01/11/2013

670-00028A

2

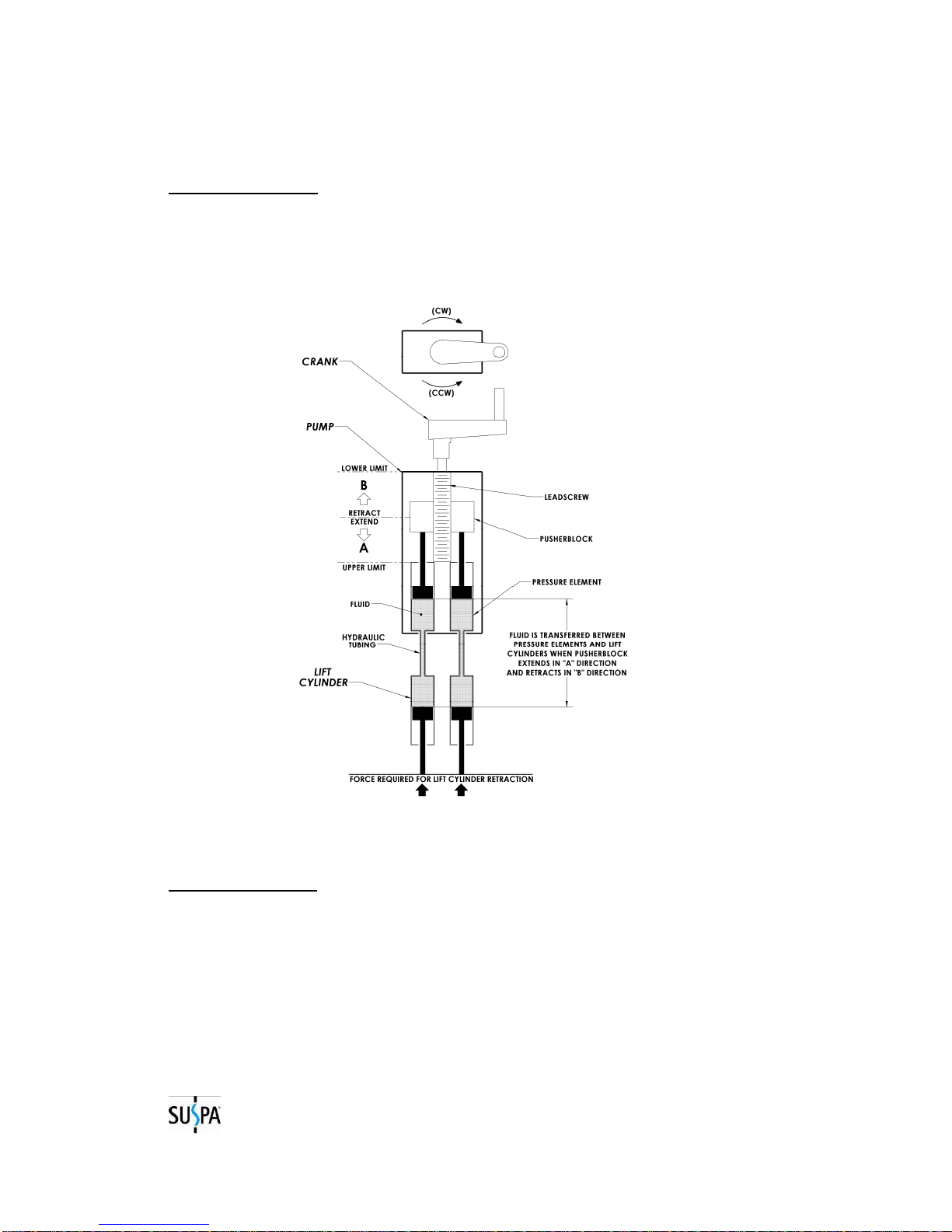

2.0 Introduction

Thank you for purchasing the Movotec

®

Crank Driven ATU Lift System.

The Movotec

®

Crank Driven ATU Lift System is a single-acting fluid displacement lift

system that is manually driven by a hand crank. This particular lift system was designed

to be used in conjunction with the Movotec

®

ATU or Aluminum Telescoping Upright.

The Movotec

®

ATU is a telescoping table leg which provides guide support for Movotec

®

lift cylinders throughout their extension and retraction cycle. The ATU also offers a

solution for customers who want to make their own height adjustable table, but do not

have the means to manufacture their own telescoping leg.

