Everything Attachments ETA Compact User manual

ADDITIONAL COPIES AVAILABLE

ETA Compact, ETA 6900, ETA 6900-HD

COURTESY OF: T.C Corriher Implement Co. Inc. DBA: Everythingattachments.com

12 South Ashe Avenue Newton, NC 28658

2

MACHINERY CAN HURT YOU

WARNINGS

DO NOT PERMIT RIDERS ON MACHINERY

MACHINERY, IN A LIFT POSITION, CAN FALL WHILE OPERATING OR WHEN

SITTING STILL

STAY AWAY FROM OPERATING MACHINERY - KEEP OTHERS AWAY

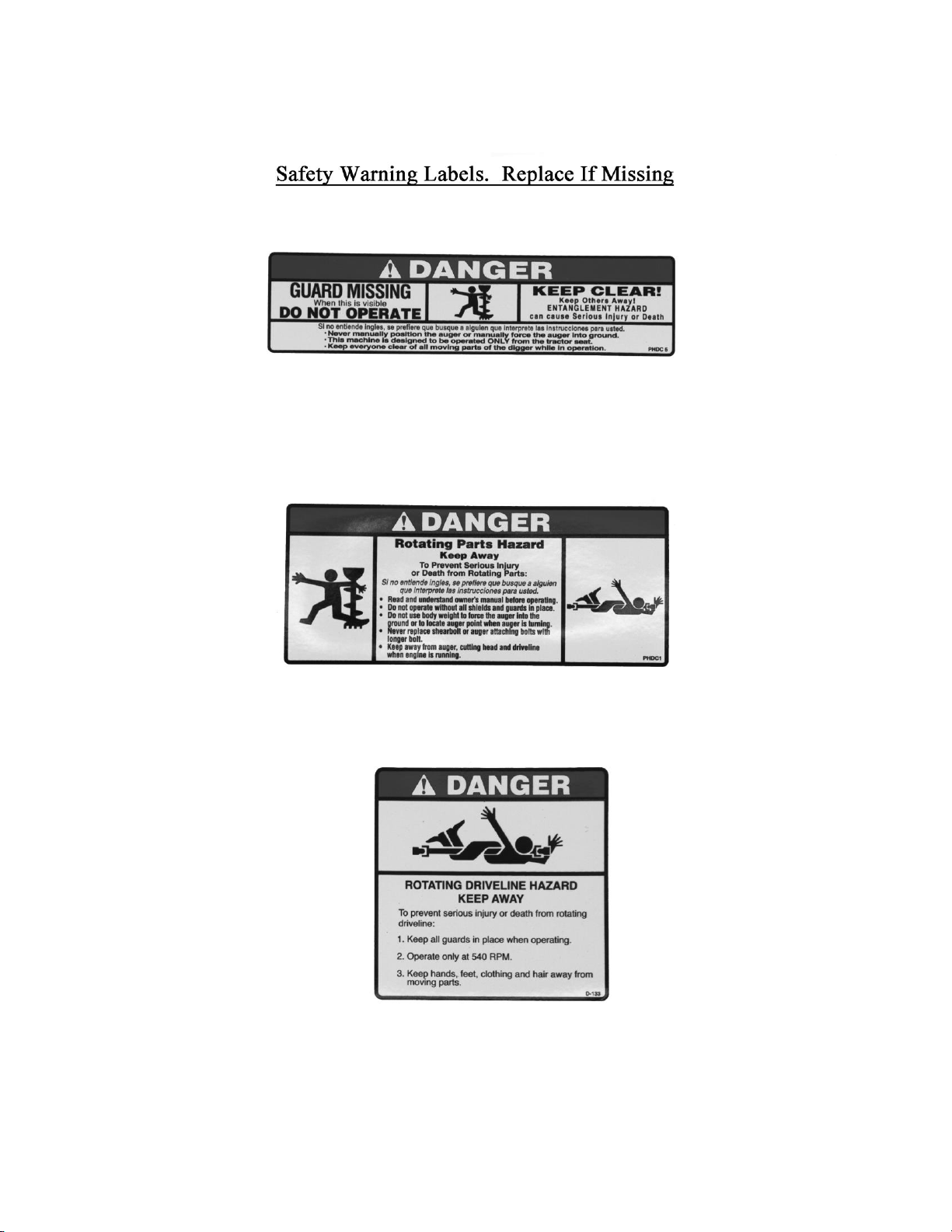

* Observe and follow instructions obtained on decals attached to farm machinery. The wide

variety of warning, caution, and instructional decals are placed on machinery for YOUR

safety. Always keep hands, feet, and clothing away from all moving pads.

