777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com

SERIES 8000 ISLIDING DOOR SYSTEM

INSTALLATION INSTRUCTIONS

3

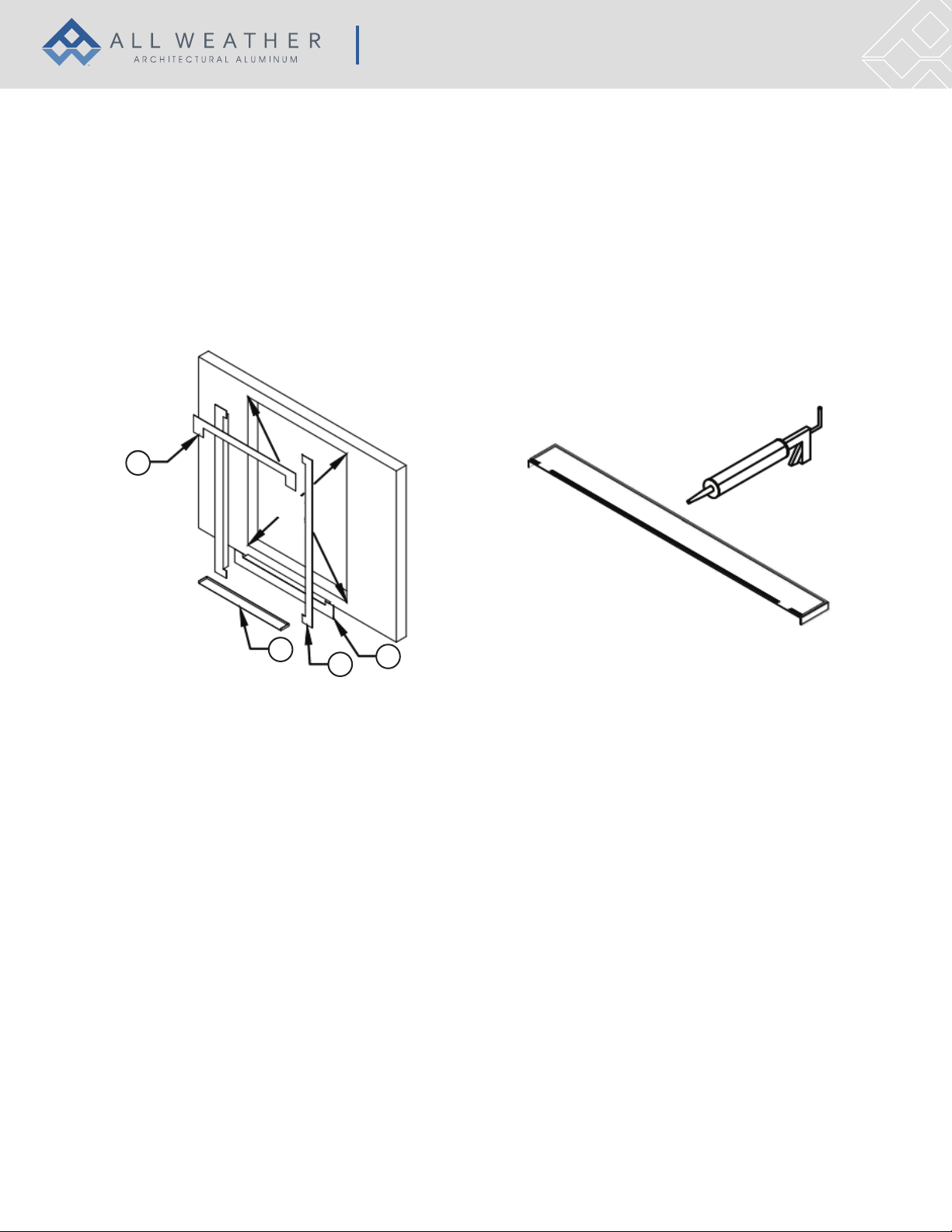

INSTALLATION

All installation materials used have been checked for compatibility

Weather resistant barrier and flashing were coordinated with contractor or authority on site

If Swing Series, correct orientation of system has been identified. Inswing or Outswing.

If Slider Series (including Stacking and Pocketing Series), location of operable and non-operable panels has been checked

If Bi-Fold Series, panel sequence has been checked from right to left, as seen from exterior

Frame has been sealed and joined at all points indicated in instructions

Opening checked for correct dimensions

Frame is installed at correct depth within the opening

Frame has been installed square, level and plumb

Plastic shims were utilized under sill when required

Jambs were shimmed to prevent rolling

Head track installed with the appropriate crown over width of frame

Installation holes prepared correctly

Sealant was applied to sill installation holes prior to inserting screws & top of screw heads once applied

Correct fastener placement has been followed as directed by manufacturer

Proper operation and adjustment has been achieved

Product was installed as directed by the Manufacturer

FINAL CHECK OF INSTALLATION

Frame has been checked for level, square and plumb

All horizontal and vertical adjustments have been made so that proper reveals are present and product is operating as designed

Weep holes have been checked and free of obstruction and debris

All trash has been discarded

All hardware has been installed correctly and checked for proper operation

Product has been closed and locked and recommended to not be used as thoroughfare by other trades

Product is protected from damage

Final inspection of weather proofing and operation has been performed

Job has been turned over to contractor or other responsible party with approval

Other

IMPORTANT

All Weather recommends that installers return to site and perform a final check of installation. Namely that the header has

not sagged under structure settlement and/or weight and necessary adjustments have been made prior to installation of exterior

siding/stucco and interior finishes.

Where applicable, each of the items checked above have been properly reviewed, verified and completed as part of my field

quality control check prior to turning over the job to the responsible party/approving authority.

Installer’s Signature: Date: