Infinity Solutions 7K Plus User manual

Infinity Solutions Manufacturing

192 Gannett Drive South Portland, ME 04106

(207) 899-1714

7K Plus Service Manual

ii

iii

Table of Contents

Table of Contents ..............................................................................................................................................iii

Service Manual Notes.........................................................................................................................................v

Tools Needed.....................................................................................................................................................................v

Parts:..................................................................................................................................................................................v

Technical Help ...................................................................................................................................................................v

Additional Notes.................................................................................................................................................................v

1. Machine Overview ..........................................................................................................................................6

1.1. Covers.........................................................................................................................................................................7

2. Drive Train.......................................................................................................................................................8

2.1. Conveyor Drive Pulley & O-Ring ................................................................................................................................8

2.2. Drive Motor: Belt, Pulleys, and Clutch........................................................................................................................9

2.3. Gears ..........................................................................................................................Error! Bookmark not defined.

2.4. Double Sided Timing Belt and Drive Pulleys............................................................................................................11

3. Feed Table.....................................................................................................................................................12

3.1. Feed Table................................................................................................................................................................12

3.2. Feed Drive Belts .......................................................................................................................................................13

4. Feed Gauge...................................................................................................................................................14

5. Nip Wheel ......................................................................................................................................................15

6. Conveyor.......................................................................................................................................................16

