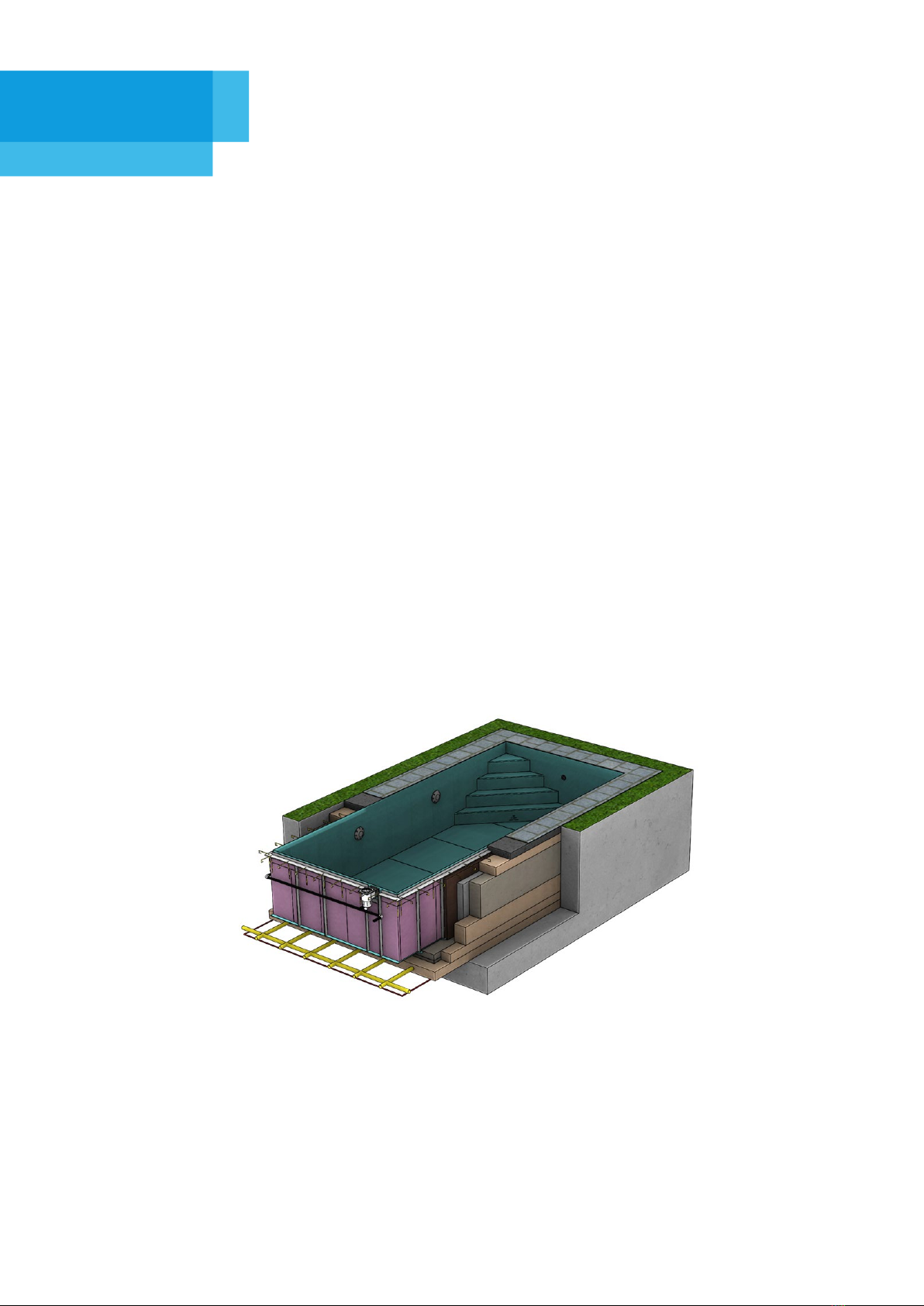

ALBISTONE®G1 BENEFIT/G1 PLUS Skimmer Pools / 7

2.

