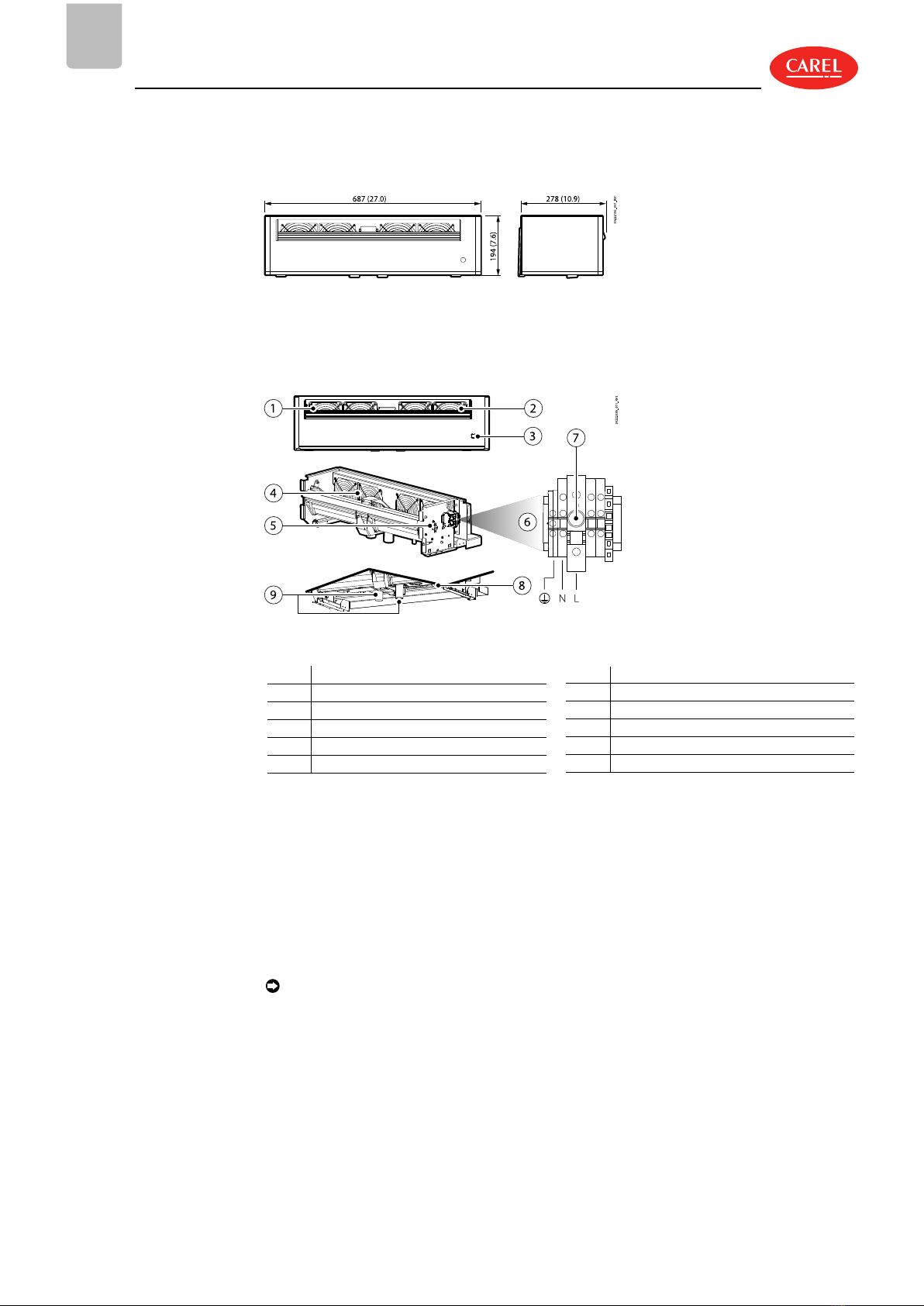

2. Preparing for assembly

The blower must be mounted or on the wall and connected to the humidifier via the steam hose.

The maximum length of the steam hose is 4 m.

Note: observe the minimum distances shown in the following figures to prevent the flow of

humidified air from coming into contact with people, electrical equipment, false-ceilings and cold

surfaces before the steam is totally absorbed by the atmosphere.

