Align PTT3 User manual

PTT3

Operation Manual

30,000 lbs. Capacity Battery Powered Tugger

ALIGNPROD.COM 800.888.0018

SUPPORT@ALIGNPROD.COM

PTT3 Power Tugger 2

PTT3 Power Tugger 3

Table of Contents

I. Important Precauons

II. Safety

III. Load Placement

IV. Sequence of Operaons

V. Baeries

VI. Maintenance

VII. Warranty

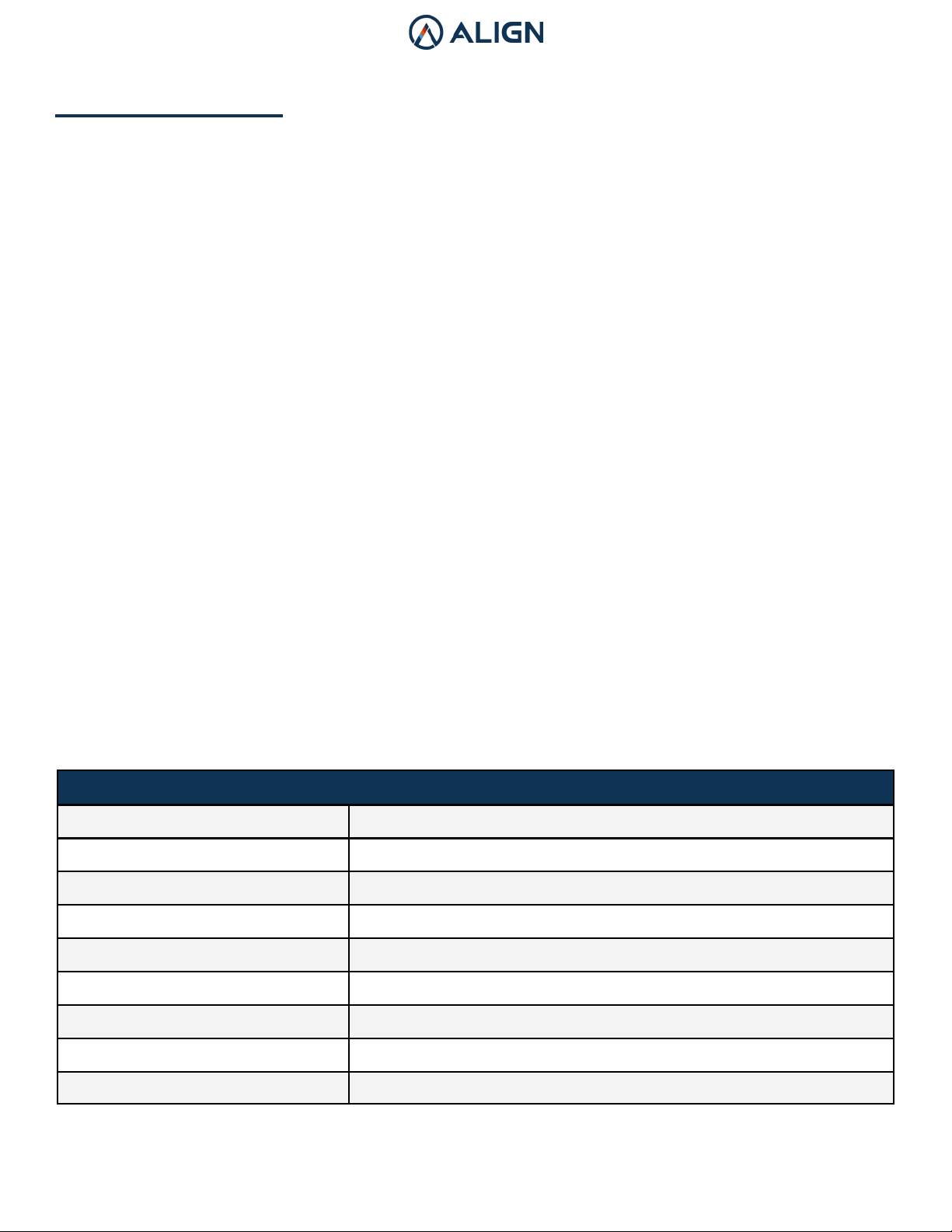

General Specifications

Model No. PTT3

Dimensions 61.3125” x 26.375” x 37.875”

Weight Approx. 800 lbs.

Capacity 30,000 lbs.

Battery 76 Ah

Charging 24 VDC / 12 A

Stroke 5.9”

PTT3 Power Tugger 4

I. Important Precauons

Read the following safety precautions before operating or servicing your equipment.

