All-Star Products RB1 Series Instruction Manual

OPERATION/MAINTENANCE

INSTRUCTIONS

REGENERATIVE BLOWER

Series and BigBertha Blower Are registered trade marks of All-StarProducts.

TM

All-Star HBTM TM

ISO

9001 RoHS

Compliant

CE

Registered and approved by one or more of these standards agency

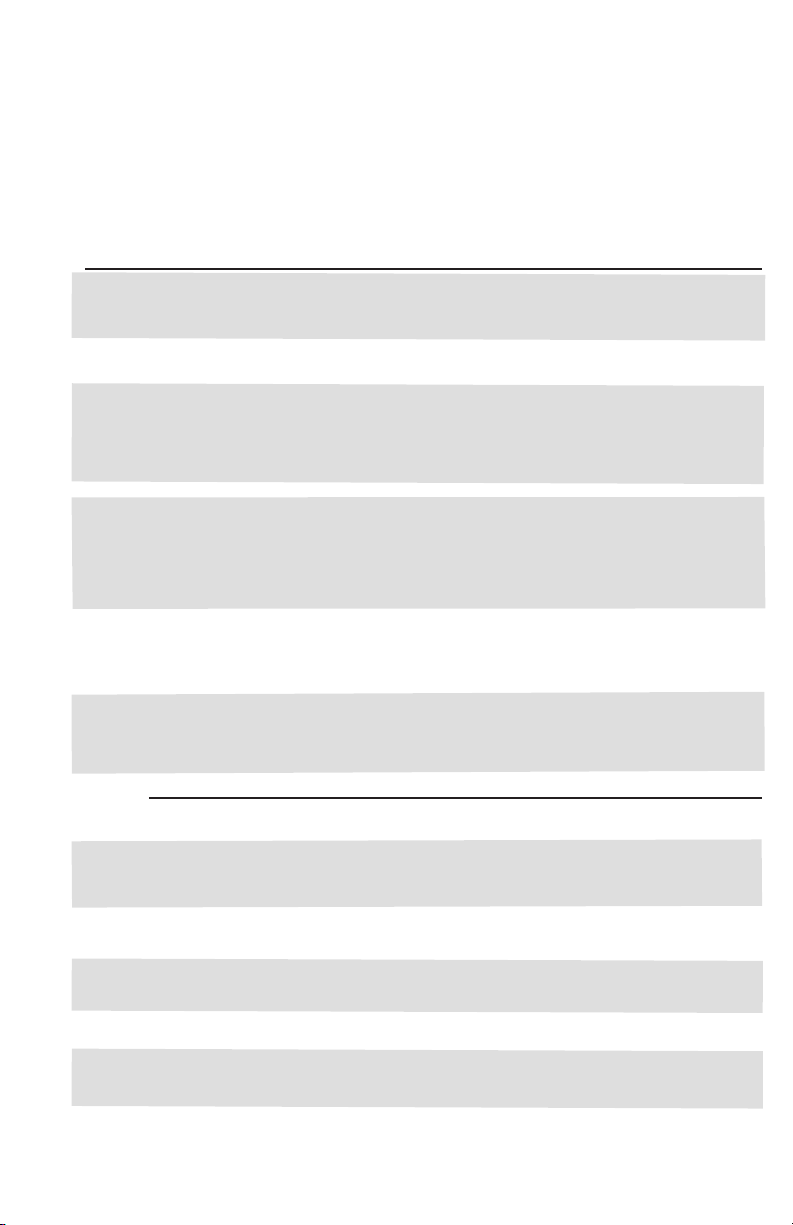

Sample Installation Layout

Typical Vacuum

Arrangement

Typical Pressure

Blower

Arrangement

Vacuum

Pressure

Inlet

Filter

Flow Meter Inlet Filter

Vent

Line

Check

Valve

Pressure

ReliefValve Pressure

Gauge

3 pipe diameters

+/-1 diameter

3 pipe diameters

+/-1 diameter System

Discharge

Min 2pipe

diameters

Min 5pipe

Diameters from

Inlet or flowmeter

Blower

Vacuum

Pressure

Intake

Silencer

Inlet

Filter

3 pipe diameters

+/-1 diameter

System

Inlet

5 pipe

diameters

3 pipe diameters

+/-1 diameter

2pipe

diameters

Vacuum

Gauge VacuumRelief

Valve

Flow

Meter

Discharge

Silencer

-1-

1. Recommended piping should be one diameter larger than the inlet and outllet

diameter until piping has reach the working area.

2. Due to the high discharge temperature, metal piping is recommended for the

first 5 to 8 feet distance from the blower on pressure applications.

3 Elbows increase frictional loss. Keep the number of right angle bends to a

minimum.

4. Pressure relief valves should be installed in a “T” fitting that is at least one

pipe diameter than the exhaust port diameter. For safety reasons, it is highly

recommended to set the relief valve below the application pressure level.

5. Discharge air temperature increases at pressures greater than 65” H2O.

All discharge piping must be marked “DANGER-HOT-DO NOT TOUCH”.

6. IMPORTANT: To insure warranty coverage on the blower, a properly sized

air filter and relief valve must be installed. If not installed, the blower will not

be covered by the All-Star warranty.