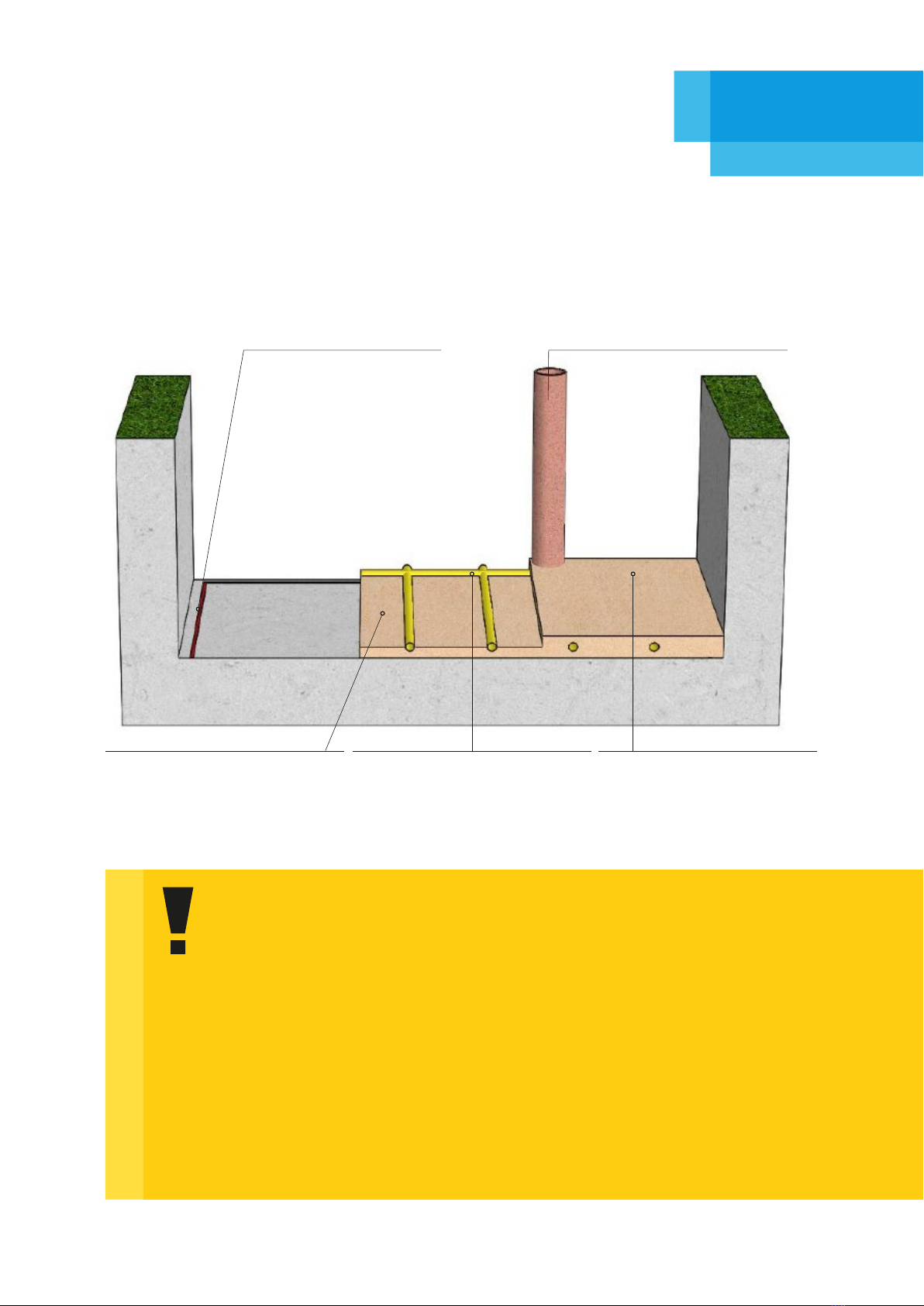

Preparations for Placement of Miscellaneous Pool Technology.