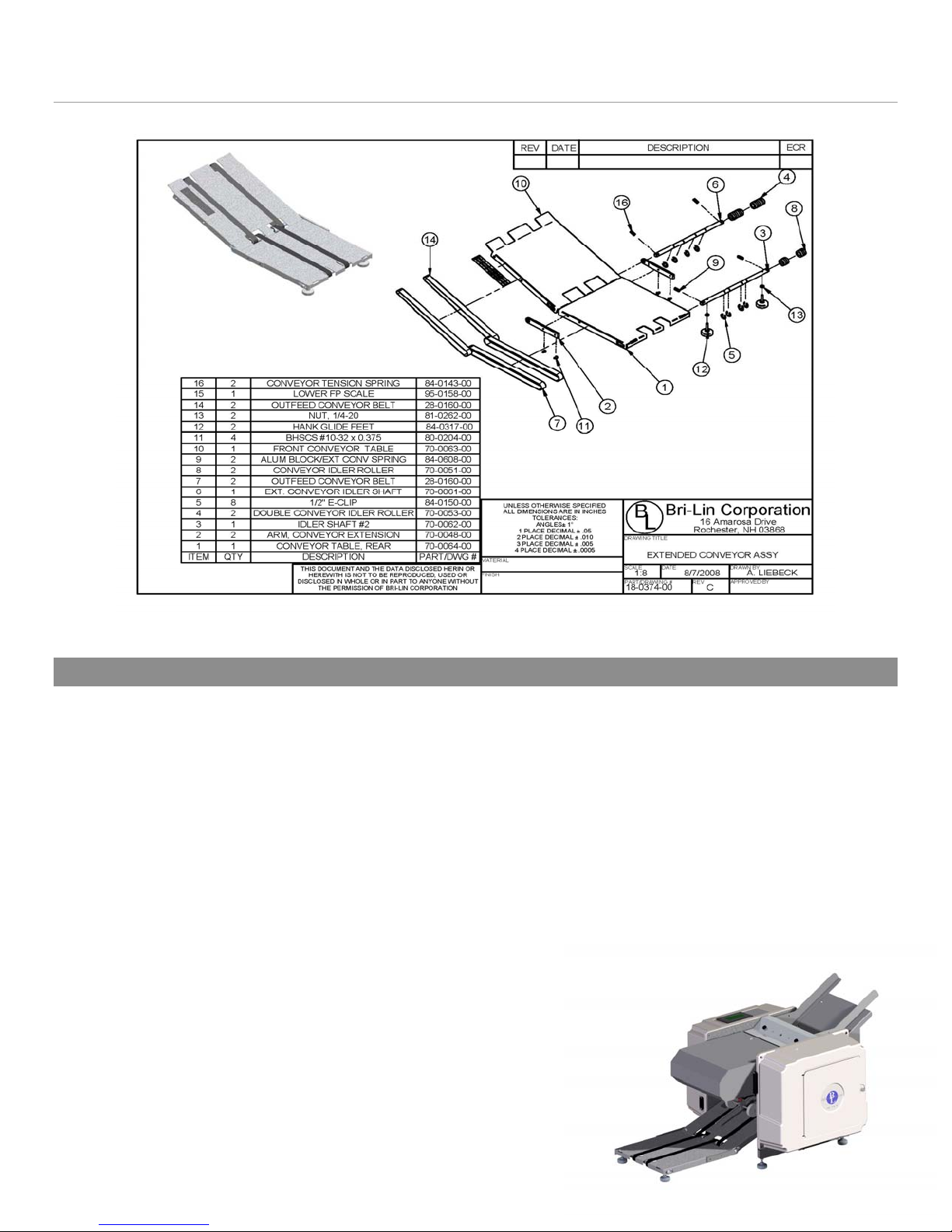

6.1. Extended Conveyor Belts .........................................................................................................................................16

6.2. Conveyor Belts............................................................................................................Error! Bookmark not defined.

7. Wiper..............................................................................................................................................................17

8. Rolls...............................................................................................................................................................18

