Alliance Rubber Oyster Banding Machine User manual

OYSTER BANDING

MACHINE

Operator's Manual

Manufactured in the USA by:

ALLIANCE RUBBER COMPANY

Hot Springs, AR

(2020.09)

User Diagram

Technical Diagram

Table of Contents

01

02

Diagram Page

Safety Procedures

Power and Air

03

03

Safety Page

Machine Setup

Functions: Manual Mode ("MAN")

Loading Bands

Functions: Auto Mode ("AUTO")

Unloading Bands

General Maintenance of Machine

Technical Instructions and Troubleshooting

04

06

07

11

13

14

15

Instructions Page

Enclosure

Enclosure

Core Assembly

Core Assembly

Core Assembly

Core Assembly

Core Assembly

17

19

21

23

25

27

29

Diagram Page

- Exterior

- Interior

- Mounting

- Knife and Stretcher Mounting

- Stretcher Assembly

- Knife Mechanism

- Feed Mechanism

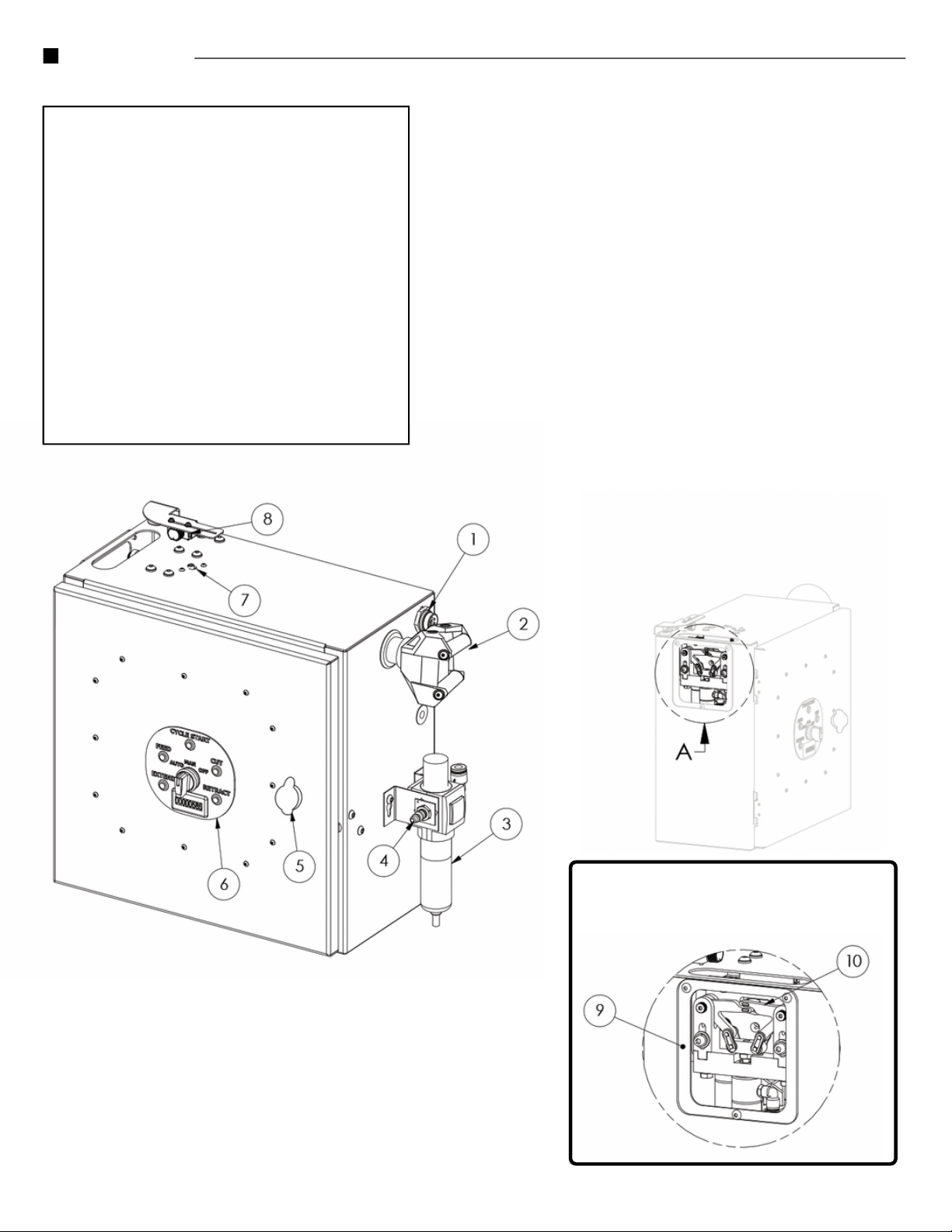

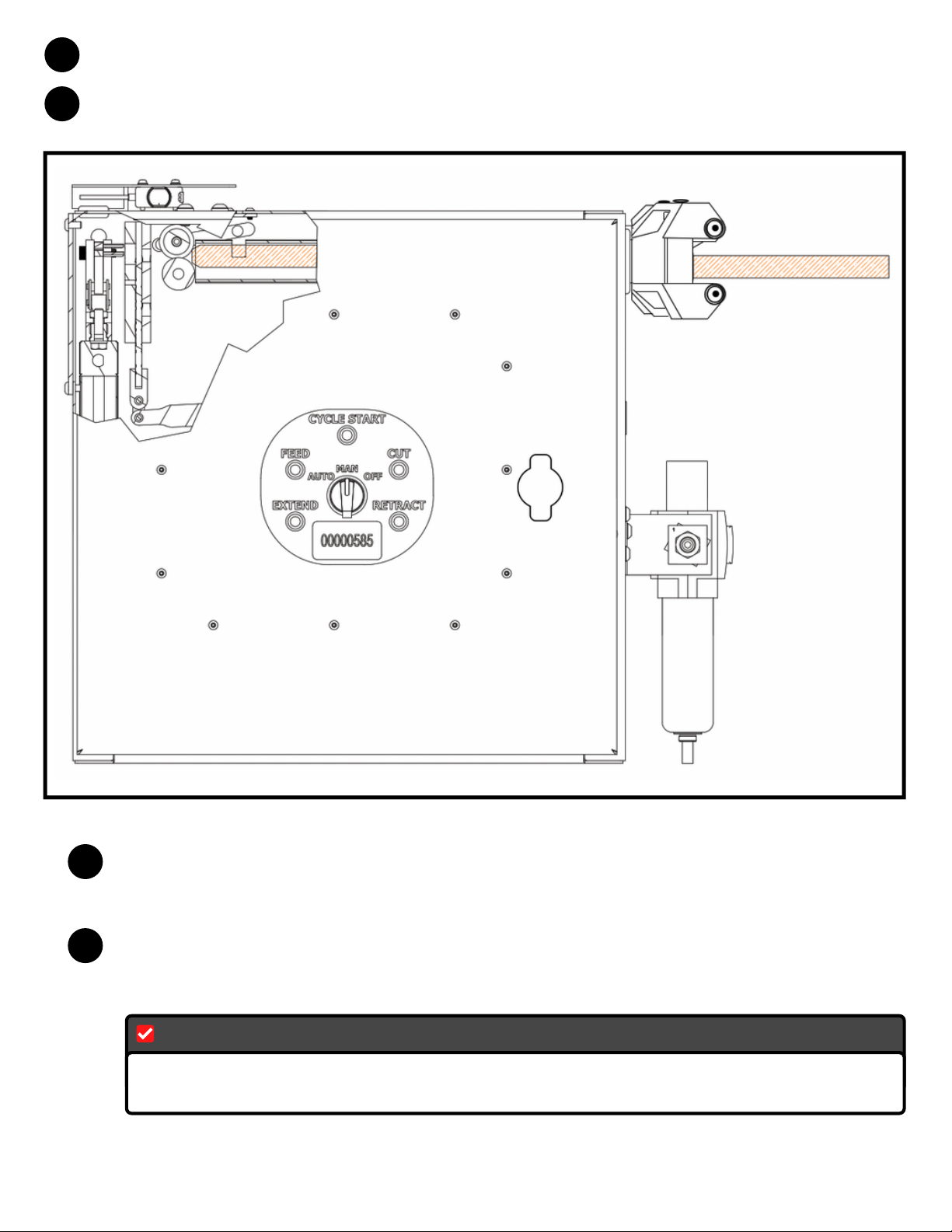

Power Connector

Feed Tube

Regulator

Compressed Air Inlet Valve

Door Lock

Control Panel

Feed Tensioner

Sensor

Safety Shield

Fingers

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

User Diagram

DETAIL A

Fingers Assembly

Page 1 Oyster Banding Machine

Core Assembly