* Make certain that everyone is clear of the machine before starting power unit or activating any

drive mechanism.

* Keep hands, feet, and clothing away from moving parts of the machine. Do not wear loose

clothing.

* Keep children off, and away, from all machinery.

* Be sure that all shields or guards are in place before any machine is started.

* Replace any damaged or misplaced guards or shields.

* Keep all machinery free of excessive accumulation of crop material or other debris.

* Stay alert from obstructions, ditches and other hazards when operating machinery.

* Operate machinery at a speed to match the field and crop condition and/or operator

proficiency.

* Shut off the tractor engine or power unit before attempting to refuel. DO NOT SMOKE!

Refuel in a well ventilated area and avoid spilling fuel.

* Always shut off the engine before leaving the operator's platform to adjust, lubricate, clean or

unclog a machine, unless otherwise specified in the operator's manual.

* Wait until all power driven pads have stopped before attempting to perform any inspection or

servicing of the machine.

ETA Compact, ETA 6900, ETA 6900-HD

COURTESY OF: T.C Corriher Implement Co. Inc. DBA: Everythingattachments.com

12 South Ashe Avenue Newton, NC 28658

3

* Provide a temporary guard for knives when working with them.

* After servicing equipment, be sure all tools, parts, or servicing equipment are moved before

starting the machine.

* Before restarting operation, replace or secure all safety shields that you have removed or

opened for access when making field repairs.

* Have a fire extinguisher available and in good operating condition. Also take first aid kit.

ETA Compact, ETA 6900, ETA 6900-HD

COURTESY OF: T.C Corriher Implement Co. Inc. DBA: Everythingattachments.com

12 South Ashe Avenue Newton, NC 28658

4

ETA Compact, ETA 6900, ETA 6900-HD

COURTESY OF: T.C Corriher Implement Co. Inc. DBA: Everythingattachments.com

12 South Ashe Avenue Newton, NC 28658

5

ETA Compact, ETA 6900, ETA 6900-HD

COURTESY OF: T.C Corriher Implement Co. Inc. DBA: Everythingattachments.com

12 South Ashe Avenue Newton, NC 28658

6

ETA Compact –ETA 6900 –ETA 6900 HD Post Hole Digger

OPERATOWS MANUAL AND SAFETY WARNING MESSAGE

!! DANGER! SAFETY FIRST, READ ALL PAGES.

1. GENERAL INFORMATION

Your Everything Attachments posthole digger has been manufactured of quality materials

and components. Care has been taken to make this implement as safe as possible to operate;

HOWEVER, any machine with moving parts can present a hazard if the operator does not follow

common sense rules of safety while operating the machine.

The purpose of this manual is to help you understand the instructions of how to use the

equipment safely and be familiar with the safety warning message in order to minimize risks that

may occur if the machine is not used properly and if the minimum precautions or attentions are

not paid.

The manual will assist you in setting up, operating, and maintaining your digger. Read it

carefully and thoroughly; it furnishes information and instruction that will help you achieve

many years of dependable performance. These instructions have been compiled from extensive

field experience. Some Information may be general in nature due to unknown and varying

conditions. However, through experience and these instructions, you should be able to develop

procedures suitable to your particular situation.

The illustrations and data used in this manual were current at the time of printing, but due

to possible in-line production changes; your machine may vary slightly in detail. Our current

production model includes as standard equipment, guards or shields for auger adapters, driveline,

input shafts, and safety signs. If you have a machine that does not have current standard safety

equipment please contact Everything Attachments about bringing your machine up to the current

level of safety. We reserve the right to redesign and change the machines as may be necessary

without notification.

2. ASSEMBLY INFORMATION

To attach the A-frame (#1) with the lift pins (#2) to the boom pole (#4) put the bolt

provided, into the middle adjustment hole on the boom pole. For adjustment to your tractor, you

may have to move the A-frame to another hole so the auger will lift clear of the ground. Tighten

the bolt but not excessively. This allows the A-frame to pivot when the digger is raised and

lowered by the tractor.