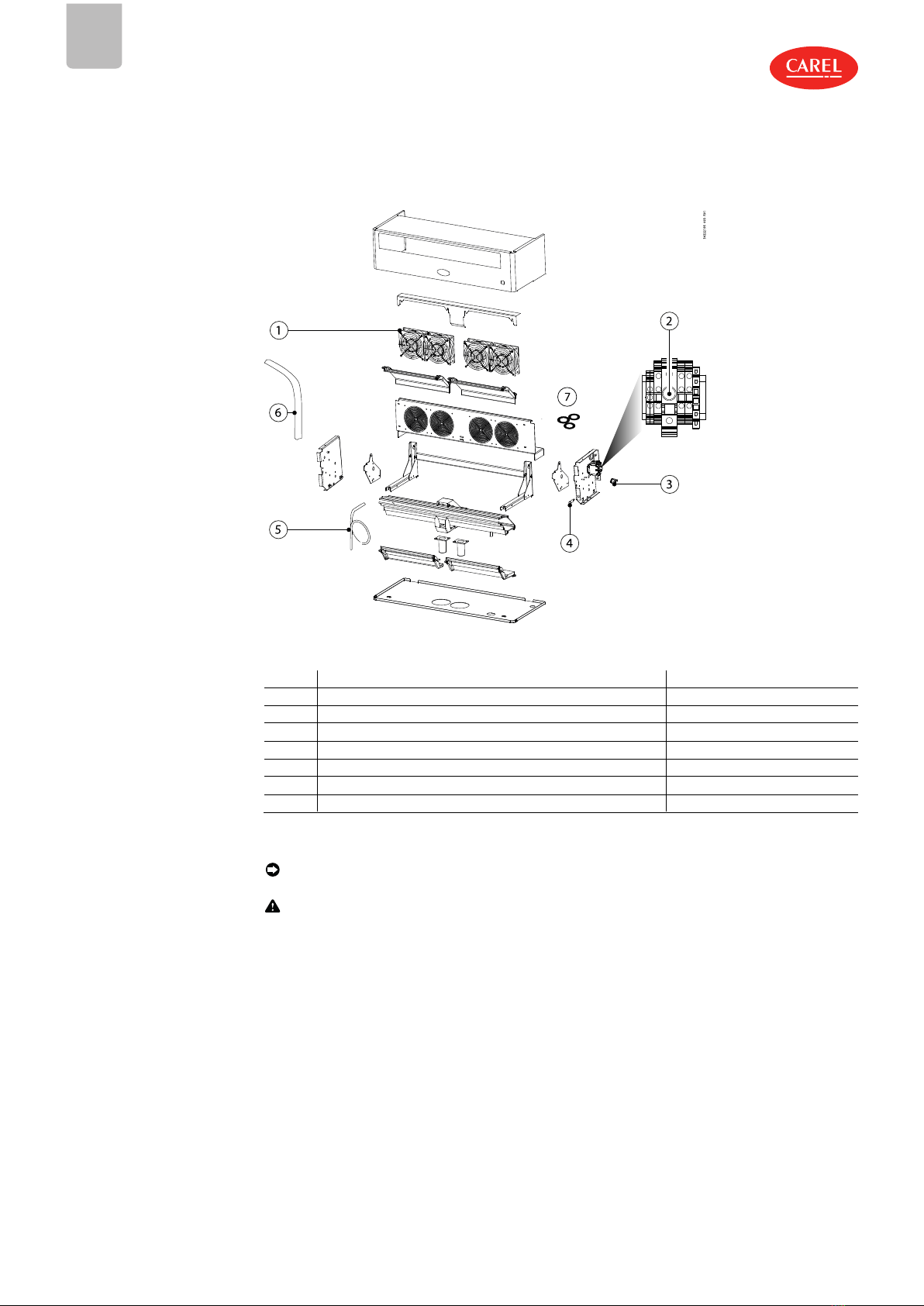

Fig.2.a

Mounting (all dimensions in m[ft])

Ref. Wall

A >5[16.4]

B ≥2[6.5]

C + E ≥ 2.1[6.8]

D >0.5[1.6]

E ≤4[13.1]

Tab.2.a

Notes:

ldimension C+E can be lower if it is not possible to transit in front of the blower unit;

lsee the humidifier manual for details on positioning.