Main Enclosure

Subpanel Assembly

Lubricator

Control Box

Knife Blade

Fingers Cylinder

Feed Cylinder

Knife cylinder

1.

2.

3.

4.

5.

6.

7.

8.

9.

Technical Diagram

2020.09 Page 2

1Safety Procedures

FAILURE TO REMOVE APPENDAGES OR OTHER FOREIGN MATERIALS

FROM THE PATH OF THE KNIFE BLADE CAN RESULT IN PROJECTILES

OR LOSS OF APPENDAGES.

This device can be operated from 110-120 VAC~ 1.4A 50-60Hz and should be used with

the provided power cable. The connection can be directly attached using the 3-prong

plug attached to the provided power cable.

Caution

DO NOT LET ANY BODY PART CROSS THROUGH THE PATH OF THE

KNIFE BLADE AT ANY TIME.

DO NOT LET ANY BODY PART GET STUCK BELOW THE FINGERS

MECHANISM WHILE OPERATING.

Power Source

Alternatively, the power can be directly wired to a 12-24VDC auxiliary power supply

(battery) and should be used with the provided power cable. The connection can be

directly wired using the 2-pin plug attached to the provided power cable. The positive

terminal should be connected to the yellow wire.

This device requires a minimum of 100psi of clean and dry air for the inlet valve for proper

operation.

