BLK RED

NOT

USED

page 20

Reprogramming Key Fobs

A fully automatic battery charger or

trickle charger may be used.

Do NOT use a high power manual or boost charger

unless the battery is disconnected!

The remote control electronics may be damaged.

1.This lift uses two 12V Group 31 marine deep-cycle batteries. When looking

for a replacement, note that the figure for Reserve Capacity is the most

important feature. Heavier batteries usually have more reserve capacity.

2.The batteries should not be allowed to remain in a substantially discharged

state. It may result in permanent loss of capacity. Do not deeply discharge

batteries more often than absolutely necessary; it may reduce the life of the

batteries.

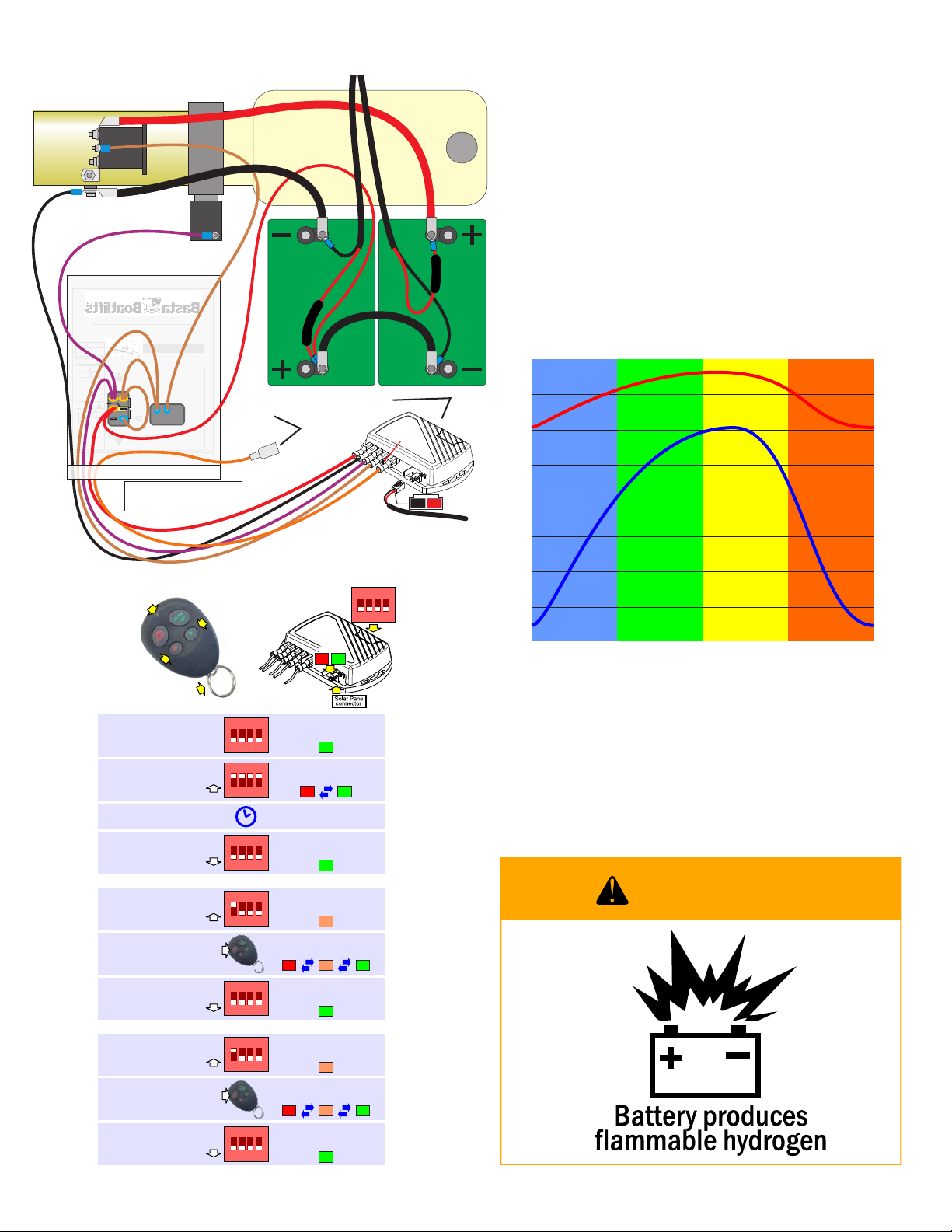

3.The following graph shows the approximate numbers of complete lift

cycles that may be expected during the day over the course of the seasons

while keeping the battery adequately charged. This data is only very

approximate and is influenced greatly by weather, temperature, solar panel

placement and cleanliness.

2

4

6

8

10

12

14

WINTER SPRING SUMMER AUTUMN

CYCLES PER DAY

Seattle-ish Miami-ish

Reprogramming Button

(Remove cover)

Control

Pendant

Serial Number

Raise

Lower

1-866-GO BASTA GOBASTA.COM

Waterline

Before use always check

that lift frame is level

!WARNING

Failure to properly position

boat on lift could cause lift

to become unstable

Exceeding lift capacity

may result in structural

failure, injury or death

90.0°

Waterline

Basta Over-Center Gravity Locking Lifts (TM)

!CAUTION

Always raise lift fully upright

Over-Center (TM)

if boat is on lift unattended

Do not use to

lift humans

Switch power off

when not in use

Off

Maid in the USA. Manufactured under one or more of the following patents #6318929, #6837651

#4895479, #4900187, # 5143182 #5184914 #5311970, Canada #2089044 other PatentsPending

