29/4/06 TECHUK-23 REV 0Page 1of 6

Installation & Operating Instructions

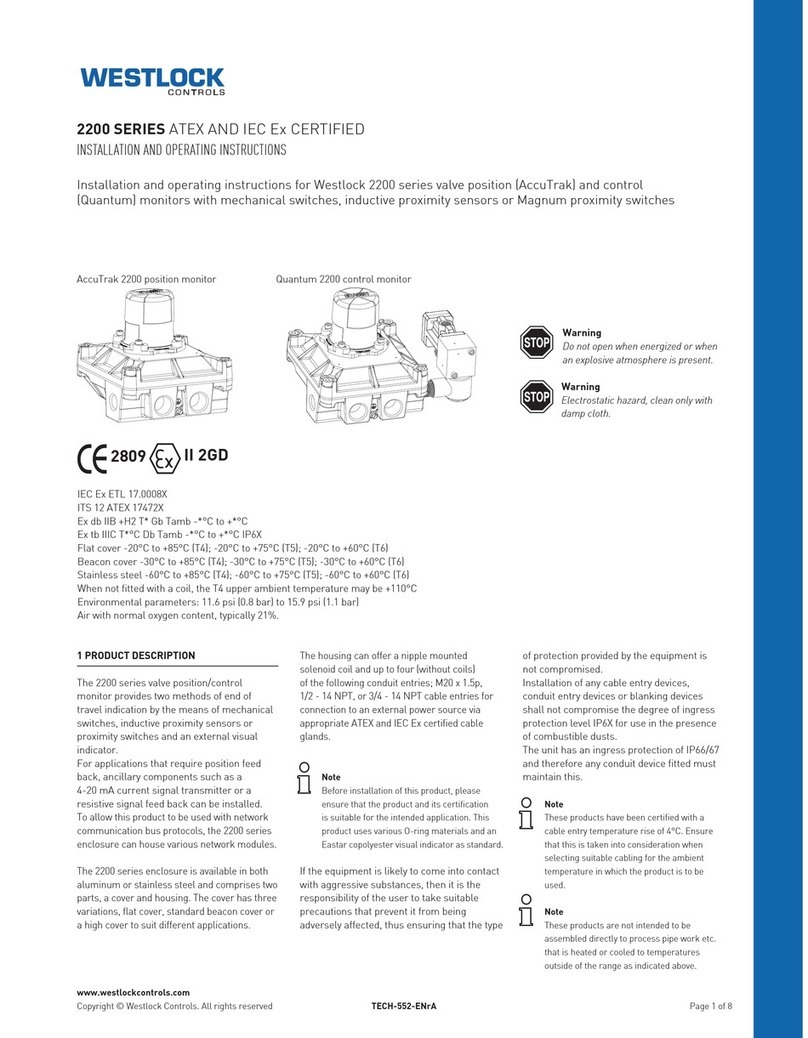

Westlock Accutrak / Quantum 2800

With Optional MAGNUM Proximity Switches.

WARNING: The Accutrak / Quantum should

always be handled with care when the cover

is removed and wired to an electrical power

1. Attach the correct mounting bracket and

adapter to the Accutrak / Quantum housing

with the hardware provided.

2. Operate the actuator to full closed position.

3. Attach the Accutrak / Quantum and mounting

bracket to the actuator.

4. To remove the cover, unscrew the cover locking

bracket and unscrew cover in a counter clockwise

5. To adjust the sensor triggers, loosen the retaining

6. Operate actuator from one end of stroke to the

other several times to check switch operation.

WESTLOCK CONTROLS UK Ltd.

22 CHAPMAN WAY, TUNBRIDGE WELLS, KENT, TN2 3EF, ENGLAND. TEL: 44 (0)1892 516277 FAX: 44 (0)1892 516279

7. The correct wiring diagram for the product is

shown on the inside of the Accutrak / Quantum

cover. Please follow carefully.

FIELD WIRING & INSTALLATION.

8. Field wiring must be carried out in accordance

with site, local and National Electrical Codes.

green screw.

cable glands. When mounting the flameproof

enclosure in the hazardous area, only

9. The ground wire should be secured under the

10. The cerification applies to equipment without

11. All unused cable entries must be plugged with

suitably certified plugs that can maintain an

12. For ambient temperatures below -10€C and

above +60€C, use field wiring suitable for both

suitably certified cable glands, that can maintain

minimum and maximum ambient temperatures.

0539 II 2 GDT80€C

PRODUCT CERTIFICATION.

EEx d IIC T6

DEMKO 03 ATEX 135478X

an ingress protection level of IP67, shall be

used.

ingress protection level of IP67.

screw and slide up or down to suit.

Complete this for both sensors.

source.

direction.