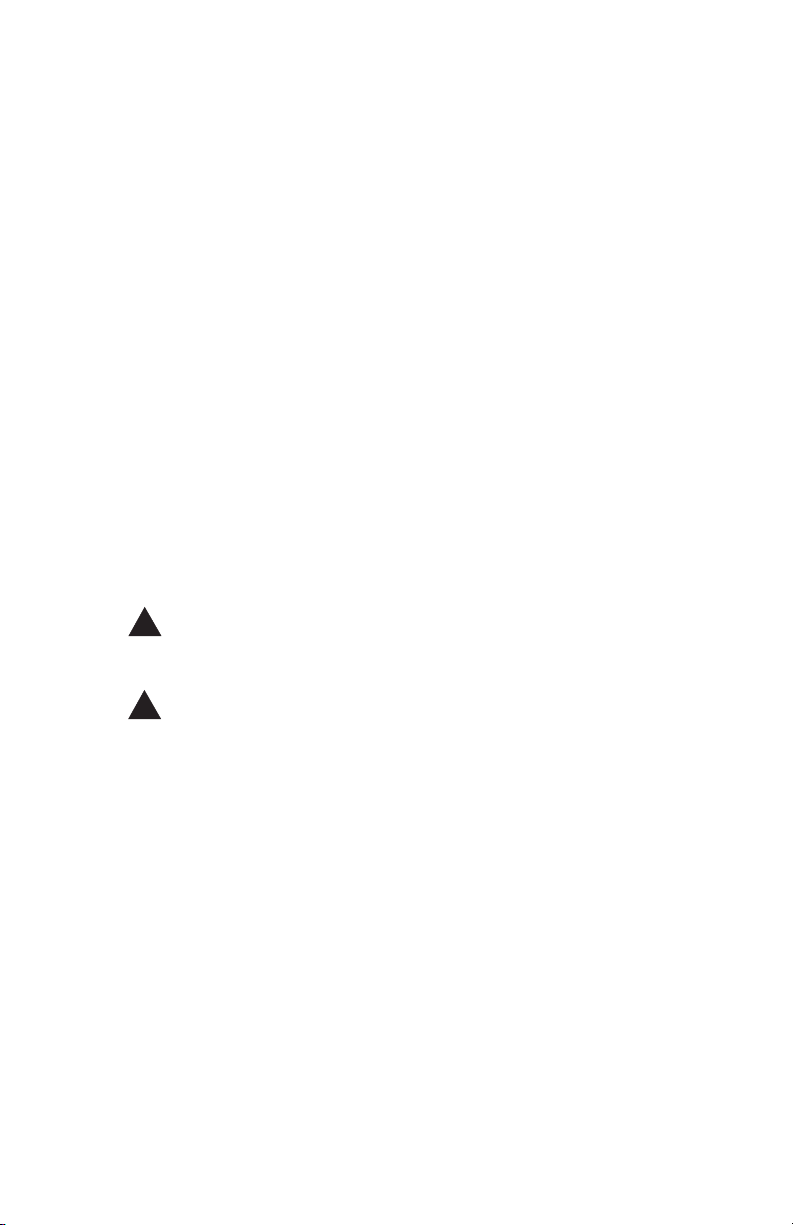

Mounting Position of Discharge Silencers

on 2-Stage High Pressure Models

Standard 2-stage high pressure blowers are now supplied with

the discharge silencer housing facing towards the rear of the

blower as shown in Position B, below.

This new mounting position provides a more compact package.

A separate set of mounting parts are included with each blower

to allow customers to change the direction of the mounting

flange to position “A”.

If mounting position “B” is desired, the extra mounting parts

can be discarded.

Should you have any questions regarding this conversion, feel

free to contact All-Star Products at 800-431-8258.

DISCHARGE POSITION “A”

-2-

DISCHARGE POSITION “B”

1 INTRODUCTION

!

!

!DANGER

CAUTION

1.1 Application

1.2 Suction and compressor pressure

1.3 Environment (Ambient) Temperature

-3-

To insure safe operation of your All-Star blower, please read this

instruction manual and pay particular attention to the instructions

marked with the following signs.

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous

situation, which, if not avoided, could

result in death or serious injury.

WARNING

Indicates a potentially hazardous

situation, which, if not avoided, may

result in minor or moderate injury.

The All-Star blower is a complete unit, ready for immediate

installation as a vacuum pump or as a compressor.

It is designed for handling air and other non-flammable

non-corrosive and non-explosive gasses only.

The drive motor can be loaded to the total differential pressure

given in the Technical Data Table. Blowers with limited

performance curves in the high pressure ranges should be

fitted with relative pressure relief valves in order to avoid

overloading of the motor. Pressure relief valve can be mounted

directly on the outlet and vacuum relief valves can be mounted

directly on the inlet of the blower.

The blower motor rating is based on an ambient temperature of

40 Deg C (104 Deg F). For operation in higher temperature

ambients, refer to All-Star Products.

forma ific

1.4 Per nce Spec ations

rP ior

el

Mod

HB-1291

-

HB-129

HB-129-12

HB 129A-

HB-22 -1

9

H -229

B

HB329-1-

HB- 9

32

HB-439

HB- 29

7

HB-829

HB-919

B-929

H

HB 939-

B3326H -

HB-4 7

33

H-434B 6

HB-6346

HB 6355

-

HB- 375

6

H-6455B

HB-6475

HB-8310

HB-8 153

HB-8320

HB-8410

HB 8415

-

HP o

Vltage Current

umMaxim

Pfo an

er rm ce ound

S

db(A)

