Allanson 2275 Series User manual

ELECTRONIC IGNITOR

INSTRUCTION MANUAL - TYPE 2275U / 2275-XXX

CANADA: 83 Commerce Valley Drive East, Markham, Ontario L3T 7T3 | T: 1.800.661.7251 | Fax: 416.752.6717

USA: 99 Adams Blvd., Farmingdale, New York 11735 | T: 1.631.293.3880 | Fax: 1.631.293.3470

This instruction manual provides you with application information on the OMNI™ Electronic Ignitor. Allanson’s

electronic ignitors are designed for intermittent duty (constant) and/or interrupted duty - providing the most reliable

ignition source for gas and oil.

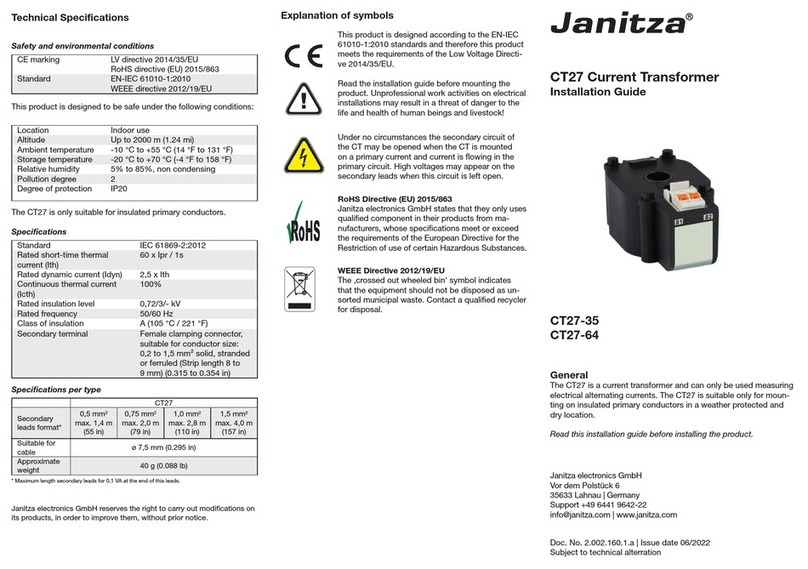

Abosolute Minimum Readings: Mechanical Specications:

Input Supply Voltage (V):

Input Supply Frequency (Hz):

Primary Volt - Amperes (VA)

Secondary Voltage (kV peak):

Secondary Frequency (kHz):

Secondary Short Circuit Current (mA):

Storage Temperature:

Operating Temperature:

Operating Relative Humidity (%):

Loading Air Gap (inches):

108-132

50/60

87

17.5

>20

28

-40 to +80

-30 to +40

90

1/16 to 3/16

ELECTRONIC IGNITOR

INSTRUCTION MANUAL - TYPE 2275U / 2275-XXX

CANADA: 83 Commerce Valley Drive East, Markham, Ontario L3T 7T3 | T: 1.800.661.7251 | Fax: 416.752.6717

USA: 99 Adams Blvd., Farmingdale, New York 11735 | T: 1.631.293.3880 | Fax: 1.631.293.3470

This instruction manual provides you with application information on the OMNI™ Electronic Ignitor. Allanson’s

electronic ignitors are designed for intermittent duty (constant) and/or interrupted duty - providing the most reliable

ignition source for gas and oil.

Abosolute Minimum Readings: Mechanical Specications:

Input Supply Voltage (V):

Input Supply Frequency (Hz):

Primary Volt - Amperes (VA)

Secondary Voltage (kV peak):

Secondary Frequency (kHz):

Secondary Short Circuit Current (mA):

Storage Temperature:

Operating Temperature:

Operating Relative Humidity (%):

Loading Air Gap (inches):

108-132

50/60

87

17.5

>20

28

-40 to +80

-30 to +40

90

1/16 to 3/16

2.01”

0.90”

1.64”

4.06”

4.92”

2.01”

0.90”

1.64”

4.06”

4.92”

Installation:

#21-590

1221

#21-590

1221

1. Before installation, inspect the case and the porcelain bushings for possible damage during transportation and handling. Do not use the

product if the secondary bushings are chipped and/or cracked.