Another possible location of the technology is oered by using the ALBIXON technology wall, in its own

dedicated shaft or in any other place (service room, garden house…). The pool technology should be placed in a

room with limited access (protected against unauthorized persons or children), where the ambient temperature

does not exceed 40 °C and where the ambient humidity is suitable for the needs of electrical components.

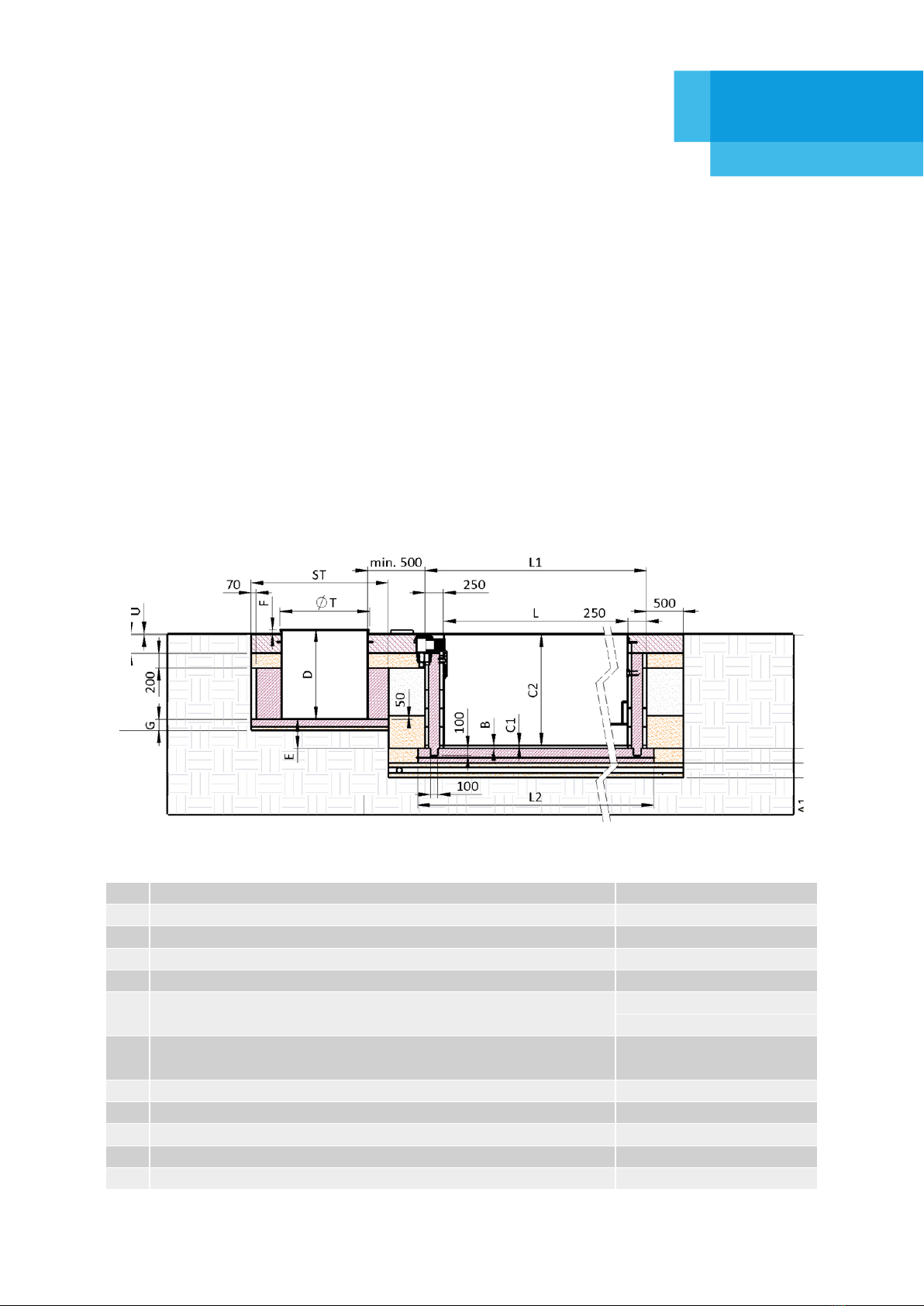

Where the technology is placed above the water level in

the pool, a maintenance (disconnecting) drain shaft should

be created. Maintenance shaft for convenient disconnection

of fittings. The disconnect at the lowest point must enable

draining all water from the shaft system used to drain water

fromthepipingfor winter. Thedimensions ofthe maintenance

shaft should be of at least 500 x 500 mm (subject to the

depth) and the depth should be adequate to the pipe route,

however always allowing for the convenient disconnection of

the pipes and discharge of water. For the location of the disconnect fitting, see the picture. The disconnect must

be placed at the lowest point of the piping.