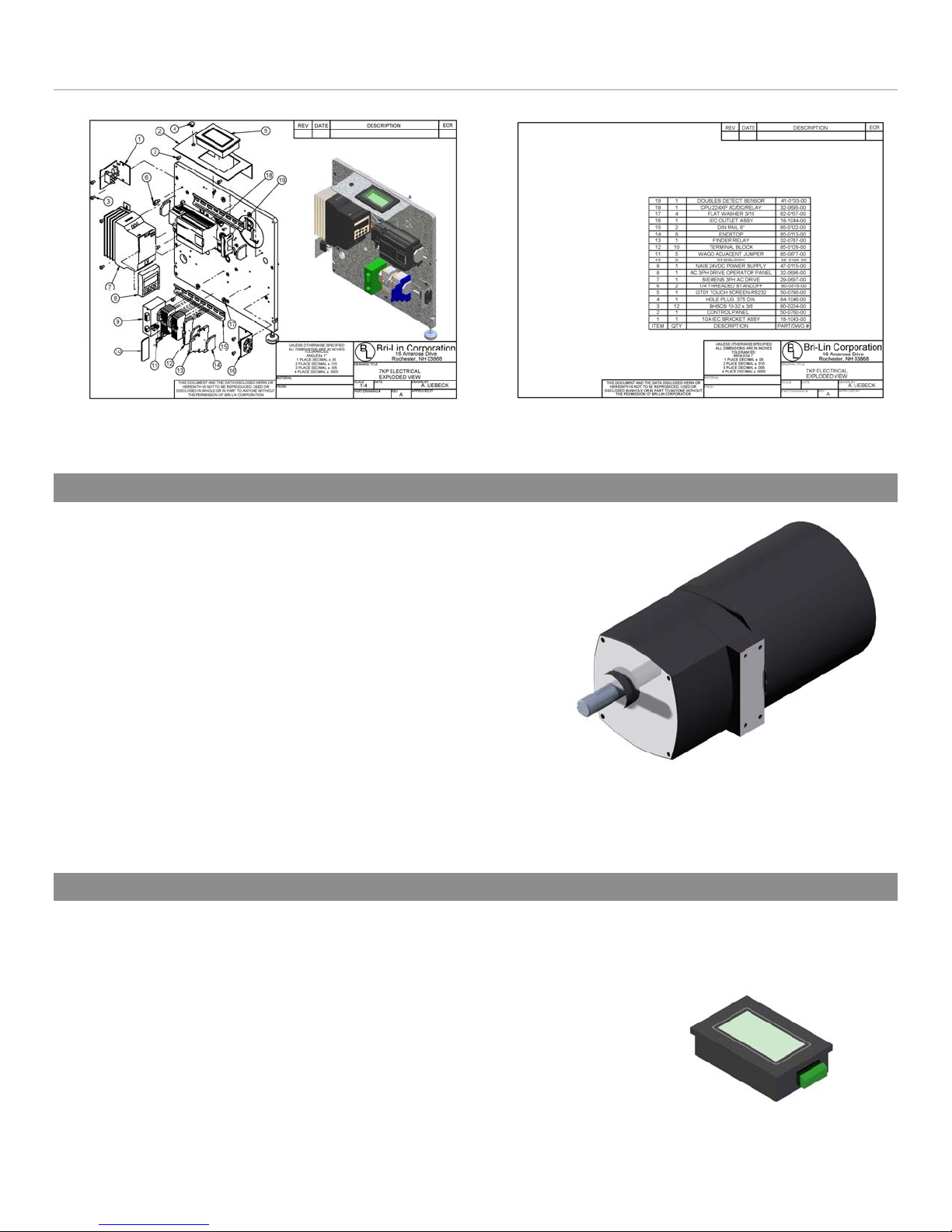

9. Electrical........................................................................................................................................................20

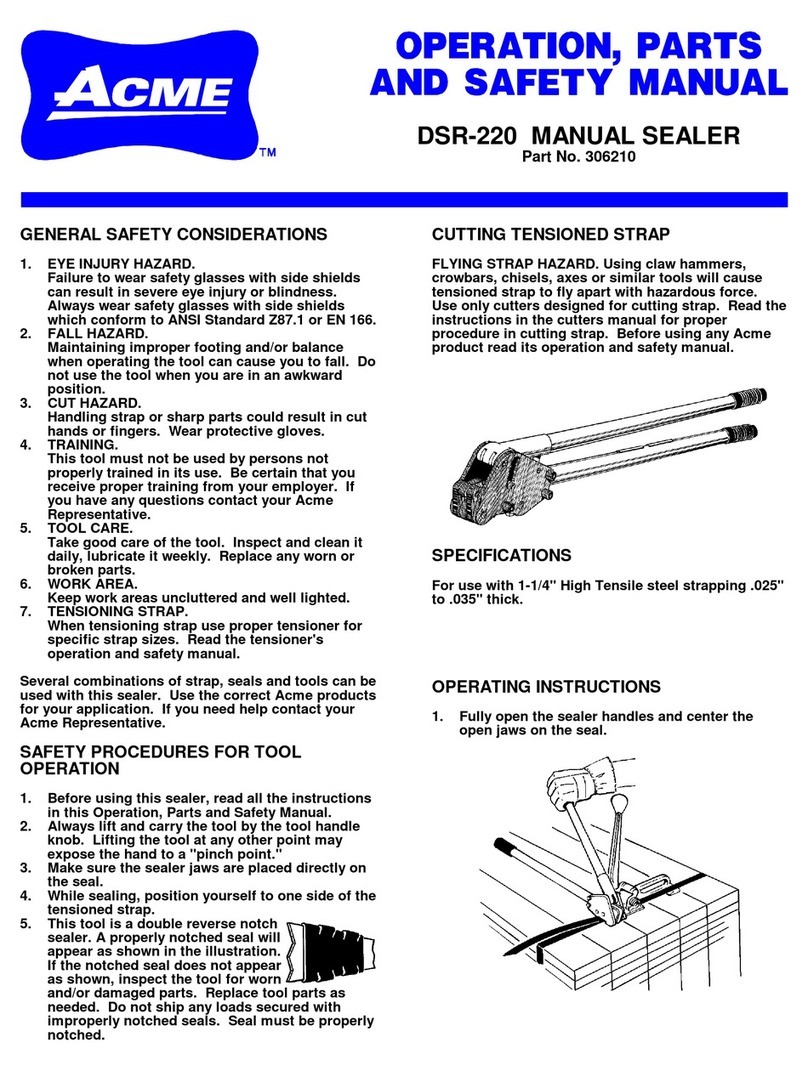

9.1. Drive Motor ...............................................................................................................................................................20

