ERT7 and ERT8 Series Tooling Alcoa Fastening Systems

10

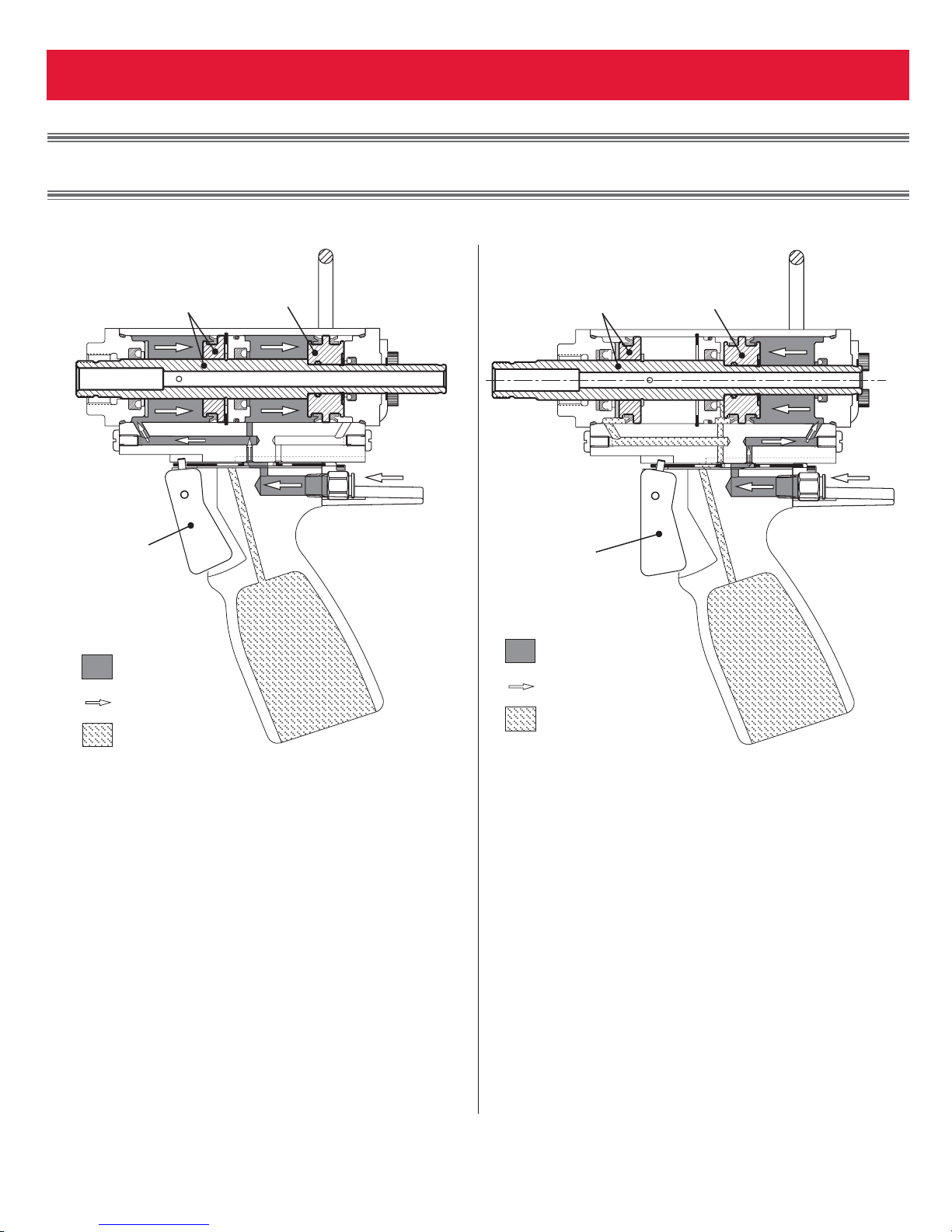

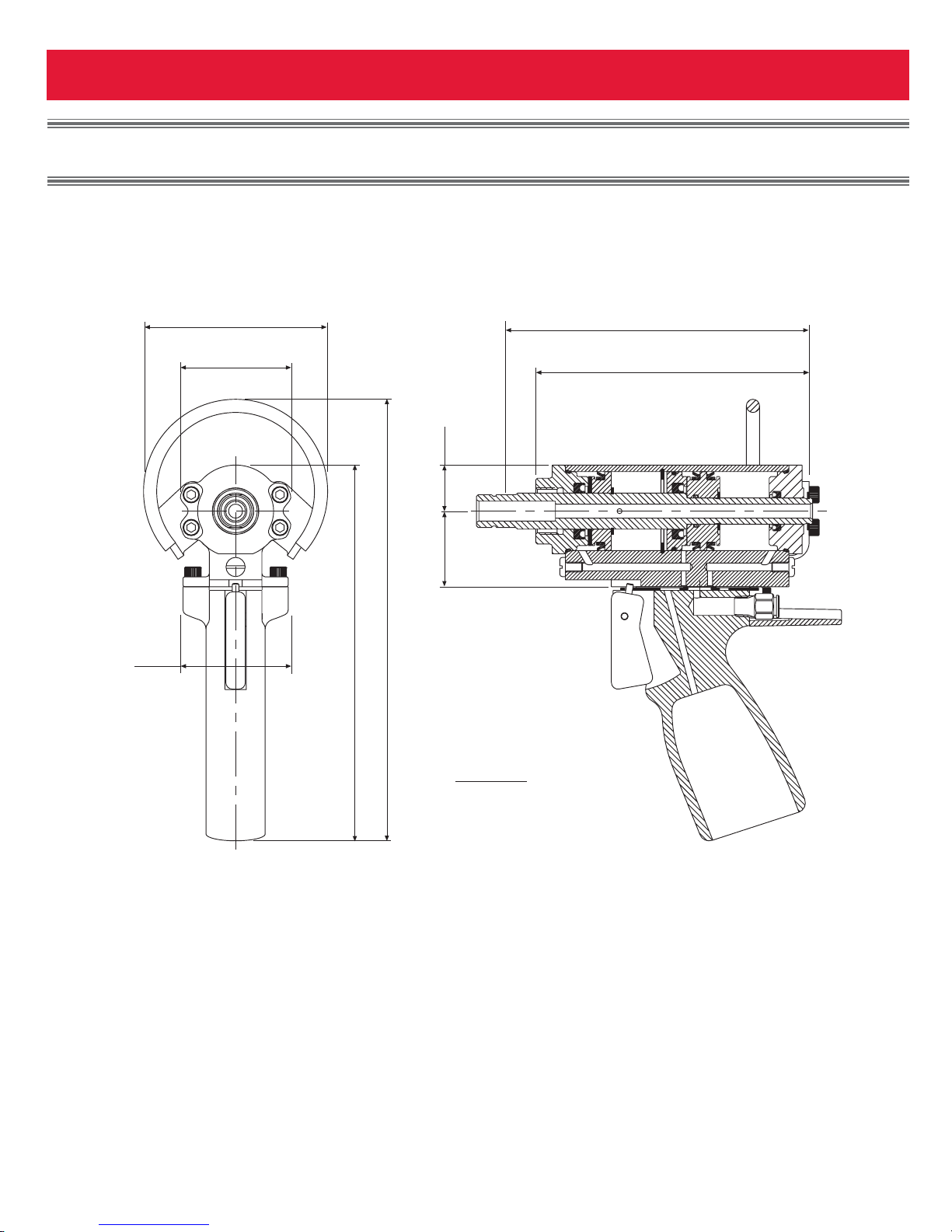

DISASSEMBLY

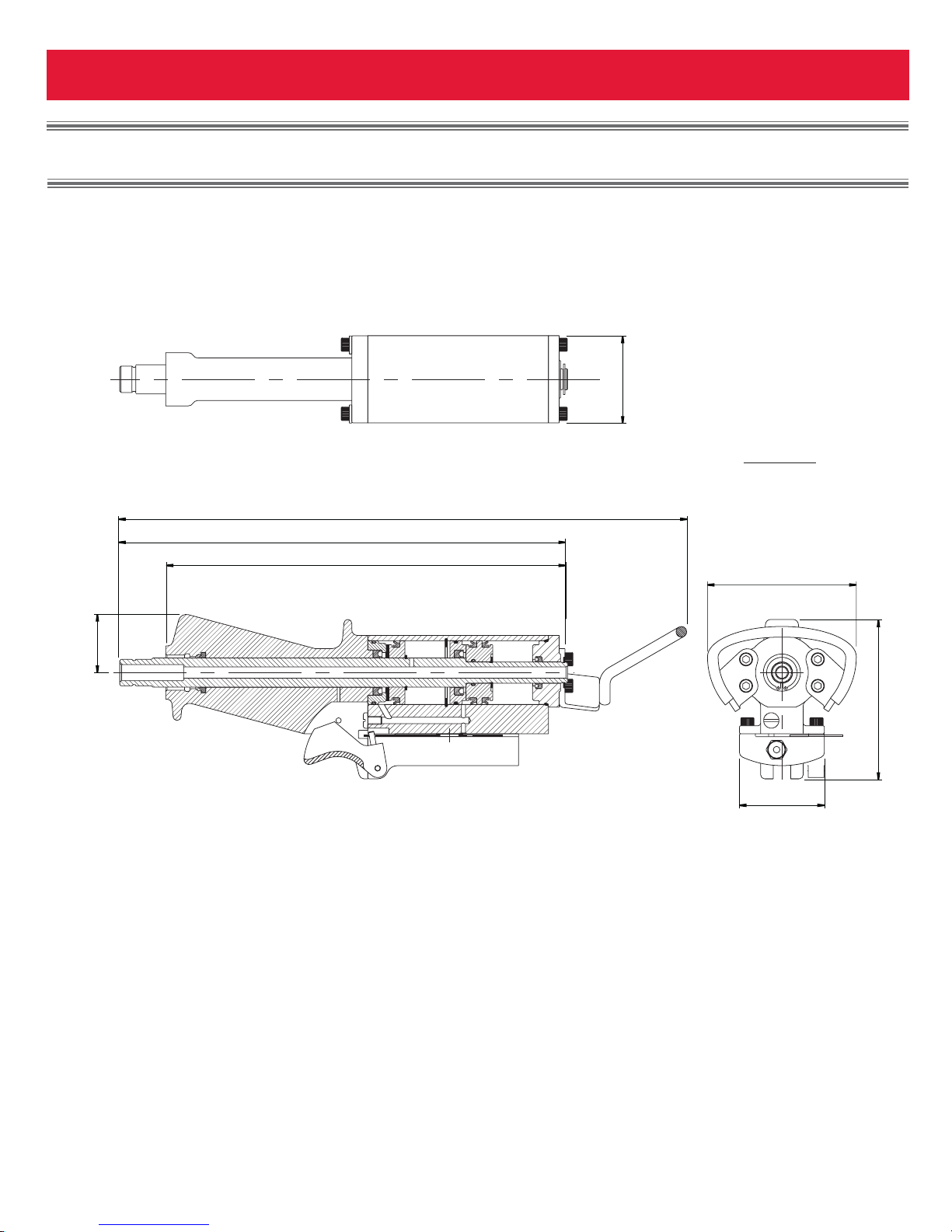

This manual provides operating and service procedures

for the Rivet Tool models ERT7 and ERT8. Close atten-

tion must be directed to the recommended service pro-

cedures contained in this manual. Specific instructions

for each tool are given under that tool model number

heading. While the tools look similar, each tool contains

parts not used on the other models and removal and

replacement methods will vary. For component identi-

fication and Parts Lists refer to Figures 2 & 3.

NOTE:The following procedure is for complete disas-