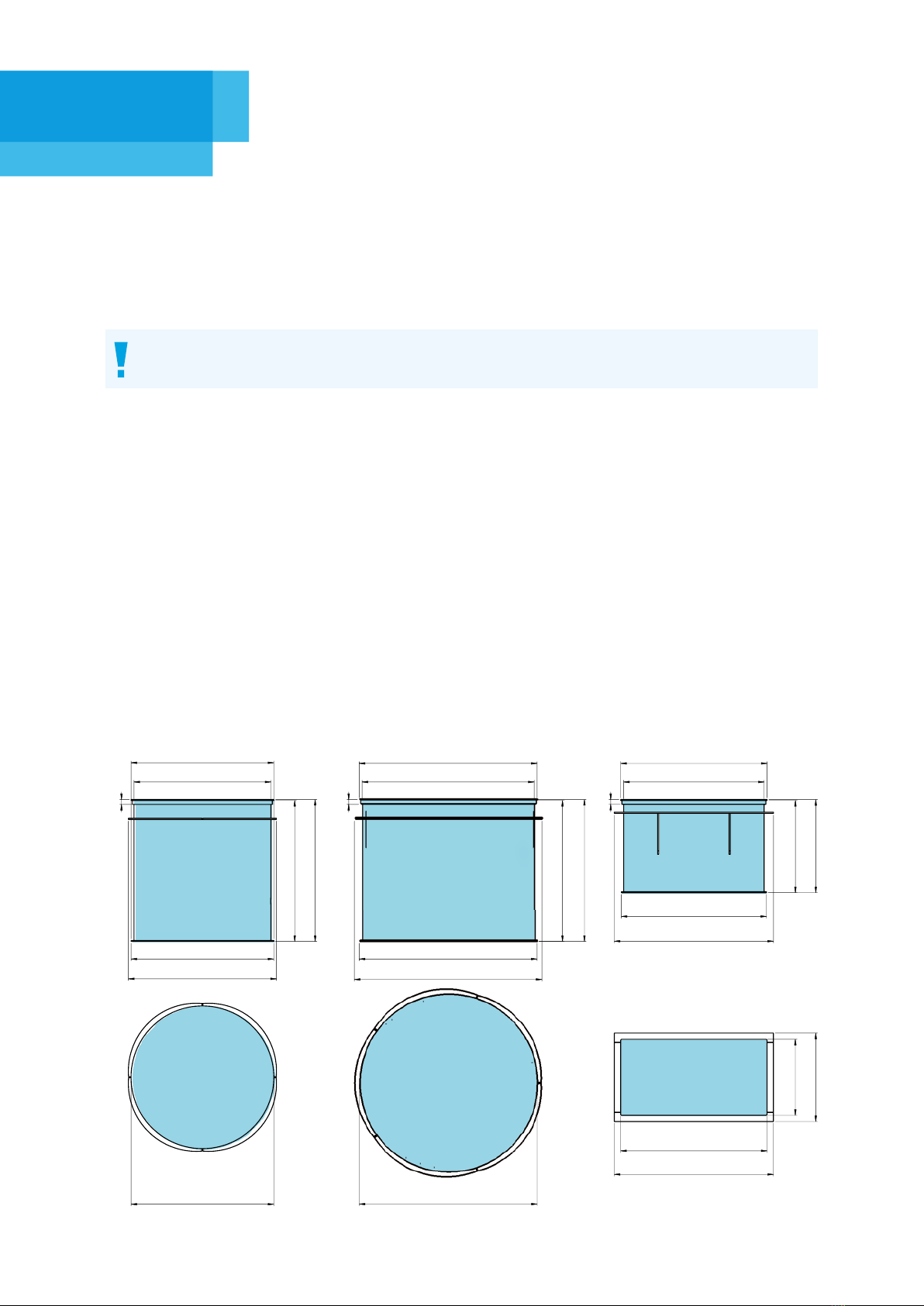

Technology wall (left, right) – a technological unit designed to be

placed in a service room or in other suitable garden structure. The

wall must be placed on a horizontal and sufficiently rigid base. On the

side of the outlets (left or right), it is necessary to leave at least 500 mm

of space for connections and further handling. To connect the pool

technology and the pool and – if applicable – external heating, make

sure to prepare pipeline routes and penetrations of the appropriate

size (pipe Ø + insulation) into the technology installation space. This

also applies to technology that is installed atypically.

Install the counterflow device separately in the counterflow shaft or in the technology shaft. The counterflow

shaft should be positioned so that the counterflow pipe from the shaft is aligned with the pool axis and runs towards

the outlets of the counterflow body placed on the pool shell. This is to achieve the lowest power losses. The

maximum distance from the exterior contour of the pool shell is 2000 mm. If the counterflow is not aligned with

the axis of the pool shell, its performance will be diminished.

