9

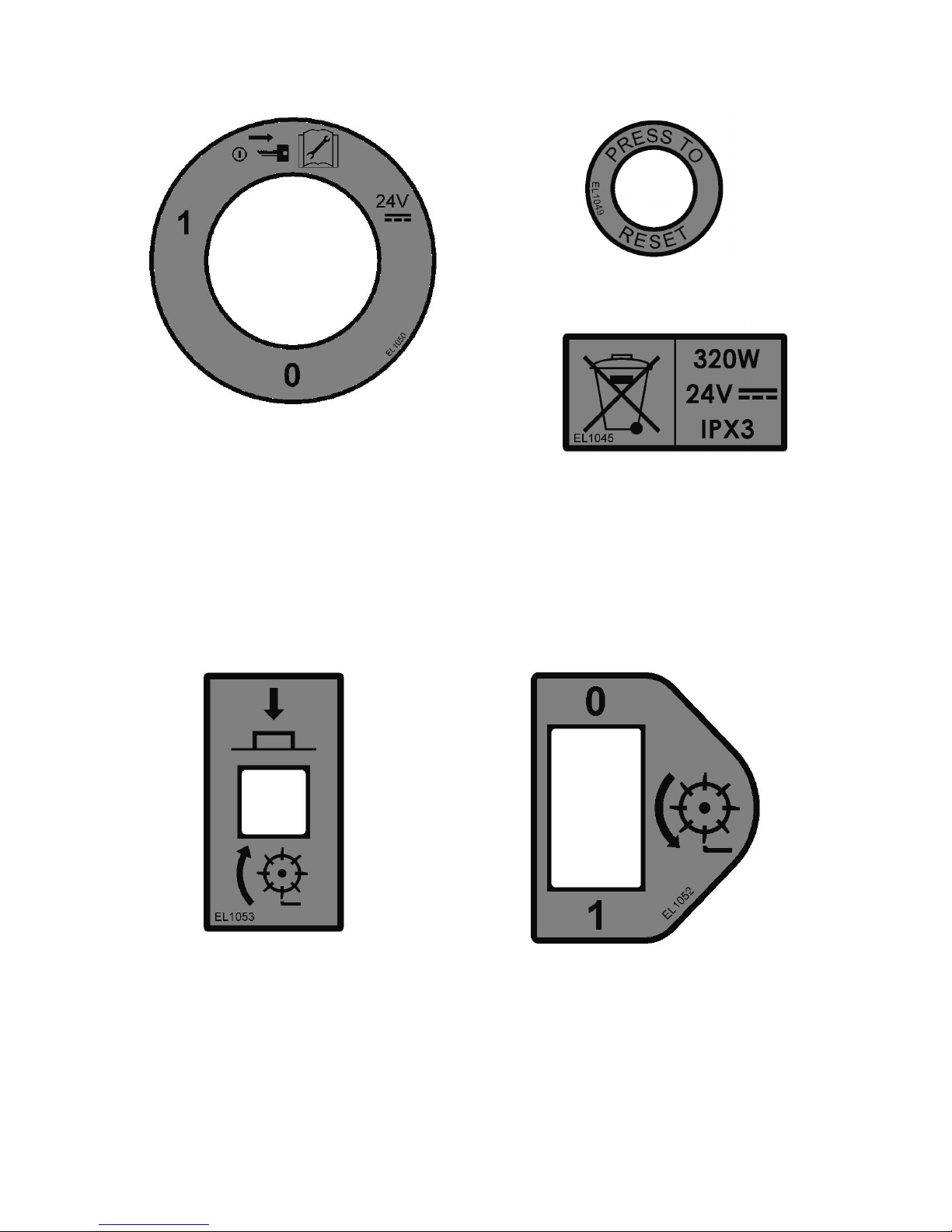

switch for operation. Wait for the green light next to the switch to show

continuously (if it does not see trouble shooting section).

•The cutting cylinder will start to spin in the reverse direction, the reverse

speed is limited to 25% of the normal speed.

•After the desired period of time has passed switch OFF (0) the cylinder

activation switch.

•Make the mower safe by removing the battery isolation key, next carefully

remove all the lapping paste from the cylinder and bottom blade.

7.0 Mowing

•Prepare to operate the mower (refer to the previous section)

•Switch ON (1) the land roll controller activation switch located on the right

hand panel. Wait for the green light next to the switch to show continuously (if

it does not see trouble shooting section).

•Press one or both of the red operator presence controls to the handle bar.