2. Choose the correct base plate from the kit (if provided) to t the burner. Route the primary lead wires to the appropriate lead exit on the base

plate and fasten the electronic ignitor to this plate with the three self-tapping screws provided.

3. Install the electronic ignitor assembly on the burner and route the primary leads to the junction box for connection. Connect the black lead

to the negative terminal (-) and the red lead to the positive terminal (+) of the supplies. (Reversing the lead connection will result in the

unit not operating properly). Use only UL Listed and CSA approved wire nuts.

Chek-Mate™(Allanson’s Ignitor/Transformer tester). Use it to touch any brand of ignitor/transformer. Simply touch the high voltage spheres to

the high voltage contacts. If the green LED lights up, the unit is performing well.

Short Circuit Current Test. Connect a true RMS high frequency milliammeter to the output terminals. Energize the primary with 120 Volts at

50/60 Hz. The reading on the milliammeter should be within 10% of the rated.

Open Circuit Test. For this test you need an oscilloscope and a high voltage oscilloscope probe. Connect the high voltage probe from one

secondary to the ground terminal (screw in front and between the high voltage bushings). Measure the peak of the wave form on the oscilloscope.

Repeat the procedure for the opposite high voltage terminal. The sum of the two readings should be within 10% of the name plate rating.

Field Testing. Connect the electronic ignitor grounding terminal to a good ground. Connect the primary leads of the electronic ignitor to 120 Volts.

Energize the primary. Holding the handle of a well insulated screw driver, touch one part of the shaft of the screw driver to one high voltage

terminal. Pivot on this terminal until you draw an arc from the opposite terminal. Gradually increase the air gap and notice the distance at which the

arc is extinguished. The minimum distance should be 1/2”.

The OMNI®Electronic Ignitor has no moving parts. The only maintenance required is the cleaning of the porcelain bushings with a soft cloth during

the annual furnace inspection.

The OMNI®2275U / 2275-XXX Electronic Ignitor can be tested as follows to ensure that it is operating properly.

WARNING

This procedure is to be carried out by qualied personnel ONLY.

The voltages and currents available can cause serious injury and/or death. Extreme caution is to be used to avoid contact with the

primary live leads. Do not allow any parts of your body to come closer than 5 inches to the energized secondary terminals or parts of the

secondary circuit. Ensure the mid-point of the transformer is grounded before energizing the primary.

Maintenance:

Testing:

1. Before installation, inspect the case and the porcelain bushings for possible damage during transportation and handling. Do not use the

product if the secondary bushings are chipped and/or cracked.

2. Choose the correct base plate from the kit (if provided) to t the burner. Route the primary lead wires to the appropriate lead exit on the base

plate and fasten the electronic ignitor to this plate with the three self-tapping screws provided.

3. Install the electronic ignitor assembly on the burner and route the primary leads to the junction box for connection. Connect the black lead

to the negative terminal (-) and the red lead to the positive terminal (+) of the supplies. (Reversing the lead connection will result in the

unit not operating properly). Use only UL Listed and CSA approved wire nuts.

Chek-Mate™(Allanson’s Ignitor/Transformer tester). Use it to touch any brand of ignitor/transformer. Simply touch the high voltage spheres to

the high voltage contacts. If the green LED lights up, the unit is performing well.

Short Circuit Current Test. Connect a true RMS high frequency milliammeter to the output terminals. Energize the primary with 120 Volts at

50/60 Hz. The reading on the milliammeter should be within 10% of the rated.

Open Circuit Test. For this test you need an oscilloscope and a high voltage oscilloscope probe. Connect the high voltage probe from one

secondary to the ground terminal (screw in front and between the high voltage bushings). Measure the peak of the wave form on the oscilloscope.

Repeat the procedure for the opposite high voltage terminal. The sum of the two readings should be within 10% of the name plate rating.

Field Testing. Connect the electronic ignitor grounding terminal to a good ground. Connect the primary leads of the electronic ignitor to 120 Volts.

Energize the primary. Holding the handle of a well insulated screw driver, touch one part of the shaft of the screw driver to one high voltage

terminal. Pivot on this terminal until you draw an arc from the opposite terminal. Gradually increase the air gap and notice the distance at which the

arc is extinguished. The minimum distance should be 1/2”.

The OMNI®Electronic Ignitor has no moving parts. The only maintenance required is the cleaning of the porcelain bushings with a soft cloth during

the annual furnace inspection.