9.2. Touch Screen............................................................................................................................................................20

9.3. PLC...........................................................................................................................................................................21

9.4. Power Supply............................................................................................................................................................21

9.5. Motor Drive ...............................................................................................................................................................21

9.6. Doubles Detection.....................................................................................................................................................22

9.6.1 Optic Cable..........................................................................................................................................................................22

9.6.2 Optic Amplifier......................................................................................................................................................................22

9.6.3 Sensor Alignment.................................................................................................................................................................23

9.6.4 “Teaching” the Optic Amplifier..............................................................................................................................................23

9.7. Feed Counter............................................................................................................................................................23

10. Troubleshooting .........................................................................................................................................24

10.1. Machine Will Not Power On....................................................................................................................................24

10.2. Machine Powers On But Will Not Run....................................................................................................................24

10.3. Machine Stops Running..........................................................................................................................................25

10.4. Paper Jams.............................................................................................................................................................25

10.5. Improper Functioning of the Machine.....................................................................................................................26

iv

10.5.1 Misaligned Folds................................................................................................................................................................26

10.5.2 Paper Feed Problems........................................................................................................................................................26

10.5.3 Dirty forms..........................................................................................................................................................................27

10.5.4 Motor Runs only in one direction........................................................................................................................................27

10.5.5 Erratic speeds......................................................................................................................Error! Bookmark not defined.

10.5.6 Excessive Noise.................................................................................................................................................................27

10.5.7 Poor Stacking.....................................................................................................................................................................27

10.6. Sensors...................................................................................................................................................................27

10.6.1 Doubles Detection..............................................................................................................................................................27

10.6.2 Reflective Counter Sensor.................................................................................................................................................28

10.6.3 Door Switch........................................................................................................................................................................28

10.6.4 Fold Plate Switch ...............................................................................................................................................................28

10.7. Electronic Components...........................................................................................................................................30

10.7.1 Touch Screen.....................................................................................................................................................................30

10.7.2 Power Supply.....................................................................................................................................................................30

10.7.3 PLC....................................................................................................................................................................................30

10.7.4 Driver .................................................................................................................................................................................30

10.7.5 Drive Motor ........................................................................................................................................................................30

11. Appendix .....................................................................................................................................................31

12. Addendums………………………………………………………………………………………………………….31

v

Service Manual Notes

Tools Needed

• Set of standard Inch Allen Wrenches

• 7/16” Deep Socket & Driver

• 1 ¼ “ Socket

• Torque Wrench, with 12 ft*lbs capabilities

• Philips head Screw Driver

Parts:

For parts please contact Infinity Solutions Manufacturing:

Phone: (207) 899-1714

Fax: (207) 228-1890

www.infinitysolutionsmfg.com

Part numbers are included for components shown in exploded views through out the manual and in the

appendix.

Technical Help

The majority of service operations are covered in this manual. However, if you are unable to resolve a

problem please contact technical support at Infinity Solutions Manufacturing.

Phone: (207) 899-1714

Additional Notes

This manual is for use with the Infinity Solutions 7K plus.