Air Source

Page 3 Oyster Banding Machine

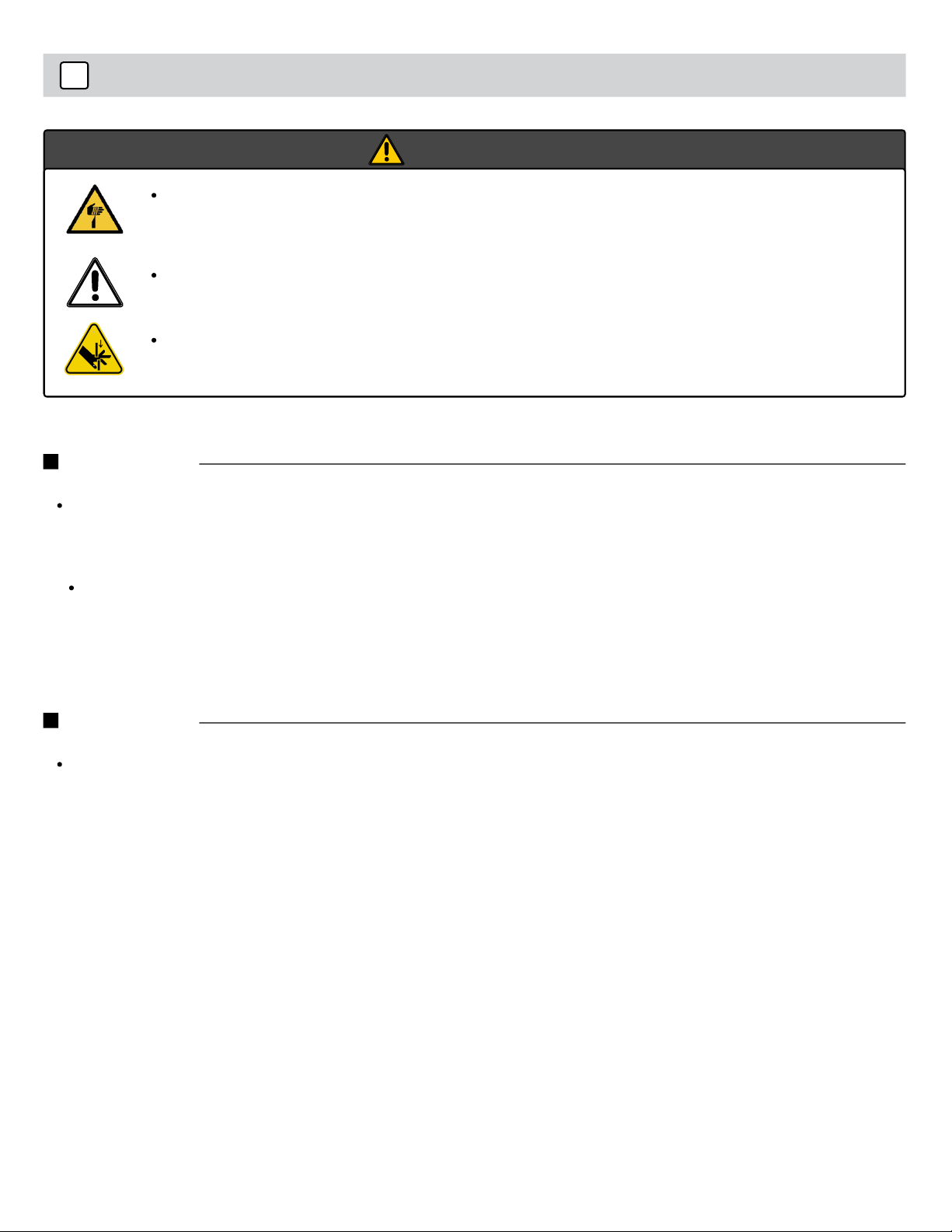

2Machine Setup

Attach the provided funnel

by placing it on the end of

the feed tube.

1

Connect an air compressor to the

regulator using the 1/4" male quick

connect coupling. Make sure the inlet

compressed air is regulated to 75 psi.

2

Pull up on the regulator adjustment knob

until it clicks to adjust pressure.

3a

Adjust the regulator pressure to 75 psi.

Turn the handle clockwise to increase the

pressure and counterclockwise to

decrease the pressure supplied to the

system. (It is not recommended for

pressure to be greater than 75 psi)

3b

Once the pressure is adjusted to 75 psi,

push back down on the handle until you

hear a click to lock the handle in place.

3c

3a 3b

Feed Tube

Funnel

Coupling

2020.09 Page 4

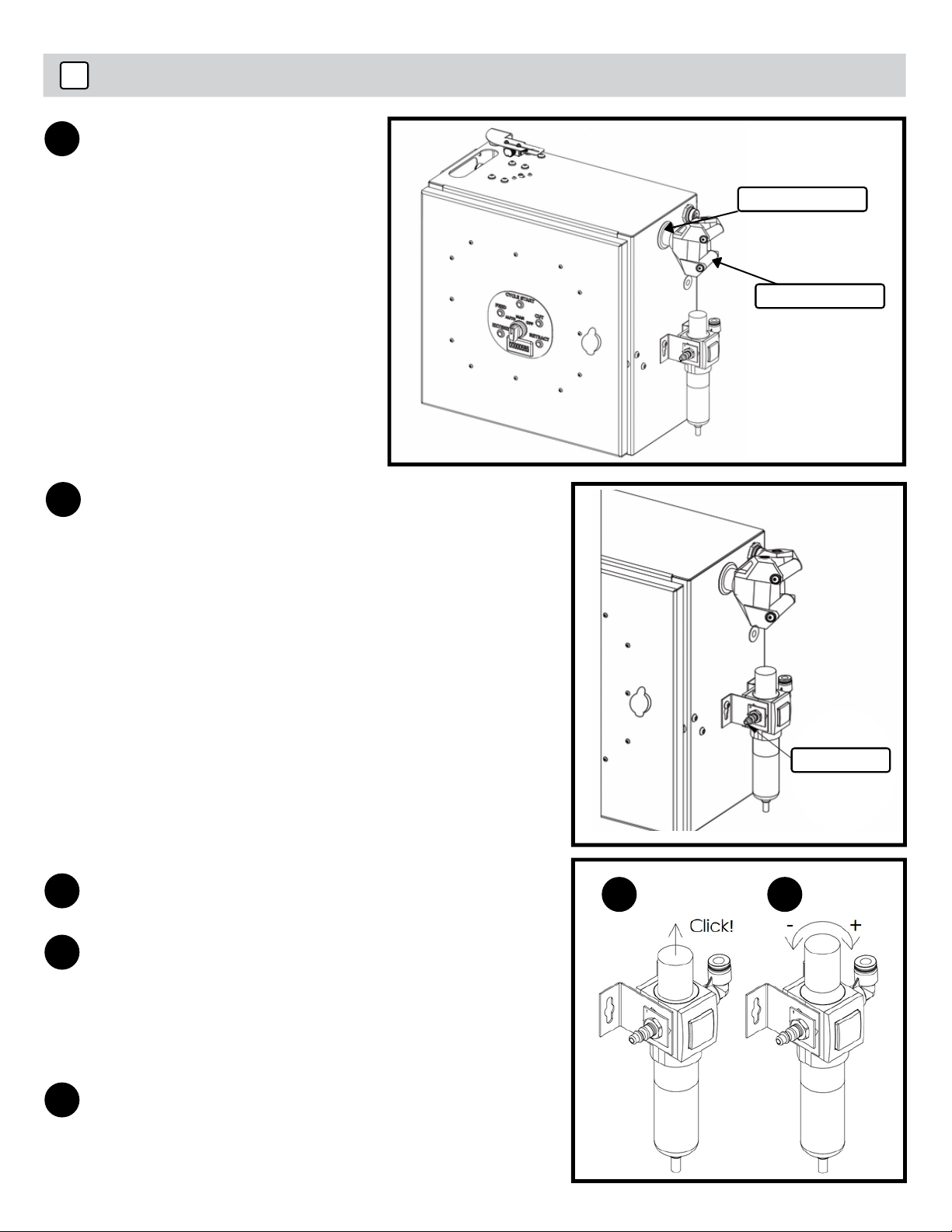

Connect power cable to the

labeled power connector

and the other end either to a

3-prong outlet (120VAC).

Please see page 3

4

Male End View

AC (in)

1 = WHITE

2 = RED

3 = GREEN/YELLOW

4 = ORANGE

5 = BLACK

Female End View

(on machine)

Close the door and lock it.

5

If the door is open, the safety switch will not allow the machine to function.

IMPORTANT!

Power

Connector

Door Lock

Page 5 Oyster Banding Machine

3Functions: Manual Mode ("MAN")

Flip the switch on the control board to "MAN" and confirm that each of the following

buttons work properly. In manual mode, each function can be independently

operated to assist in band loading or troubleshooting.

