10 AuV ALFIX Mobile Scaffold Tower Series 6000

Instructions for Erection and Use4. General Notes

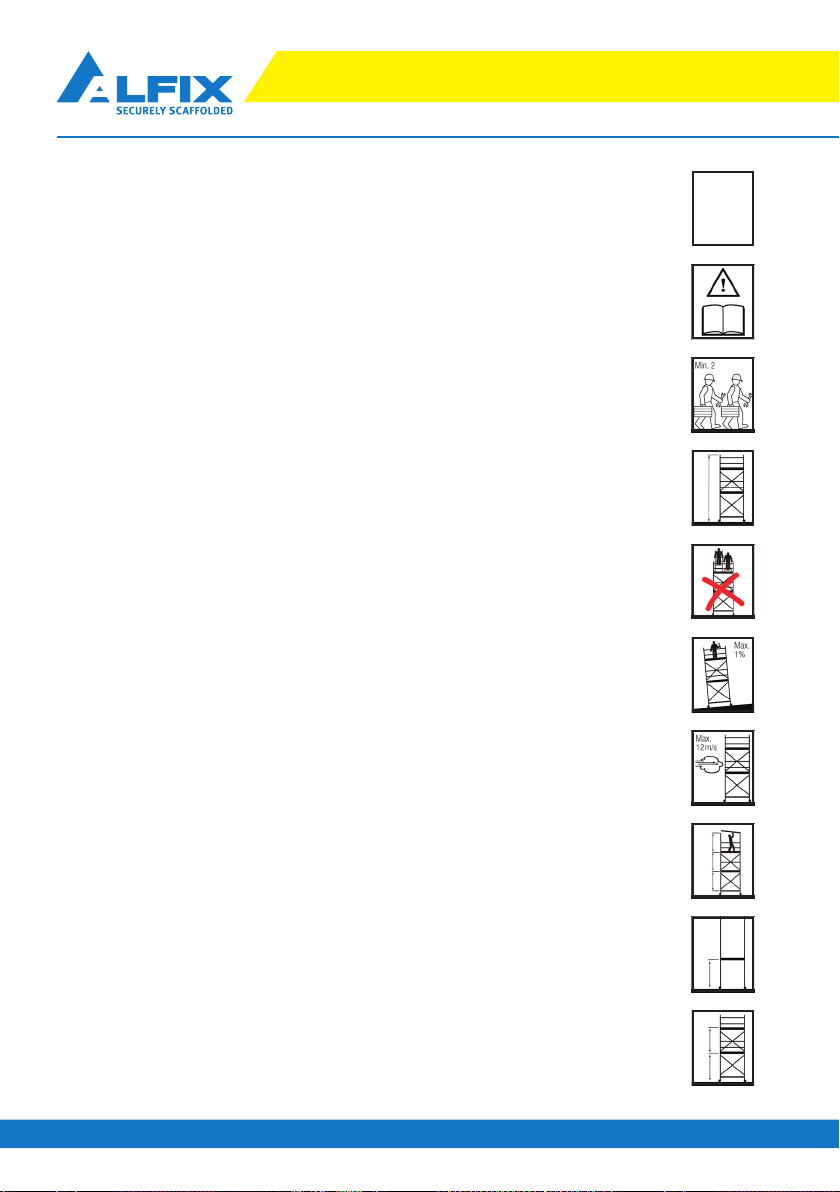

1. Erection, rebuilding and dismantling of the Mobile Working Platform must be

carried out in accordance with the Instructions for Erection and Use or upon

consultation with the manufacturer. The Instructions for Erection and Use

must always be available at the site of use! When handing over the Mobile

Working Platform to any third party, the Instructions for Erection and Use

must be forwarded to the user as well.

2. When working, a helmet and safety shoes must be worn.

3. When using the Mobile Working Platform outdoors or in open spaces at

wind forces exceeding six on the Beaufort scale (large branches in motion,

whistling in overhead power lines, difficulties to use an umbrella), the

platform is to be moved to a sheltered area or is to be secured against

overturning through appropriate measures (e.g. a compression-resistant

and tension-proof anchorage to a building structure) or is to be dismantled.

4. The scaffolding is to be placed perpendicular using the adjusting spindles.

5. Only original ALFIX counterweights may be used (no “equivalent weights”,

such as canisters with water, buckets of sand, etc.), the arrangement of

which is defined in these Instructions for Erection and Use.

6. The vertical frame joints are to be secured against accidental lifting using

locking clips or hinged pins.

7. Prior to using the scaffolding, its proper and correct erection must be

checked.

8. Access to the working platform shall only take place at the inside of the

scaffolding. The platforms with hatch-type access are to be alternately

arranged. The hatches are to be closed after climbing through.

9. Persons working on Mobile Scaffold Towers are not allowed to push

themselves against the side protection.

10. During movement, one must be certain that no people or loose objects are on

the Mobile Scaffold Tower.