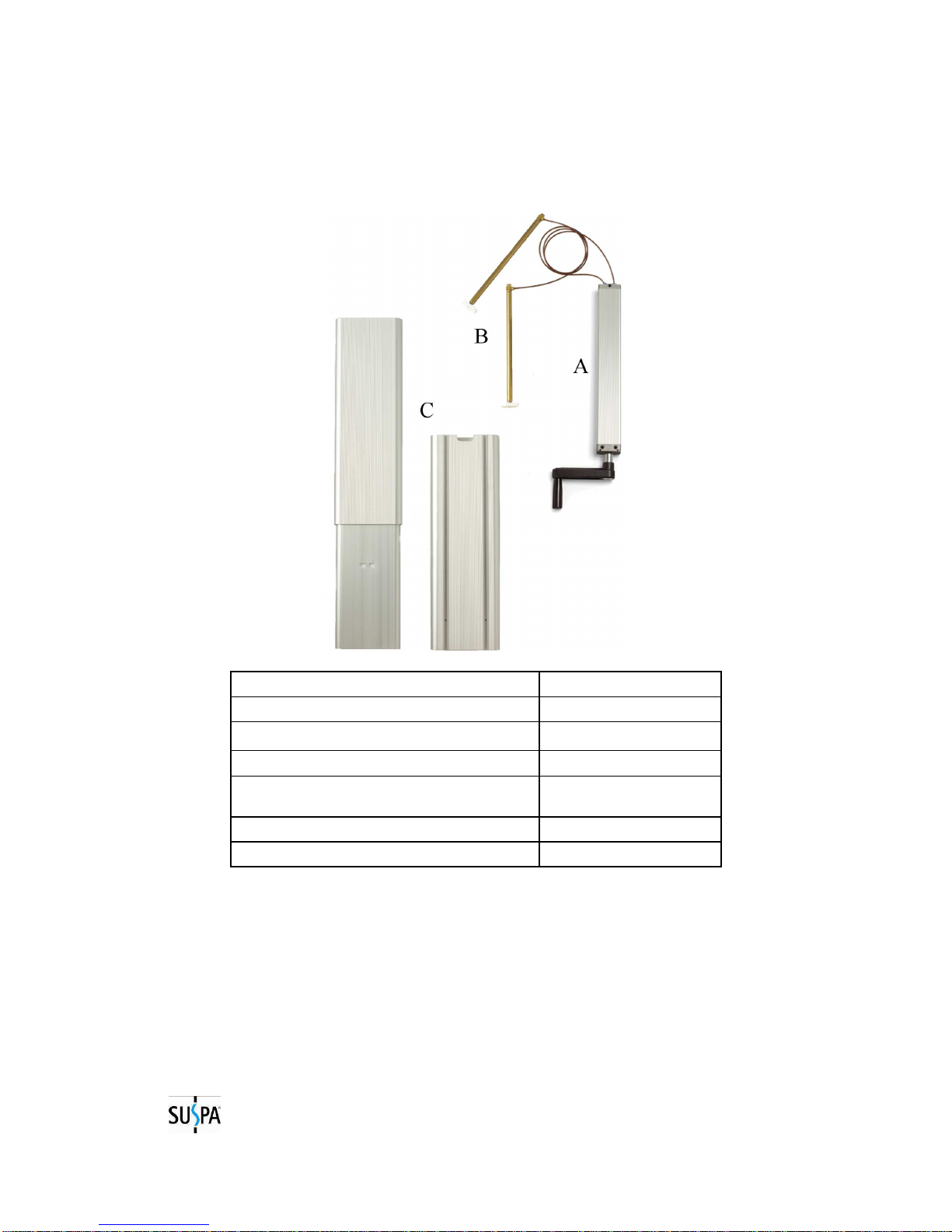

Suspa also offers a Movotec

®

ATU Workstation Kit. The workstation kit contains all of

brackets and hardware necessary to construct a complete height adjustable workstation

base and includes everything but the work-surface.

For over twenty years, Movotec

®

systems have been used on industrial workbenches,

small machine bases, physical therapy equipment, massage tables, office furniture,

biological and chemical vented hoods, autopsy and necropsy tables, sewing machine

bases, home healthcare beds, packaging equipment, custom yachts, and many other

applications.

Movotec

®

lift systems are subjected to life cycle testing on a regular basis. The tests are

performed in a temperature and humidity controlled environment under full system load

conditions. Movotec

®

lift systems perform consistently well in this controlled test

environment. However, due to the wide variety of possible lift system applications and

operating conditions, Suspa

®

does not warrant that any particular lift system is suitable

for any specific application. It is the responsibility of the person who specified the

system to determine its “fitness for use” in the application, through testing and analysis,

to ensure safe and reliable performance. A complete statement including terms and

limitations of the Movotec

®

Crank Driven ATU Lift System warranty can be found in

Section 11.0 of this manual.

Movotec

®

lift systems are assembled and subjected to a full function quality test before

they leave our manufacturing facility. Suspa guarantees products are free from material

and manufacturing defects, but cannot support the warranty for our products if they are

altered, misused, misapplied, or abused in any way. It is the responsibility of system

installers, users, and service technicians to read and carry out the instructions in this

manual correctly to prevent these potentially unsafe and unwarranted occurrences from

happening.

Thank you again for purchasing the Movotec

®

Crank Driven ATU Lift System.

Suspa

®

Incorporated