1

KEEP ALL GUARDS AND COVERS IN PLACE AT ALL TIMES

IMPORTANT!

Feed:

This button will feed the band tubing through two rolls towards the knife blade and

extension fingers.

Cut:

This button will operate the knife blade upwards to cut whatever is in its path.

BE SURE TO KEEP ANY BODY PART OR PLIERS OUT OF THIS PATH BEFORE

PRESSING.

IMPORTANT!

Extend:

This button will extend the fingers that hold the bands at full extension and ready for

banding of objects.

Retract:

This button will retract the fingers out of the way and is the best way to store the

machine when not being used.

TURN SWITCH BACK TO OFF WHEN NOT IN USE

IMPORTANT!

2020.09 Page 6

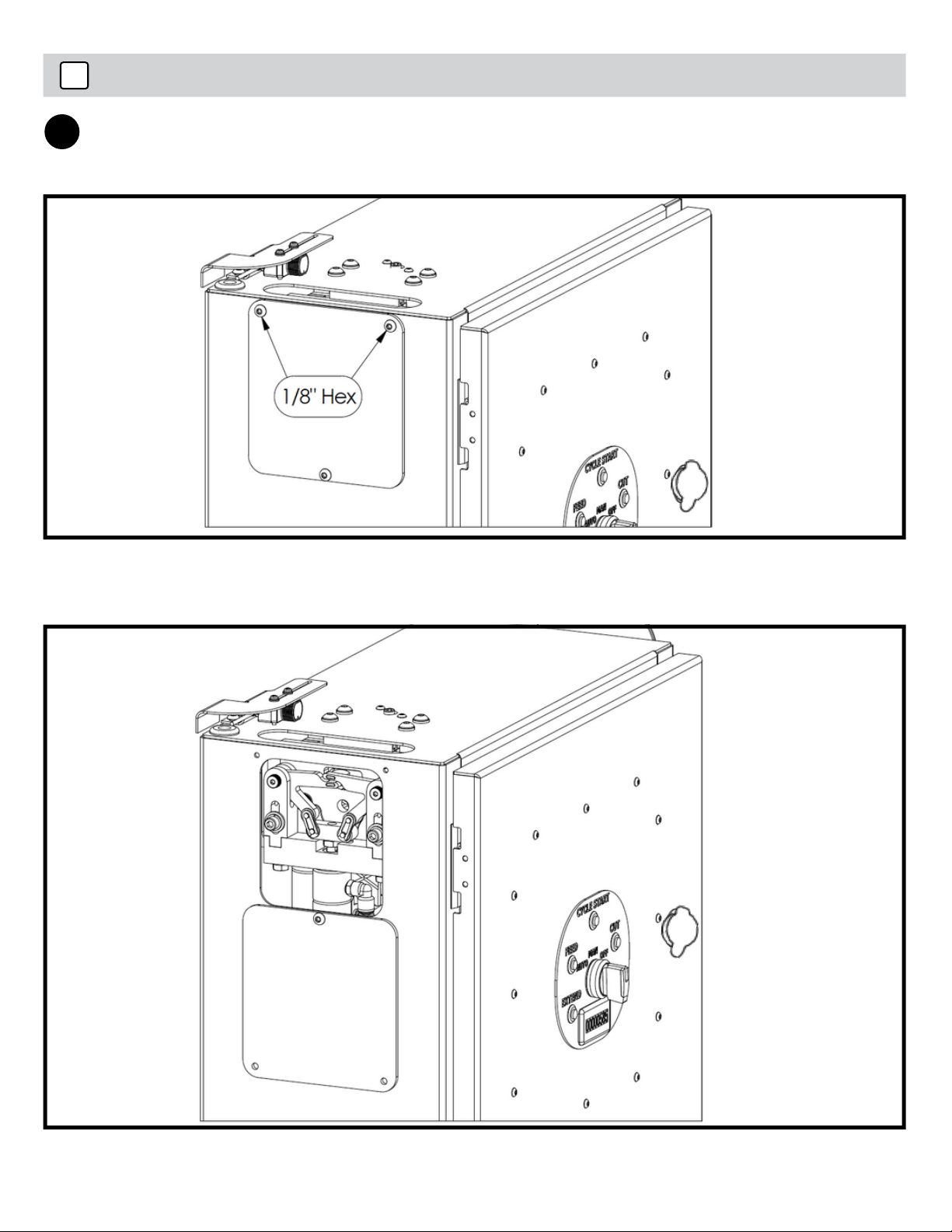

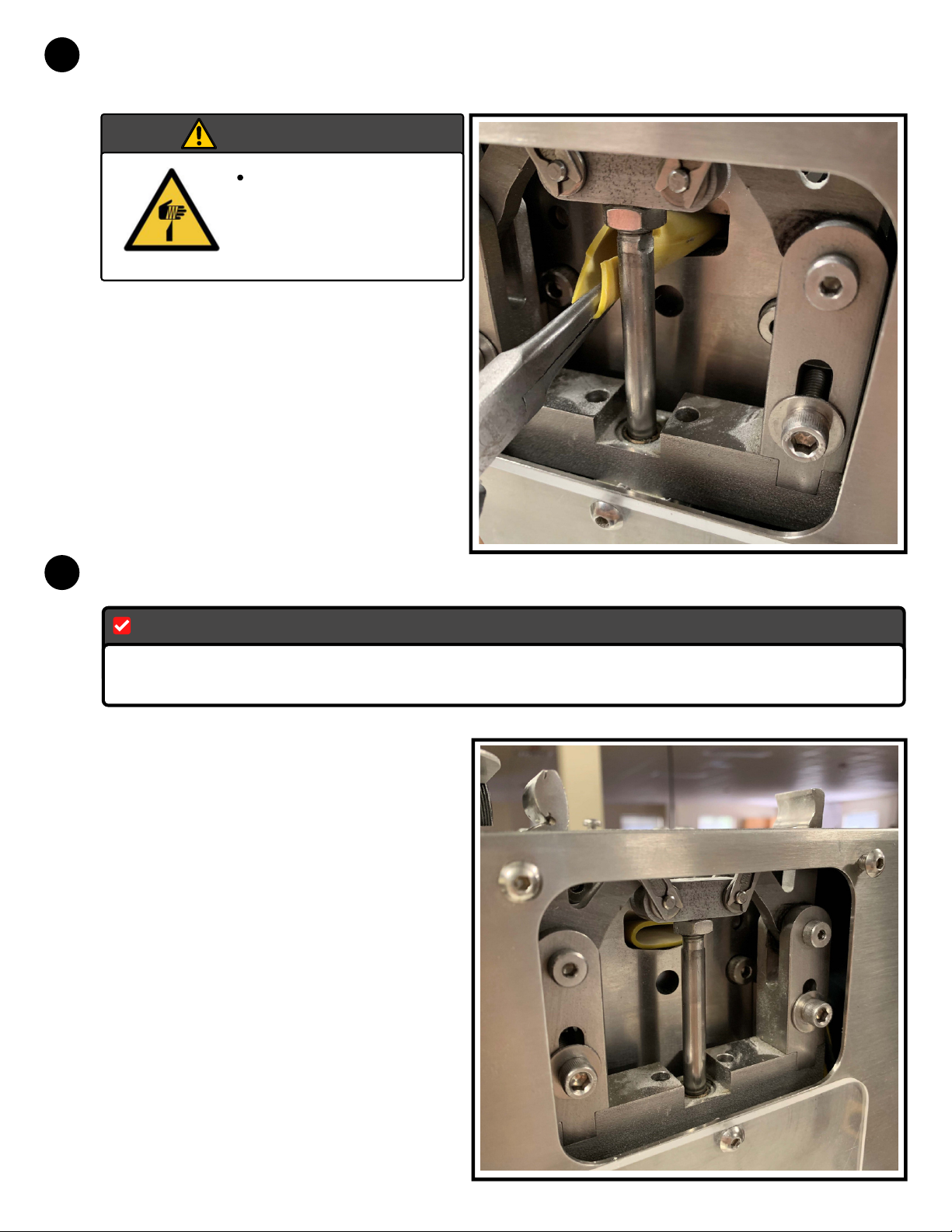

4Loading Bands

Use a 1/8" hex key to remove the (2) socket head screws and turn the safety shield

down temporarily.

1

Page 7 Oyster Banding Machine

Make sure the compressed air is on and the regulator is at 75 psi.

2

Load the tubing into the funnel.

3

Push the tubing all the way through the funnel until you feel it stop. It should have

stopped against the feed wheel. Hold the band tubing in place keeping some

pressure against the feed wheel.

4

Press the "FEED" button on the the control panel until you feel the feed wheel

engage and apply pressure, pulling the tubing. Make sure to not press "FEED" more

than 1-2 times after you feel it pull the tubing.

5

If it does not engage and pull the tube after a few attempts, see step 7a. If it

engages, continue to step 8.

IMPORTANT!

2020.09 Page 8

Look through the window on the side of machine where the safety shield was located.

Press FEED 1-3 more times until you see enough tubing to grab with pliers.

6

While pulling the tubing towards the window, make sure that it is fully through the

feed wheel.

7

MAKE SURE THE PLIERS ARE NOT IN THE PATH OF THE KNIFE BLADE ONCE

COMPLETE.

IMPORTANT!

Press the "CUT" button on the control panel to cut the band.

DO NOT PLACE

ANY APPENDAGES

IN PATH OF KNIFE

BLADE

Caution

Page 9 Oyster Banding Machine

Turn the switch on the control panel to "AUTO" and then press the button labeled

"CYCLE START" or trigger the sensor until a band is loaded onto the fingers.