!DANGER

!

Avoid all moving parts

to prevent serious

injury or death

Battery

ON

Fuse

To

Auxiliary

Lights

(if used)

Control Panel

Motor

Pump

Tank

'Down'

Solenoid

Motor

Relay

bottom view

15

Amp

BLACK

PURPLE

RED

BROWN

RED

BLACK

ORANGE

jumper

connected

on raise

connected

on lower

Group 31

marine

deep cycle

RAISE > RED AND BROWN = 12V

LOWER > RED, BROWN, PURPLE = 12V

ORANGE IS TURNED ON AND OFF BY THE "LIGHT"

BUTTONS ON THE KEY FOB - IT IS NOT AUTOMATIC

TURN POWER SWITCH OFF WHEN UNATTENDED

Battery

Group 31

marine

deep cycle

From Solar Panels

Isolation Diode

Isolation Diode

WARNING

1234

Slide open small

cover for access

LEDs

7

6

4

2

This is the normal

state of the switches.

Push all the

switches into the

OFF position.

Use the tip of a pen

to push all of the

switches into the

ON position.

Push switch #1 into

the ON position.

Push switch #1 back

into the OFF position.

The green LED located

near the solar panel

connector is on.

The green LED will stay on.

The red and green LEDs will

flash alternately, showing that

the memory is being erased.

The red LED will turn on,

making the LED orange.

The green LED will stay on.

FIRST, ERASE THE MEMORY

THEN PROGRAM ONE FOB

REPEAT FOR EXTRA FOBS

Push the UP button

on one of the fobs

for a few seconds.

1234

1234

1234

1234

1234

Wait 15 seconds.

1

3

5

10

9

Push switch #1 into

the ON position.

Push switch #1 back

into the OFF position.

The red LED will turn on,

making the LED orange.

The green LED will stay on.

Push the UP button

on the other fob

for a few seconds.

LEDs will alternate colors.

1234

1234

8

1

2

LEDs will alternate colors.

TWIST THIS RING TO POP

THE FOB HALVES APART

LED SHOULD

BE BRIGHT

TURNS AUXILIARY

LIGHTS ON

TURNS AUXILIARY

LIGHTS OFF

From

Solar Panel