6

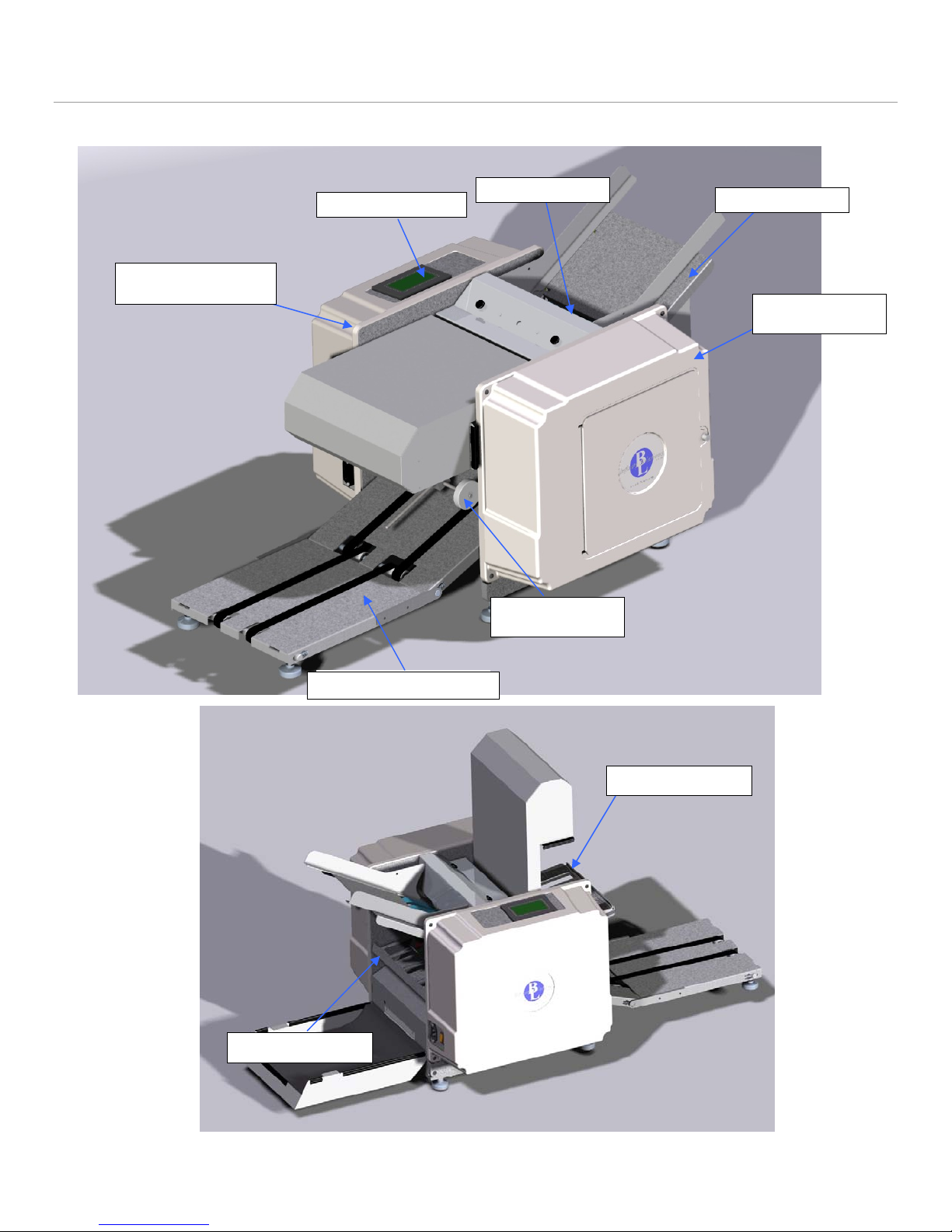

1. Machine Overview

•Read the operators manual to become familiar with the machine operation.

Feed Gauge

Electrical Side

Cover

Control Panel

Motor Side

Cover

Conveyor Nip

Wheels

Feed Table

Extended Conveyor

Lower Fold Plate

Upper Fold Plate

Figure 1: Overview

7

1.1. Covers

a) Removal

1. Remove the cover screws (4x).

2. Slide the cover off the machine.

b) Installation

1. Installation is the reverse of removal.

Cover

Power Switch / Breaker

Power Cord Plug

Figure 2: Power Connection and Switch

Figure 3: Covers

Cover Screw (4x)

8

2. Drive Train

2.1. Conveyor Drive Pulley & O-Ring

a) Removal

•Disconnect the power cord from the machine.

1. Remove the drive train side cover.

2. Roll the o-ring off of the conveyor pulley.

3. Remove the conveyor pulley.

a)Loosen the set screw.

b)Pull the pulley off of the shaft.

b) Installation

1. Place the conveyor pulley onto the shaft with the hub on the

inside.