Wt

lbs

CFM * V S P *

.25

.25

.33

.33

.67

.67

1.1

1.1

2

3

8.5

11.5

15

20

30

3.5

5

6.1

6.1

8.5

11.5

8.5

11.5

11.5

17.5

25

11.5

17.5

/61 0/115/230

/23/60 08-230/460

11/60/1 5/230

3/60/208-230/460

1/60/115/230

60 0

3/ /208-230/46

3

1/60/115/2 0

303/60/208-2 /460

3 /4/60/208-230 60

3

3/60/208-2 0/460

3/4/60/208-230 60

/2

3/60 08-230/460

8-3/60/20 230/460

23/60/208- 30/460

-

3/60/208230/460

03/60/208-23 /460

/6 63 0/208-230/4 0

8

3/60/20 -230/460

3/60/208-230/460

33/60/208-2 0/460

0 03/6 /208-230/46

03/60/2 8-230/460

2

3/60/208- 30/460

03/60/208-23 /460

/6 6

30/208-230/4 0

083/60/2 -230/460

3/60/208-230/460

3.4 / 1.7

.94 / .86 / .43

3.6 / 1.8

.2 / 1.1

1 4 /.67

5.8 / 2.9

.12.4 / 2.2 / 1

14 / 7

/ 1.9

4 / 3.7

/ 4.59.7 / 9.0

28.6 / 26.0 / 13.0

36.3 / 33.0 / 16.5

47 .4.4 / 42.8 / 21

65 / 59.6 / 29.8

/ 88

93 / 44

0.0 / 9

1.1 / 4.6

2.9 / 6

14.3 / 1 .5

/ 7.817.2 / 15.5

17.6 / 16.0 / 8.0

8.6 / 26.0 /13.02

/ 33.0 /

36.3 16.5

/ 12.2

27.9 / 25.3

35 .2

.9 / 32.5 / 16

.3 / 32.536 / 16.2

53 / 48.0 / 24.0

75.0 / 68.5 / 34.3

38

63

105

105

105

551

400

850

850

850

105

165

165

230

230

230

340

340

410

410

410

600

600

28

32

67

58

58

126

116

160

76

118

173

141

167

197

153

217

271

88

102

128

240

317

60

106

28

30

58

59

59

102

139

76

118

151

141

165

168

153

171

1

18

80

108

371

183

68

104

55

55

55

55

61

64

64

73

79

79

69

77

77

79

79

79

79

79

81

18

81

81

81

15

15

51

15

27

36

32

58

172

182

221

724

351

73

89

95

52

1

159

165

159

178

247

314

353

43

2

309

Model No

RB1-025-1

RB1-025-3

RB1-033-1

RB1-033-3

RBH2-067-1

RBH2-067-3

RBH3-101-1

RBH3-101-3

H-329AB 1.47 003/6 /208-230/46 5.2/4.7/2.4 105 67 73 64 34

RBH3-2-2

HB-449-1

H-449

B

HB-429

2

2

2.5 1/60/230

/6

3 0/208-230/460

/2

3/60 08-230/460

11.0

6.6 / 6.0 / 3.0

7.4 / 6.7 / 3.8

155

515

155

72

72

89

64

64

85

37

73

73

46

49

51

RBH4-2-2

RBH4-2-3

RBH4-205-2

RBH4-3-3

HB-529 .53 03/60/2 8-230/460 11.8 / 10.7 / 5.4 228 89 88 77 73

RBH6-305-3

B-529-1

H 3.5 1/60/230 21.6 228 89 88 77 73

RBH6-305-2

HB-6 9

2

HB-639

5

6.1

03/60/208-23 /460

83/60/20 -230/460

12.9 / 6

14.3 / .5

17.2 / 15.5 / 7.8

228

228

119

129

112

125

7

7

77

78

48

RBH6-5-3

HB-629-1 5/6

1/60/30 30.0 228 19

1112 77 79

RBH6-5-2

RBH6-601-3

RBH8-805-3

RBH8-1105-3

RBH9-15-3

RBH9-20-3

RBH9-30-3

HB-3319-2 2.5 13.0 105 117 1

19 69 56

RBH33-205-2

RBH33-305-3

RBH43-5-3

RBH43-601-3

RBH63-601-3

RBH63-8.5-3

RBH63-1105-3

RBH64-805-3

RBH64-1105-3

RBH83-1105-3

RBH83-1705-3

RBH83-25-3

RBH84-1105-3

RBH84-1705-3

2 STAGE

-4-

RBH4-105-2 HB-419-1 1.5 1/60/230 8.0 155 59 58 73 48

RBH4-105-3 HB-419 1.5 3/60/28-230/460 5.0 / 4.5 / 2.3 155 59 58 73 46

ll

ll

RBH23-101-1 HB-2308 1.1 1/60/115/230 14.0 / 7.0 67 100 98 66 53

RBH23-101-3 HB-2308 1.1 3/60/208-230/460 4 / 3.6 / 1.8 67 100 98 66 51

N

All blower motors are 2 pole design and operate at approximately 3450 rpm on

60Hz and 2850 rpm on 50Hz. Motors are suitable for operation on 50Hz at

3/50/220/380 volts. Motor rated current can vary from the table below. It is

recommended to use the name plated current values in those cases.

Notations: P=Pressure V=Vacuum in inches of water.

38

38

38 28 28

32 30

63 67 58 61 27

HB-319-1 471. 1

1/60/1 517 / 8.5 105 76 73 64 33

RBH3-105-1 /230

B339H -23/60/208-230/460 .1/5.56 /2.8 105 90

82 64 43

RBH3-2-3

HB-339-1 1/60/230 11.0 90

82 64 43

RBH4-205-3

HB-429-1

2.5

1/60/230

155

13.0 89 85

73 51

400 120

81

81

81

RBH33-2-2 HB-3315-1 2 1/60/230 11.0

HB-3319 2.5 0

3/60/2 8-230/460 7.4 / 6.7 / 3.8 105 117 119 69 56

RBH33-205-3

1/60/230

105 100 94 69 62

RBH43-305-2 HB-4326 5 1/60/230 21.6 165 155 155 77 81 3. -- .

261

.3 / 32.536 / 16.2

53 / 48.0 / 24.0

RBH3-105-3

!

