Alemite 9950-A User manual

Other Alemite Water Pump manuals

Alemite

Alemite 7795-A5 Series User manual

Alemite

Alemite 8540-B User manual

Alemite

Alemite 9668 User manual

Alemite

Alemite 9940 User manual

Alemite

Alemite 8595-A User manual

Alemite

Alemite 7889-6 User manual

Alemite

Alemite 9911 User manual

Alemite

Alemite 9911-J User manual

Alemite

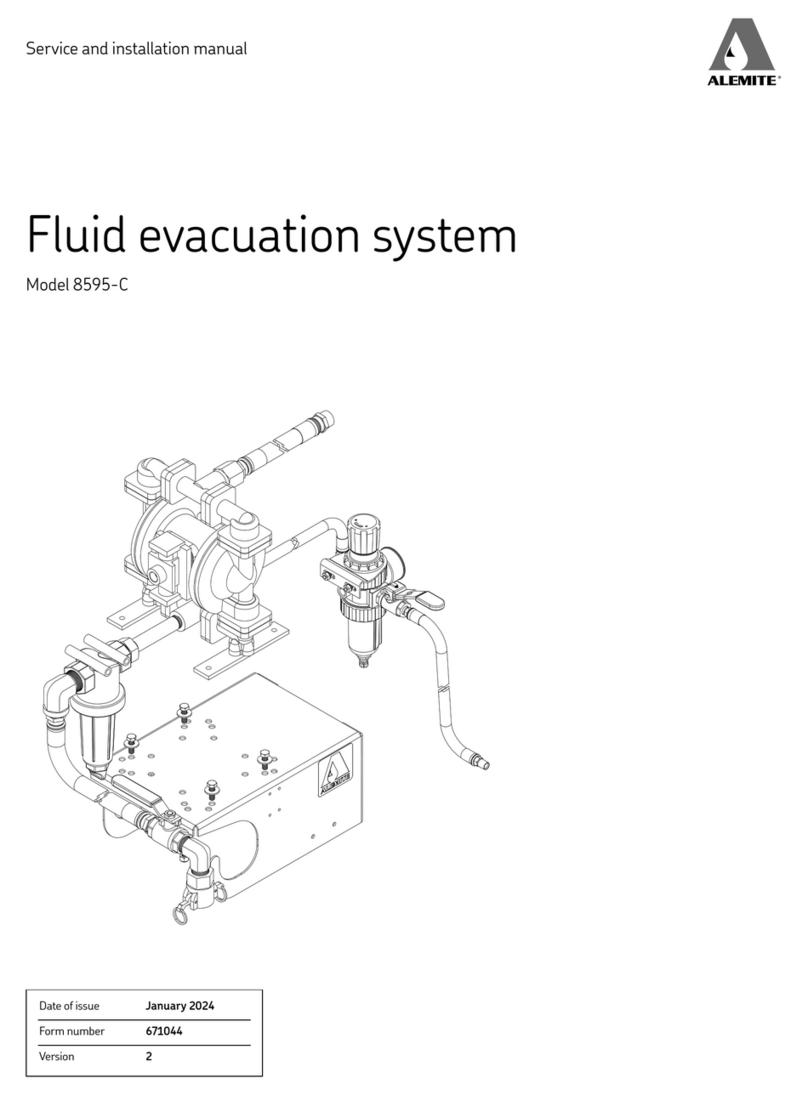

Alemite 8595-C User manual

Alemite

Alemite 9930 User manual

Alemite

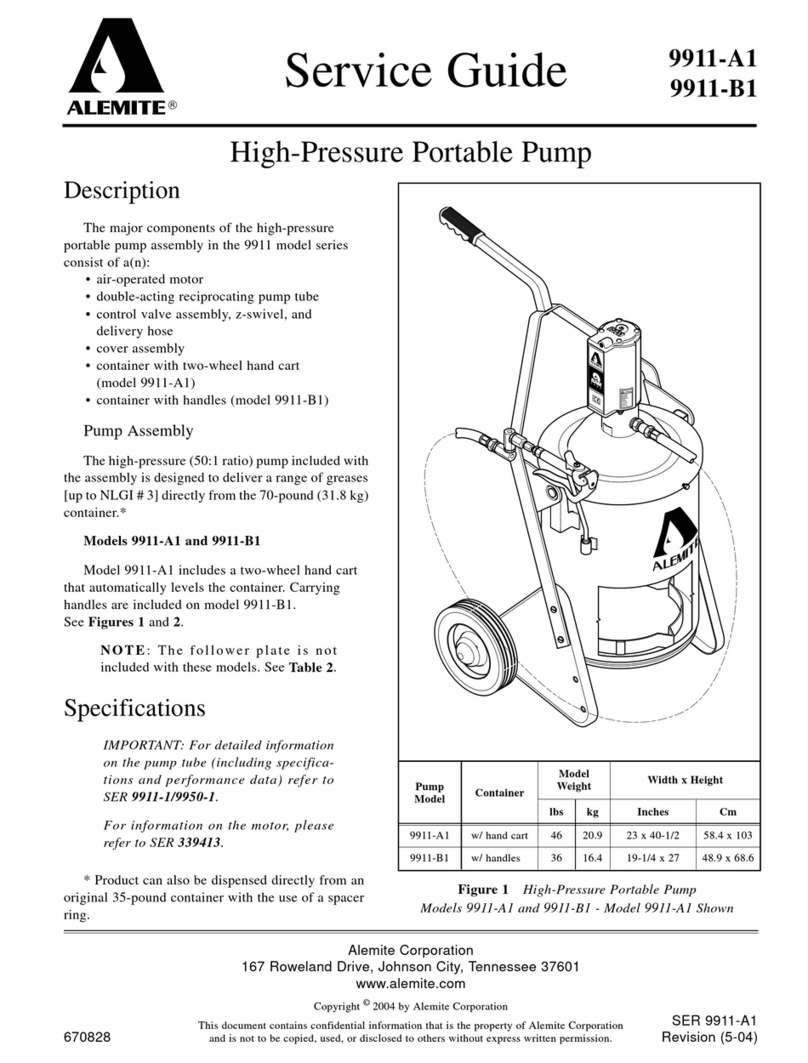

Alemite 9911-A1 User manual

Alemite

Alemite 7896 Series User manual

Alemite

Alemite 9979-A User manual

Alemite

Alemite 8702 Series User manual

Alemite

Alemite 6713-4 User manual

Alemite

Alemite 7783 Series Operating instructions

Alemite

Alemite 8550-A1 User manual

Alemite

Alemite 9911-A User manual

Alemite

Alemite 7175-R4 User manual

Alemite

Alemite 8430 User manual

Popular Water Pump manuals by other brands

Watershed Innovations

Watershed Innovations HYDRAPUMP SMART FLEX Instructional manual

Graco

Graco Modu-Flo AL-5M instructions

Messner

Messner MultiSystem MPF 3000 operating instructions

Xylem

Xylem Bell & Gossett WEHT0311M Installation, operation and maintenance instructions

WilTec

WilTec 50739 Operation manual

Franklin Electric

Franklin Electric Little Giant 555702 HRK-360S instruction sheet

Ingersoll-Rand

Ingersoll-Rand PD02P Series Operator's manual

VS

VS ZJ Series Operating instruction

Flotec

Flotec FPZS50RP owner's manual

SKF

SKF Lincoln FlowMaster II User and maintenance instructions

Xylem

Xylem Lowara LSB Series Installation, operation and maintenance instructions

Water

Water Duro Pumps DCJ500 Operating & installation instructions

Action

Action P490 Operating instructions & parts manual

Flo King

Flo King Permacore Reusable Carbon Bag Disassembly. & Cleaning Instructions

ARO

ARO ARO PD15P-X Operator's manual

Pumptec

Pumptec 112V Series Operating instructions and parts manual

Virax

Virax 262070 user manual

Neptun

Neptun NPHW 5500 operating instructions