!

WARNING!

DANGER!

DANGER!

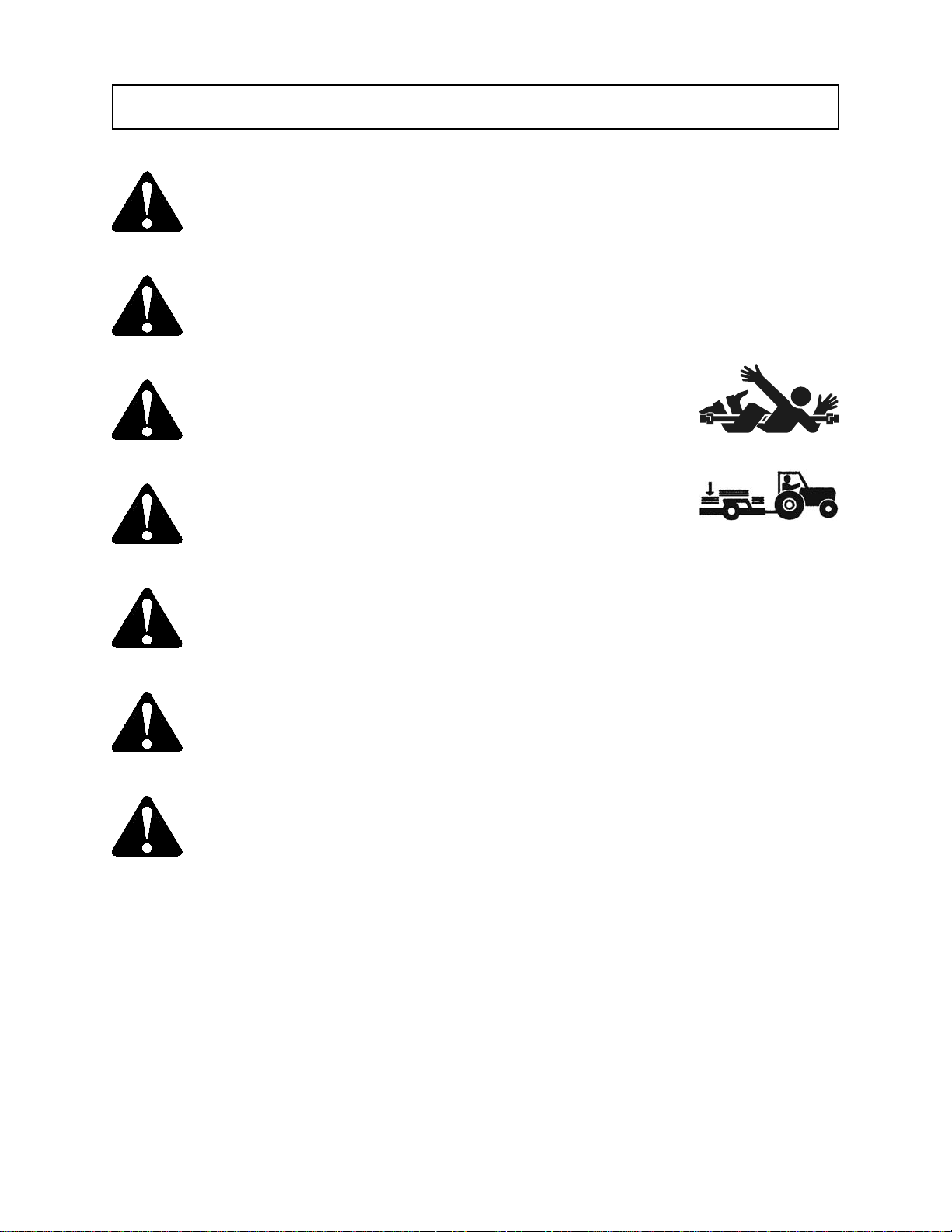

NeverleaveTractorand ImplementunattendedwhiletheDrumis in theliftedposition.Accidental

operation of lifting lever or a hydraulic failure may cause sudden drop of Drum with injury or

death by crushing.To properly park the Implement when disconnecting itfrom the Tractor,raise

the drum and put the transport pin securely in place,or lower the Drum carefully to the ground.