2.1

Requirements

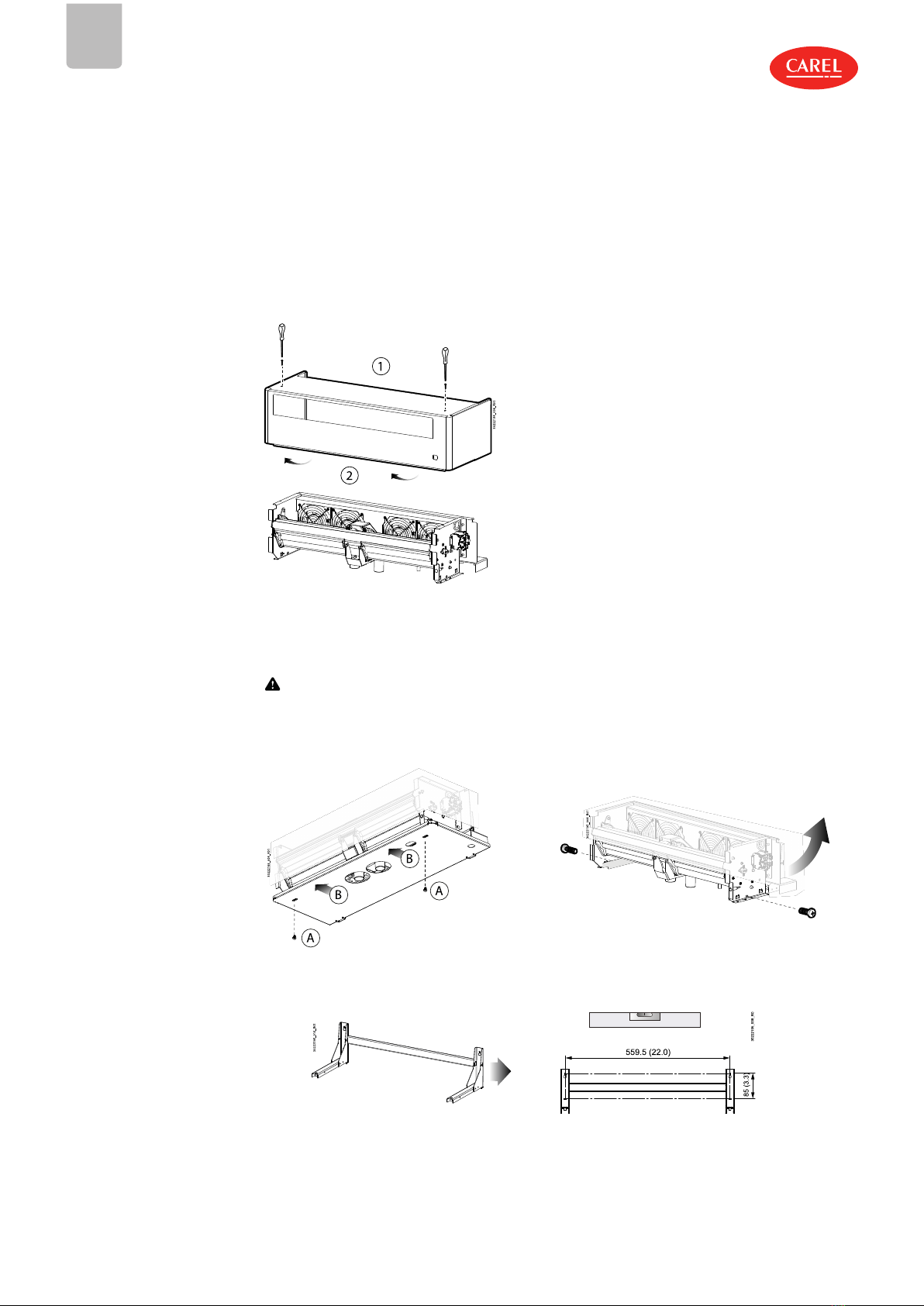

2.1.1 Steam hose

Follow these instructions when installing the steam hose:

lonly use hoses supplied by CAREL; hoses made from other materials may adversely affect operation of

the system;

lthe steam hose must be secured by supports (clamps, brackets) so that it does not bend and does not

weigh on the humidifier. A hot hose is more likely to bend;

lthe minimum radius of curvature of the steam hose is 5 times the inside diameter;

lthe steam hose must have a minimum slope in order to drain condensate back to the humidifier; in

any case, always install a condensate drain at the lowest point on the steam hose;

lminimise the length of the steam hose so as to reduce heat loss. Avoid the formation of pockets or

traps where condensate may accumulate;

lchoking (due to bends or twisting of the hose) can cause excessive back-pressure in the humidifier

cylinder when the unit is operating and consequently sudden steam outlet.

Important:

ldo not install a stop valve in the steam hose;

lwhen installation is complete, flush the steam line to remove any contaminants and processing

10|2. Preparing for assembly VRDXL00001 +030222195 rel. 1.4 - 11.02.2021

Оборудование Carel: автоматика, увлажнители, комплектующие