2. Align the O-Ring grove in the pulley with the O-Ring grove on the roll shaft.

Figure 4: Drive Train

Note: if motor belt is marked 5M450 15, then see addendum

Motor Pulley and Clutch

Feed Drive

Pulley

Motor Belt

28-0832-00

Door Switch

Double Sided Belt

Conveyor Pulley

Roll Gears

Feed Pinion

Pulley

Feed Drive

Belt

O-Ring

Figure 5: Conveyor Drive

9

Note: The conveyor pulley is mounted on a floating shaft and the pulley will self align itself, however is best if they

are closely aligned to begin with. Tighten the set screw

3. Roll the o-ring onto the conveyor pulley.

4. Ensure the o-ring or pulley can not contact any other drive train components.

Note: For conveyor pulley and O-ring part #’s see the Appendix. If existing pulley does not have shown hub,

then the clear o-ring must be used. Otherwise, the black one is needed.

2.2. Drive Motor: Belt, Pulleys, and Clutch

a) Removal

•Disconnect the power cord from the machine

1. Loosen all four motor screws and slide the drive motor forward to loosen the belt tension.

2. Slide motor belt off of the motor pulley.

3. Remove the motor clutch and pulley.

a)Loosen set screw.

b)Pull the motor clutch and pulley off of the motor shaft.

Note: If the motor pulley needs to be removed from the clutch,

remove the set screws, the large center nut on the clutch and

disassemble. To break the nut loose reinstall the belt, place a

socket driver on the end of the hex shaft and loosen the center

nut on the clutch. Alternately, if the clutch is already removed,

the inside can be placed in a vise and the center nut can be

loosened.

4. Remove the roll drive pulley.

a)Loosen both the set screws.

b)Slide the pulley off of the shaft.

b) Installation

1. Install the roll drive pulley onto the roll shaft with hex end. Ensure the drive key is properly placed in the

keyway. Butt the pulley up with the coinciding pulley on the shaft and tighten both set screws.

2. Install the motor clutch and pulley onto the motor shaft. Ensure the drive key is properly placed in the

keyway. Note that an undersized 3/16 key is used.

3. Slide the belt onto the pulleys. Align the motor clutch and pulley on the motor shaft so that the belt rides on

the middle of the pulley. Tighten the set screw.

4. Adjust the belt tension (See Section 2.2.c)

5. Check for clearance of the belt between nearby pulleys and ensure there will be no interference. If any

interference is found realign pulleys.

c) Adjustments

Belt Tension

1. With the motor mounting screws loose, slide the drive motor back until the belt is taut. Tighten the motor

mounting screws.

Motor Clutch Adjustment

The motor clutch must be adjusted if:

(i) Being replaced

(ii) The motor pulley has been removed from the clutch

(iii) The center nut on the clutch has been loosened or

tightened.

Figure 7: 1 and 2/3 forms

folded together

Figure 6: Drive Motor System

10

Note: If improperly adjusted premature component failure or poor machine performance can occur.

1. Use a torque wrench to tighten the center nut of the clutch to 12 ft/lbs.

2. With the drive train completely assembled and all protective guards in place plug in the machine and power it

on.

3. Test the adjustment by running a 1 2/3 folded form (See Figure 7) through the back of the machine while it

runs at full speed (See Figure 8 ).

a)To feed the form into the back of the machine, remove the rear fold plate. The fold plate switch will have to

be depressed to run the machine in the forward direction.

b)The form should make it through with minimal slipping of the motor. Note: by listening to the motor you

will be able to hear if it slips. If the form does not make it through the machine then the clutch is too loose:

tighten the clutch and repeat.

4. To determine if the clutch is too tight run two forms folded together through the back of the machine. The

paper should not make it through the machine, however the clutch should slip. You will be able to briefly hear

this just as the motor shuts down. If the clutch does not slip at all loosen the center nut.

