STS 6000-4GPM ALGAE-X2007-Rev. B

INSTALLATION

! IMPORTANT ! It is recommended that only qualified, experienced personnel, familiar with this

type of equipment, who have read and understood all the instructions in this manual should

install, operate and maintain the system.

MOUNTING

The STS-6000 is a totally enclosed system and should be permanently wall mounted on a hard, level surface.

Use provided mounting feet for proper fastening. This weatherproof unit is designed for well-ventilated indoor

or outdoor use within specified temperature range and should be located as close to the tank as possible.

Please allow about 1 ft of space between the side louvers of the enclosure and nearby objects. This space is

necessary to ensure sufficient ventilation of cooling air for the system and motor.

ELECTRICAL

! WARNING ! To avoid the risk of electric shock make sure that the power supply to the system is

disconnected and ensure that the system is at zero volts, before working on any of the system‟s

electrical parts.

Make sure that the systems power requirements and rated voltage / frequency match your electrical system (See

wiring diagram). The STS 6000 may only be connected to properly grounded power sources for operator safety.

Connect all components to the ground studs provided as shown on the electrical drawings.

! WARNING ! The whole system (Enclosure, doors, plumbing, motor, electric sub panel) must be

properly grounded for operator safety.

Depending on length of run, use #12 AWG or larger copper wiring and connect system to a separate UL listed

20A breaker (not included) appropriate for branch circuit protection.

Note: Wiring and electrical installation must be in accordance with all applicable Federal, State and

Local rules, laws, standards and regulations.

Remote Pump Shut-Down Feature:

If required, connect the “external pump shut down input terminal”(Terminal 15 on Terminal Block “TB2” –see

wiring diagram) for customers use per specification on electric diagram to disable pump (e.g.: remote shut down,

external emergency stop button). Please note that the contact needs to be supplied with +24V DC from the power

supply of the STS 6000 Algae-X Smart Filtration Controller.

