2

1Introduction.............................................................................................................................3

1.1 Control theory................................................................................................................................... 3

1.2 OPERATING ABILITY OF THE INSTRUMENT ...................................................................... 3

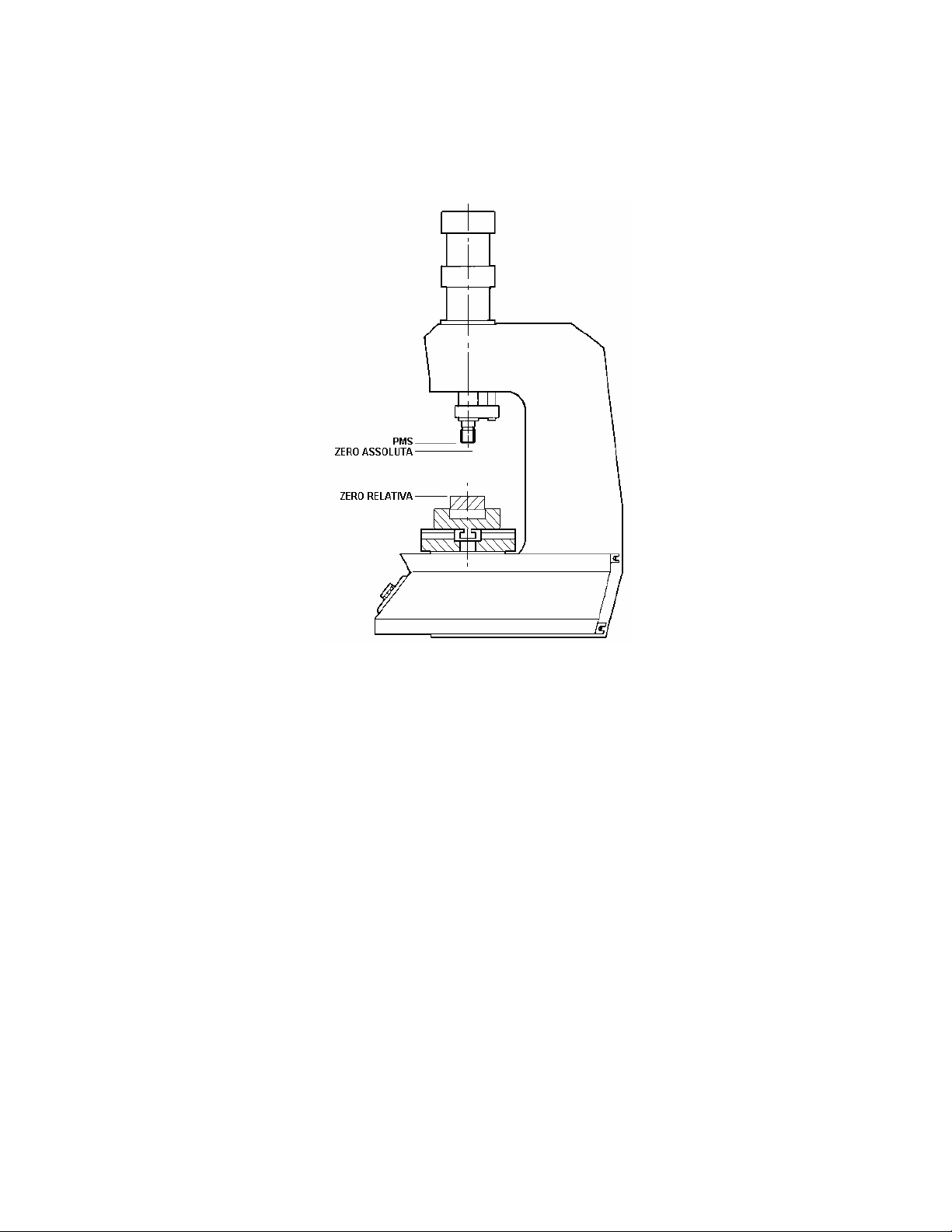

1.3 Start position ..................................................................................................................................... 4

1.4 Absolute or relative positions .......................................................................................................... 5

2Implementation of VISUAL POINT........................................................................................6

3HOW TO BEGIN ....................................................................................................................7

3.1 INTRODUCTION FOR THE USE OF VISUAL POINT............................................................. 7

3.2 ENTERING OF A VALUE.............................................................................................................. 8

3.3 THE WORK...................................................................................................................................... 8

3.4 GETTING ACCUSTOMED TO THE INSTRUMENT................................................................ 8

3.5 REJECTED PIECES MANAGMENT ........................................................................................... 9

4MENU DESCRIPTION ........................................................................................................10

