150 T / 150 W

Ultima modifica/ Last Modify: 18/03/2008 Rev0 pagina 10 di 17

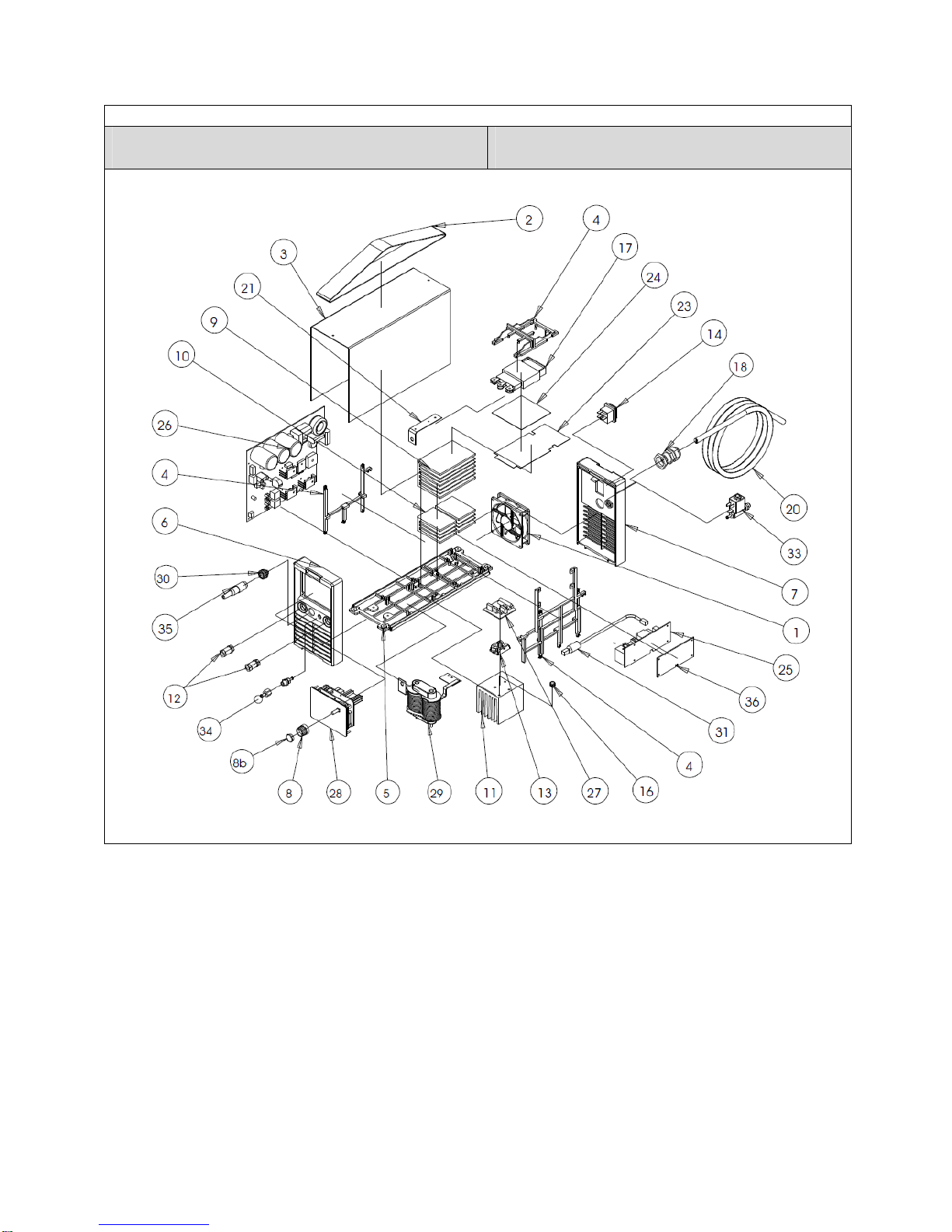

PROBLEM CASE SOLUTION

The machine does not

switch on.

Electrical power does not reach the ma-

chine.

Voltage reaches the machine switch but

there is no voltage after the contacts.

There is voltage after the disconnecting

switch but the machine does not go on.

!Make sure the line switches are closed, the

protection devices (fuses) have not been

enabled and that the power supply cable is

intact.