2 OPERATION

2.1 Transport and Storage

2.2 Installation

WARNING On installation or after maintenance, it is

required to check that the blower rotation is

correct before returning to service.

WARNING Do not operate the blower with the outlet

blocked or restricted.

!

-5-

When lifted by crane, All-Star blowers must be secured at the

eyebolt on the pump casing

Attention should be paid to the load bearing capacity of the

hoisting equipment (refer to Table 1 for unit weight).

All-Star blowers can be installed and mounted in any horizontal or

vertical position. Quiet vibration-free running is achieved by insuring

the blower is mounted onto a firm foundation or structure.

Keep intake and discharge ventilation openings clear. The direction

of flow is indicated by an arrow marked on the silencer housing.

Solid particles and impurities must be filtered and eliminated from the

air or gas from entering the blower by installing a filter on the intake.

Open discharge or intake are to be fitted with protective screens.

If the blower is mounted on its cover or close to a wall, a minimum of

30mm (1-½”) clearance must be maintained between the housing and

the mounting surface or wall.

Oh the discharge side, the cover, impeller, silencer housing must not

come in contact with flammable materials.

2.3 Electrical Connection

DANGER The electric power must be disconnected

before any work is performed on the blower

or associated equipment.

!

CAUTION High surface temperatures of more than

70 Deg C (158 Deg F) can occur on the

blower's surface. No heat-sensitive parts

such as normal electrical leads or electronic

components can make contact with or be

attached to the blower. Warning signs and

protective screens must be installed around

the blower surfaces to prevent accidental

contact by individuals.

!

-6-

The flow noise is reduced by the built-in silencers. In the case of

free-gas intake or exhaust, the noise can be further reduced by

attaching silencers to the blower. In order to reduce the noise emissions

further, the blowers should not be attached onto components that radiate

sound, such as thin-walled structural steel or metal plates. If necessary,

intermediate sound absorbent materials should be included in the

installation.

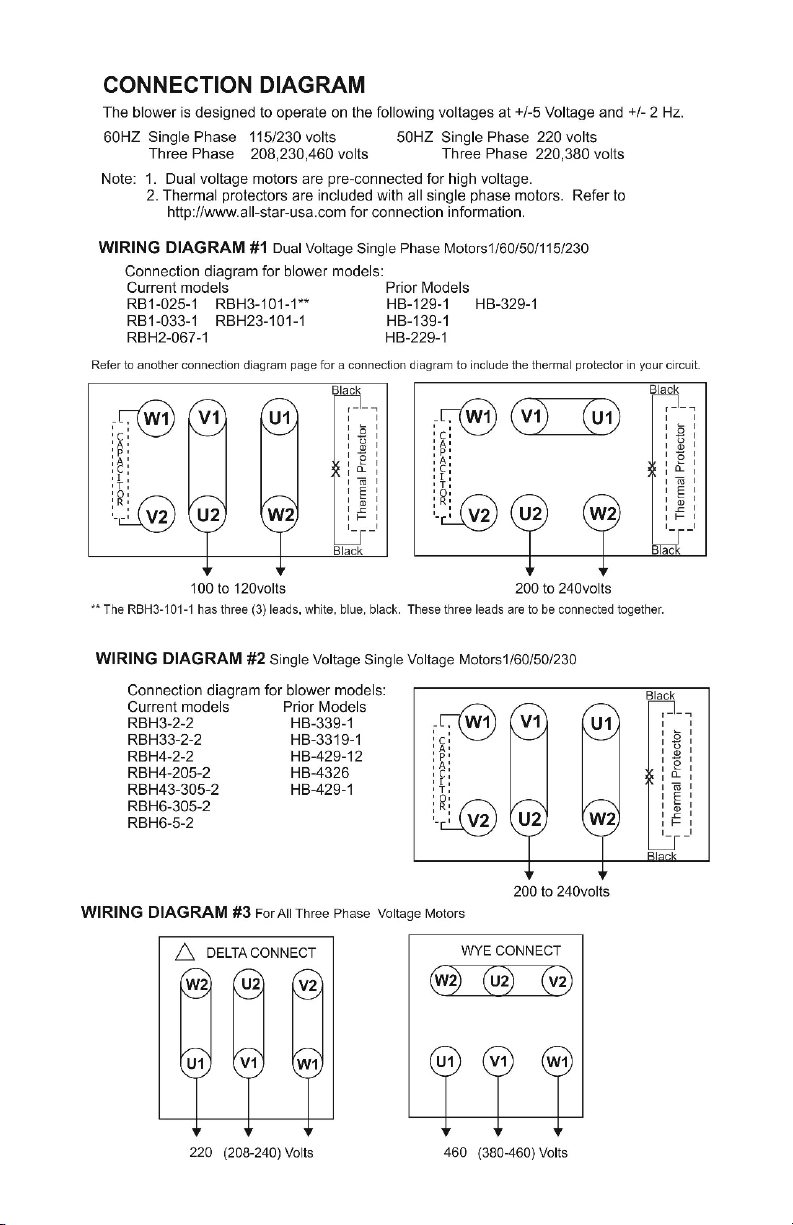

The system voltage and frequency must be the same as stated

on the blower nameplate. +/-5% voltage and +/- 2% frequency

variations are permitted without affecting the blower performance.

The incoming electrical power should be connected

according to the wiring diagram located in this brochure or in

the conduit box. The protective earth connections should be

connected to the terminal.

The rated motor current and operating temperatures are based

on a 40 Deg C ambient.

Select motor circuit breakers to match the rated motor full

load and starting currents, which typically are 600-650%

higher than full current. Due to the high inertia of the blower’s

impeller, starting time can extend to 5-9 seconds. As a result

“slow blow” fuses should be considered.