sembly of tool. Disassemble only components neces-

sary to replace damaged O-rings, Seals, Back-up Rings,

and worn or damaged components. Always use soft jaw

vice to avoid damage to tool.

Removing the Hose Assembly

Model ERT7: (Figure 2)

Remove Guard (16).

Models ERT7 & ERT8: (Figures 2 & 3)

Remove pintail tube from pulling head assembly.

Remove Cable Attachment from Cylinder Base. Pull

heavy plastic Sleeve off air line Connector (15). Depress

red Collet on air line connector and pull air line out of

connector.

Rivet Tool Disassembly (Figures 2 & 3)

1. With Pulling Head off, remove all nicks and burrs

from front of Piston Rod Assembly (5).

2. Model ERT7: (Figure 2)

Remove four Screws (24) and Piston Rod Guide (1)

from front of tool.

Model ERT8: (Figure 3)

Remove four Screws (24) and Handle (19) from

front of tool.

3. Push Piston Assembly (5) to full back position, and

remove Retaining Ring (12) from rear of Piston

Assembly. Remove all nicks and burrs from rear

of Piston to ensure removal of End Cap and

Double Piston without damage to them.

4. Remove four Screws (24), Support Loop Assembly

(25), and End Cap (14) from rear of tool.

5. Remove Retaining Ring (12) from rear of Double

Piston. Pull Piston Assembly (5) out through the

front end of the tool.

6. Push out Double Piston (11) and Bulkhead (7)

through rear of tool. It is not necessary to remove

Retaining Ring (6) from Cylinder.

ASSEMBLY

For component identification and Parts Lists, refer

to Figures 2 & 3.