5. Repeat steps 3 and 4 until both above criteria are met.

Note: If pulley material is aluminum, then see addendum

Figure 9: Motor Clutch Exploded View

Figure 8: Back of the Machine

Insert folded form Here

for clutch adjustment

11

2.3. Double Sided Timing Belt and Drive Pulleys

a) Removal

•Disconnect the power cord from the machine.

1. Remove the conveyor pulley, motor belt and the gears. (See Section 2.2)

2. Remove the double sided belt.

a)Loosen the idler tension bracket and slide the bracket and pulley down to release tension on the belt.

b)Remove the idler pulley from the bracket.

Note: The pulley uses a double screw attachment and both sides must be held to unscrew the screws.

3. Remove the roll pulleys.

a)Loosen the set screws and remove the pulleys.

4. Remove the belt.

b) Installation

1. Installation is the reverse of removal.

12

2. Adjust belt tension. (See Section 2)

c) Adjustments

1. With the idler bracket loose, slide the idler wheel and bracket up until the belt is tight. Tension the belt so

that the belt and gears move freely with minimal resistance. If the belt is too loose excess noise and

premature belt failure can occur.

3. Feed

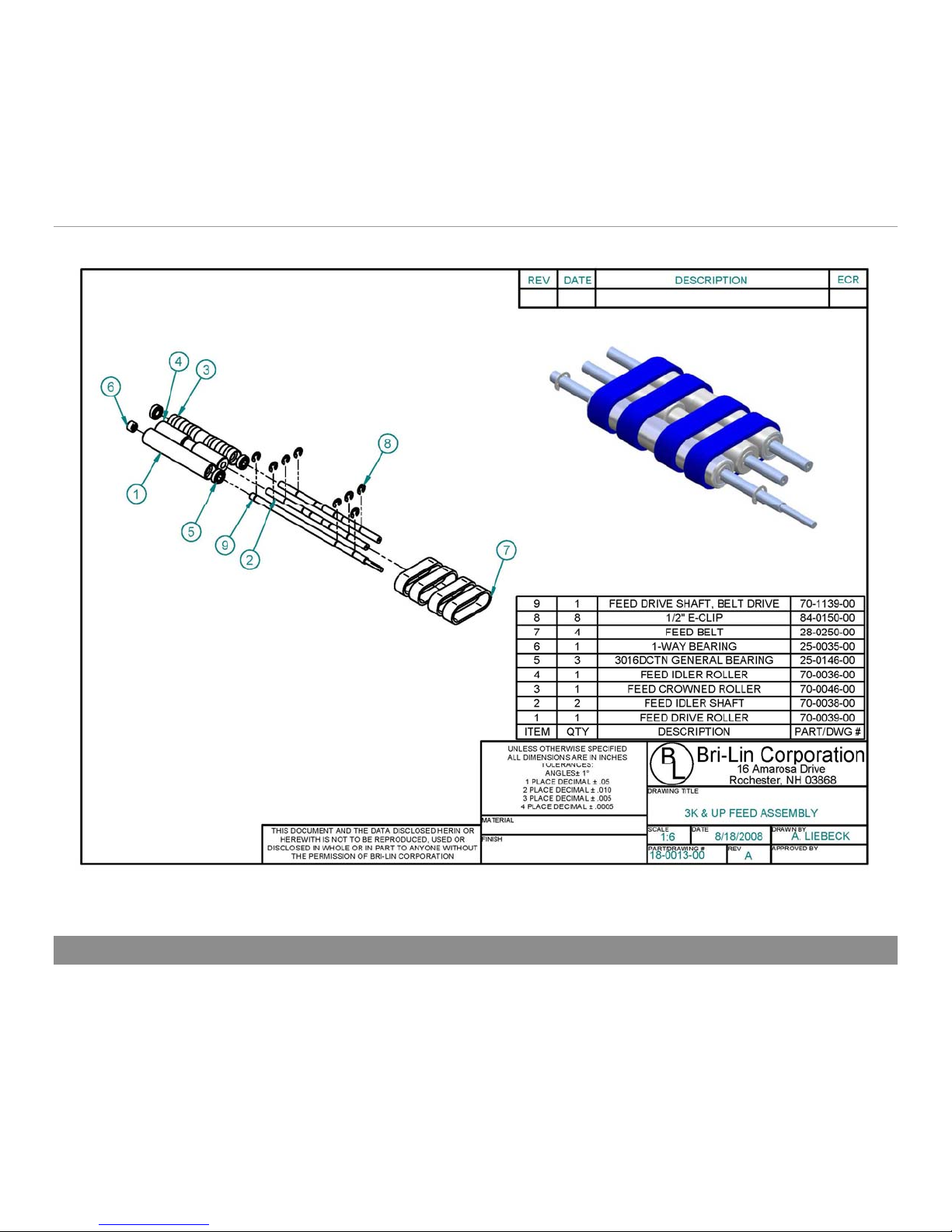

Figure 10: Feed Assembly

3.1. Feed Table

a) Removal

•Disconnect the power cord from the machine.

1. Remove both the side covers.

2. Remove the feed pulleys and belt.

3. Remove the feed table screws, 2x per side (4x total). (See Figure 19)

4. Remove the feed table.

13

b) Installation

1. Installation is the reverse of removal.

3.2. Feed Drive Belts

a) Removal

•Disconnect the power cord from the machine

1. Remove the E-clips from the drive shaft (4x).

2. Remove shaft support screws from the side frames. (See Figure 19)

3. Slide the drive shaft through the drive train side frame.

4. Pull the idler shafts out the back side of the chassis.

5. Remove the belts.

a)Inspect the belts for any wear or damage. If any is found replace the belts.

b) Installation

1. Place the idler rollers onto the idler shafts and place the belt around the rollers.