8

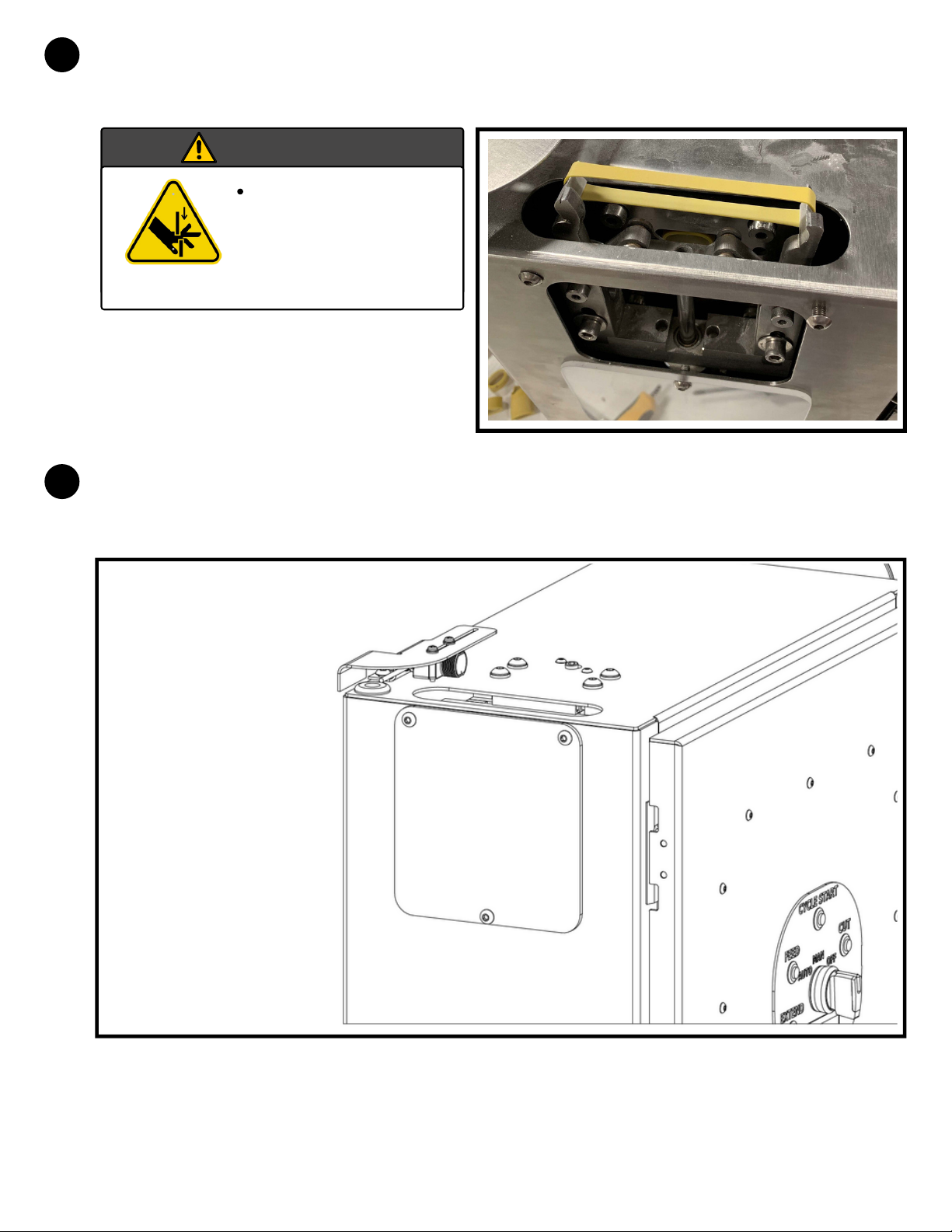

Finish by turning the safety shield and fastening the (2) socket head screws back into

place. You are now ready to start auto loading of bands.

9

DO NOT PLACE

ANY APPENDAGES

IN PATH OF

FINGERS

MECHANISM

Caution

2020.09 Page 10

5Functions: Auto Mode ("AUTO")

Flip the switch on the control board to "AUTO".

1

KEEP ALL GUARDS AND COVERS IN PLACE AT ALL TIMES

IMPORTANT!

Cycle Start:

This button will initiate a full cycle of RETRACT, FEED, CUT, and EXTEND to prepare

for the automatic feeding function.

Auto Mode:

While the switch is turned to AUTO, the sensor can be utilized for control of the

machine without touching the control panel. When an object is detected by the

sensor and then moved out of the sensor's line of sight, a new band will be loaded

into the fingers and ready for the next object. See page 16 to change the AUTO

sequence.

Place object to be banded inside the stretched band.

A

To use this mode, you must follow the following procedure:

Page 11 Oyster Banding Machine

BMove the object through the sensor's line of sight where you pass all the way

through (start in sensor's line of sight, then move out of sensor's line of sight) to

enact the sequence and automatically set up the next band.

Sensor

2020.09 Page 12

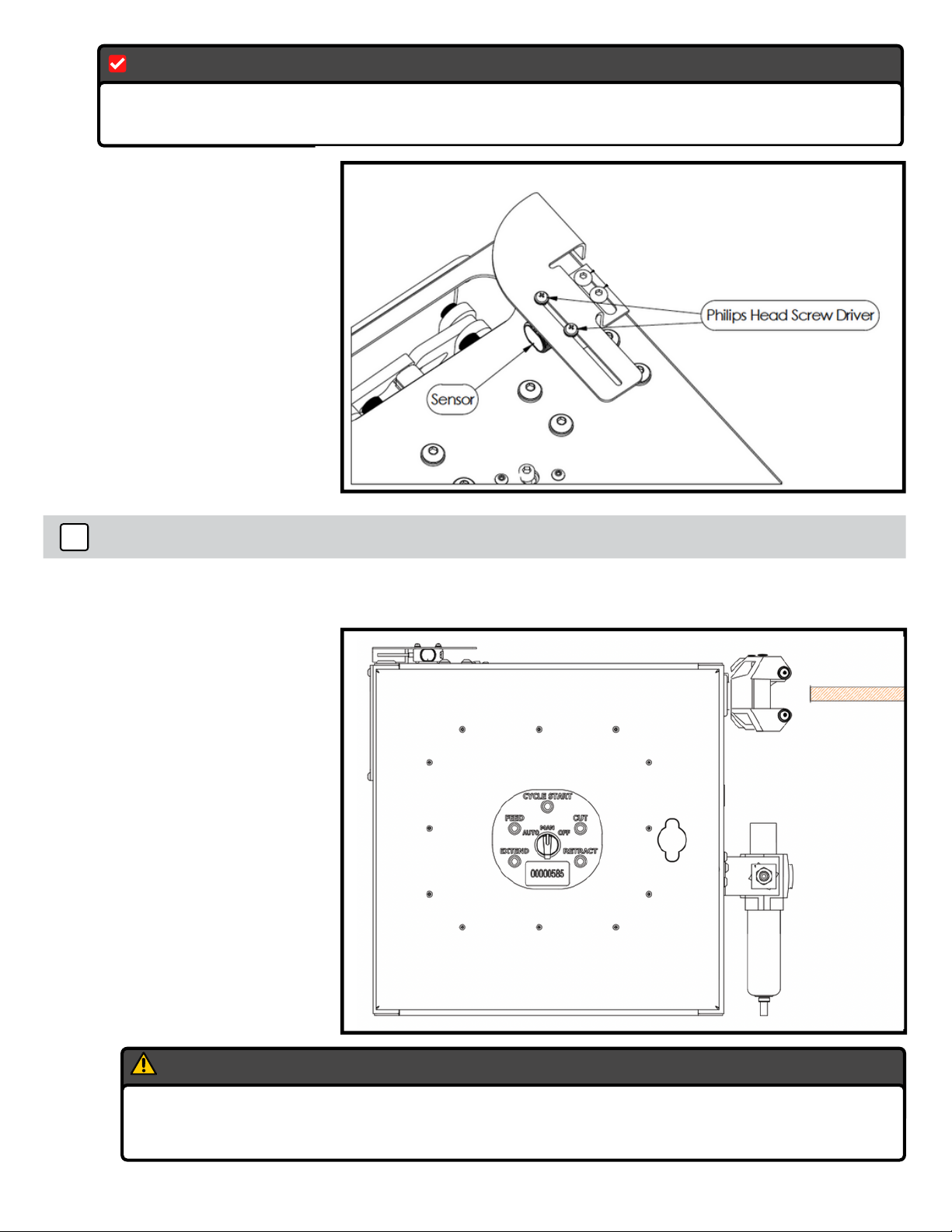

1

2

3

10

To adjust the sensor for different lengths of objects being banded, loosen the

shown screws with the tools listed and adjust accordintly.

NOTE:

To unload tubing, simply pull the tubing from the funnel side of the machine until it

comes back out from where it was fed in.

