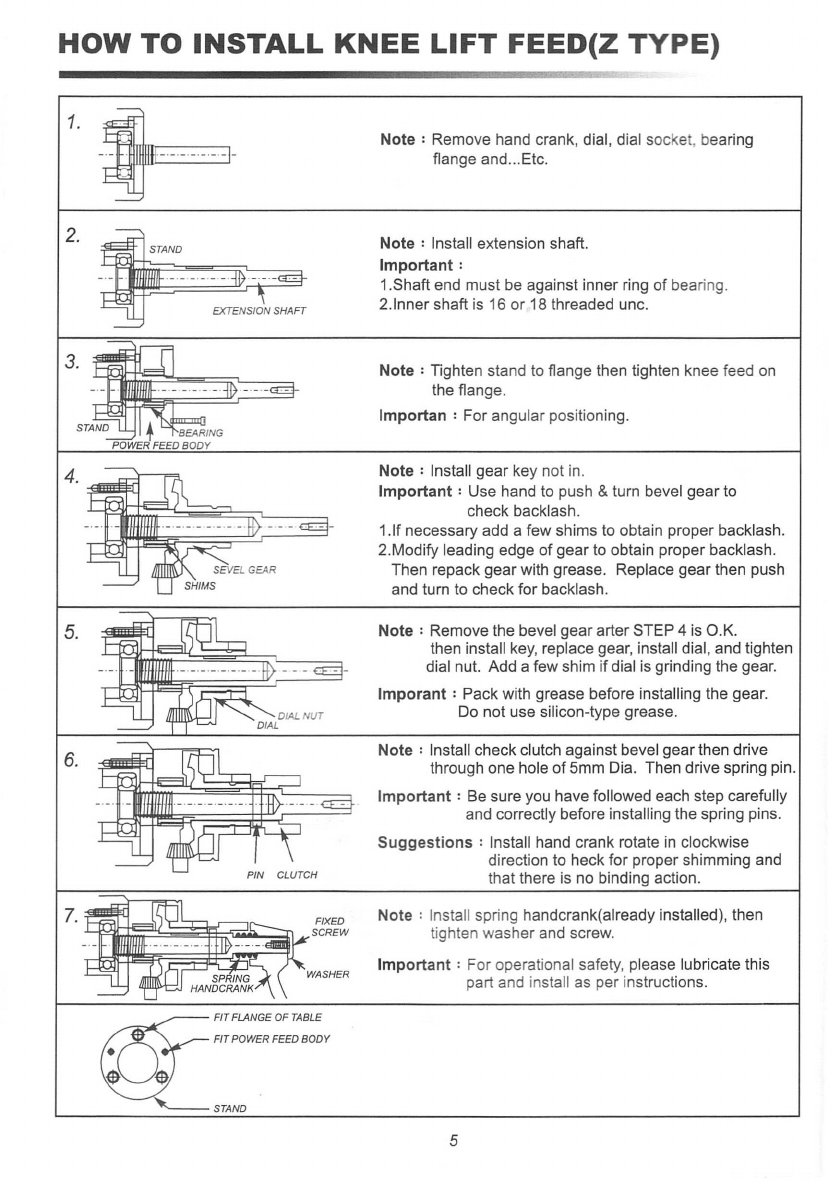

HOW TO INSTALL KNEE LIFT FEED(Z TYPE)

1.

2.

3.

4.

5.

6.

7.

