Installation Instructions

Original Instructions

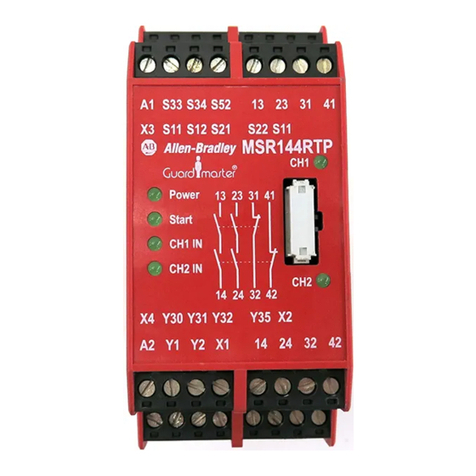

MSR127 Minotaur Monitoring Safety Relays

Catalog Number 440R-N23124, 440R-N23125, 440R-N23126, 440R-N23127, 440R-N23128, 440R-N23129, 440R-N23129M, 440R-N23130,

440RN23131, 440R-N23132, 440R-N23132S, 440R-N23133, 440R-N23134, 440R-N23135, 440R-N23135M, 440R-N23135S, 440R-N23213

Summary of Changes

This publication contains the following new or updated information. This list

includes substantive updates only and is not intended to reflect all changes.

Translated versions are not always available for each revision.

Safety

This device is intended to be part of the safety-related control system of a

machine.

Safety Notes

Before installation, a risk assessment must be performed to determine whether

the specifications of this device are suitable for all foreseeable operational and

environmental characteristics of the machine to which it is to be fitted. At regular

intervals during the life of the machine, check whether the characteristics

foreseen remain valid.

Rockwell Automation cannot accept responsibility for failure of this device if the

procedures given in these instructions are not followed or if it is used outside the

recommended specifications in these instructions.

Repair

If there is any malfunction or damage, do not attempt to repair. The unit must be

replaced before machine operation is allowed.

Declaration of Conformity

Rockwell Automation declares that all MSR127 safety relays are in

conformity with Directives 2014/30/EU, 2006/42/EC, 2011/65/EU as

specified in the Declaration of Conformity available from

rok.auto/certifications.

Functional Description

The unit is enabled once supply is powered up and the safety circuits are closed.

The PWR status indicator is on.

A valid reset operation activates the safety outputs. The CH1 and CH2 status

indicators of the output are lit. At demand of the safety function and if any fault,

the safety outputs are de-energized within the specified response time.

Fault Detection

If a fault occurs, the internal relay circuit forces the safety outputs off. One or both

output status indicators may be off. The PWR indicator may be flashing. Remove

the fault and cycle the safety input to re-enable the device. Cycling power to the

safety relay can also clear the fault condition.

Diagnostics

Auxiliary (N.C.) outputs 41…42 monitor the safety output state.

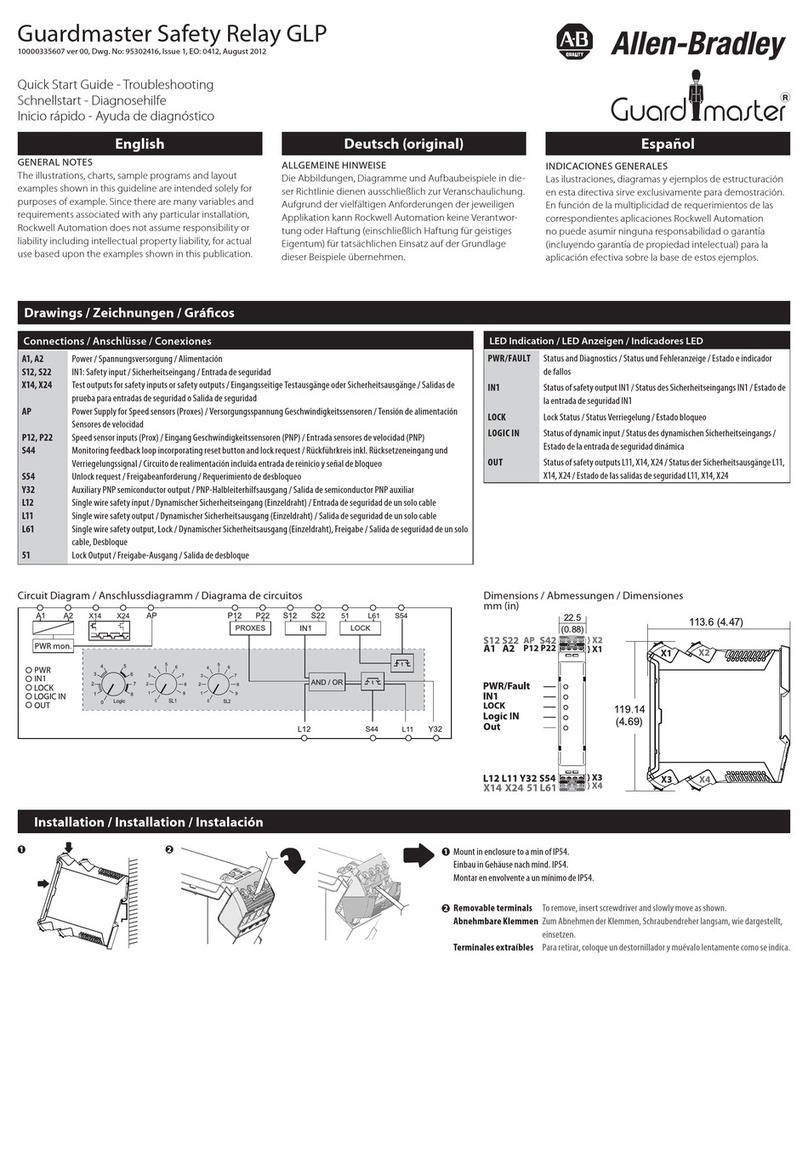

Topic Page

Summary of Changes 1

Safety 1

Declaration of Conformity 1

Functional Description 1

Diagnostics 1

Safety Input 2

Reset 2

Wiring Examples 2

Circuit Diagram 2

Approximate Dimensions 3

Installation 3

Safety Specification 3

Technical Specifications 3

Topic Page

Updated title of publication 1

Updated Declaration of Conformity section 1

Updated Positive Edge section 2

Updated Circuit Diagram section 2

Updated Safety Specification section 3

ATTENTION: Danger of serious injuries.

Misuse can result in malfunction.

• Only authorized and trained personnel must start up,

assemble, install, manipulate, or retrofit the device.

• Installation must be in accordance with these instructions.

• Do not defeat, tamper, remove, or bypass this unit.

IMPORTANT The safety inputs of these products are described as

normally closed (N.C.), that is, with the guard closed,

actuator in place (where relevant) and the machine able to

be started. Exposure to shock and/or vibration in excess

of what is stated in IEC 60068 part: 2-6/7 must be avoided.

Adherence to the recommended inspection and

maintenance instructions forms part of the warranty.

ATTENTION: MSR127 safety relays are not repairable.