Follow correct lockout/tagout procedures.

Prevent personnel from leaning on equipment and containers or placing their arms, hands, legs or

any bodily member in pinch-point areas throughout the system.

Instruct personnel on the proper placement of product on the equipment. Failure to place containers

or loads in the engineered locations may hinder the operation of the equipment or cause structural

damage.

Never walk or climb into or onto the product while it is in motion.

Never alter the equipment in any way unless authorized by a qualified employee of Align.

Thoroughly read the manual and understand how to use the PTT3.

The operator should wear protective footwear at all times.

Keep the floors clean and smooth for efficient operation.

Keep the weight on the drive wheel while moving a load.

When driving the PTT3, try not to create any sudden stops / changes in direction.

Stop the unit slowly with the accelerator rather than letting go of the handle.

PTT3 Power Tugger 5

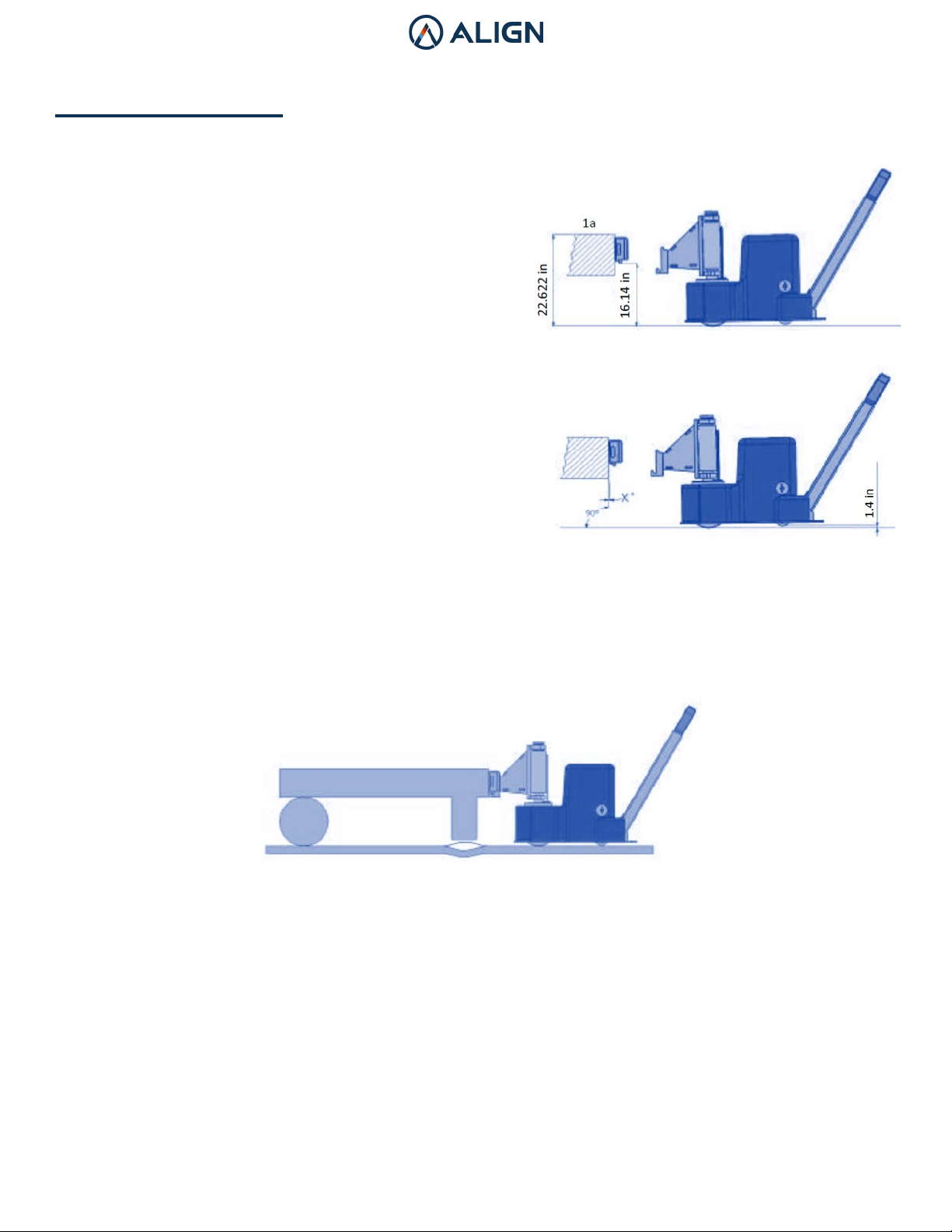

II. Safety

PTT3 Safety

Charge the batteries after using the PTT3 Tugger.