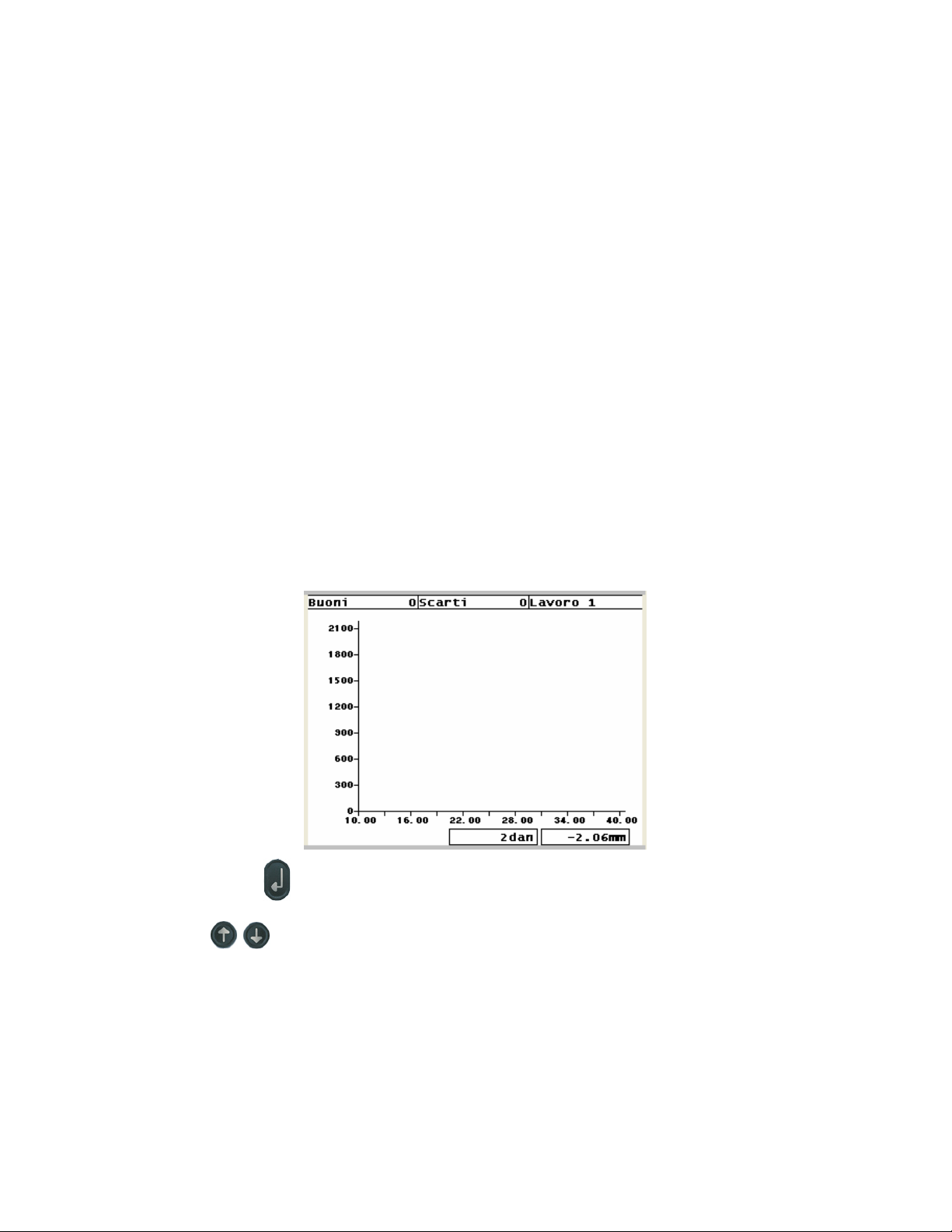

4.1 MEASUREMENTS ........................................................................................................................ 10

4.2 SELECT WORK ............................................................................................................................ 12

4.3 EDIT WORK .................................................................................................................................. 12

4.4 GRAPH SETUP .............................................................................................................................. 14

4.5 PRINT.............................................................................................................................................. 14

4.6 GOOD .............................................................................................................................................. 15

4.7 REJECTED..................................................................................................................................... 15

4.8 COONTRAST................................................................................................................................. 15

4.9 CONFIGURATION ....................................................................................................................... 15

5WORK PARAMETER...........................................................................................................18

5.1 STOP VALUES............................................................................................................................... 18

5.2 Check point ..................................................................................................................................... 18

5.3 Limits ............................................................................................................................................... 19

6Configuration ........................................................................................................................21

6.1 Ethernet connection........................................................................................................................ 22

7Calibration ............................................................................................................................23

7.1 Force transducer calibration ......................................................................................................... 23

7.2 Position transducer calibration ..................................................................................................... 23

7.3 Encoder calibration ........................................................................................................................ 24

7.4 Potenziometer calibration.............................................................................................................. 24