All-Star blower motors are suitable for operation on VFDs as

standard. Shielded power leads are recommended to control

high requency currents and voltage harmonics caused by EMF

(electro-magnetic interference).

When operating the blower with a VFD, the blower speed should

not exceed 4000 rpm. For higher speed operation, contact All-Star.

!

2.4 Commissioning

CAUTION The blower must not be operated with the

Intake or outlet closed or blocked.

!

CAUTION If the blower is started without being

bolted to a mounting base, the initial

starting torque of the motor will cause

the blower to move suddenly and

possibly topple over.

!

!CAUTION The intake ports must be sited so that no

foreign elements are allowed to enter the

blower and to be ejected through the

exhaust (discharge) port. this is a hazard

for eyes and skin.

CAUTION When air is drawn in from the atmosphere,

the intake port must be covered with a

protective screen to prevent foreign matter

from being sucked into the blower, including

parts of the body and clothing.

-7-

For safe operation, the following conditions, as a minimum

must be followed:

1. The blower should be assembled and operated according to

the data on the nameplate.

2. When a VFD is used, the blower motor speed must not exceed

4000 rpm, unless the blower has been specifically approved to

operate at a higher speed.

3. The blower must be properly assembled, aligned and connected to

the intake and discharge piping or hose.

4. Installation elevation is taken into account when adjusting the blower’s

pressure or vacuum relief valves.

5. The direction of the motor rotation is correct.

6. The intake and discharge connections are corrent.

7. All fastenings, bolts and electrical connections are correct.

8. Earth and equi-potential bonding connections are proper.

9. All measures are taken to prevent contact with any moving

or energized parts.

3.0 Lubrication

!DANGER

!DANGER

!WARNING After removing the blower cover some parts held with

centering fits and can suddenly separate, fall and

possibly cause injury and damage to the parts. Care

needs to be taken during disassembly to insure all

3.1 Disassembly

Blower models RB8 series and larger and all 2-stage blowers have an

parts are securely held in place.

external grease fitting for the blower end bearing. Other models do not,

therefore disassembly is required to lubricate the bearings.

To lubricate the bearings, the rolling contact bearings and adjacent

bearing housing should have the spent grease removed and replaced

with resh grease. About 50% of the rolling balls should be filled and not

more than 65% of the adjacent bearing housing should be filled.

Sealed bearings, should be replaced within the above conditions with

new bearings or as conditions warrant.

Lubricating these bearings, the blower needs

be at full operating temperature. REMOVE grease relief located at the

6 o’clock position on the blower end cover; add grease through the

grease fitting until new grease begins to discharge from the relief, then

STOP. Wait for approximately 30 minutes to allow the fresh grease to

reach the blower temperature, then install the grease relief plug.

External Grease Fittings:

3.2

Shielded and open bearings require lubrication. The frequency of

greasing depends upon the application. As a guideline, in normal clean

environments with less than a 40 deg C ambient, bearings should be

relubricated after approximately 10,000 hours of service or 2.5 years.

If service conditions are dusty, dirty or include high operating

Bearing Types

temperatures, bearings should be lubricated more frequently.

Grease Type Mobil Hi-TemperaturePolyrex EP2

3.3

-8-

The bearings in All-Star blowers are filled with this lubricant, suitable for

service from -30 to + 350 Deg F. Detailed information is available at

http://www.mobil.com/USA-English/Lubes/PDS/NAUSENGRSMOMobil_Polyrex_EP_2.aspx?Print=yes

If possible different manufacturers grease should not be mixed. Check

your local supplier for a compatible grease.

Before any work is performed on the blower, equipment

and especially when removing covers on moving parts,

the motor is to be disconnected from electrical power.

Do not connect electrical power supply until the blower

and other equipment are completely re-assembled.

!

WARNING

WARNING

!

TABLE 3.4 Bearing Types,Sizes and Lubricantion

Model

Impeller

Side

Bearing Type Deg F

Motor

Fan End

Bearing Type Deg F

RB1 Series

RBH2 Series

RBH3 Series

RBH4 Series

RBH6 Series

RBH33 Series

RBH43 Series

RBH63 Series

6202zz Shield 285 6201zz Shield 285

6203zz Shield 6202zz Shield 385

6204z Shield 385 6204zz Shield 385

6205zz Shield 385 6204zz Shield 385

6304zz Shield 385 6204zz Shield 385

6205z Shield 385 6204zz Shield 385

6208z Shield 385 6209zz Shield 385

Open

6206z Shield 385 6207zz Shield 385

6206zz Shield 385 6304zz Shield 385

6206zz Shield 385 6207zz Shield 385

6309zz Shield 385 6208zz Shield 385

6203zz Shield 385 6202zz Shield 385

6207zz Shield 385 6207zz Shield 385

6207zz Shield 385 6209zz Shield 385

Note: Bearing sizes, types and lubricant are subject to change and may be different from

the bearings in your particular blower model.

-9-

RBH8 Series

RBH9 Series

RBH23 Series

RBH63 Series

RBH83 Series

RBH84 Series

RBH64 Series

Max

Max

On installation or after maintenance, it is

required to check that the blower rotation is

correct before returning to service.

Do not operate the blower with the outlet or

inlet blocked or restricted.

385

Open

!DANGER

4 MAINTENANCE

!DANGER

!DANGER

4.1 Cleaning

!WARNING

!

-10-

Covers which prevent contact with rotating parts

are not to be opened during operation.

Before any work is performaned on the

blower, equipment and especially when

removing covers on moving parts, the

motor needs to be disconnected from the

electrical power supply.

Do not connect the electrical power supply

until the blower and other equipment have

been completely re-assembled.