Do not put hands or feet under lifted components. (SGR-6)

Never stand between the Tractor and Implement when Tractor is being backed up to hitch, or

when the Implement is being prepared for transportation. (SGR-7)

Make sure the PTOshield, integral driveline shields,and input shields are

installed when using PTO-driven Equipment. Always replace any shield if

it is damaged or missing. (S3PT-8)

Relieve hydraulic pressure prior to doing any maintenance or repair work

on the Implement.Place the Implement on the groundor securely blocked

up,disengage the PTO, and turn off the Tractorengine. Pushand pull the

Remote Cylinder lever in and out several times prior to starting any

maintenance or repair work. (S3PT-9)

The rotating parts of this machinecontinue to rotate even after the PTO has been turnedoff. The

operator should remain in his seat for 60 seconds after the brake has been set, the PTO

disengaged, the Tractor turned off, and all evidence of rotation has ceased. (3PT-10)

"Wait a minute...Save a life!"

This Implement is wider than the Tractor. Be careful when operating or transporting this

EquipmenttopreventtheImplementfromrunningintoor strikingsign posts,guardrails,concrete

abutments or other solid objects. Such an impact could cause the Implement and Tractor to

pivotviolently resulting in loss of steering control, serious injury, or even death. Never allow the

Implement to contact obstacles. (3PT-12)

Be particularly careful when transporting the Implement using the Tractor. Turncurves orgo up

or down hills only at a low speed and at a gradualsteering angle.Make certain that atleast20%

of the Tractor's weight is on the front wheels to maintain safe steerage. Slow down on rough or

uneven surfaces. (STI-1)

SAFETY

1-9Schulte SRW 1400 March, 2003

PARTS INFORMATION

Schulte Industries Ltd. Windrowers use matched system components for roller chain, drivetrain components

and bearings. These parts are made and tested to Schulte specifications. Non-genuine “will fit” parts do not

consistently meet these specifications. The use of “will fit” parts may reduce Windrower performance, void

Windrower warranties,and present a safety hazard.Use genuineSchulte Windrower parts for economy and

safety. (SPRM-1)

SEE YOUR SCHULTE DEALER

In addition to the design and configuration of this Implement, including Safety Signs and Safety Equipment,

hazard control and accident prevention are dependent upon the awareness, concern, prudence, and proper

trainingofpersonnelinvolvedintheoperation,transport,maintenance,andstorageofthe machine.Refer also

toSafetyMessages andoperation instructionineachoftheappropriatesectionsoftheTractor andEquipment

Manuals. Pay close attention to the Safety Signs affixed to the Tractor and Equipment. (SG-18)