The OMNI®2275U / 2275-XXX Electronic Ignitor can be tested as follows to ensure that it is operating properly.

WARNING

This procedure is to be carried out by qualied personnel ONLY.

The voltages and currents available can cause serious injury and/or death. Extreme caution is to be used to avoid contact with the

primary live leads. Do not allow any parts of your body to come closer than 5 inches to the energized secondary terminals or parts of the

secondary circuit. Ensure the mid-point of the transformer is grounded before energizing the primary.

Installation:

Maintenance:

Testing:

This manual suits for next models

1

Table of contents

Popular Transformer manuals by other brands

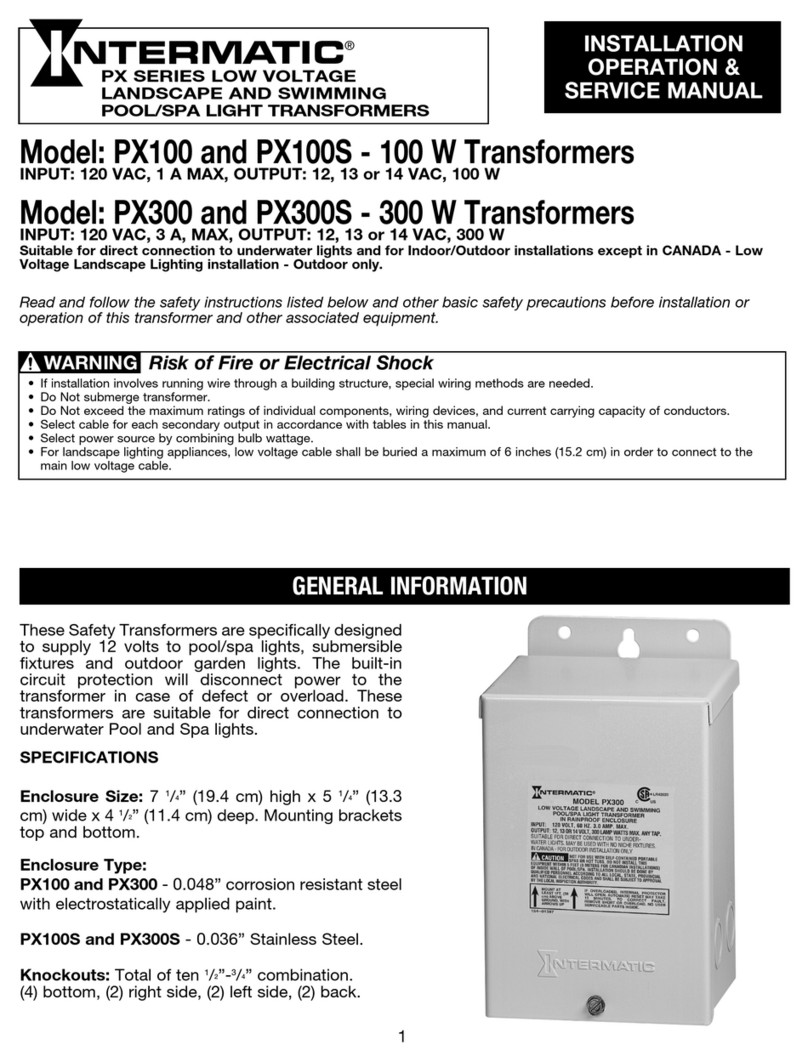

Intermatic

Intermatic PX Series Installation, operation & service manual