Slide the socket of the lower LEFT lift arm of the tractor over the lift (#2) on the

A-frame, then slide the right lift arm onto the lift pin, using the adjustment crank lever to

position the lift arm at the correct height. Now attach the boom to the tractor where the top-link

mounts behind the tractor seat. The top link is not required for operation. Stabilizers should be

used to prevent side motion (available from your tractor manufacturer). Remove both sides of

auger safety shield (#13) and take auger shear bolts from auger. Use the tractor to raise the

boom pole until you are able to slide the auger onto to the gearbox output shaft (#18 on

gearbox listing). Now lower the lift on the tractor to slide the output shaft inside the auger. KEEP

HANDS CLEAR OF AUGER IN CASE OF LIFT FAILURE TO REVENT PINCHING OF

OPERATOR'S HANDS BETWEEN THE AUGER AND THE DIGGER. Align the hole for the

ETA Compact, ETA 6900, ETA 6900-HD

COURTESY OF: T.C Corriher Implement Co. Inc. DBA: Everythingattachments.com

12 South Ashe Avenue Newton, NC 28658

7

shear bolt and replace the shear bolts. Tighten lock washers and hex nuts. (CAUTION: USE OF

SHEAR BOLT HARDER THAN GRADE TWO 2 FOR ETA COMPACT AND ETA 6900 OR

GRADE 3 FOR ETA 6900 HD COULD CAUSE DAMAGE TO YOUR GEARBOX). NOTE: A

longer or protruding shear bolt is more likely to grab loose clothing or gloves, which can result in

serious injury or death. Replace two halves of auger safety shield and secure with wing nuts.

Depress the locking spring on the (PTO) shaft (#11) and slide coupler onto tractor output shaft

until the PTO locking pin clicks in place. Make sure set screw (#10) is tight on PTO shaft at

gearbox. The setscrew holds the PTO shaft on the gearbox shaft if the PTO shear pin breaks. Fill

gearbox with 90W-gear oil. Unscrew ½” fill plug on top of gearbox and 1/4'' overflow plug on

side. Fill until oil runs out of side plug (about 1 Qt.). Install both plugs. Grease the PTO universal

joints, the metal PTO shaft and spray lube the plastic cover tube so that both will slide in and out

freely. Fasten chain on plastic PTO cover at gearbox to the hole in side of PTO shield. Fasten

PTO chain at the tractor end of the cover to the lift arms of the actor. This allows the shaft to turn

but the outside plastic shield remains stationary to protect the operator from becoming entangled

in the PTO shaft and thus causing personal injury.

3. PRE-USE CHECK LIST

Inspect the digger thoroughly after assembly to be certain it is set up properly before operation

and use the following checklist as a reminder of points to inspect. Check off each item as it is

found satisfactory or after proper adjustment is made.

- Check that all safety shielding is in place.

- Check all bolts to be sure they are tight.

- Check gearbox oil level. It is full when oil runs out of the overflow hole on side of gear

box (1/4 inch pipe plug). Use 90 weight gear oil.

- Check that all lubrication points and that all grease fittings have been lubricated

(2 fittings).

- Check that cutting edges have been properly installed on auger.

4. PREPARATION

- Always wear relatively tight and belted clothing to avoid entanglement in moving

parts. Wear sturdy, rough-soled work shoes. Never operate tractor or implements in bare

feet sandals, or sneakers.

- Clear area of branches or other debris that might be thrown by the auger, causing

personal injury or damage to the machine.

-NEVER ALLOW ANYONE AT REAR OF TRACTOR OR NEAR AUGER

WHILE OPERATING. The posthole digger was designed for one-man operation from

the tractor seat. It is the responsibility of the operator to see that no one is within twenty

five feet (25’) of the digger when it is in operation.

- Operate only in daylight or good artificial light.

- Ensure digger is properly mounted, adjusted and in good operating condition.

- Ensure all safety shielding is properly installed.

- Remember, stabilizers should be used to prevent side swing.

ETA Compact, ETA 6900, ETA 6900-HD

COURTESY OF: T.C Corriher Implement Co. Inc. DBA: Everythingattachments.com

12 South Ashe Avenue Newton, NC 28658

8

5. OPERATION

This digger is designed for use only on tractors with a 540-RPM power takes off. The auger is

designed to operate just above idle speed. Clear the work area of objects that might be picked up

and thrown or entangled in the auger such as vines, tree limbs, wire, etc.

