6

ADJUSTMENTS & SEAM GAUGE

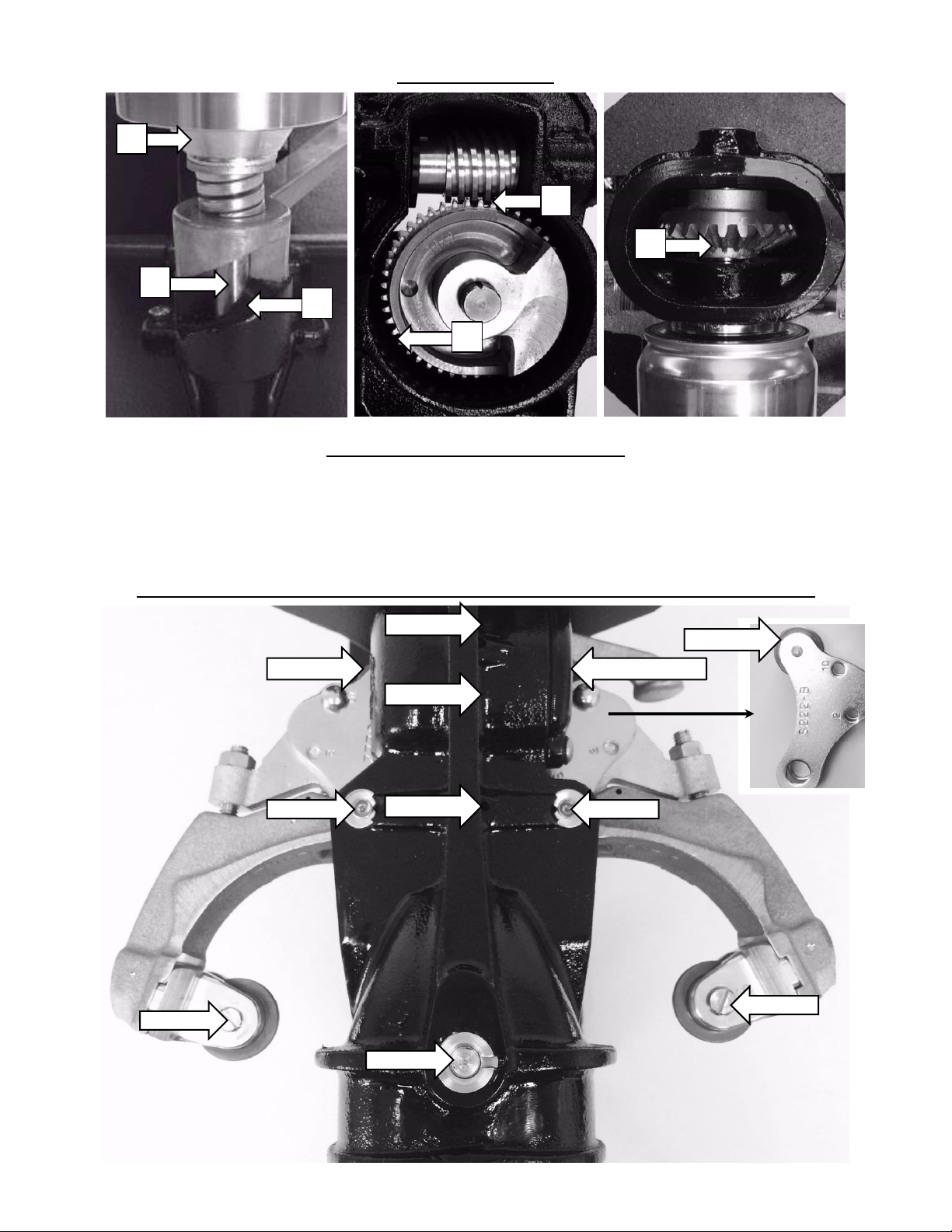

Check the adjustment of the Seaming Rolls occasionally. First

check the height adjustment as follows: When Chuck (A in sketch)

is held up tightly against the Ball Bearing (S-201BB), the underside

of the top flange on the Seaming Roll (B in sketch) must fit closely

on top of Chuck (A). To make adjustments, push the Cam Roller

Lever (S-222B) toward Chuck until Seaming Roll touches the Chuck.

Slightly loosen Screw (CY-9LS) which is “C” in sketch, push down on

Roller Bearing Lever that contains Seaming Roll (B) until top flange

of Seaming Roll (B) rests on top of Chuck (A). Now tighten Screw

(CY-9LS) which is “C” in sketch as tight as possible.

This adjustment should be made on both 1st and 2nd Operation

Rolls. After height adjustment has been made, use the Seam

Gauge which is for checking the seam on 24 or 32oz aluminum beer

cans with a 300 diameter only.

