1/15Alcatel Vacuum Technology France - User’s Manual ASD 2001/2002/2003/2004 2/15 3/15 4/15

7/15

Capacitance Diaphragm Gauge ASD

Manual Reference:

113196

Edition : 03 - Date : 09/2010

6/155/15

Alcatel Vacuum Technology France - User’s Manual ASD 2001/2002/2003/2004 Alcatel Vacuum Technology France - User’s Manual ASD 2001/2002/2003/2004 Alcatel Vacuum Technology France - User’s Manual ASD 2001/2002/2003/2004

Alcatel Vacuum Technology France - User’s Manual ASD 2001/2002/2003/2004 Alcatel Vacuum Technology France - User’s Manual ASD 2001/2002/2003/2004 Alcatel Vacuum Technology France - User’s Manual ASD 2001/2002/2003/2004

Measurement principle Capacitance diaphragm gauge

Measurement range ASD2001 : 1x10-1…1333 mbar

ASD2002 : 1x10-3…133.3 mbar

ASD2003 : 1x10-3…13.33 mbar

ASD2004 : 1x10-4…1.333 mbar

Full Scale ASD2001 : FS = 1333 mbar

ASD2002 : FS = 133.3 mbar

ASD2003 : FS = 13.33 mbar

ASD2004 : FS = 1.333 mbar

Measurement accuracy

(with ambiant temperature 25 °C)

± 0.25% of reading

Temperature Influence on zero ± 0.005% FS /°C

± 0.015% FS /°C for ASD 2004

Respons time 40 ms

Supply Voltage range 15 to 24 V DC ±10%

Power consumption 0.5 W (current < 30 mA)

Protection IP40

Gauge identification resistance 7.5 kΩ

Analog output 0-10 V linear

10 V = FS - 1 V = FS x 0.1

Electrical connection D-sub 9 Pin (Male)

Max. cable length 30 m - 0.34 mm2

Temperature Operation +5 to +50 °C

+15 to +42 °C for ASD 2004

Storage –20 to +70 °C

Relative humidity 70% without any condensation

Vacuum connection DN16 ISOKF, 8VCR® (1) female

Operating position Any orientation

Internal volume 2.5 cm3

Recevable maximum pressure (DN16 ISOKF) 2 bars

Materials exposed with vacuum SUS304, SUS316L, Glass, FPM,

AL2O3 (ASD2001, 2002, 2003) SiO2

(ASD2004)

(1) VCR is a trade mark of Swagelock Company

Capacitance Diaphram Gauges

ASD 2001, ASD 2002,

ASD 2003, ASD 2004

User’s Manual

Alcatel Vacuum Technology France - 98, avenue de Brogny - BP 2069 - 74009 Annecy cedex - FRANCE

Tel. (33) 4 50 65 77 77 - Fax. (33) 4 50 65 77 89

Web site: www.adixen.com

Realization : Axess - www.axess-groupe.com - Publication: Alcatel - P/N. : 113196 - Ed 03 - Date :09/2010

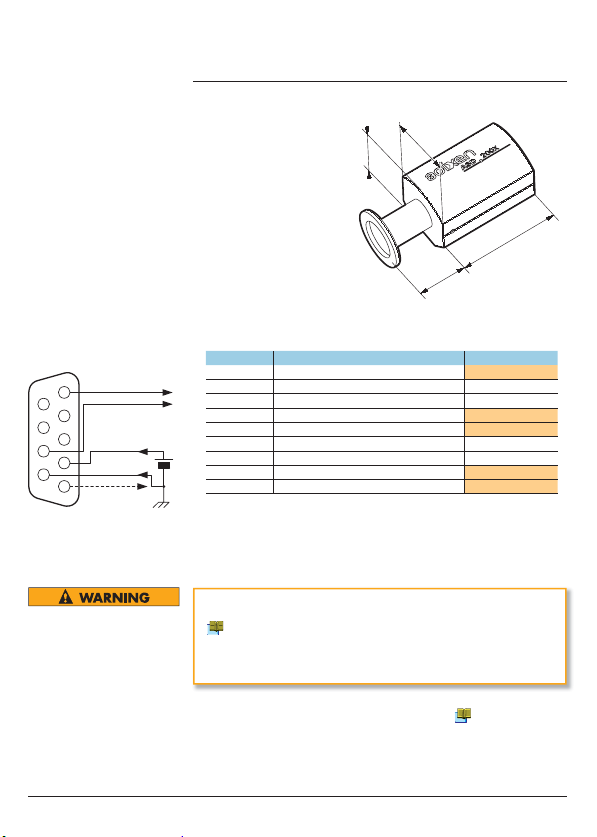

69.5

44.4

44.4

X

Connecting flange DN 16 ISO KF X = 30.8 mm

Connecting flange VCR®X = 27.7 mm

/41.9 mm (swivel nut)

The capacitance diaphragm gauge ASD2001, ASD2002,

ASD2003, ASD2004 has been designed for vacuum measurements

of gases in the pressure range of 1333 mbar to 10-4 mbar.