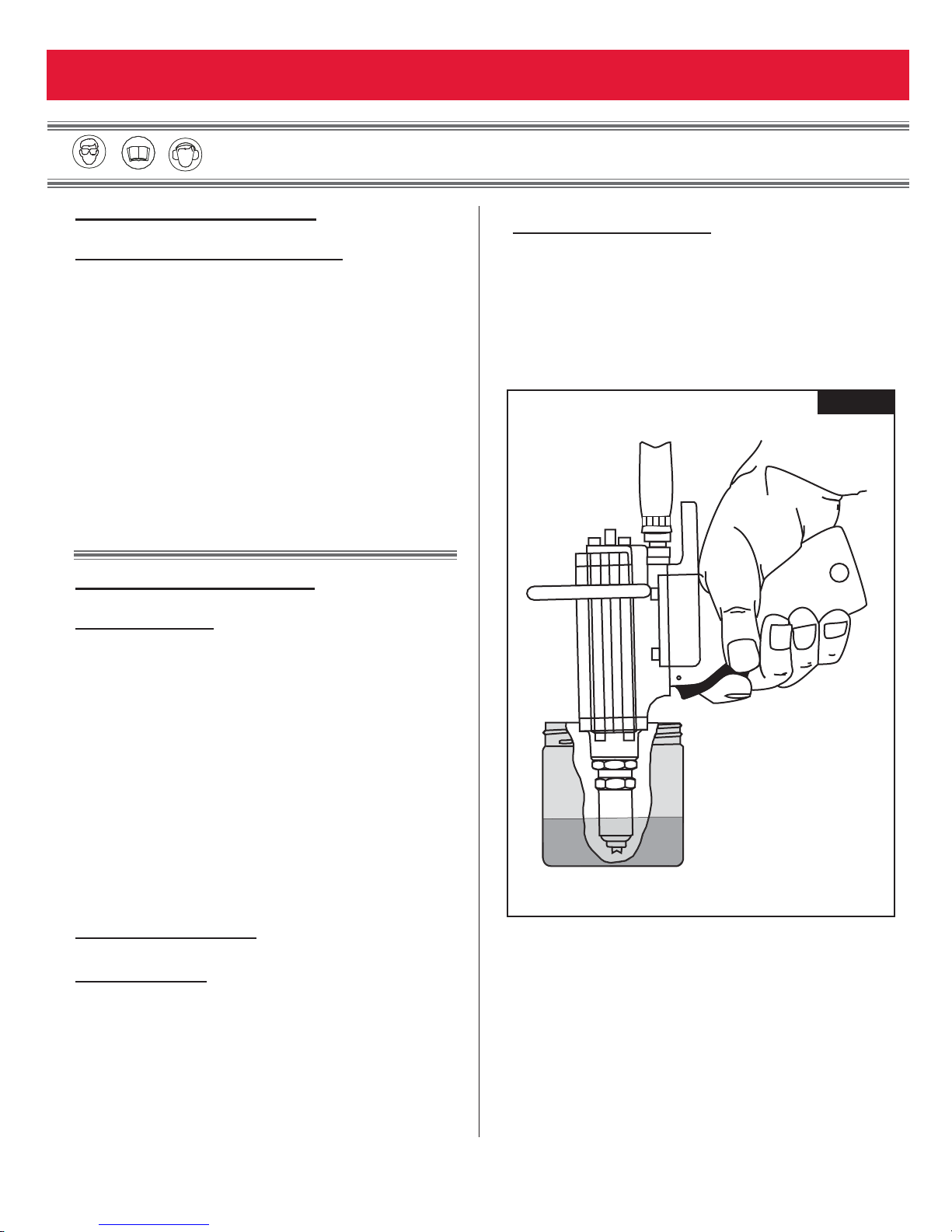

NOTE: Clean components with mineral spirits, or similar

solvent. Inspect for wear/damage and replace as neces-

sary. Replace all seals of disassembled components.

Use O-rings, Quad-Rings and Back-up Rings in Service

Parts Kit ERT7KIT or ERT8KIT. Smear O-ring lubricant

on O-rings, Seals, Back-up Rings and mating parts to

ease assembly. Assemble tool taking care not to damage

O-rings, Seals, or Back-up Rings.

NOTE: When installing Retaining Rings, they must

be installed with sharp edge of Retaining Ring

toward rear of tool.

NOTE: When replacing Seals, make sure they are

correctly positioned as shown on the tool drawing.

1. Wipe all seals with a thin film of lubricant prior to

reassembly.

2. Inspect Cylinder (2) wall to ensure the surface is

free of any gouges or nicks that will damage a new

seal. Small gouges or nicks can normally be

removed by using a fine crocus cloth.

3. Install Bulkhead (7) into the rear of the Cylinder (2)

until it seats flat against the Retaining Ring (6) in the

center of the Cylinder.

4. Upon ensuring there are no nicks or burrs on the

front or rear of the Piston Assembly (5), insert the

assembly into the front of the tool, and push it to the

full back position.

5. Install the Double Piston (11) onto the rear of the

Piston Rod Assembly and into the Cylinder until it

bottoms on the shoulder of the Piston Assembly.

S

SER

ERVICING

VICING THE

THE T

TOOL

OOL (cont.)