The surface of the blower should be clean and free from dust or

other contaminants. Surface dust can be blown off with a low

pressure air hose periodically to prevent a build-up of material.

When required by the operating conditions, dismantle the cover

from the blower by removing the screws or nuts on the cover. Do

not lose the screws or nuts because they are required for re-assembly.

Remove and clean the cover. Clean the impeller and the internal

portion of the blower with low pressure air after covering the rolling

contact bearing and the bearing grease housing. Be careful not to

blower dirt or contaminants into the bearing grease. If dirt does enter

the lubricant, wash out the contaminated bearing grease, clean the

bearing and replenish the bearing with fresh grease.

After removing the blower cover screws or nuts,

some parts held with centering fits can suddenly

separate, fall and possibly cause injury and

damage other parts. Care needs to be taken

during re-assembly to insure no parts remain in

the blower and are securely held in place.

Covers which prevent contact with rotating parts

are not to be opened during operation.

DANGER

4.2 Troubleshooting

Motor does not start,

No rotor noise.

Motor does not start,

Humming noise

Motor-protective

Circuit breaker trips

Again after motor is

Switched on, power

Consumption too high

No vacuum or too

Weak vacuum is

produced.

Compressor is not

Air tight.

At least two power

Supply conductors

interrupted

Interruption in one power

Supply conductor

Impeller jammed

Impeller defective

Bearing defective

Short circuit in

The winding

Motor overloaded

Compressor jammed

Leak in the system

Wrong direction of

rotation

Compressor too small

Sealing disc defective

Problem Cause CorrectiveSteps

Eliminatei nterruption by

Means of fuses,

Terminals or lead feeder.

See"Motor does not start,

No running noise."

Open cover, remove foreign

matter, clean; if necessary,

check impeller gap and

adjust if necessary

Replace impeller

Replace bearing

Inspect motor winding

Reduce operating pressure,

clean filter, silencer,

connecting pipes.

See "Motor does not start,

humming noise."

Make system air tight

Change direction of

rotation

Use larger compressor

fit new shaft seal

confirm calculations

clean impeller

replace worn impeller.