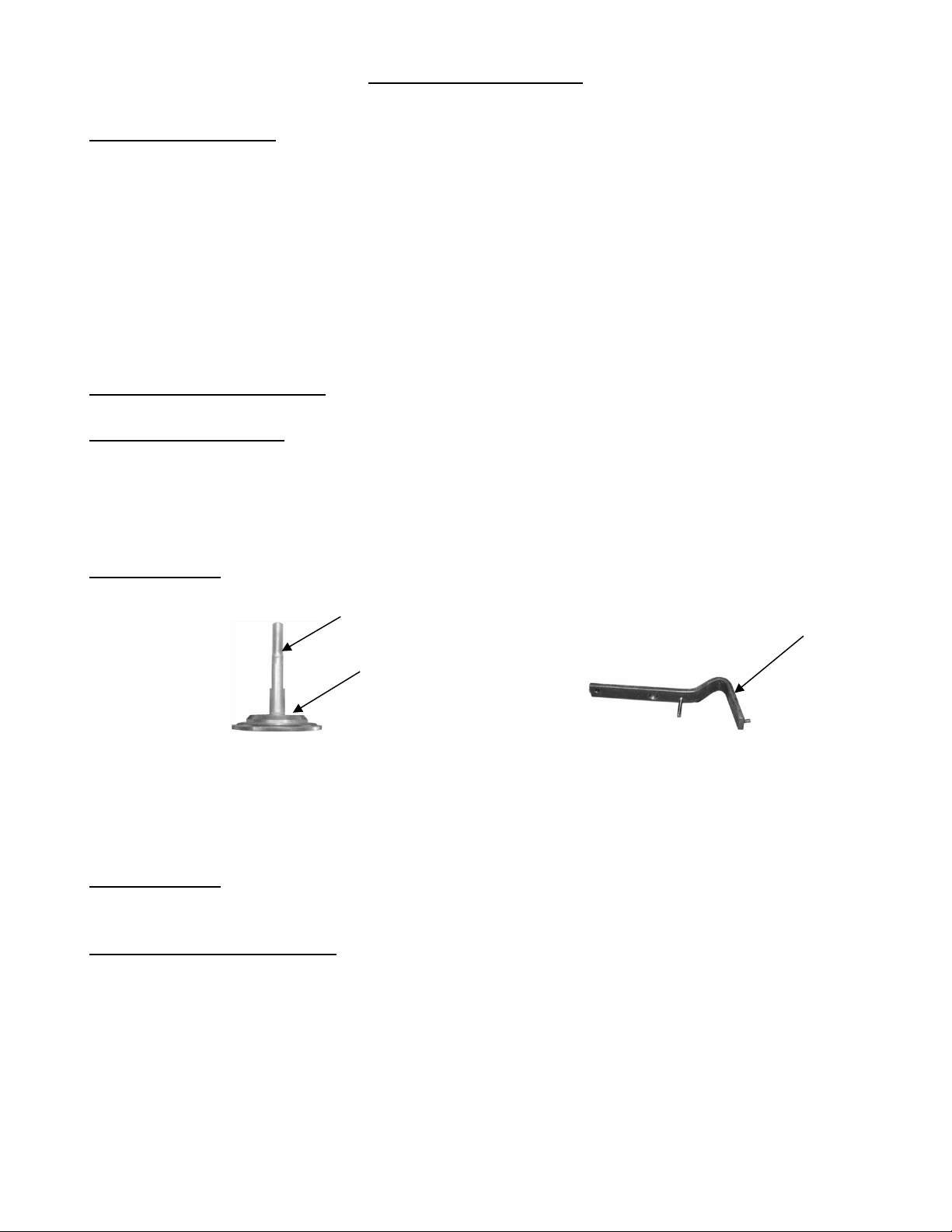

Use the seam gauge as follows: Remove the Rivet (CY-22R) on the Second Operation Cam Roller

Lever (S-222B). The second operation is on the right side if you are facing the front of the machine.

Run an empty can in the machine to seal the First Operation. Remove the can and slip the Gauge

over the seam. The groove marked “1st” should slide over seam on can. The seam will not fill the

entire length of the groove but the Gauge should slip on far enough so that it touches the can cover.

If groove in Gauge will not slip over seam, tighten Seaming Roll (CY-14B) by loosening Lock Nut (No.

24N) and turning Adjusting Screw (No. 24AS) not more than a quarter turn to the right. If the groove

in Gauge is loose on the seam, turn the Adjusting Screw to the left. Repeat above operation with

another empty can until Seam Gauge fits over seam correctly. When first operation seam is correct,

change the Rivet (CY-22R) from the First Operation Levers to the Second Operation Levers and adjust

the Second Operation Roll in the same manner as the First Operation Roll using the can that has a

proper first operation roll seam. The groove in the Seam Gauge marked “2nd” is used when adjusting

the Second Operation Roll (CY-15B). Be sure to tighten the Lock Nuts (No. 24N) after adjusting each

roller.

If it is necessary to operate sealer without a can in place, remove Chuck (No. 300) to prevent

damage to it and Seaming Rolls.