•Switch ON (1) the cutting cylinder controller activation switch located on the

left hand panel. Move the small red central switch first to unlatch the main

switch for operation. Wait for the green light next to the switch to show

continuously (if it does not see trouble shooting section).

•The cylinder will start to spin.

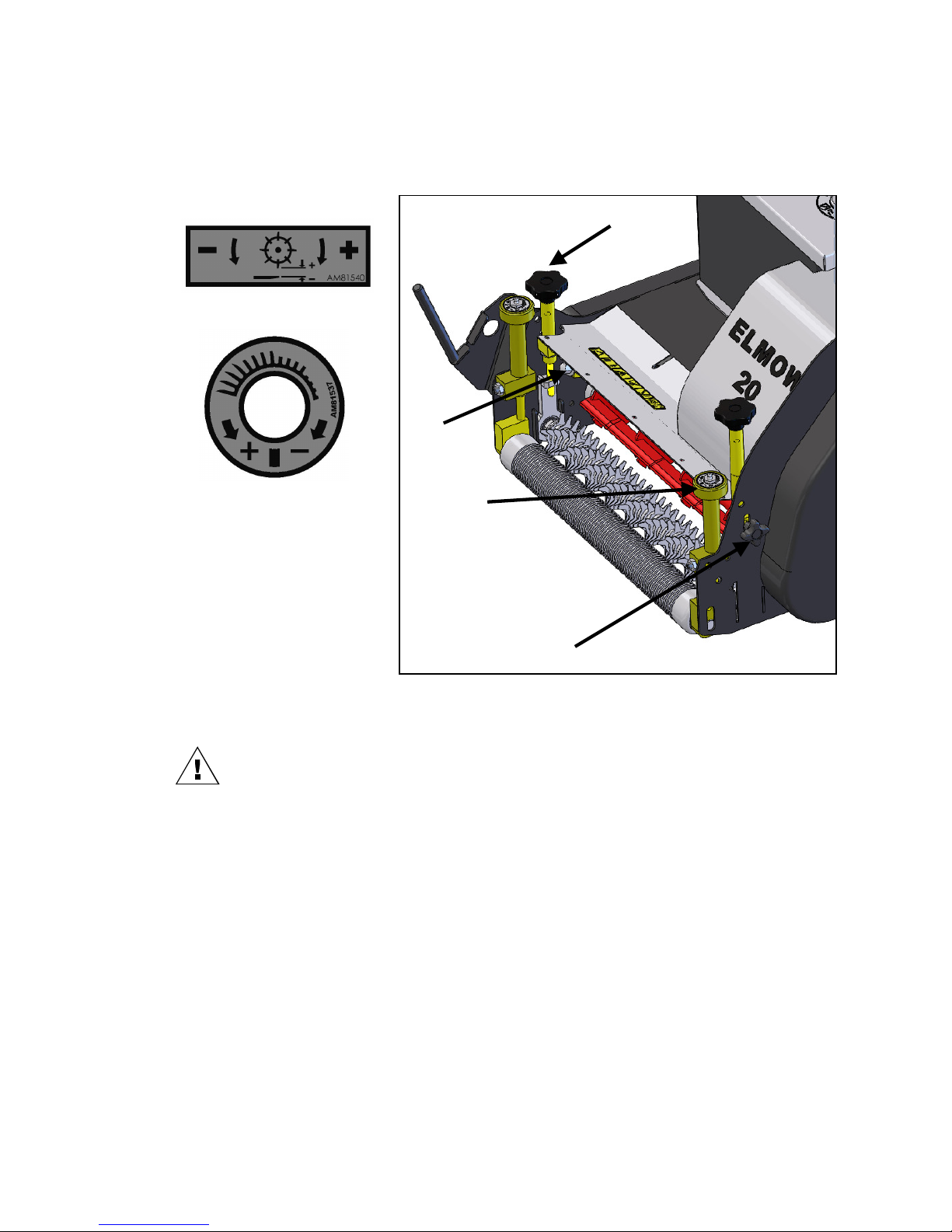

•With both hands firmly holding the handle bars move the central throttle

control forwards gradually. The mower will move forwards. Increasing the

forward rotation of the throttle control will increase forward speed.