Inspect sealing disc

-11-

-12-

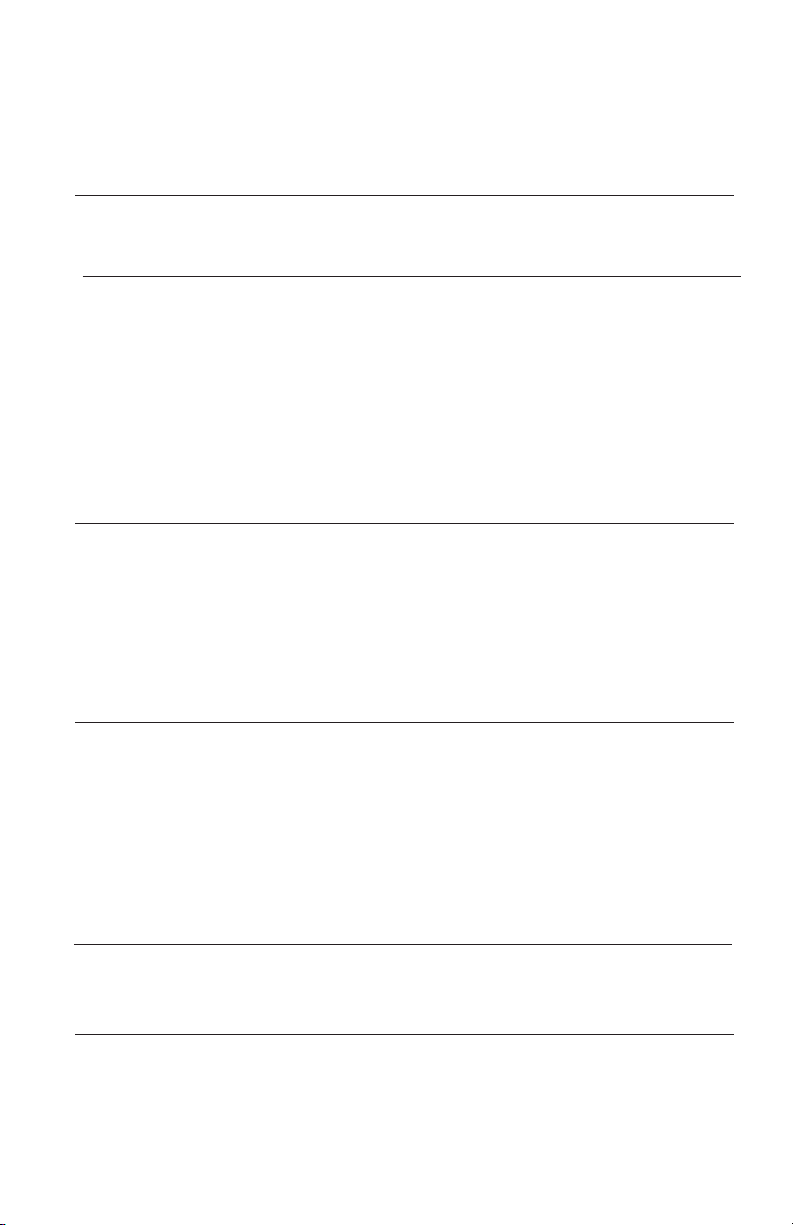

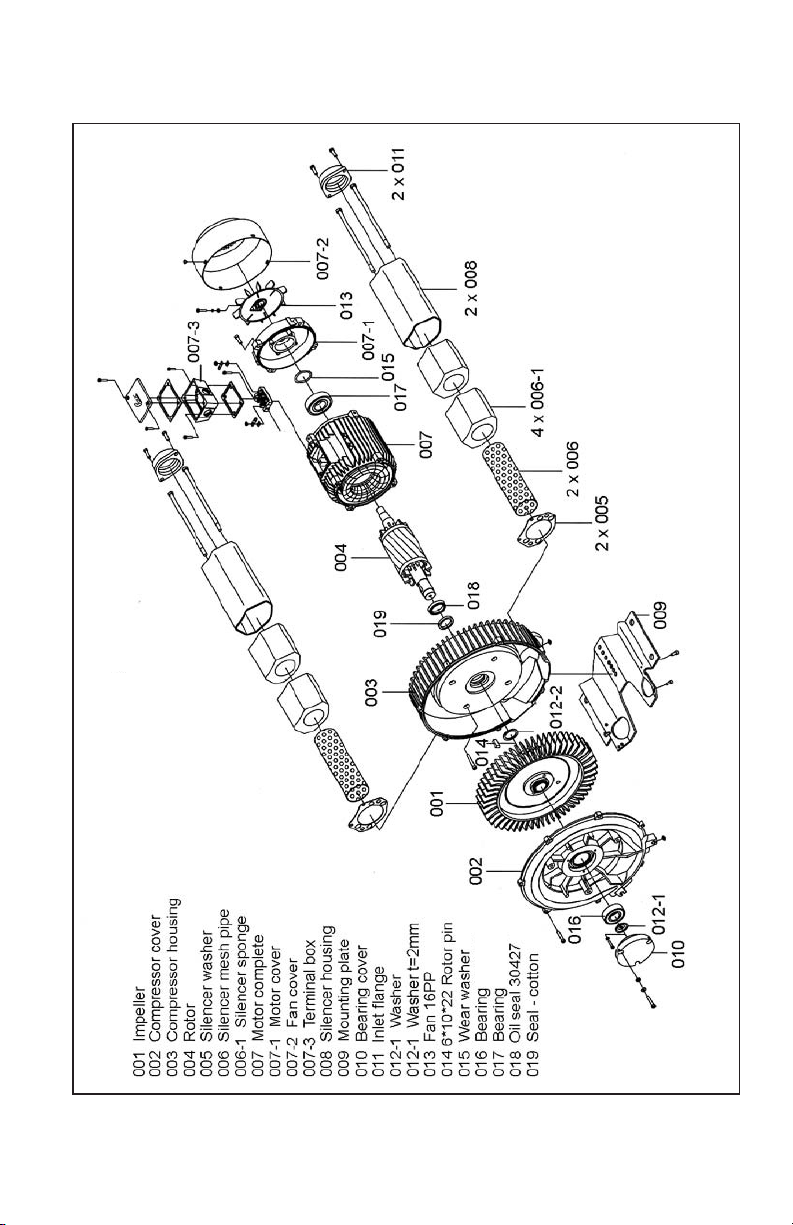

5.0 SingleStageSampleAssembly

SINGLE STAGE MODEL

June 2013

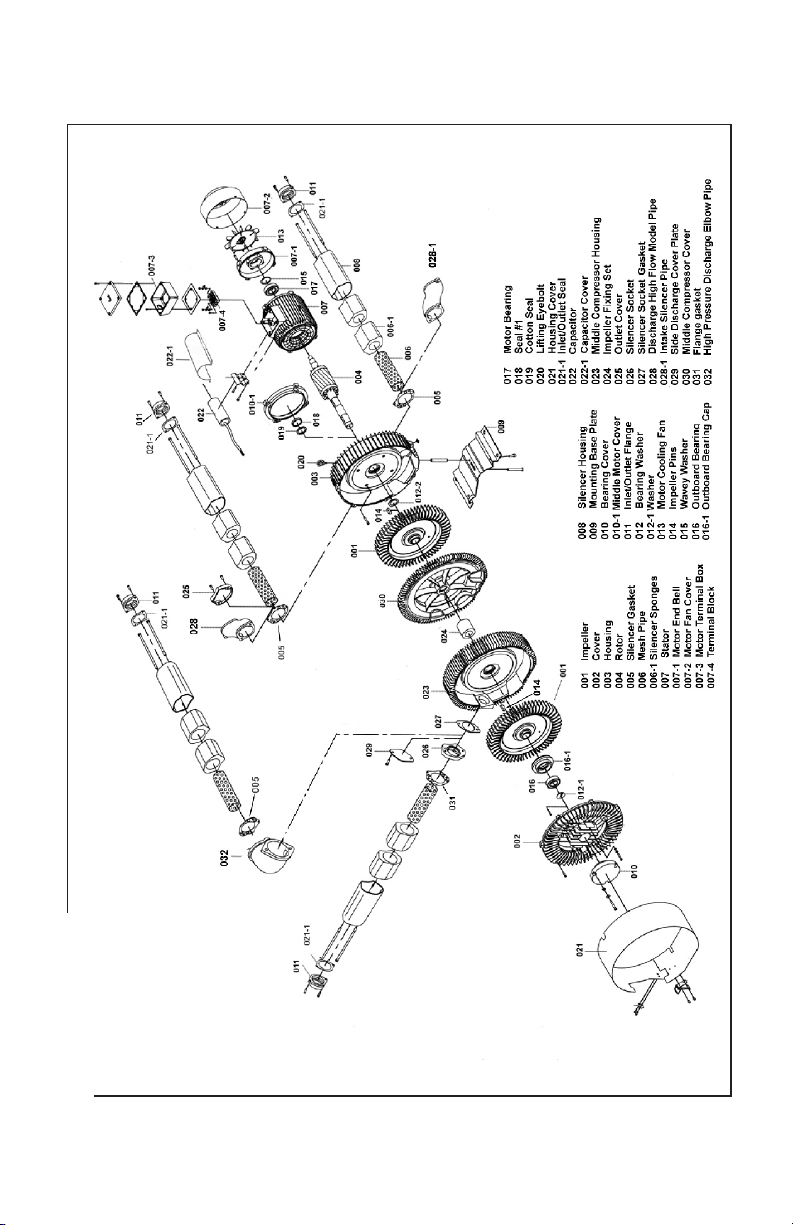

5.1 Two Stage Sample Assembly

-13-

TWO STAGE MODEL

September 2007

14

Thermal Overload Connection Diagrams

Models

RB1-025-1

RB1-033-1

RBH2-067-1

1. The capacitor connection to W1 and V2 is already connected at the factory.

2. Remove the metal spade connectors on the two black wires.

3. Connect these two black wires as follows:

a. Connect one of the black leads to terminal W2.

b. Connect the other black leads to the incoming power.

4. Brass metal jumpers (connectors) should be attached as shown above, between V1 and U2;

U1 and W2 and for high voltage, between V1 and U1.

Low Voltage

1/60/115

W1 V1 U1

V2 U2 W2

CAPACITOR

THERMAL PROTECTOR

INCOMING POWER

High Voltage

1/60/50/230

W1 V1 U1

V2 U2 W2

CAPACITOR

INCOMING POWER

Blue

RB1-025-1

RB1-033-1

RBH2-067-1

Low Voltage

1/60/115

W1 V1 U1

V2 U2 W2

CAPACITOR

THERMAL PROTECTOR

INCOMING POWER

High Voltage

1/60/50/230

W1 V1 U1

V2 U2 W2

CAPACITOR

THERMAL PROTECTOR

INCOMING POWER

Black

Black

Black

Black

AUTO RESTART DUAL VOLTAGE MOTORS WIRED WITH THERMAL OVERLOAD IN CIRCUIT

** Note: The thermal protector in these models can be wired for Auto or Pilot Duty.

White

Black

THERMAL PROTECTOR

Blue

Black

X

White

Model

RBH3-101-1

June, 2013

Models High Voltage

1/60/50/230

W1 V1 U1

V2 U2 W2

CAPACITOR

THERMAL PROTECTOR

INCOMING POWER

Black

Black

RBH3-105-2

RBH3-2-2

RBH33-2-2

RBH4-105-2

RBH4-2-2

RBH4-205-2

RBH43-305-2

RBH6-305-2

RBH6-5-2

SINGLE VOLTAGE 1/60/50/230 - PILOT DUTY ONLY - zREQUIRES A MOTOR STARTER WITH AN AUXILARY RELAY

Low Voltage

1/60/115

W1 V1 U1

V2 U2 W2

CAPACITOR

THERMAL PROTECTOR

INCOMING POWER

High Voltage

1/60/50/230

W1 V1 U1

V2 U2 W2

CAPACITOR

THERMAL PROTECTOR

INCOMING POWER

Black

Black

Black

Black

Models

PILOT DUTY DUAL VOLTAGE MOTORS - REQUIRES A MOTOR STARTER WITH AN AUXILLARY RELAY

Thermal protectors are supplied loose as standard in all single phase motors. If you choose to wire the thermal protector into your power

circuit, you need to follow the instructions below. Depending on the blower model, the thermal protector can be wired to operate in

either an automatic or pilot duty mode only. For use in a pilot duty mode, a starter with an auxiliary relay is required. Two black leads

(except for the RB3-101-1 which has three leads) in the conduit box belong to the thermal protector and are referred to below.

