3

Type 8692, 8693

1. QUICKSTART .....................................................................................................5

1.1. Symbols .............................................................................................. 5

2. AUTHORIZED USE .........................................................................................6

2.1. Restrictions ........................................................................................ 6

2.2. Predictable misuse ..........................................................................6

3. BASIC SAFETY INSTRUCTIONS .............................................................7

4. GENERAL INFORMATION ...........................................................................8

4.1. Contact address ...............................................................................8

4.2. Warranty ............................................................................................. 8

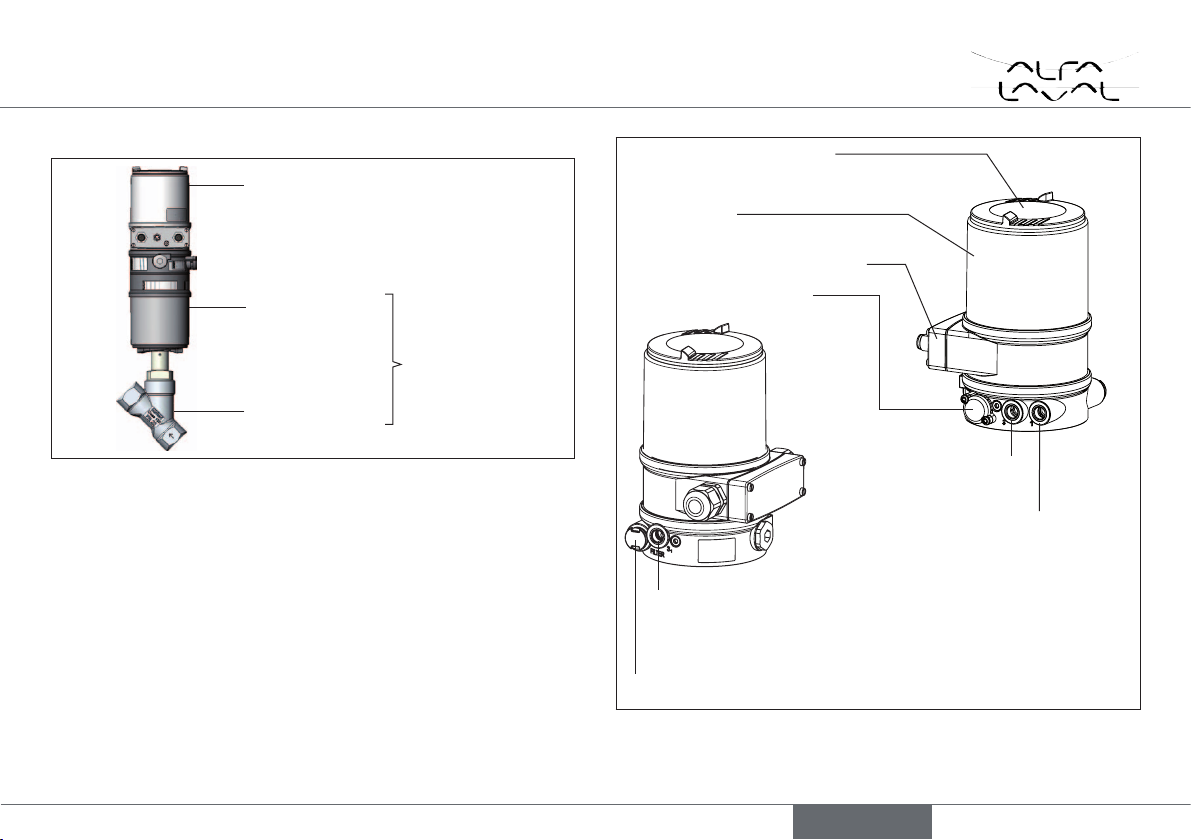

5. DESCRIPTION OF SYSTEM .......................................................................9

5.1. Functions ..........................................................................................10

6. TECHNICAL DATA ........................................................................................10

6.1. Conformity .......................................................................................10

6.2. Standards .........................................................................................10

6.3. Operating conditions .....................................................................10

6.4. Mechanical data .............................................................................11

6.5. Type label ........................................................................................11

6.6. Pneumatic data ...............................................................................11

6.7. Electrical data..................................................................................12

7. CONTROL AND DISPLAY ELEMENTS ...............................................13

7.1. Function of the keys ........................................................................ 13

7.2. Operating state ................................................................................ 14

7.3. Operating levels ............................................................................... 14

7.4. Display in operating state AUTOMATIC .................................... 15

8. INSTALLATION ...............................................................................................15

8.1. Safety instructions .........................................................................15

8.2. Installing the positioner / process controller

on process valves belonging to series 2103 and 23xx .........16

8.3. Installing the positioner / process controller

on process valves belonging to series 26xx and 27xx ............. 17

9. FLUID INSTALLATION ................................................................................19

9.1. Safety instructions .........................................................................19

9.2. Installing the process valve ..........................................................19

9.3. Pneumatic connection of the positioner /

process controller ..........................................................................19

10. ELECTRICAL INSTALLATION ...............................................................21

10.1. Safety instructions .......................................................................21

10.2. Electrical installation 24 V DC ..................................................21

10.3. Electrical installation PROFIBUS DP ......................................27

10.4. Electrical installation DeviceNet ...............................................29

Positioner Type 8692 and process controller Type 8693

english