SAFETY

1-10Schulte SRW 1400 March, 2003

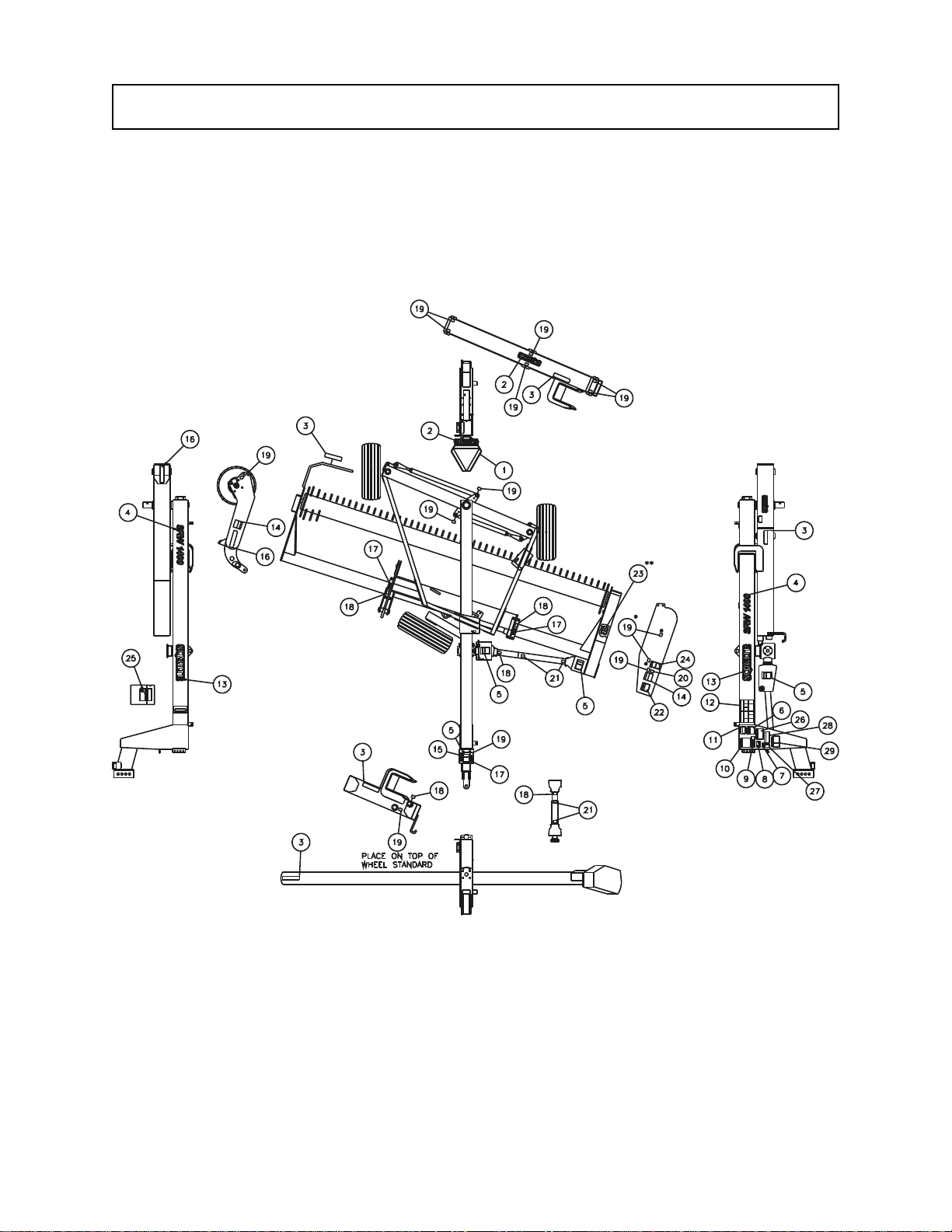

Decals

SAFETY

1-11Schulte SRW 1400 March, 2003

Decals

Ref. Part No. Description Qty.

