5

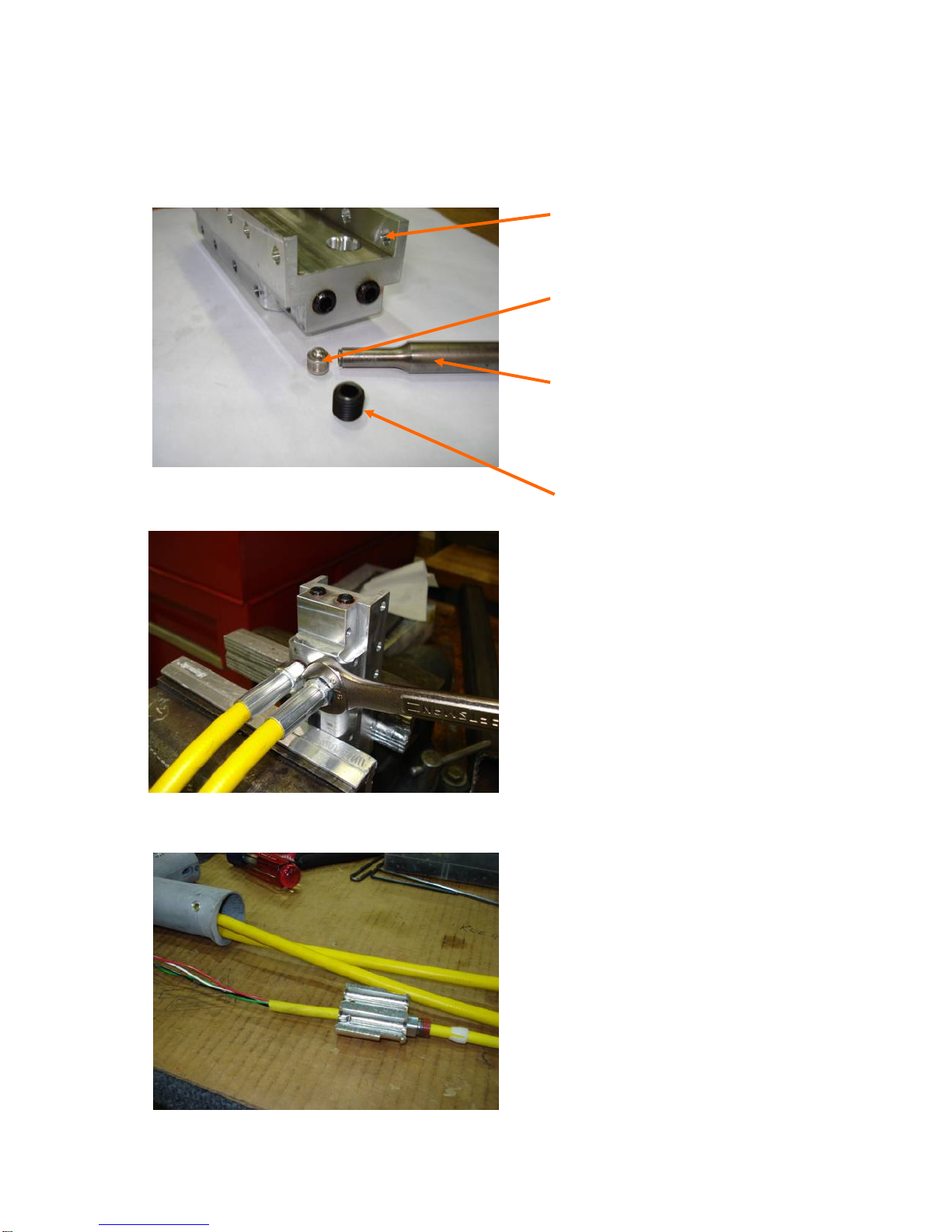

Hydraulic Manifold for the

BTT20SF tool.

Now the Hydraulic hoses can

be screwed into the manifold

using a hydraulic loctite thread

sealer and tightened down.

Slide the handle over the

hydraulic quick disconnects and

up the hoses to the manifold.

Then insert the lemo wire

through the strain relief which is

attached to the alum. Base

plate and feed the wires up

through the handle and attach

the alum. Base plate using two

#10-24x1/2” long BHCS.

CV plugs (CVES2503231A Dia.

.250” short) are put into the

manifold first using a hammer

and the installation tool

Then a 1/16x5/16 socket

pressure plug (3/4 taper) with

blue loctite is screwed into the

manifold.

Installation tool

(CVTS060) required by the CV

manufacture.

Handle Assembly (cont’d)