Note: As noted below, the RB3-101-1 has three leads to connect the thermal protector.

15

For more detailed information, visit http://www.all-star-usa.com

All-Star Products Inc

Sales Office & National Warehouse

2095 Exeter Rd Ste 80-324 Memphis TN 38138

Tel 800-431-8258 Tel 901-755-9613 Fax 901-758-0816

All Star blowers are high quality engineered and manufactured blowers. They

Are designed to meet international standards and have received approvals and

Recognition from the following agencies.

Warranty

All Star Products warrants all of its products against defects in material and

to a maximum of eighteen (18) months from the date of shipment, which ever occurs

first. Purchaser is responsible for providing adequate and approved storage during

the18 month period. Not withstanding the foregoing, any equipment or components

of the products not of All StarsProducts own manufacture and/or specified by the

Purchaser, is sold under only such warranty as the maker thereof extends to All Star

Products and All Star Products is able to enforce, but such items are not warranted

by All Star Products in anyway. All Star Products is not responsible for product

failures caused by the purchaser or their custome rmisapplying the product, operating

the product beyond the published ratings and values, misuse, field alterations and

changes, lack of proper maintenance or improper storage, neglect or accidents are

also excluded from this Limited Warranty. This Limited Warranty is effective, provided

(1)The purchaser

immediately notifies All Star Products in writing of the alleged

defect after it becomes known to the purchaser and (2) no alterations, repairs or

services have been performed by the purchaser or third parties on the product,

This Warranty is in lieu of all other expressed or implied warranties, including

any warranty of merchantability or fitness for any purpose.

The warranty does not cover misuse or misapplication, abuse, neglect or other

causes of failure beyond the manufacture's control. Do not disassemble or try to

repair the blower/pump or any component. Any attempt to repair or correct a problem

by the customer or their agent will void the warranty. A disassembled unit will not be

considered as a warranted failure under any circumstances.

This warranty is voided unless an air filter has been installed and a correctly set pressure

or valcuum relief valve has been installed.

ISO

9001 RoHS

Compliant

CE

Registered and approved by one or more of these standards agency

This manual suits for next models

61

Table of contents

Other All-Star Products Blower manuals