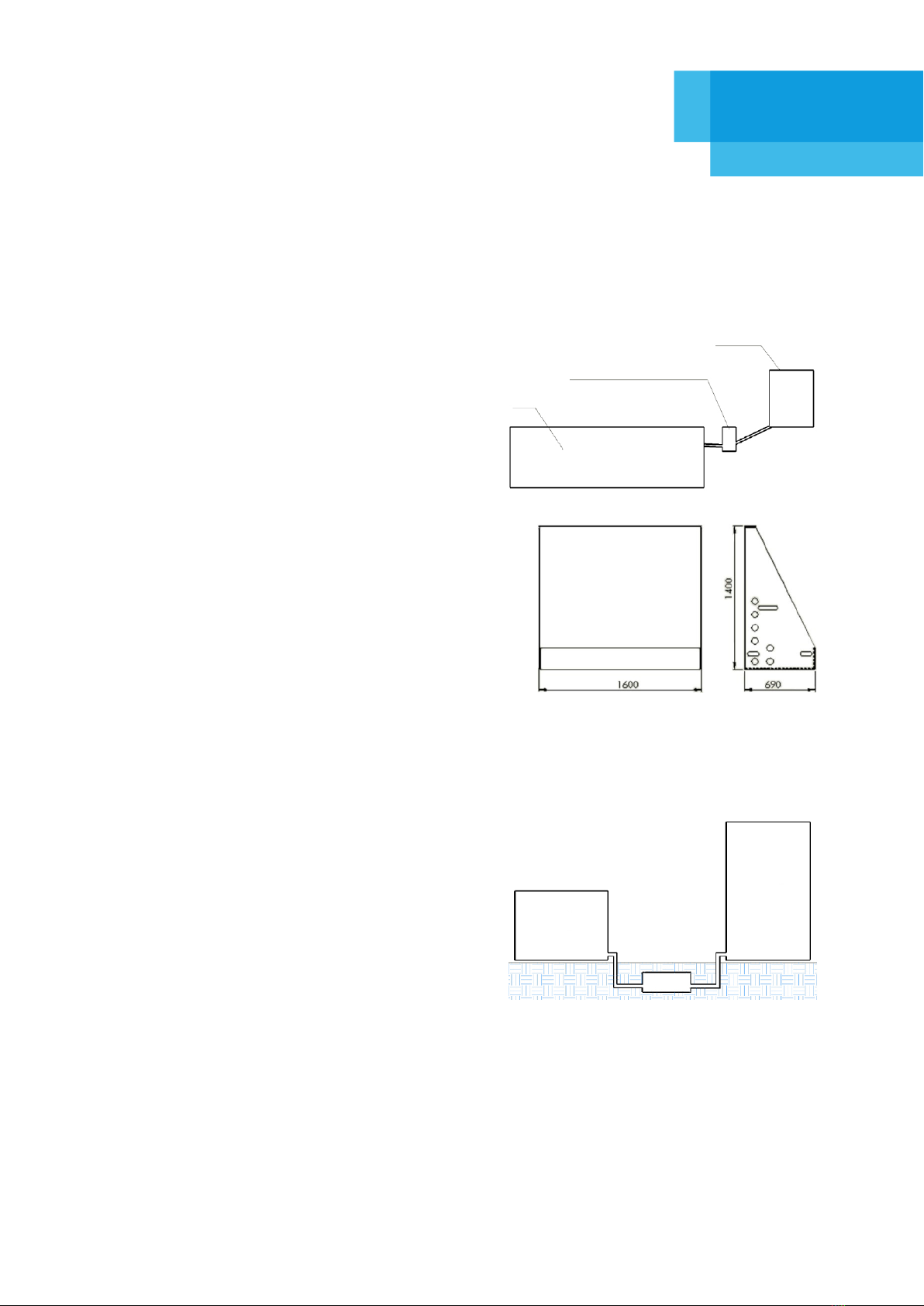

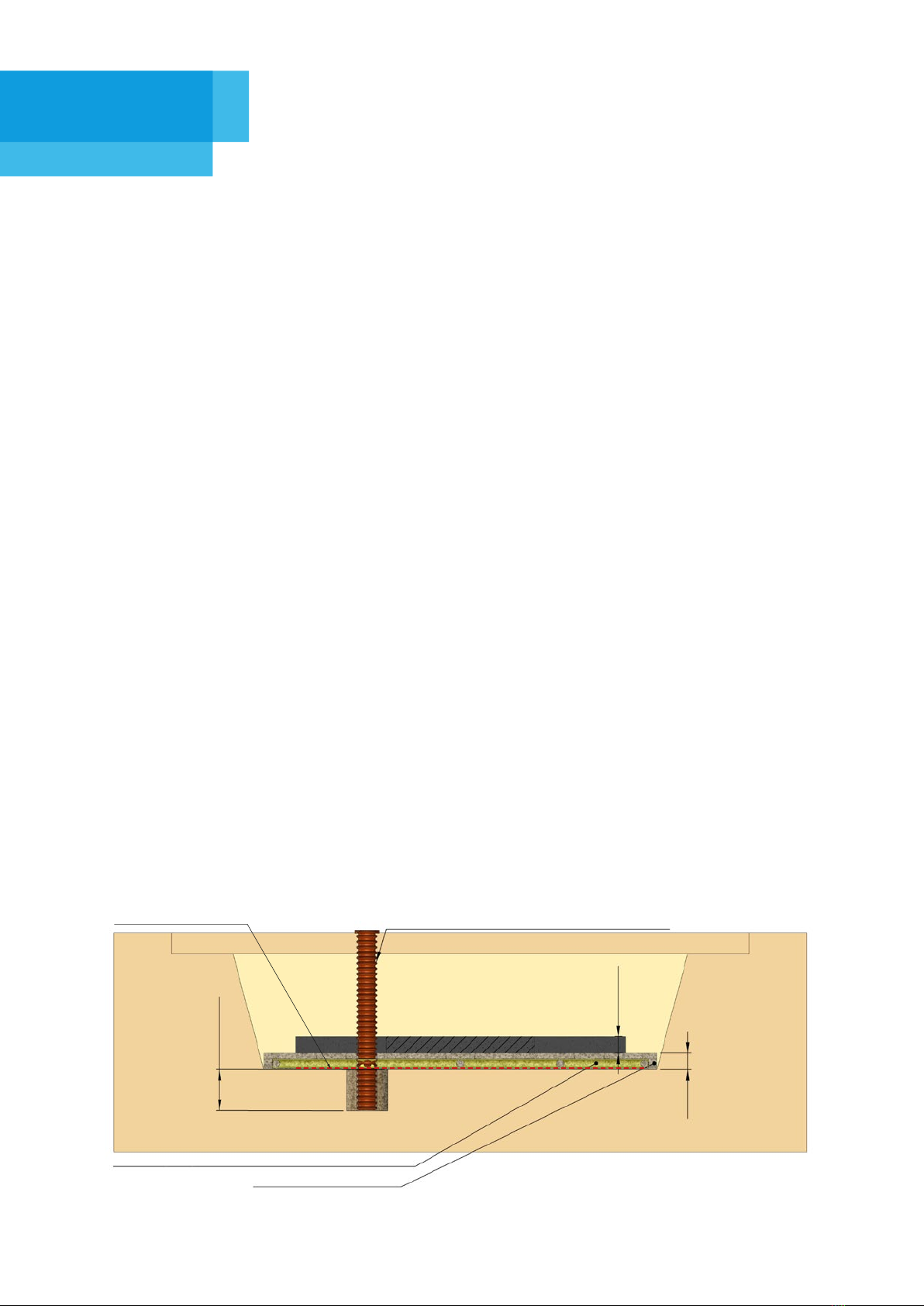

Heat pump – to connect the pool technology and the heat

pump, it is necessary to create routes for laying the connecting

pipe (excavation width 200 mm at minimum, pipe slope 1.5 °

along its entire length towards the shaft). To connect the heat

pump and the technology wall, it is necessary to place the

disconnectors for water discharge in the maintenance drain

shaftat thelowest pointof thepipe. Theheat pumpfoundation

slab must be suciently firm and level (a concrete foundation

150mm high with floor plan dimensions that exceed those of

the heat pump by at least 40mm on each side). Install the heat pump in a spacious and sunny location with good

ventilation. Its position must allow for smooth air circulation; see the instructions for the respective heat pump.

During its operation, the heat pump may produce a considerable amount of water condensate. This needs to be

accounted for and drainage must be provided. Ensure that after installation the device is in an upright position

without any tilt. Do not install the device in places with the presence of contamination or corrosive gases, or where

dirt or fallen leaves collect. The place where it is installed must not be near flammable or explosive environments

with usual fire hazards. Observe distances from obstacles, always in accordance with the respective heat pump

manual. Install the heat pump at least 3500 mm from the edge of the pool (according to ČSN 33 2000-7-702)

and up to 7500 mm from the pool technology and with a vertical dierence of up to 1000 mm between the

water level in the pool and the bottom edge of the heat pump. This installation does not result in an excessive

decrease in the performance of the circulation pump and does not cause heat loss in the longer piping.

Swimming pool

Technology wall

Maintenance shaft for convenient

disconnection of fittings. Discon-

nection at the lowest point must

drain all water from the system.

Technology

shaft/wall

Heat

pump

Disconnecting

shaft

Surveying and excavation