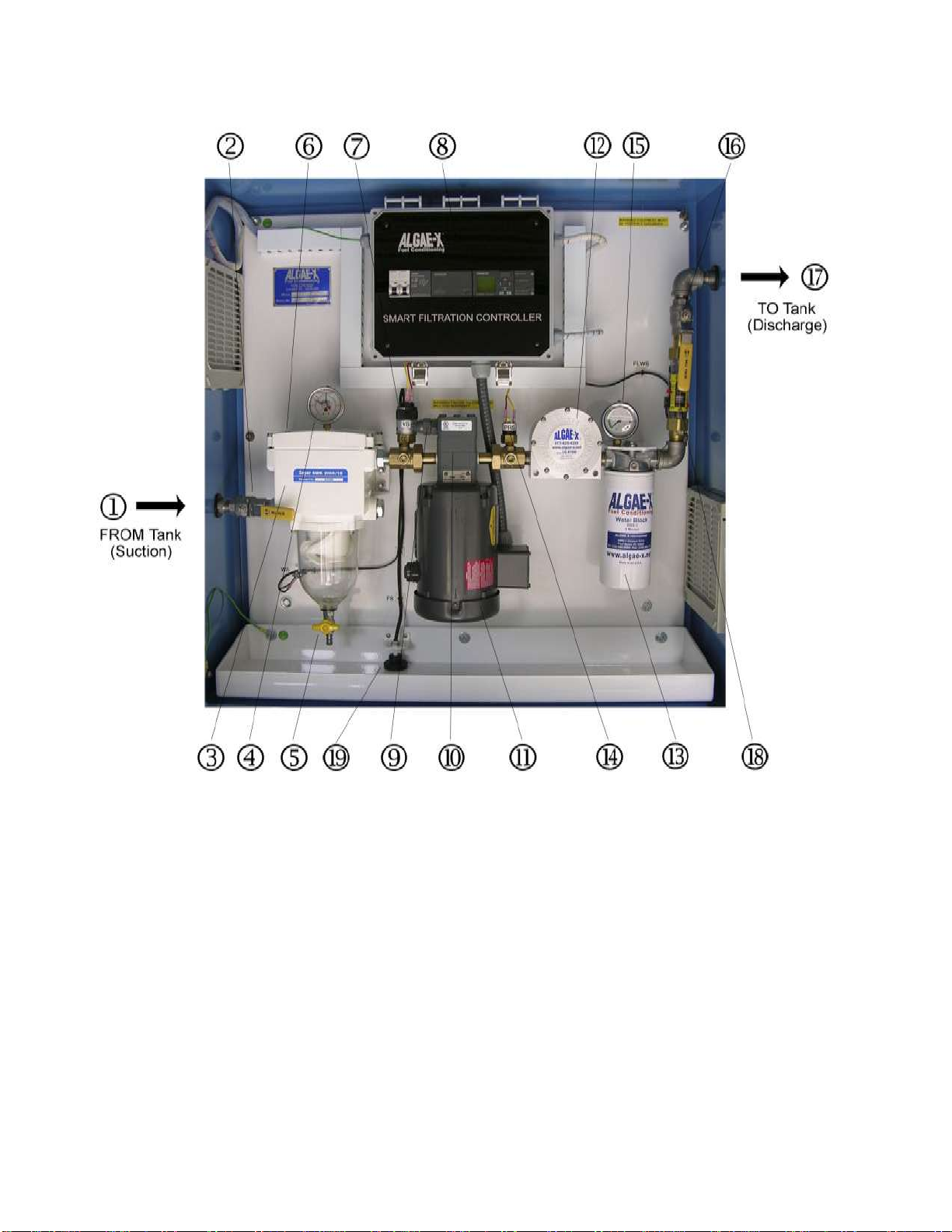

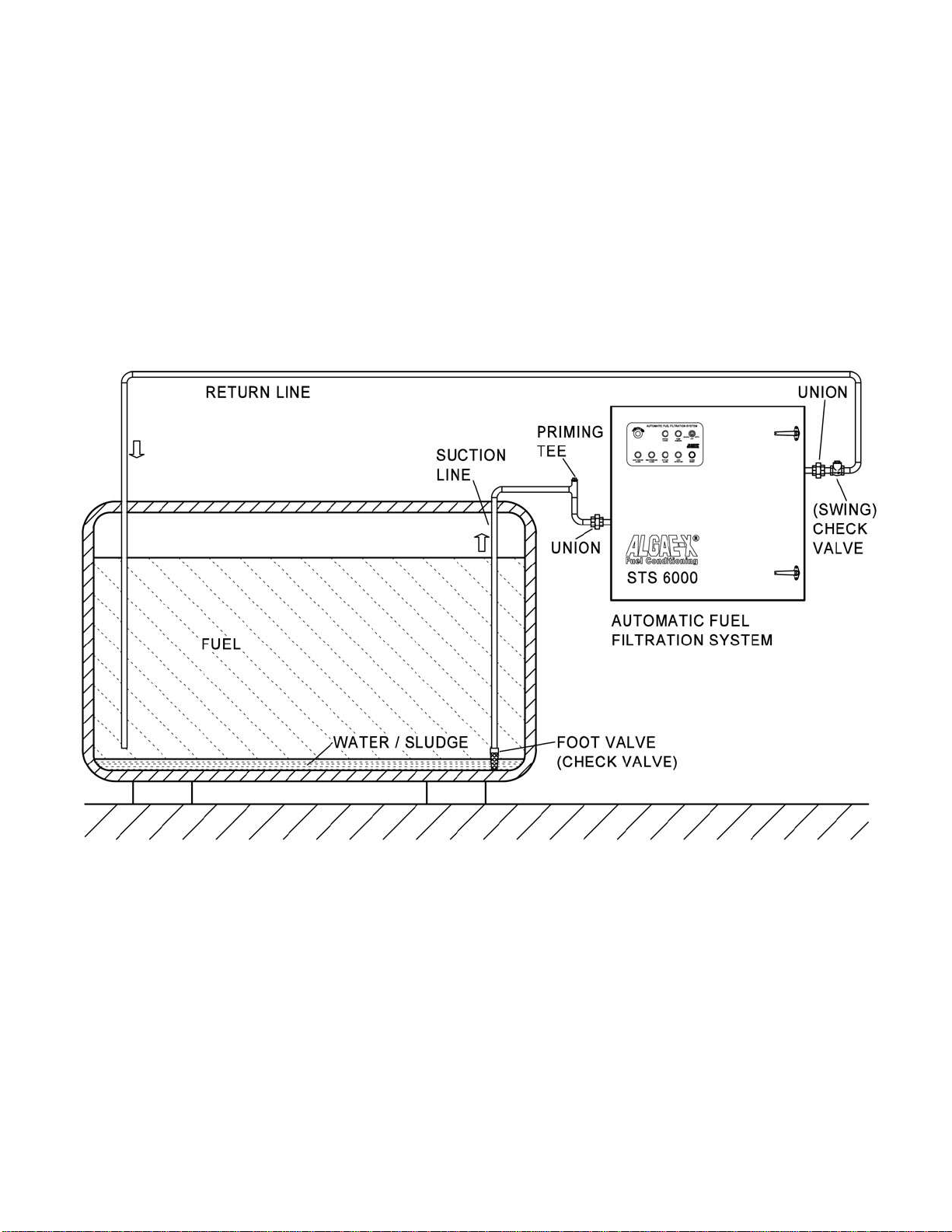

PLUMBING

Use proper quality approved fuel line materials with at least 3/4” inner diameter on the suction side from

the tank and at least 1/2” inner diameter on the return / discharge side back to the tank.

The pick-up tube/line(s) should originate from the lowest point of the tank (to remove all water), should be

connected directly to the system’s “PUMP INLET –SUPPLY FROM TANK” port located on the left hand side of

the enclosure and kept as short as possible. It is recommended to install an oversized, low restriction foot

valve to keep the system primed, especially if the “PUMP INLET –SUPPLY FROM TANK” port of the system is

located above the lowest possible fuel level in the tank. A priming tee should be installed on the highest point

of the suction line to be able to easily prime the lines and system.

The return line(s) should be plumbed to the “PUMP OUTLET –RETURN TO TANK” port (on the right side of the

system) and enter the tank as far as possible from the pick up tube close to the tank bottom. A (swing) check

valve may be required on the return line(s) on some installations to prevent back flow pressure.