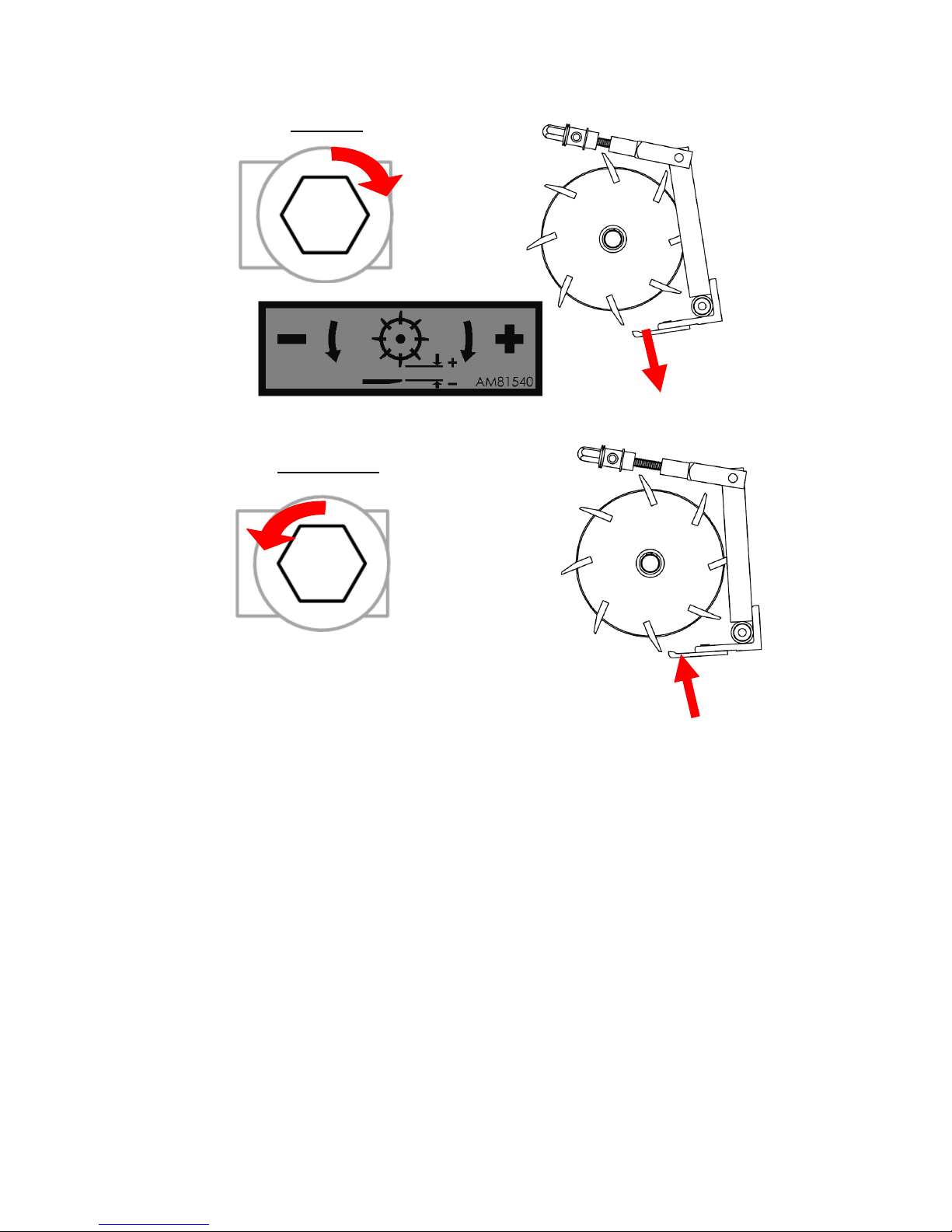

•Maximum speed can be adjusted by the rotary speed switch located on the

right hand control panel. Turn the dial to select between the three speeds. As

forward speed is increased by this rotary switch, clip rate will automatically

increase.

8.0 Stopping and charging

•Turn OFF (0) both the cutting cylinder controller activation switch and the land roll

controller activation switch.

•When the mower and cutting cylinder are stationary let go of the handle bars (the

park brake will be applied automatically)

•Turn the battery isolation key to the OFF (0) position and remove the key.

•Unplug the battery pack lead from the mower power socket.

•Plug the charger into the battery pack lead.

•Turn ON (1) the battery isolation key, so the batteries can be charged by the charger

9.0 Hints and tips for mowing

•Only one operator presence lever needs to be held to activate the cylinder.

•The operator presence levers are not needed for transport, the presence of

the operator is confirmed by an input into the throttle.

•It is recommended for battery life and ease of use to leave the cylinder

spinning when turning at the end or each mowing run.

•The mower can be easily slowed on the approach to a turn by using the

central throttle. This will allow the operator more time to make a turn with out

the need to reverse.

•The mower can not be pulled back, in tight spaces use the powered reverse

which is selected via the central throttle. Take care as reverse is powered.