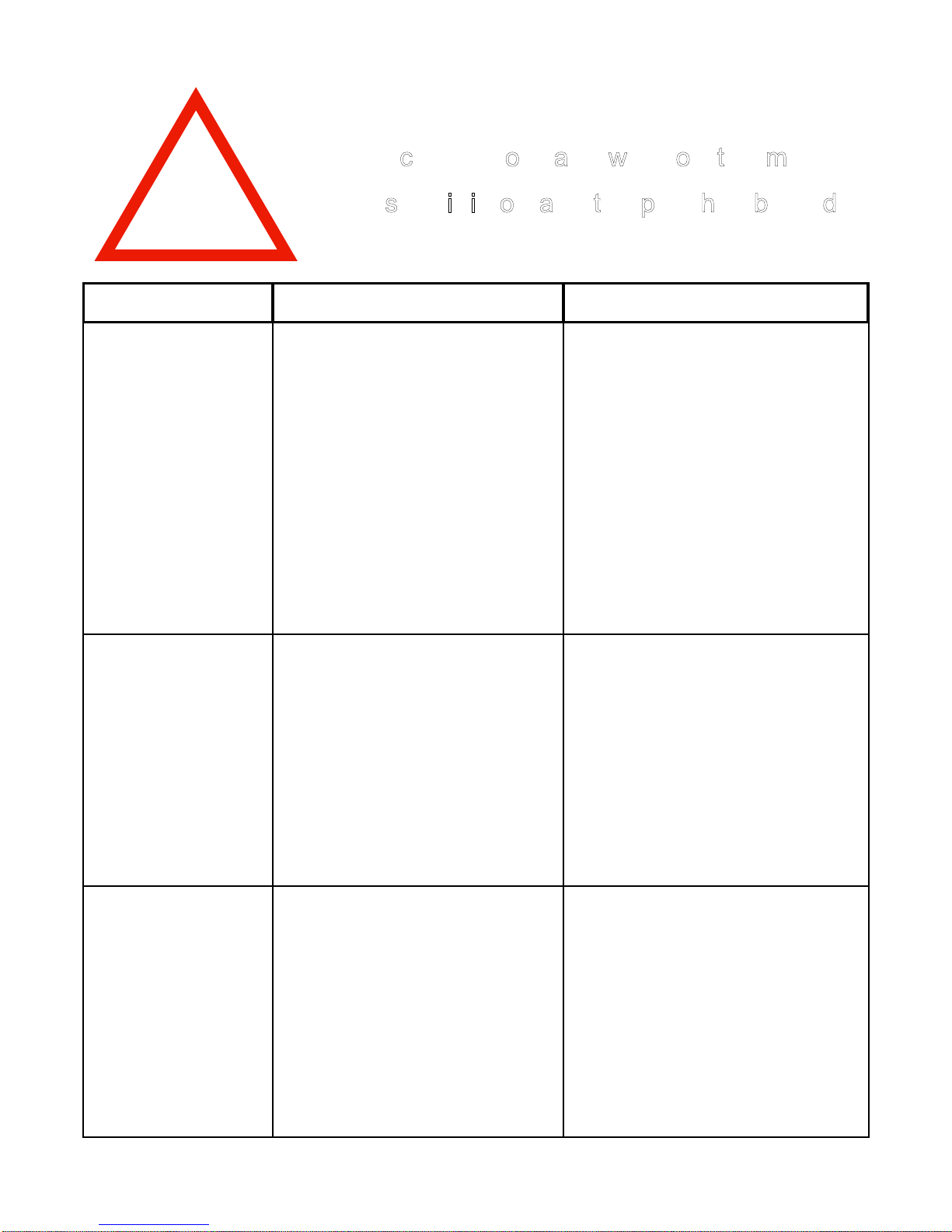

!Switch the machine off and disconnect the

plug. Make sure that when the switch is

closed, there is continuity between the

contact input and output and that the varis-

tor is not broken (picture 5). If it’s dama-

ged, the Power Board must be replaced.