Unloading Tubing

DO NOT STAND INLINE WITH TUBING IN THE MACHINE WHEN UNLOADING

BANDS, AS THE TUBING COULD EXIT THE MACHINE QUICKLY WITH FORCE

AND CAUSE AN INJURY TO A BODY.

CAUTION:

6

Page 13 Oyster Banding Machine

7General Maintenance of Machine

Cleaning:

A typical occurrence of these machines is to have a large buildup of talc within the

whole assembly. To clean this powder from the machine, make sure to disconnect

power/air. For cleaning, it is recommended to use compressed air with safety

glasses and gloves. Be sure to clean the feed tube, inside the main enclosure,

around the knife blade, the feed wheel, and idler wheel. Please see diagrams if you

do not know where any of these components are located.

Oil:

In order for the knife blade to function properly, hydraulic oil is used and fed onto

the knife blade. The lubricator is located in the main enclosure and must be

refilled periodically. The amount of lube is set at the factory, but the oiler can be

adjusted based on what the end user sees in operation. Too much oil is better

than not enough. A bowl of oil will last roughly the consumption of one 15# reel of

tubing. Only use ISO VG 32 Hydraulic Oil. (Operating temperature of this oil

is18F/-8C to 147F/64C)

Air Filter:

Contact the manufacturer for detailed instructions on how to replace filter,

though this is generally not considered to be a maintenance item with proper

filtration on the compressor side.

*Replacement oil can be ordered from Alliance Rubber Company.

2020.09 Page 14

8Technical Instructions and Troubleshooting

If tubing is pulling through the feed wheel, but no tubing is coming out:

Tubing Not Feeding

STOP feeding.

Turn off the compressed air, unhook the quick connect coupling, or open the

main enclosure door to release back pressure in the system.

Disengage the feed wheel using the feed adjustment screw.

Pull tubing out in typical unloading situation.

Re-engage the feed wheel using the adjustment screw.

Feed tubing and look to make sure the tab cutout, as instructed in "Loading

Bands", is between the feed wheel and idler wheel.

Make sure to grab with pliers and pull through.

If tubing is not being pulled through the feed wheel:

Check on the regulator that pressure is at 75 psi.

Check and make sure the adjustment screw on the top of the machine is

engaged properly.

Check and make sure that you have cut a tab into the tubing as instructed in

"Loading Bands."

Check for a build up of talc on the feed wheel and idler wheel.

Check that the band tubing is not tangled or caught on the funnel.

Not grabbing with pliers to pull through while continually feeding. This can

lead to clogs.

TYPICAL CAUSE:

Adjusting Length of Band

Open enclosure and locate stroke limiter (item 46) on Core Assembly.

Reference page 24.

Loosen the set screw (item 17) on Core Assembly. Reference page 24.

The stroke limiter is threaded onto the feed piston.

Moving the brass stroke limiter upwards will shorten the stroke and

therefor decrease the length of band.

Moving the brass stroke limiter downwards will increase the stroke and

therefor increase the length of band.

Clog in the Feed Tube or Feed Wheel

Turn off the compressed air, unhook the quick connect coupling, or open the

main enclosure door to release back pressure in the system.

Make sure the feed wheel is disengaged by tightening the adjustment screw.

Unload band tubing in usual unloading circumstances. Apply extra pressure if

needed until tubing comes out.

Page 15 Oyster Banding Machine

Operating Settings

To decrease the speed of a cycle:

Speed Adjustment

Turn control switch into MANUAL mode

Hold CYCLE START and then press EXTEND

Switch to AUTO mode

Press CYCLE START button

To reset the speed back to default mode:

Turn control switch into MANUAL mode

Hold CYCLE START and then press FEED

Switch to AUTO mode

Press CYCLE START button

CYCLE Switch Adjustment

Turn control switch into MANUAL mode

Hold CYCLE START and then press RETRACT

Switch to AUTO mode

Press CYCLE START button

To switch to a normally closed switch (for example, a foot pedal switch):

Turn control switch into MANUAL mode

Hold CYCLE START and then press CUT

Switch to AUTO mode

Press CYCLE START button

To reset the switch to the default normally open switch (proximity sensor):