That’s It is an active gauge. It can be operated in connection with the

an Adixen controller (ACS 2000 or ACM2000) or as a stand alone

gauge sending a signal directly to other equipment.

Pin Signal ASD 200x 0/10 V

1Analog output 0-10 V (+) X

2 Not used

3 Not used

4 DC power input (+) X

5 Gauge ID X

6 Not used

7 Not used

8 Analog output 0-10 V (–) X

9 DC Power input (O V) (–) X

1

2

3

4

5

6

7

8

9

Analog out (+)

Gauge

identificate

resistance

Protective earth

+

–

Analog out (–)

24 V DC

ASD 200x - 0/10 V

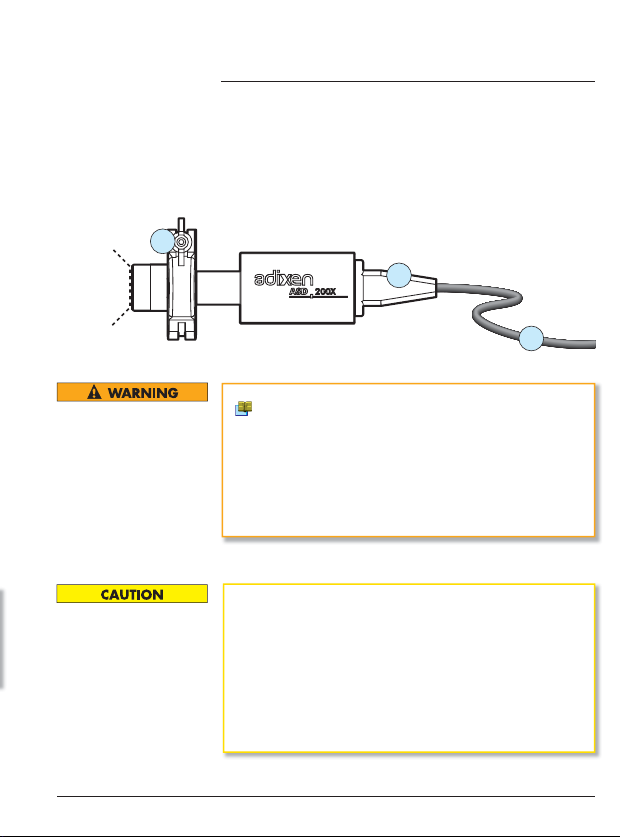

5- Gauge Installation

Connection

1

2

3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . .p. 2

Responsibility and Warranty . . . . . . . . . .p. 3

Accessories . . . . . . . . . . . . . . . . . . . . . .p. 3

Technical Data . . . . . . . . . . . . . . . . . . . .p. 5 and 6

Gauge Installation . . . . . . . . . . . . . . . . .p. 7

Operation . . . . . . . . . . . . . . . . . . . . . . .p. 8 to 10

Gauge Removal . . . . . . . . . . . . . . . . . . .p. 11

Maintenance . . . . . . . . . . . . . . . . . . . . .p. 12

Returning the Products . . . . . . . . . . . . . .p. 13

Decontamination and Product Recycling. .p. 14

Declaration of Conformity. . . . . . . . . . . .p. 15

Contents

Symbols used

This type of warning is used to indicate a potential risk that can

cause serious injury or death if instructions are not followed.

This type of warning is used to indicate an imminent risk that can

cause serious injury or death if instructions are not followed.

This type of warning is used to indicate a potential risk that can

cause significant damage to the equipment and/or installations if

instructions are not followed.

1- Safety

General instructions

Use an Appropriate Power Source: Do not use this gauge with a

power supply over 30V DC. Disregarding this maximum voltage can

cause product damage or personnel injury.

Use appropriate grounds: An appropriate protective ground

connection is mandatory to avoid electric shock in the event of a

fault. Make sure there is no difference in protective ground potential

between gauge head and controller device/power supply.

Use Caution when installing this gauge.

Check that there are no harmful gasses or vapors within the lines

or chambers before opening them to install this gauge. Clean and

purge with a clean dry gas to remove these harmful gasses or

vapors if necessary.

Do not over pressure: Do not pressurize the inside of this gauge

beyond the receivable maximum pressure. Disregarding this can

lead to either damage to this gauge, or a gas leakage which may

cause personnel injury.

Maintenance of the product: Do not disassemble the gauge head

or electronics sub-assembly. Refer to section 8 for sub-assembly

replacement Instructions.

Do not modify the product: Do not modify the electrical or

mechanical components of this gauge. Any modification could cause

damage or personnel injury.

Skilled personnel: All work described in this document should be

carried out only by qualified persons who have suitable technical

training and the necessary experience.