!Switch the machine off and disconnect the

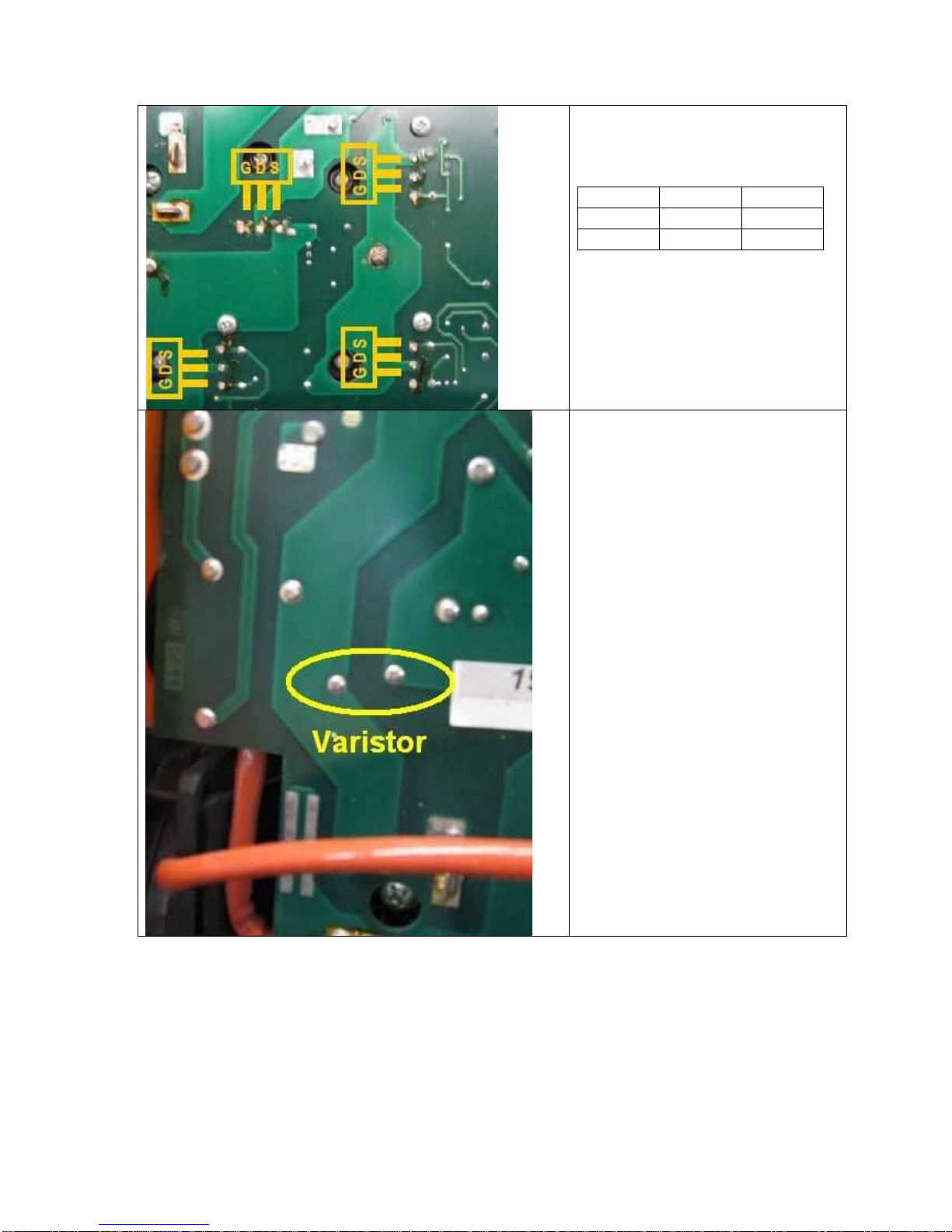

plug. Check the mosfet of the switching

power supply unit on the power board

(picture 6). If it’s damaged, the Power

Board must be replaced.

The protection devices

of the line set off when

the switch is activated

and the machine does

not go on.

Damaged power supply cable with short-

circuited wires.

Inverter is damaged.

!Switch off the machine and disconnect the

plug. Make sure that there are no short cir-

cuits between the poles of the plug caused

by a damaged power supply cable.

!Switch off the machine, disconnect the

plug and check:

- varistors (picture 5);

- l’inverter (picture 4);

- Input bridge rectifier (picture 3)

switching power supply unit (picture 6).

If one of these components is damaged

replace the power board.

The front panel does

not switch on.

The fan works but the front panel does

not go on.

Both the fan and the front panel do not

work.

!Switch off the machine and disconnect the

plug. Make sure the flat cable that con-

nects the front panel to the power board is

inserted correctly. If correctly inserted, re-

place the front panel. If the front panel

does not go on, one of the switching power

supply unit outputs is broken. Therefore

the power board must be replaced.

!Switch off the machine, disconnect the

plug and check the mosfet of the switching

power supply unit (picture 6).

!"#$%&'(

)*+,-*( ./--0123( ,45( /20( 6,-7( ,2( 58*( 9/.812*(

9/7*( :4-*(15(1:( ,++(/2;(58*(<=43( 8/:( >**2(;1:?

.,22*.5*;@(

'(