2020.09 Page 16

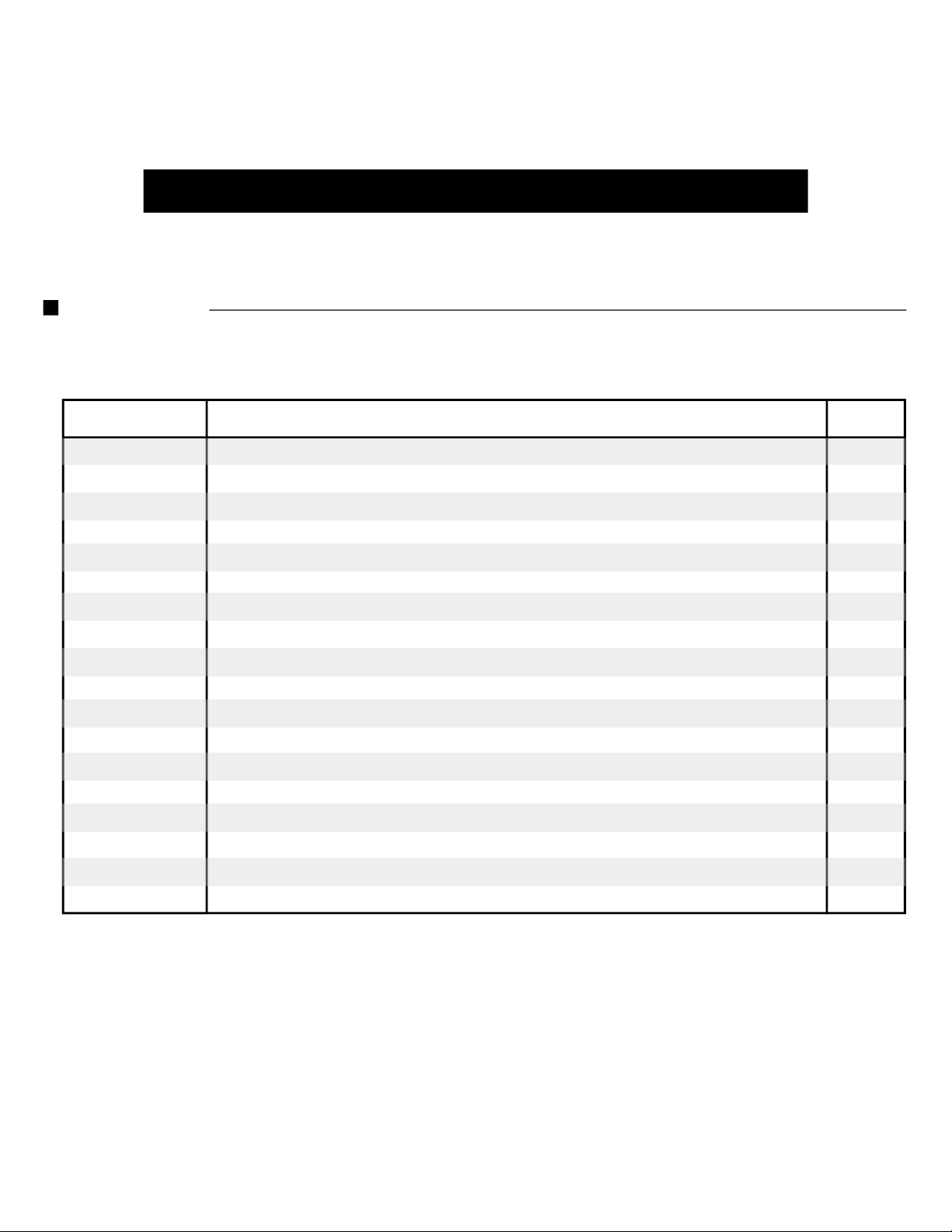

Bill of Materials

Item Part Number Qty.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

BM1-0001-0032 NC1 Sensor Z Bracket

BM1-0001-0041 NC Enclosure

BM1-0001-0061 NC NC Cover

BM1-0001-0084 NC Locking Grommet

BM1-0001-0086 NC Grommet

BM1-0001-0087 NC Grommet

BM1-0001-0091 NC Sensor

BM1-0004-0011 NC Male Quick Disconnect

BM1-0004-0012 NC FRL Assembly

BM1-0004-0014 NC Connector, Tubing

BM1-0005-0016 NC 5 Pos. Male Receptacle

BM1-0002-0041 NC Infeed Funnel

M3.0-.50 Nut, Hex

M3.0-.50 X20.00 18-8 SS Screw, Pan-Head Philips

#4 18-8 SS Washer, Internal Tooth

1/4-20 St Stl Nut, Self-Locking

1/4-20 X0.75 St Stl Screw, Button-Head Socket

10-32 X0.375 St Stl Screw, Button-Head Socket

2

1

1

1

1

1

1

1

2

1

2

1

2

2

2

2

2

5

ENCLOSURE

ASSEMBLY:

Exterior

Page 17 Oyster Banding Machine

Table of contents

Popular Food Saver manuals by other brands

Teknika

Teknika MUL-331 Operation manual

Signode

Signode B-250 Operation, parts and safety manual

3M

3M 3M-Matic 700r3 Instructions and parts list

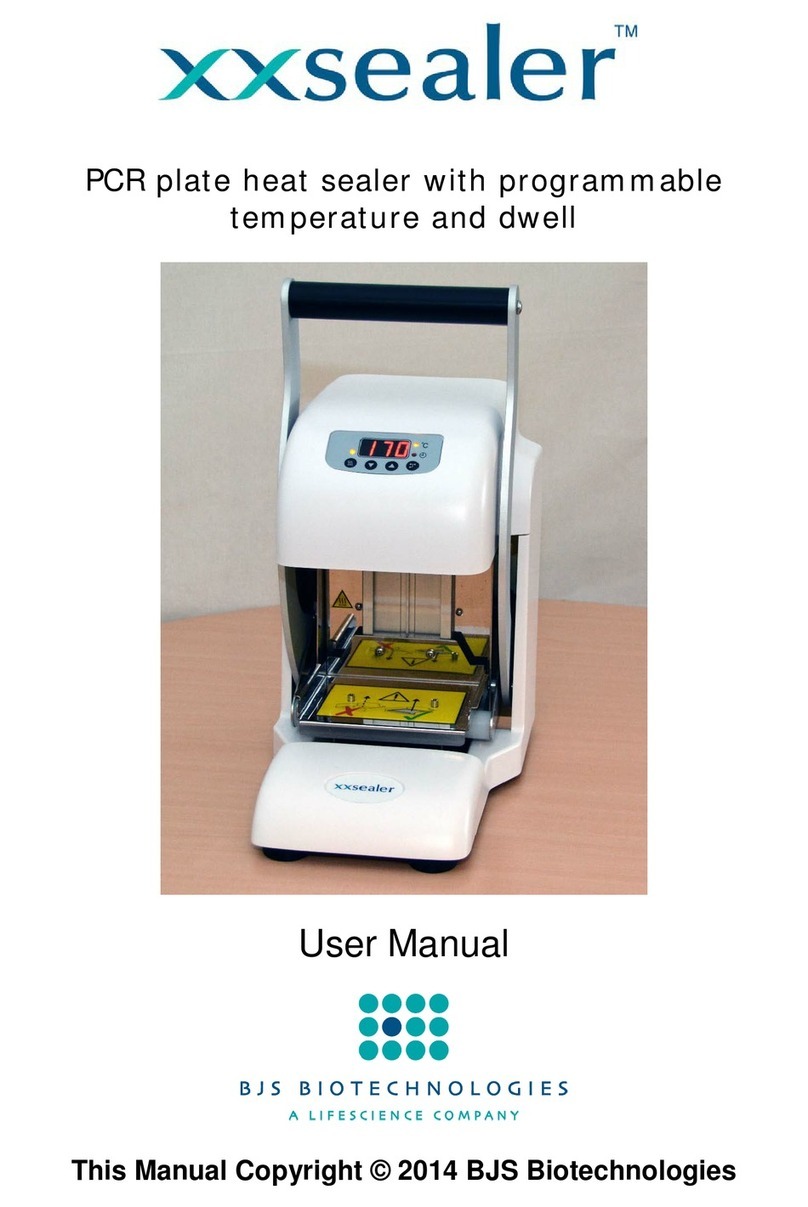

BJS Biotechnologies

BJS Biotechnologies xxsealer user manual

Thermopatch

Thermopatch HS-4-C user manual

Infinity Solutions

Infinity Solutions 7K Plus Service manual