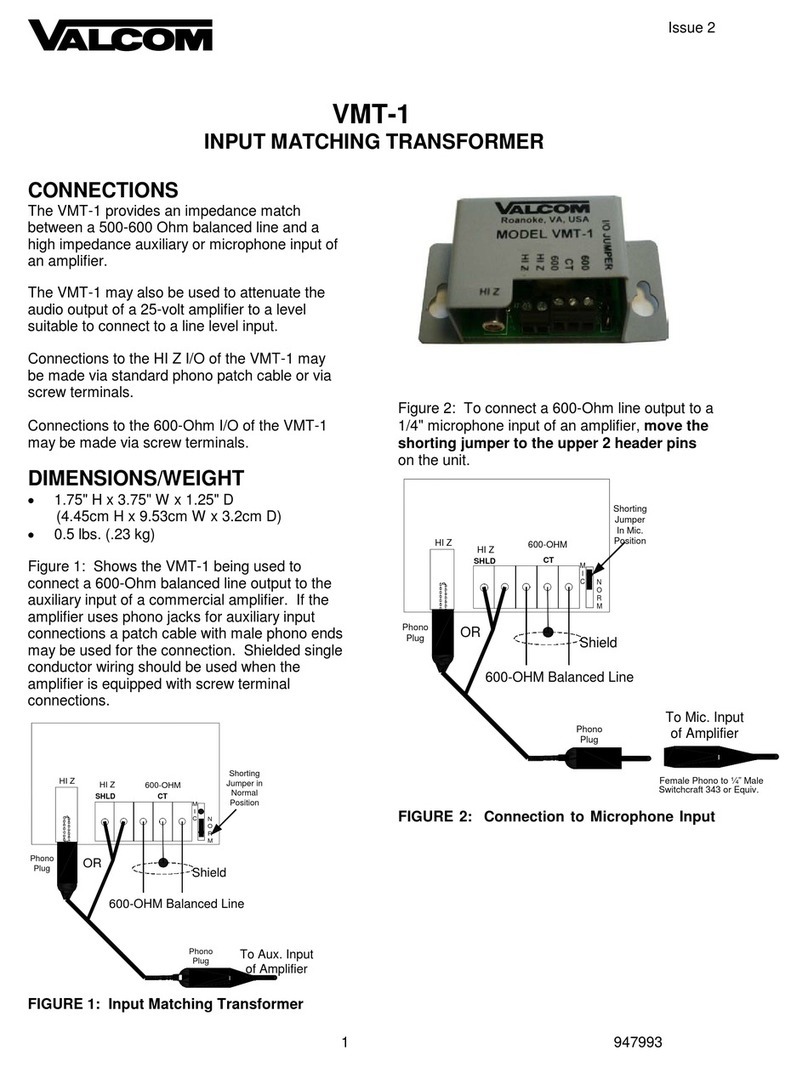

Valcom

Valcom VMT-1 Product guide

Torus Power

Torus Power TOT Series Series manual

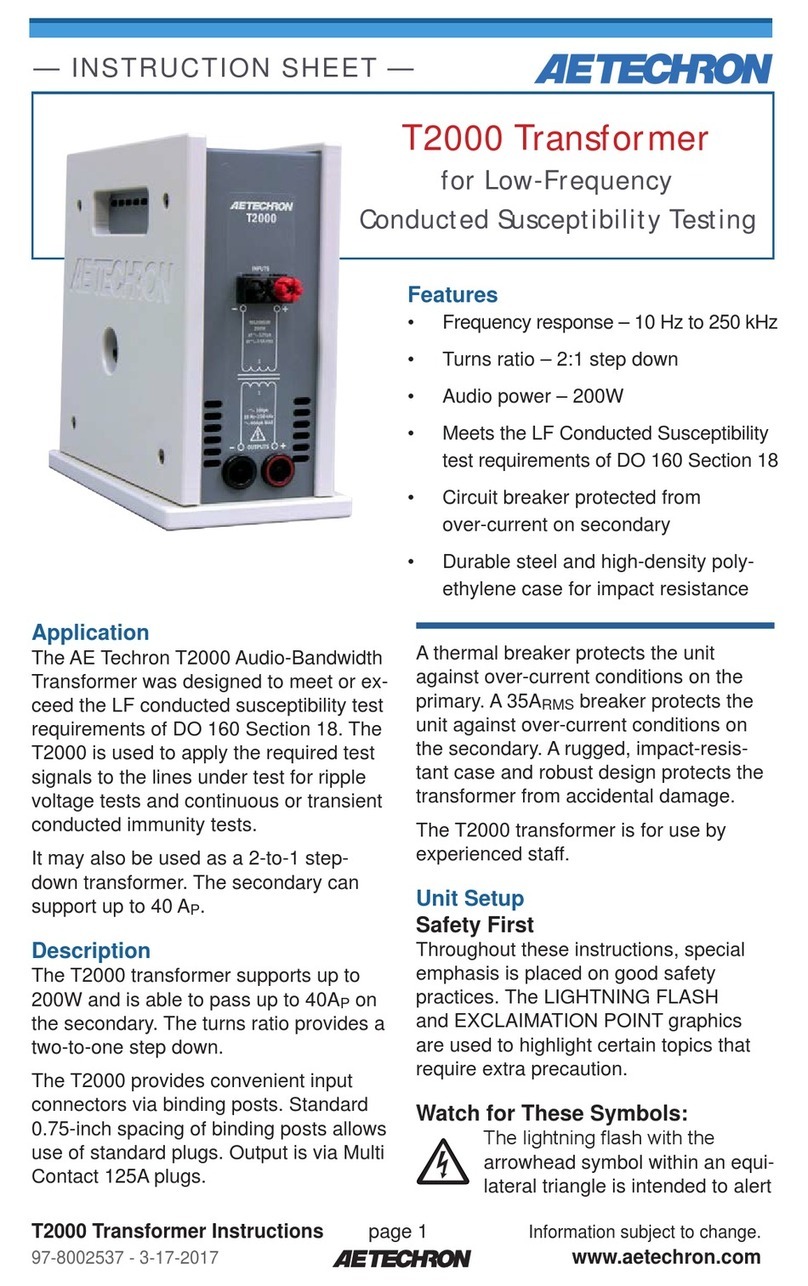

Aetechron

Aetechron T2000 instruction sheet

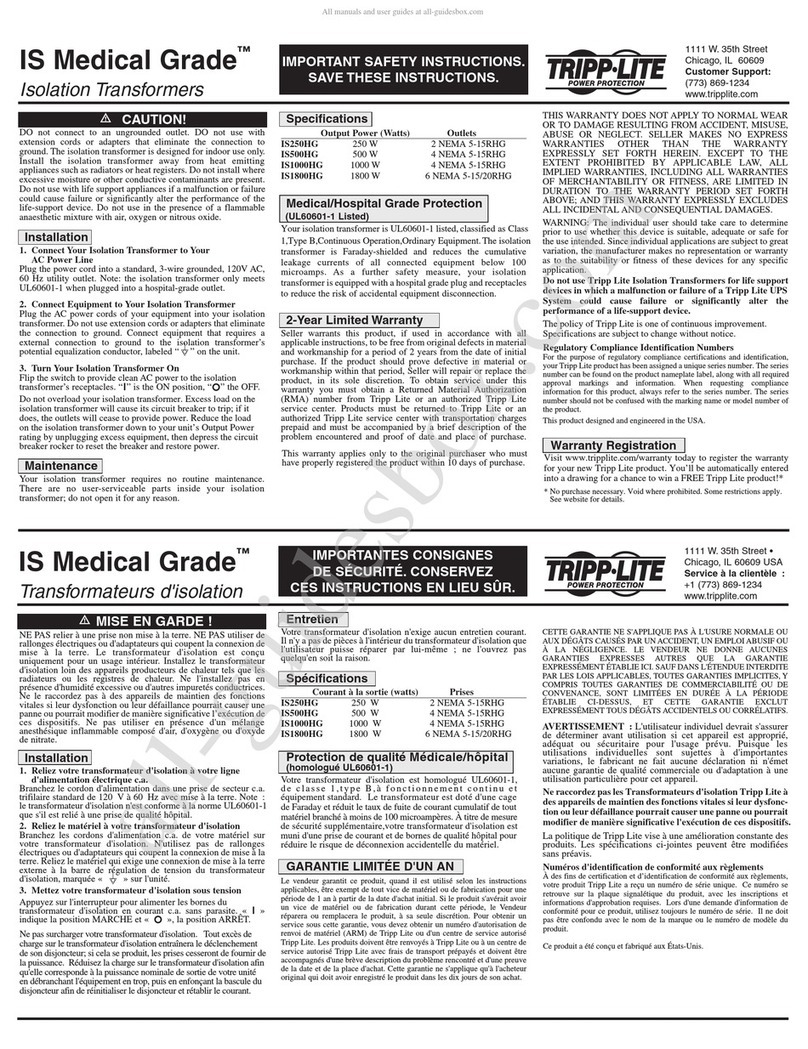

Tripp Lite

Tripp Lite IS Medical Grade IS1000HG Important safety instructions

Vents

Vents TRF-220/12-25 quick start guide