1226-013 Decal 'Slow moving vehicle' 1

2226-117 Decal 'SCHULTE', medium profile 2

3226-154 Amber Reflector 5

4226-178 Decal 'SRW 1400' 2

5226-032 Decal 'Danger Rotating Driveline' 4

6226-148 Decal 'Warning High Pressure Fluid' 1

7226-163 Decal ‘Patent Pending’ 1

8226-100 Serial # Plate 1

9226-084 Decal 'Made In North America' 1

10 226-146 Decal 'Warning... review manual...' 1

11 226-081 Decal 'Check Oil Level......Gear Boxes' 1

12 226-179 Decal Windrower Transport Instructions 1

13 226-118 Decal 'SCHULTE’, large profile 2

14 226-151 Decal ‘Thrown Rock Hazard’ 2

15 226-037 Decal 'Warning 540 RPM only ...’ 1

16 226-153 Red Reflector 2

17 226-044 Decal ‘Grease nipple on underside...’ 3

18 226-181 Decal Greasing, 8 hour 5

19 226-182 Decal Greasing, 50 hour 14

20 226-183 Decal Oil, 8 hour 1

21 226-180 Decal Greasing, 4 hour 4

22 226-192 Decal, Warning Moving Part Hazard 1

23 226-193 Decal ‘Danger Guard Missing’ 1

24 226-191 Decal ‘Peligro...’ 1

25 226-197 Decal ‘Operator’s Manual Inside...’ 1

26 226-142 Decal 'Tractor drawbar....' 1

27 226-004 Decal ‘FEMA Member’ 1

28 226-049 Decal ‘Use Genuine Schulte Parts’ 1

29 226-048 Decal, ‘Do Not Transport’ 1

SAFETY

1-12Schulte SRW 1400 March, 2003

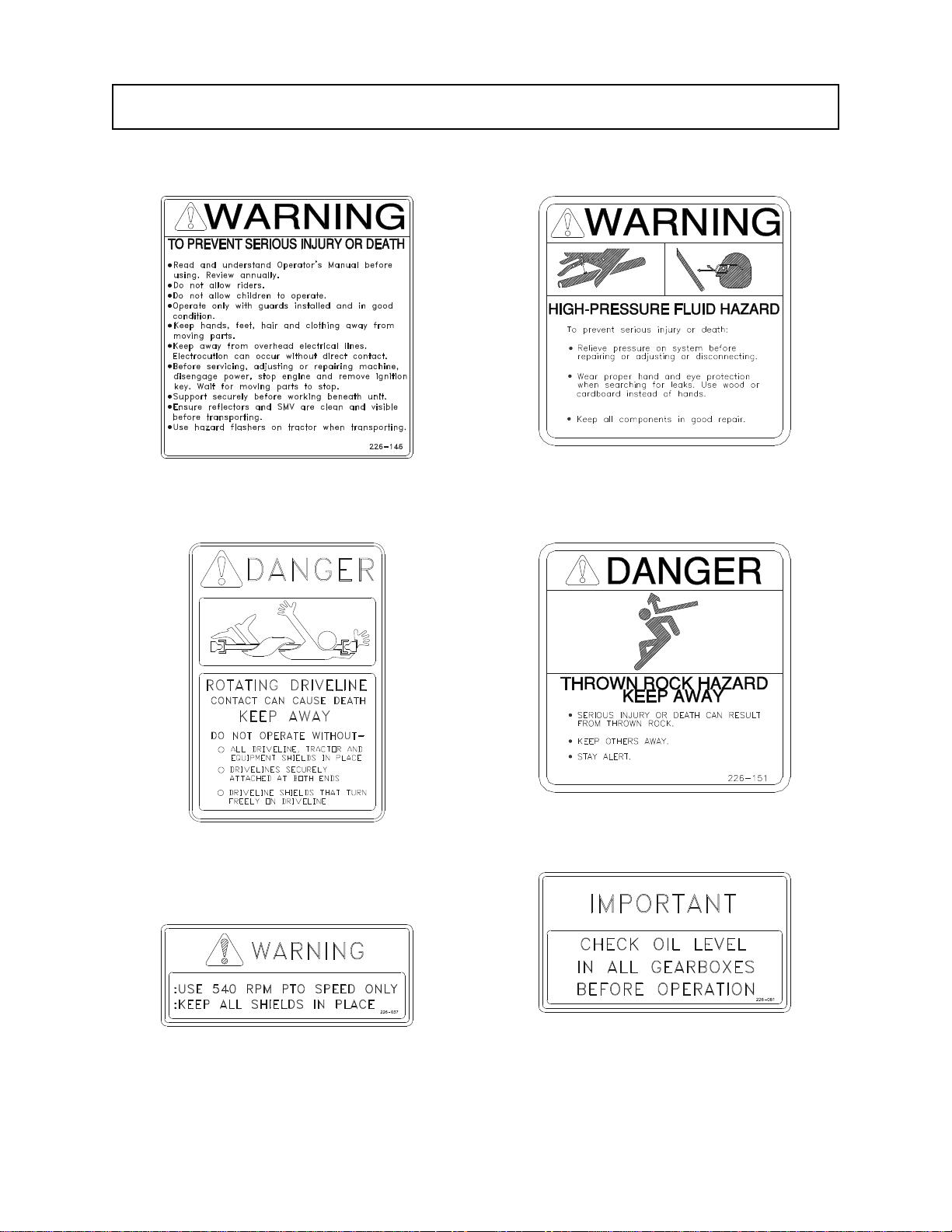

Decal # 226-146

Location: Left side of main frame.

Decal # 226-032

Location: All universal joint assemblies, exterior

shields.

Decal # 226-037

Location:Over power takeoffinputshaftonthemain

frame of the windrower.

Decal # 226-148

Location: Left side of main frame.

Decal # 226-151

Location: Drum support frame right arm and chain

case cover.

Decal # 226-081

Location: Left side of the main frame.

