www.ademsan.net

------------------------------------------------------------------------------

!!! WARNING !!!

xThe machine should be run without vibration.

xThe machine should not be handled in wet environment.

xAny parts lost or damaged while handling should be reported to OSTIM.

xWhile using hoisting and handling equipment, their maximum handling capacity should

be considered.

xMass center of the equipment should be considered while hoisting.

------------------------------------------------------------------------------

!!! WARNING !!!

Cautionary marks on all handling equipment should be considered

------------------------------------------------------------------------------

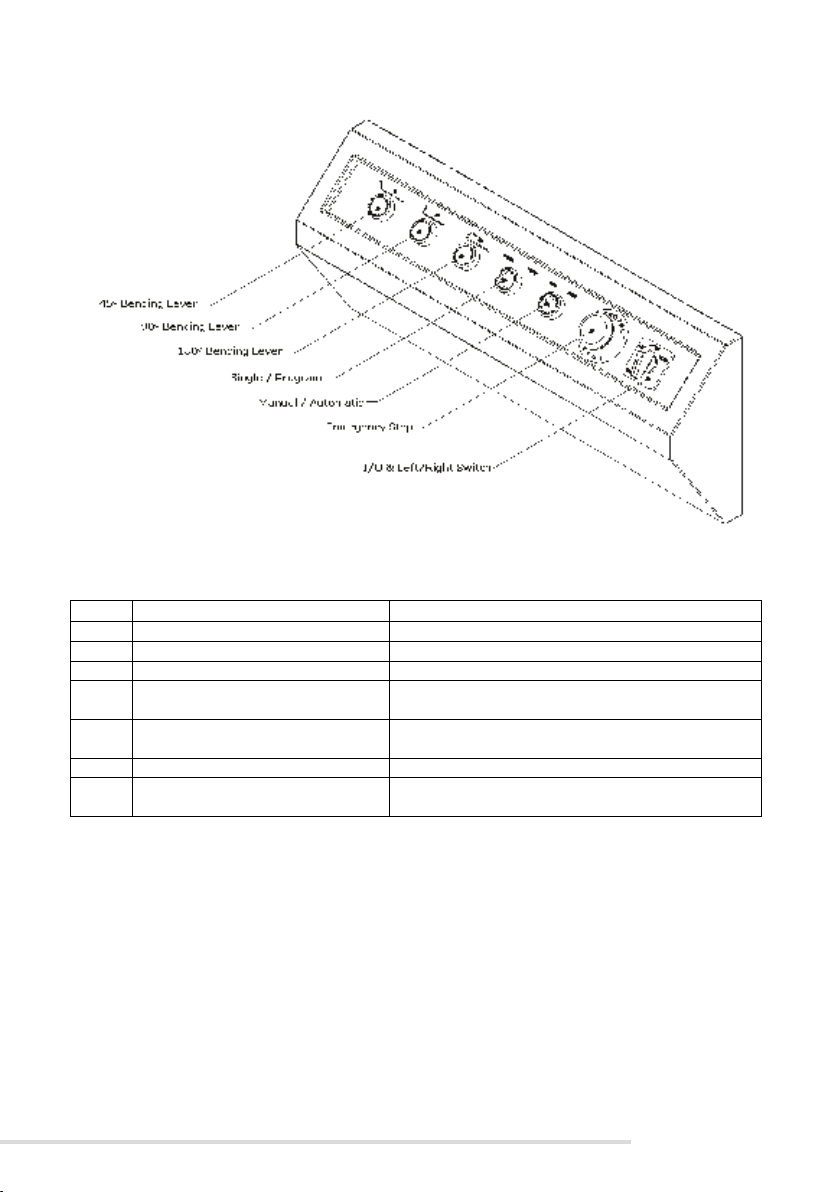

CONTROLS & SETTINGS

NO BUTTON FUNCTION

1 45° Bending Lever Used in setting bending degrees

2 90° Bending Lever Used in setting bending degrees

3 180° Bending Lever Used in setting bending degrees

4 Manuel / Automatic Allows to control the machine automatically or

manually

5 Emergency Stop Used when the machine should be turned off

6 Left/Right Key Ensures the machine to run in left or right direction

7 FootSwitch Ensures operation of the disc

8 Switchboard Includes automation system

45, 90 AND 180ºBENDING:

There are switch adjusting pins in three sizes on the bending disc. These pins are set

upon delivery of the machine. A bending degree is selected by the bending adjusting lever

attached in front of the machine. MAN-AUTO switch left side on the control board should be

moved to MAN position, and rotation direction should be checked. After these checks are

completed, hook bending operation is carried out in the machine. Is the switch pins are

replaced, the switch pin should be moved forward and backward through angle adjusting

grooves installed in edges of the bending disc to readjust, and thus a bending angle should be

set properly for hook bending (When the switch pin approaches the switch, the bending

degree decreases. When the switch pin move away from the switch, the bending degree

increases).

After setting operation is completed, the pin is attached to the spindle rim of the

bending disc, install the bending bush appropriate diameter of any steel plate to be bended on

the pin. Install one of other pins into one of the grooves on the bending disc, and install one of

proper bending balls on the pin to ensure a proper opening according to thickness of the steel

plate to be bended. Put of the steel plate to be bended on the machine, and one of the bending

pins into one of the grooves on the bending sledges. According to thickness of any steel plate

10

to be bended, steel plate of the bending disc should be installed to its front side over bending

sledges for safety to prevent it from moving and causing any injury during bending return.

The bending sledges are moved forward and backward by means of an adjusting wrench, and

it is ensured that the steel plate to be bended is aligned as length of the machine. Thus bending

operations should be completed. The machine should be moved to automatic position for

serial bending operations.

While the machine in Manual position, as long as the foot lever is pressed, the bending

disc of the machine rotates, and then stops at the time when the machine completes bending

operations and comes to standby position. While the machine is in automatic position, after

the foot lever is pressed and released once, the bending disc stops at the time when the

machine completes bending operations and comes to standby position. Further, while the

machine is in automatic position, the bending disc stops at the time the machine completes

bending operations, and the foot lever is held and pressed during return. When the foot lever

is released, it rotates in the return direction, and stops at the zero point.

To change foot, the bending change lever in its front side is moved to the position

shown in figure.

STIRRUP & SINGLE REBAR BENDING:

Single Bending:

The machine will bend single bar when “SINGLE” is chosen in the button. It will, for

example, bend only and only 45ºin every push to footswitch. The bending angle in Single

Bending could also be observed from the buttons, each time, the light inside the button will

appear once during bending.

Stirrup Bending:

In multiple stirrups bending, the SINGLE / PROGRAM button should be turned to

PROGRAM side. The program allows the operator to select the angles consecutively. Each

angle is selected by a single button push, and the next angle is selected by the same. The

operator should enter the angles he wants the stirrup to be bended. After the program is

selected and the angles are determined, the bending disc will turn to each angle consecutively

after each single push to FootSwitch. The memorized angles would be deleted by turning the

button to SINGLE once and back to PROGRAM side.

NOTE: After setting the machine, never run it in adverse direction. It may damage to all

mechanical parts.

10