Table of Contents

1.Introduction.................................................................................................................................................... 1-1

General ............................................................................................................................................................ 1-1

DESCRIPTION ................................................................................................................................................ 1-1

MIXER OPERATION - LPG-VAPOR/AIR MIXING PROCESS .......................................................................... 1-2

LPG-Vapor/Air Mixing Process ........................................................................................................................ 1-2

Figure 1 - VAPORAIRE Mixing System Components .................................................................................1-3

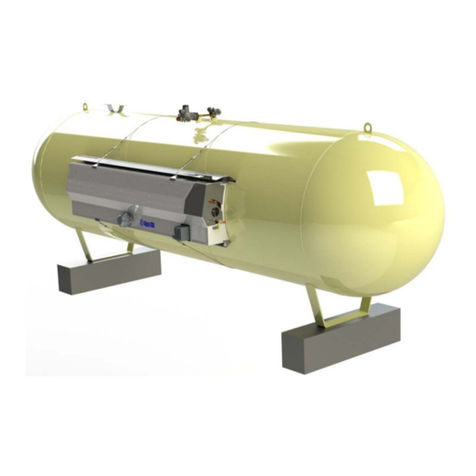

Figure 2 - VAPORAIRE with Surge/Accumulator Tank Configuration.........................................................1-4

Figure 3 - VAPORAIRE M-Series Mixing System Components.................................................................. 1-5

Major Components of a Vaporaire M-Series Mixer ......................................................................................... 1-5

Figure 4 - VAPORAIRE M-Series Configuration .........................................................................................1-6

Figure 5 - Single Venturi Control Box..........................................................................................................1-7

Figure 6 - 8100 Sequencer Control Box......................................................................................................1-8

Control Box Components for Mixers using the Sequencer ............................................................................. 1-9

Figure 7 - SEQUENCER Diagram.............................................................................................................1-10

Figure 8 - 2080-TRIMPOT6(C), 6 Channel Potentiometer (Pot.)..............................................................1-11

Figure 9 - 2080-IF2, Analog Input Module(D)............................................................................................1-11

2.Installation.................................................................................................................................................... 2-13

Figure 10 - Typical VAPORAIRE Installation Drawing ..............................................................................2-14

Figure 11 - Typical VAPORAIRE M-Series Installation Drawing...............................................................2-15

Installation Instructions for all LPG-Air/Vapor Mixers .................................................................................... 2-16

Mixed Gas Outlet Installation for VAPORAIRE M-Series ................................................................................. 2-17

Surge/Accumulator Tank Requirements for Vaporaire M-Series Mixers ...................................................... 2-17

Surge/Accumulator Tank Sizing Formula ...................................................................................................... 2-17

Surge/Accumulator Tank Sizing .................................................................................................................... 2-18

Table 4 - Surge/Accumulator Tank Requirements .................................................................................... 2-18

3.Startup.......................................................................................................................................................... 3-19

4.Operation...................................................................................................................................................... 4-21

SINGLE VENTURI SYSTEMS .......................................................................................................................... 4-22

Mixer Operation ............................................................................................................................................. 4-22

Mixed Gas Operating Pressure Adjustments ................................................................................................ 4-22

High Mixed Gas Pressure Safety Switch ...................................................................................................... 4-23

Low Vapor Pressure Switch .......................................................................................................................... 4-23

MULTIPLE VENTURI SYSTEM ........................................................................................................................ 4-24

SEQUENCER Operation ............................................................................................................................... 4-24

Venturi Sequencing ....................................................................................................................................... 4-24

PLC Controller LED Indicators and Mode Switch ......................................................................................... 4-25

Analog Input Module(s) ................................................................................................................................. 4-25

Mixed Gas Pressure Transmitter ................................................................................................................... 4-25

Memory Module: ............................................................................................................................................ 4-26

Discrete Inputs ............................................................................................................................................... 4-27

Table 1 - Discrete Inputs............................................................................................................................ 4-27

Optional Alarm Inputs #1 to #3 ...................................................................................................................... 4-27

Discrete Output .............................................................................................................................................. 4-28

Pressure Adjustments ................................................................................................................................... 4-28

Mixed Gas Operating Pressure Control Setpoint: Trimpot MODULE(c) ...................................................... 4-28

Table 2 - Mixed Gas Pressure and Setpoint Ranges................................................................................4-29

High Mixed Gas Pressure Switch .................................................................................................................. 4-29

High Mixed Gas Pressure Safety Backup (no adjustment required) ............................................................. 4-29

Low Vapor Pressure Switch .......................................................................................................................... 4-30

LPG/Air Venturi Type Mixers ............................................................................................................................ 4-31

Figure 12 - LPG/Air Venturi Assembly Diagram........................................................................................4-31

Venturi Motive Pressure ................................................................................................................................ 4-32

Venturi Motive Pressure Adjustment................................................................................................................. 4-32

Adjusting the Heating Value of the Mixed Gas .............................................................................................. 4-32

Adjusting the Heating Value of the Mixed Gas with Individual Regulators ................................................... 4-32

Adjusting the heating Value of the Mixed Gas with a Single Regulating Station .......................................... 4-33

Figure 13 - Typical Venturi Performance Curve........................................................................................ 4-34