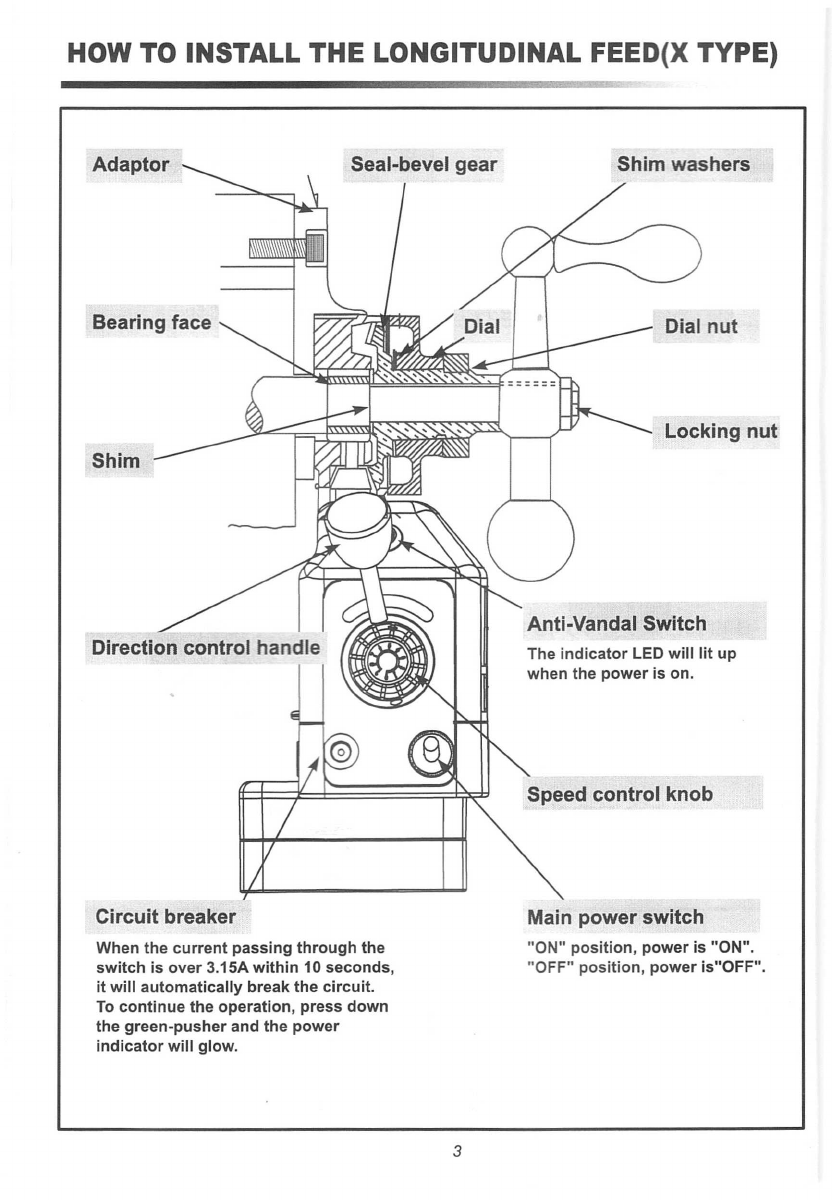

Note: Remove hand crank, dial, dial socket, bearing

flange and ...Etc.

Note: Install extension shaft.

Important:

1.Shaft end must be against inner ring of bearing.

2.lnner shaft is 16 or 18 threaded unc.

Note : Tighten stand to flange then tighten knee feed on

the flange.

Importan : For angular positioning.

Note: Install gear key not in.

Important: Use hand to push & turn bevel gear to

check backlash.

1.lf necessary add a few shims to obtain proper backlash.

2.Modify leading edge of gear to obtain proper backlash.

Then repack gear with grease. Replace gear then push

and turn to check for backlash.

Note: Remove the bevel gear arter STEP 4 is O.K.

then install key, replace gear, install dial, and tighten

dial nut. Add a few shim if dial is grinding the gear.

Imporant : Pack with grease before installing the gear.

Do not use silicon-type grease.

Note: Install check clutch against bevel gear then drive

through one hole of 5mm Dia. Then drive spring pin.

Important: Be sure you have followed each step carefully

and correctly before installing the spring pins.

Suggestions: Install hand crank rotate in clockwise

direction to heck for proper shimming and

that there is no binding action.

Note: Install spring handcrank(already installed), then

tighten washer and screw.

Important: For operational safety, please lubricate this

part and install as per instructions.

5