SAFETY

1-13Schulte SRW 1400 March, 2003

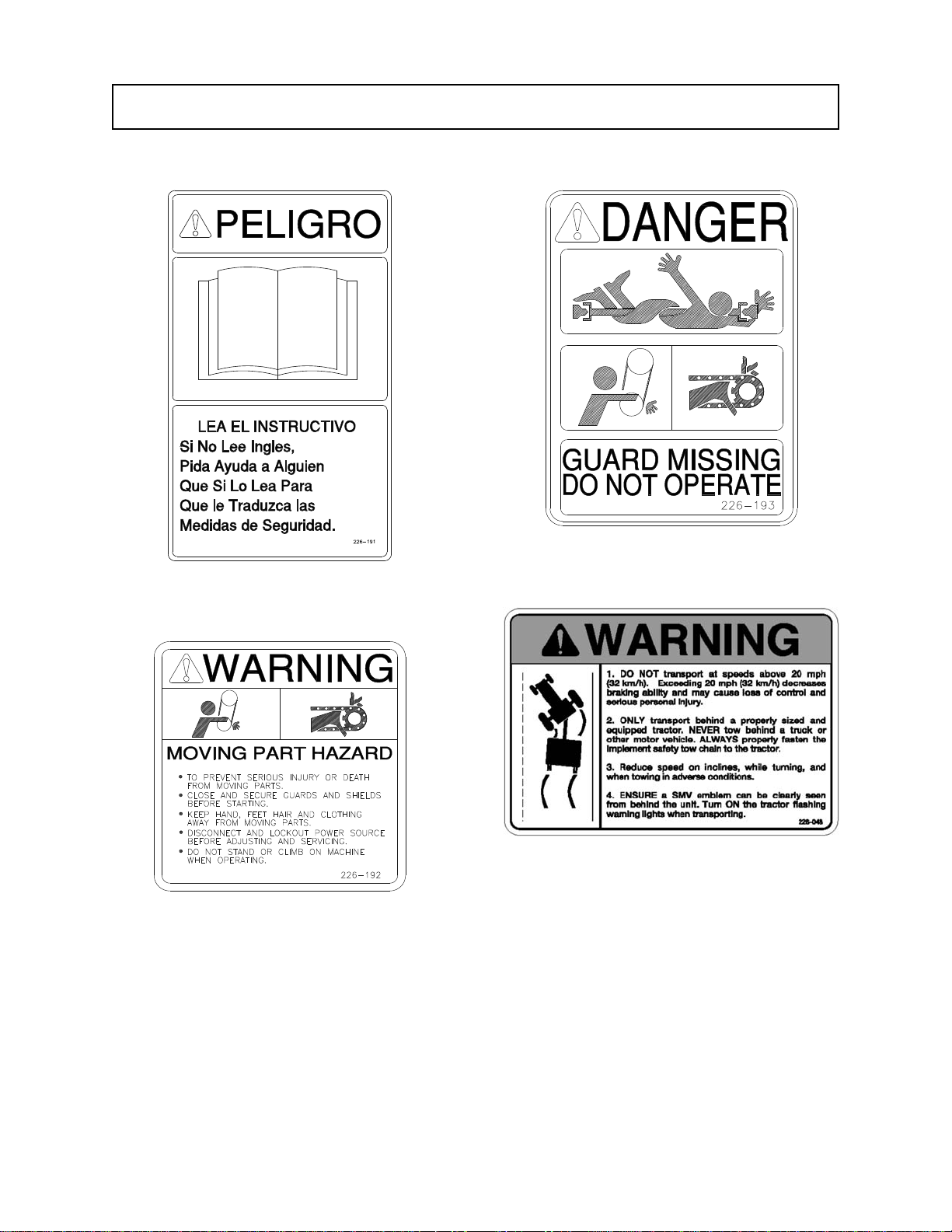

Decal # 226-191

Location: Drum chain case cover.

Decal # 226-192

Location: Drum chain case cover.

Decal # 226-193

Location: Inside drum chain case cover.

Decal # 226-048

Location: Left side of main frame.