The auger is of the pendulum swinging type and should hang in a vertical position when

raised clear of the ground. On the ETA 6900 and ETA Compact there is an Optional directing

rod (#15) attached to the gearbox to control the swing of the gearbox. It can be moved in or out

by loosening the setscrew on the side of the gearbox. This allows the tractor operator, from his

seat to straighten the angle of the auger to dig a straight hole. Due to the design of the ETA

6900-HD gearboxes, the directing rod is not required. To prevent possible instantaneous

driveline failure, never move digger from hole to hole or transport it while auger is rotating. This

could lead to injury from flying pieces of the failed driveline. With auger raised clear of ground

drive into position and engage PTO with tractor idling; lower digger slowly and permit it to dig

one foot (1ft.) deep. Raise digger and allow auger to clear itself by operating PTO, lower digger

and dig another foot deep. Repeat this until hole is to desired depth. To prevent entanglement and

possible serious injury or death all persons except for the operator seated on the tractor, should

maintain a minimum safe distance of twenty five (25’) feet from the auger at all times. In loose

and sandy soil, you get a cleaner hole by stopping rotation of the auger before lifting it from the

hole and starting it just before it clears the hole to throw the soil on the auger out and away from

the hole. DO NOT SHOVEL dirt away from a rotating auger as the shovel can be caught and

thrown by the auger causing serious personal injury. In wet clay, be very careful not to let the

auger go too deep as it may get stuck If the auger is stuck either in wet clay, roots, or stones,

DISENGAGE PTO, shut off tractor engine and use large wrench on auger and reverse rotation of

the digger. One complete turn of the auger will usually free the auger. Then gently lift the auger

with the tractor lift. If it is not free, continue reversing procedure until it can be lifted clear.

Do not operate digger on steep hillsides. When digging on uneven or hilly terrain, position the

tractor with the posthole digger uphill. If the posthole digger is pointed downhill, the tractor

could tip over when attempting to pull the auger from its hole.

!!!!WORK SAFELY-FOLLOW THESE RULES!!!!

6. DAILY CHECK LIST

- Check that digger is properly and securely attached to tractor.

- During inspection, check that all nuts and bolts are secure.

- Check conditions of auger Cutting edges and security of attachment.

- Check that all safety shields are in place.

7. MAINTENANCE

*keep tractor and digger in good operating condition and all safety devices in

place.

*Periodically tighten all bolts, nuts and screws to ensure digger is in a safe

condition to operate.

*The shear bolt is where the PTO (power take off) shaft yoke fits to the gearbox

ETA Compact, ETA 6900, ETA 6900-HD

COURTESY OF: T.C Corriher Implement Co. Inc. DBA: Everythingattachments.com

12 South Ashe Avenue Newton, NC 28658

9

input shaft. Check it for wear before each use.

*Never replace the shear bolt or auger retaining bolt with any length other than

what Everything Attachments specified in the manual.(A longer or protruding fastener is

more likely to grab loose clothing or gloves, which can result in serious injury or death).

*Check that retaining screw in the PTO yoke is in place and tight. It keeps the PTO yoke from

coming off the gearbox input shaft if the shear bolt breaks.

*Use ONLY GRADE 2 SHEAR BOLTS ON ETA COMPACT AND ETA 6900. USE ONLY

GRADE 3 SHEAR BOLTS ON ETA 6900-HD.

*Always use, and maintain in place, all power take off guards furnished with the tractor as well

as the power take off-guards and shield furnished with the digger. If a safety shield or

guard is removed for any reason, it must be replaced before the machine is operated

again.

*Spray lubrication on both halves of PTO so the cover freely slides in and out.

*Check point and width of auger bit. If bit is worn to the place that it is smaller in width than the

round flighting on the auger then replace the bit. If point is bent or dull then replace bit.

8. STORAGE

* When removing digger from tractor, (A) stand digger upright and brace it to prevent it from

falling, (B) chain digger upright by hanging from loop on top of boom, (C) back digger

up to a post and chain it upright.

*In storage position lower the boom end to ground level so no one can bump their head or trip

over unit.

* Do hot leave auger drilled in ground as moisture may rust auger and bit.

* Clean all accumulated debris from digger to prevent rust.

* To prevent moisture damage during storage, lubricate all lubrication points on digger.

* Coat auger with oil as needed.

* Do not lay digger on ground as personnel injury may occur in pushing the digger into an

upright position.

9. Training

*Know your controls and how to stop the tractor engine and digger quickly in an emergency.

*To avoid injury, do not allow anyone to operate this equipment without proper instructions.

Any Person who operates this equipment must be instructed in and be capable of safely

operating this unit, attachments and controls.

*Always use two (2) people to handle heavy, awkward components during assembly,

installation, removal or moving the digger.

*Do not move the tractor while the auger is turning.

*Do not move tractor while auger is still in the ground. The final responsibility for safety rests

with the operator of the machine. He or she is ultimately responsible for safety of himself

or herself as well as others in the operating area of the digger.