Do not use this gauge with corrosive gases and take special

care with toxic gases, which can lead to gas leakage and cause

injury. In case of doubt contact Adixen application support for

recommendations.

The end-user assumes the responsibility in conjunction with the

process gases used.

- fails to observe the instructions in this document,

- uses this product in a way that is not consistent with the

manufacturer’s intended use,

- modifies this product in any way whatsoever,

- uses the product with accessories not listed in the product

documentation,

Gauge failures due to contamination, as well as expendable

parts (filament), are not covered by the warranty.

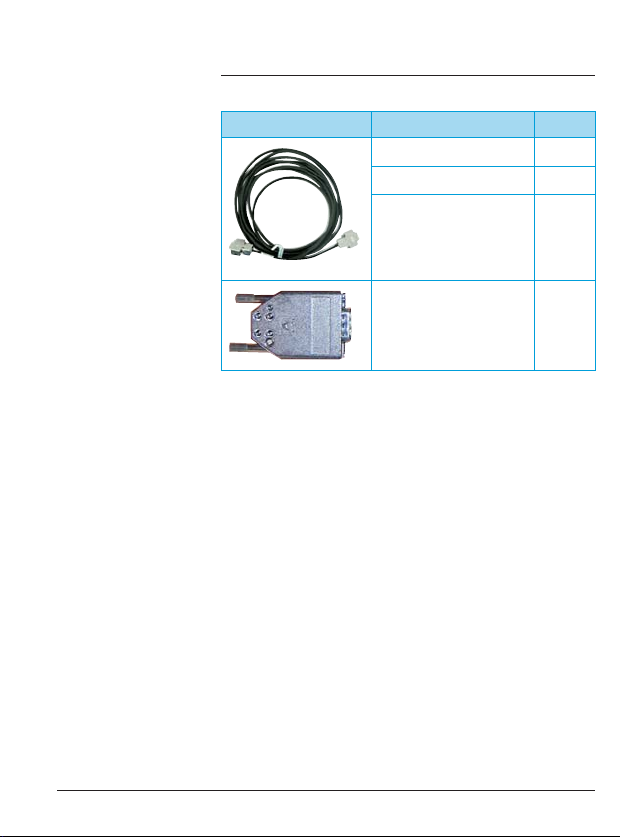

2- Responsibility and Warranty 3- Accessories

Description P/N

Gauge cable length (5 m) 112752

Gauge cable length (10 m) 112753

Gauge cable length (20 m) 112754

“D-Sub“ 9P (female)

connector (for custom

equipment connections)

114848

Specifications

4- Technical data

Gauges dimensions

4- Technical Data (ctd)

Electrical Connections

Do not use or apply voltage or ground to the pins marked “not used”.

Select the correct wire size for voltage if you use your own cable

( 4 p. 5) (1).

Always connect the protective ground wires or an electric shock can result.

Install a circuit breaker on the power source. Disregarding these

instructions can cause damage and/or injury.

(1) ”D-Sub” 9P (female) connector is available to allow the gauge

to be connected directly to customer equipment. ( 3 p. 4).

Connect the gauge to the installation using appropriate fitting

accessories (1) (from the Adixen product catalog).

Connect the cable (2). Use cable ties or other methods to support

the cable so that its weight does not put excessive strain on the

connector (3).

Do not touch the inside surfaces of this gauge with bare hands,

especially the inlet flange. Fingerprints will increase outgassing in

the gauge and cause erroneous pressure readings.

Install this gauge on the vacuum system with care. If it is

necessary to reposition it, do not twist or bend the sensor by the

electronic enclosure. Disconnect the gauge, position it in the correct

position, and connect it again.

Install this gauge away from vibration. High vibration can cause

the gauge to malfunction.

Install this gauge away from drastic temperature changes (away

from any heat sources or fans) for higher accuracy.

Do not exceed the max. overpressure rating of the gauge

( 4 p. 5). If the maximum pressure of the gauge is exceeded, it

can lead to gas leakage and cause injury.

Do not open the installation on which a gauge is installed when

the internal pressure is above 1 bar. Internal components may be

ejected and cause personal injury.

Do not use this gauge with corrosive, toxic, flammable or

explosive gasses.

Do not heat this gauge beyond 70 °C. Disregarding this instruction

can cause damage to the gauge circuits or a vacuum leak.

Intended Use: The capacitance diaphragm gauge ASD2001,

ASD2002, ASD2003, ASD2004 have been designed for vacuum

measurement of gases in the pressure range of

ASD2001 : 1x10-1…1333 mbar, ASD2002 : 1x10-3…133.3

mbar, ASD2003 : 1x10-3…13.33 mbar, ASD2004 :

1x10- 4…1.333 mbar. The gauge must not be used for measuring

flammable or combustible gases which react in air.

English original version