SAFETY

1-14Schulte SRW 1400 March, 2003

Other manuals for Schulte SRW 1400

1

Table of contents

Popular Tractor Accessories manuals by other brands

McConnel

McConnel ROBO-FLAILHEAD 1300 Operation manual

RadTech

RadTech LS Tractor LW3150 Operator and parts manual

Sears

Sears CRAFTSMAN C 151 61581 0 owner's manual

MTD

MTD 490-900-0024 Operator's manual

Tiger

Tiger HEXA SERIES OPERATOR'S MANUAL AND SPARE PARTS

matev

matev SRM-SF 140 Original operating manual

Degelman

Degelman 6900 Series Operator's Manual/Parts Catalog

BAUMAN

BAUMAN Hay Fluffer Tedder Operator's manual

FARM STAR

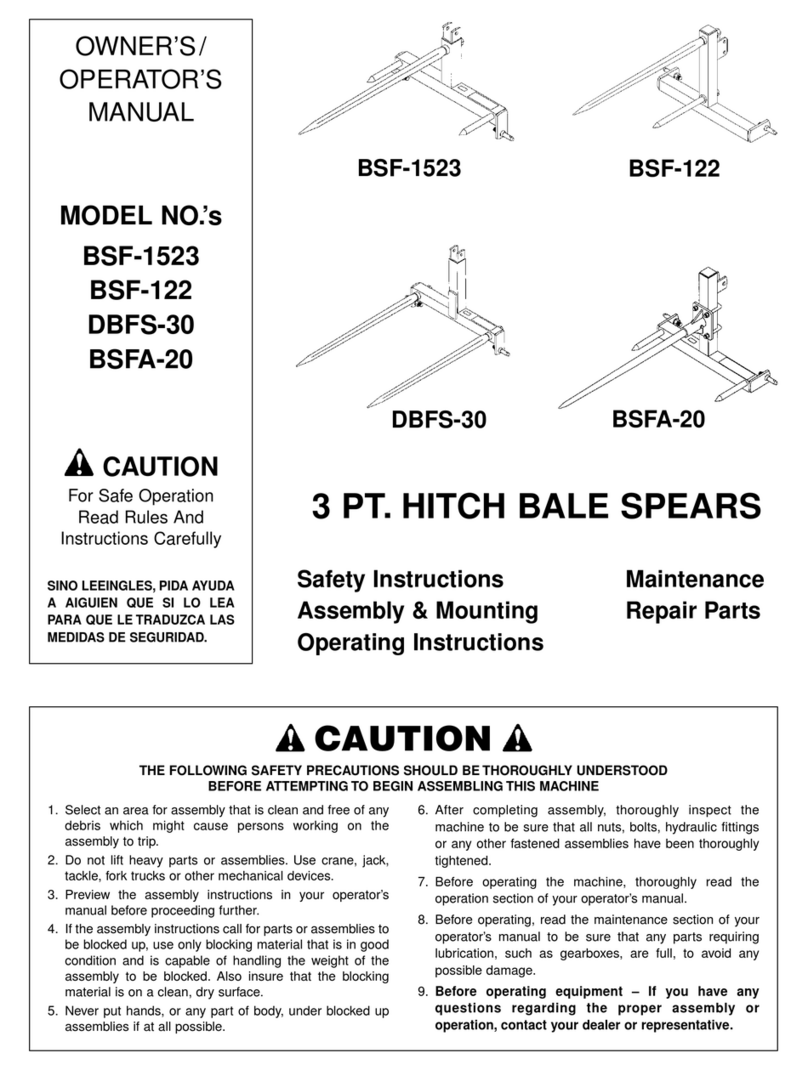

FARM STAR BSF-1523 Owner's/operator's manual

Bomet

Bomet S239 owner's manual

Grouser Products

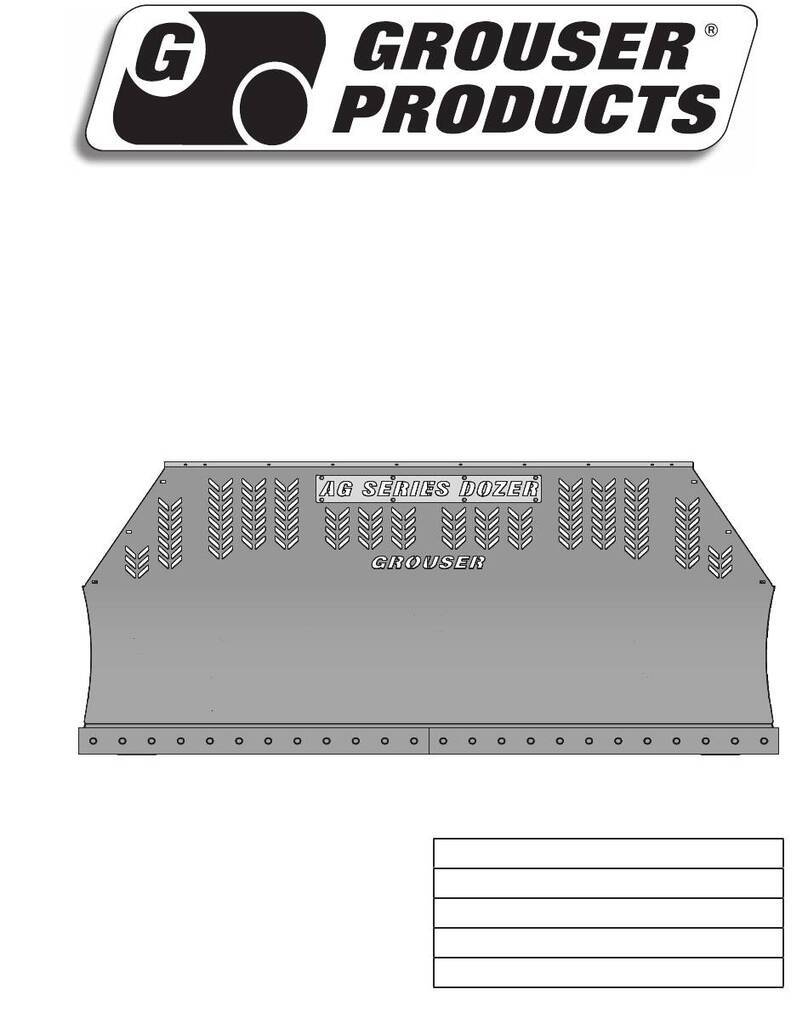

Grouser Products AG240 Owner's manual & parts book

Everything Attachments

Everything Attachments ETA Compact Owner's and operator's manual