ETA Compact, ETA 6900, ETA 6900-HD

COURTESY OF: T.C Corriher Implement Co. Inc. DBA: Everythingattachments.com

12 South Ashe Avenue Newton, NC 28658

10

10. SAFETY WARNING MESSAGE

Carefully read thoroughly and understand your operator's manual as well as the safety-warning

message. Failure to understand and obey a safety warning, or recognize a safety hazard, could

result in an injury or death to you or others around you.

- This posthole digger was designed for one man operation from the tractor seat. It is the

responsibility of the operator to see that no one is within twenty-five feet (25') of the

digger when it is in operation.

- Do not operate the digger with another person near, or in contact with any part of the digger,

PTO driveline, or auger. Serious personal injury or death may result if any attempt is

made to assist digger operation by hand.

- A Person who has not read or understood the owner's manual and safety signs is not qualified

to operate the machine. If you do not have an owner's manual or current production

safety signs, contact the Everything Attachments.

- Be careful and make sure that everyone who operates this machine knows and understands that

it is a very powerful piece of machinery, and if used improperly, serious injury or death

may result.

- All things with moving parts are potentially hazardous. There is no substitute for a cautious,

safe minded operator who recognizes potential hazards and follows reasonable safety

practices. The manufacturer has designed the machine to be used with all its safety

equipment properly attached, to minimize the chances of accidents.

- Personal protection equipment including hardhat, safety glasses, safety shoes, and gloves are

recommended during assembly, installation, operation, adjustment, maintaining,

repairing, and removal or moving the digger.

12. OPERATIONAL SAFETY

*Disengage power take off (PTO) and shift tractor into neutral before attempting to start the

engine. NEVER ALLOW ANYONE NEAR AUGER WHILE OERATING. STAY 25

FEET AWAY.

* Never make an adjustment while engine is running; operator must dismount from tractor.

* Keep children and pets a safe distance away, at least 25 FEET.

* Always comply with all state and local lighting and marking requirements when operating on

highways.

* Watch for traffic when crossing roads.

* Consult local utility companies to make certain there are no buried gas lines, electrical cables,

etc. in the work area before beginning operation.

* Stop digger and tractor immediately upon striking an obstruction. Turn engine off, inspect

digger and repair any damage before resuming operations.

* Disengage power to digger and stop engine before dismounting from tractor, making

adjustments or unclogging digger.

* NEVERPLACE HANDS OR FEET NEAR DIGGER WHEN TRACTOR ENGINE IS

RUNNING. STAY CLEAR OF ALL MOWNG PARTS

* Do not walk or work under a raised digger or attachment unless it is securely blocked or held

in position. Do not depend on the tractor hydraulic system to hold the digger or

attachment in place.

ETA Compact, ETA 6900, ETA 6900-HD

COURTESY OF: T.C Corriher Implement Co. Inc. DBA: Everythingattachments.com

12 South Ashe Avenue Newton, NC 28658

11

* Do not allow anyone who is not familiar with the safety rules and operational instructions to

use the machine.

* Never allow children to operate or be around this digger.

*Never place a part of your body where it would be in danger if movement should occur during

assembly, installation, operation, mounting removing or moving a digger.

* Keep in mind that all things with moving parts are potentially hazardous.

* Never allow the digger to operate while the operator is off the tractor.

* The digger should be operated with the tractor motor just above idle speed. Faster speeds

could be damaging and dangerous.

* Take all possible precautions when leaving the tractor unattended; Stop engine and remove the

key from ignition, disengage PTO, lower digger, shift into gear, set parking brake.

*Use stabilizer bars, adjustable sway chains, or sway blocks on your tractor lift arms to keep the

posthole digger from swinging side to side. Adjust as tightly as possible for best performance.

WARNING!

DO NO LET TRACTOR

MOVE OR ROLL

WITH AUGER IN GROUND

THE AUGER WILL BEND

AND VOID THE WARRANTY.