Always place the female coupling (1a) at the correct

height. It’s important that the coupling is at the correct

angle and is firmly fastened to your trailer.

Raise / lift the coupling until the casters have enough

ground clearance (1.5”).

Only lift the coupling high enough to perform the transport.

Load Placement

The image below shows the correct setup that should be used with the PTT3, as well as where to

place the load. These trailers should consist of one wheel axle. When the trailer and the PTT3’s cou-

pling are attached to each other, and the PTT3’s arm is raised, the trailer leg will be lifted off

the ground.

As mentioned above, trailers should consist of one wheel axle. If there are two axles and the floor is

uneven, the front wheel will be lifted up by the PTT3 and overload the wheels. Uneven floors put the

trailer coupling at risk of unfastening and can disconnect from the trailer.

PTT3 Power Tugger 6

III. Load Placement

Load Placement

The image below shows the correct setup that should be used with the PTT3, as well as where to

place the load. These trailers should consist of one wheel axle. When the trailer and the PTT3’s cou-

pling are attached to each other, and the PTT3’s arm is raised, the trailer leg will be lifted off

the ground.

As mentioned above, trailers should consist of one wheel axle. If there are two axles and the floor is

uneven, the front wheel will be lifted up by the PTT3 and overload the wheels. Uneven floors put the

trailer coupling at risk of unfastening and can disconnect from the trailer.

The PTT3 has a maximum load capacity of 6,614 lbs on the drive wheel under normal conditions.

The load capacity depends on the configuration of the load. Max capacity could be under 6,614 lbs.

depending on if there is a swing bearing or a lift cylinder. Contact Hedin USA if you unsure of your lift

capacity.

The drive wheel needs ground force on it to make sure friction between the floor and wheel provides

the traction required to perform the transport.

The load center has to be in between the trailer’s wheels and the PTT3’s drive wheel. If not, there is

a chance the load could overturn.

Heavier loads must be balanced on the trailer - see picture below.

PTT3 Power Tugger 7

IV. Sequence of Operaons

As operator, you are responsible that no one is in harm’s way whilst you are

operating the transporter.

Starting the Equipment

Turn the key switch on the handle when it is in its upright position.

Check the battery indicator to make sure the PTT3 is charged and ready for use.

Push the “lift cylinder down” button to assure that the cylinder is in its lowest position.

PTT3 Power Tugger 8

IV. Sequence of Operaons

As operator, you are responsible that no one is in harm’s way whilst you are

operating the transporter.

Connecting the PTT3 to a Trailer

Ensure the coupling between the PTT3 and the trailer is properly connected.

When the lift is performed, do not lift higher than necessary as it puts additional strain on the

lift cylinder.

The casters at the back of the PTT3 will lift from 1.5” from the floor. This applies the load to the drive

wheel for easy maneuverability.

The coupling must be attached vertically so the casters in the back of the PTT3 are in the air when it

has been connected to the trailer.

If the trailer is fixed to the PTT3, the casters can be removed to avoid becoming stuck on

uneven floors.

Connecting the PTT3 to a Trailer

The direction and speed of the PTT3 is controlled and adjusted by the accelerator at the top of the

handle.

A safety switch is located on the handle. When triggered, the PTT3 will stop and take a small leap

forward to prevent the pinning of the operator.

PTT3 Power Tugger 9

IV. Sequence of Operaons

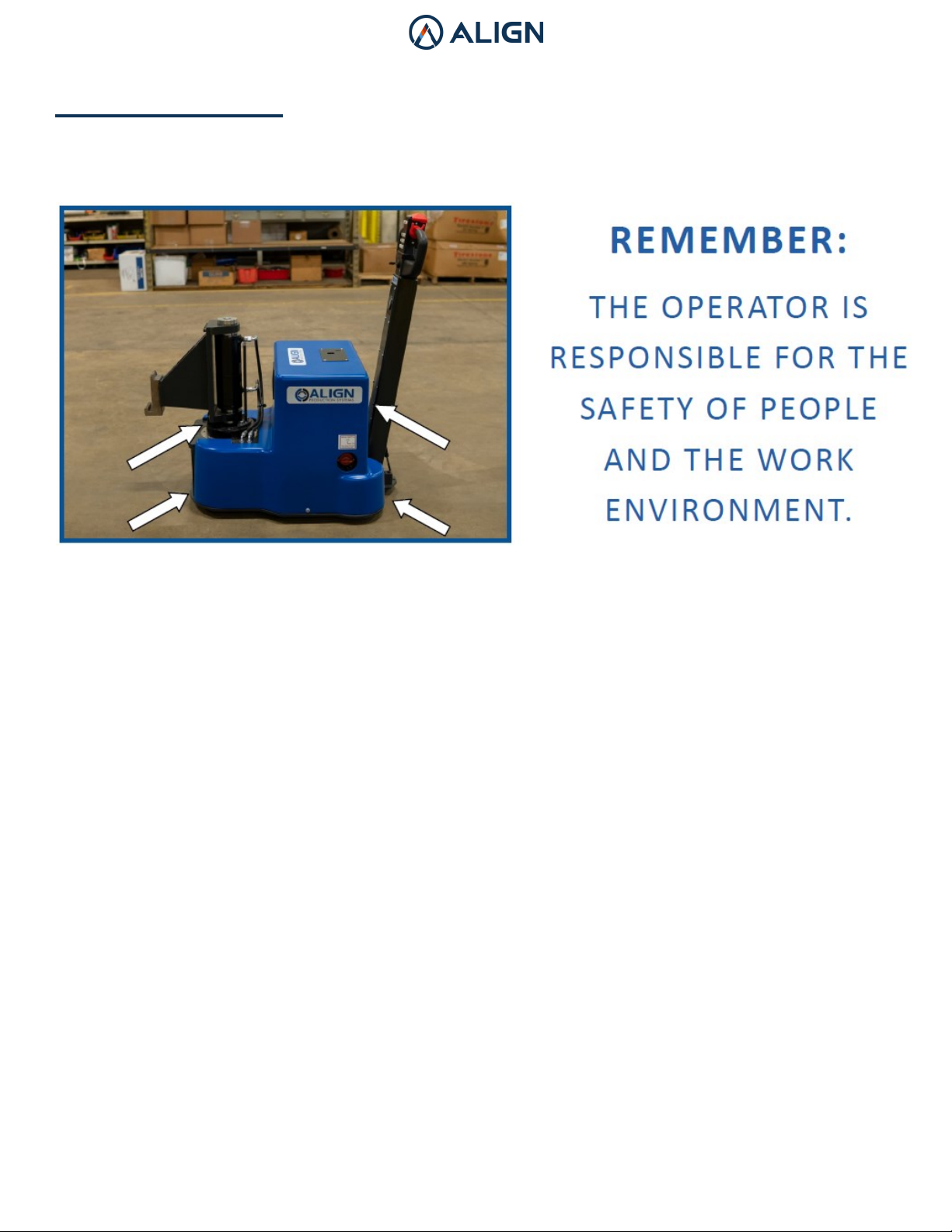

Pinch Points

Be careful of pinch points. They can occur:

• Between the PTT3 and moving or fixed objects

• During lifting—between the floor and the PTT3 or between the object being connected and the

PTT3.

• When operating the hydraulic cylinder.

• While driving the PTT3. Be cautious of surroundings.

PTT3 Power Tugger 10

V. Baeries

Charging the Batteries

Always switch the battery charger off before connecting / disconnecting the battery cables.

The batteries are to be charged a minimum once a week to maintain their capacity over time.

The charging cable is to be connected to the outlet on top of the PTT3.

“Charging” is indicated by a yellow light.

“Charge Complete” is indicated by a green light.

The charger has an extra green light which indicates that the charging current (1 Ah) is not reached

in the maximum charging time of 20 hours to prevent overcharging and harm to the battery.

Table of contents

Popular Lifting System manuals by other brands

probst

probst SDH-H-15 operating instructions

Bruno

Bruno OUTDOOR ELITE CRE-2110E Operator's manual

matev

matev FPS Mounting Assembly Installation Guide

Vestil

Vestil CYL-HLT Series instruction manual

Butts Tools

Butts Tools BXS0002 operating instructions

Safelift

Safelift MoveAround MA60 Original instructions

R. Beck Maschinenbau

R. Beck Maschinenbau HS 600 operating manual

Nova Technology International, LLC

Nova Technology International, LLC NAS Series quick start guide

Genie

Genie Z-60/34 Operator's manual

Screen Technics

Screen Technics INTERFIT Vertical Up Lift instructions

Drive

Drive DUPONT SAMERY Hermes user manual

Custom Equipment

Custom Equipment Hy-Brid 3 Series MAINTENANCE & TROUBLESHOOTING MANUAL