ETA Compact, ETA 6900, ETA 6900-HD

COURTESY OF: T.C Corriher Implement Co. Inc. DBA: Everythingattachments.com

12 South Ashe Avenue Newton, NC 28658

12

Reference #

Quantity

Description

Fits Models

1

1

A-frame

ETA Compact

1A

A-frame

ETA 6900

1B

A-frame

ETA 6900-HD

2

1

Category I pull pin w/lock washer and nut

All

3

1

¾” x 2½” bolt, lock washer and nut (A-frame to boom)

All

4

1

Boom Pole

ETA Compact

4A

1

Boom Pole

ETA 6900

4B

1

Boom Pole

ETA 6900-HD

5

1

Hanger shaft w/2 cotter pins

All

6

1

Gearbox

ETA Compact

ETA 6900

6B

1

Gearbox

ETA 6900-HD

7

1

⅜x 3 ¼ grade 2 bolt w/nut

ETA Compact

ETA 6900

7B

1

⅜x 3 ¼ grade 2 bolt w/nut

ETA 6900-HD

10

1

¼” x ¾” cone point set screw w/jam nut

All

11

1

Complete class 4 PTO shaft

All

12

1

PTO safety shield

ETA Compact

ETA 6900

12A

1

PTO safety shield

ETA 6900-HD

13

2

Auger safety shield

All

14

2

Brackets for auger shields

All

15

1

Optional Guide rod w/set screw

Continued on next page

ETA Compact

ETA 6900

ETA Compact, ETA 6900, ETA 6900-HD

COURTESY OF: T.C Corriher Implement Co. Inc. DBA: Everythingattachments.com

12 South Ashe Avenue Newton, NC 28658

13

BOLTS-Buy Local

1 ¾” x 2½” bolt w/lock washer/nut, A-frame to boom.

4 5/16”Wing nut w/lock washer, Auger safety shield to brackets.

1 ⅜” x 3 ½” Bolt w/lock washer/nut, PTO shaft to gear box. Grade 2 on ETA Compact and ETA

6900, Grade 3 on 6900 HD.

1 ½” x 3” Grade 2 bolt w/lock washer/nut, Auger to gear box.

2 7/16 “ x 1½” Carriage bolt w/lock washer/nut, Cutting head to auger.

4 5/16” x ¾” Bolt w/lock washer/nut, Shield bracket to gear box.

4 ⅜” x ¾” Continuous thread bolt w/lock washer/nut, Shield bracket to gear box. ETA Compact

and ETA 6900.

ETA Compact, ETA 6900, ETA 6900-HD

COURTESY OF: T.C Corriher Implement Co. Inc. DBA: Everythingattachments.com

12 South Ashe Avenue Newton, NC 28658

14

WARRANTY AND DISCLAIMER

Everything Attachments (hereafter the “Company”) and sellers of its products warrant products

and parts of products it manufactures to be free from defects in material and workmanship for a

period of (90) days from date of purchase when such products and parts of products are

maintained and used in a customary and ordinary manner.

No warranty is made by the Company either expressed or implied on products manufactured by

others.

THIS WARRANTY IS THE SOLE

WARRANTY

AND IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY

OR WARRANTY OF FITNESS

FOR A PARTICULAR PURPOSE.

The exclusive remedy for breach of this Warranty is repair or replacement of parts upon delivery,

postage and freight prepaid to the Company at 12 South Ashe Avenue Newton, NC 28658

U.S.A. or refund of purchase price if repair or replacement cannot be practically provided.

In no event shall the Company or the Sellers be liable for consequential or incidental damages,

direct or indirect(including but not limited to loss of crops or livestock), due to defects in

workmanship or defects in products

manufactured by it.

This is the only warranty of the Company. No Seller or any other person has authority to alter or

waive any provision of this Warranty as it applies to the Company or to make or add warranties

on behalf of the Company. The Company expressly disclaims all liability due to the use or resale

of its products or parts of products manufactured by it whether based on contract, negligence,

strict liability in tort or otherwise except as expressly provided for in this Warranty as set forth

above.

This manual suits for next models

3

Table of contents

Popular Tractor Accessories manuals by other brands

Raven

Raven SmarTrax Supplement Installation Manual

brent

brent THE GRAIN TRAIN 740 Operator's Manual/Parts Catalog

Harvest TEC

Harvest TEC 602 Operation manual

Stark

Stark U-AURA Operating and maintenance manual

BROWNS

BROWNS BALE HANDLER Owners Illustrated Instruction Book & Parts List

Field Tuff

Field Tuff ATV-45ABM owner's manual

BCS

BCS DUPLEX GOLD owner's manual

SpeedEPart

SpeedEPart Agri-Fab 45-0302 owner's manual

Grouser Products

Grouser Products FH-443 Owner's manual & parts book

Walker

Walker A44 Assembly instructions operator's manual

Classic Accessories

Classic Accessories 73967 Instructions & Care

MTD

MTD 19A30045OEM Operator's manual