a)Insert the drive roller inside the belts. (Note: ensure that

the 1-way bearing is positioned on the side closest to the

electrical side frame)

b)Insert the idler shafts, rollers and belts into the chassis and

insert shaft screws into the side frame.

Note: The crowned roller goes to the back of the machine. (See

Figure 10)

2. Insert the drive shaft through drive train side frame, insert the

shaft into the drive roller as the shaft is being inserted into the

side frame.

3. Replace the E-clips (4x).

4. Ensure belts are aligned and are oriented with the blue side

visible.

5. Reinstall feed pulleys and belt.

c) Adjustment

Paper Feed Tray Width Adjustment

Place a squared up stack of the paper to be used into the tray and align the paper to the fixed side of the tray.

Adjust the sliding side so that there is approximately 1/8 inch between the stack of paper and the guide. If there is

no gap the paper may bind and not feed; if too loose paper may feed crooked.

Fi

g

ure 12: Feed Rollers and Belts

14

4. Feed Gauge

Figure 11: Feed Gauge Assembly

a) Removal

•Disconnect the power cord from the machine.

1. Remove the feed gauge cover.

2. Remove both side covers.

3. Remove the x-tie screws from both side frames.

(See Figure 19)

4. Pull the feed gauge assembly up and out of the

machine.

Note: If the x-Tie is too tight in the chassis to remove it

maybe necessary to loosen the feed table, feed idler

shafts, conveyor, sensor x-tie, and front & rear

motor guard screws on the motor side frame. (See

Figure 19)

b) Installation

1. Assembly is the reverse of the removal.

2. Adjust the feed gauge.

c) Adjustment

•Disconnect the power cord from the machine.

1. Remove feed gauge cover

2. Place 1 form on the feed table and hand feed the form into the machine by moving the feed belt with your

hand.

3. Pull the paper out of the machine. You should feel resistance, but not too much. Turn the adjustment screw

clockwise for less resistance and counter-clockwise for more resistance.

Figure 12: Cross-section of Feed Gauge

Adjustment Screw

15

5. Nip Wheel

ITEM PartNo DESCRIPTION QTY.

1 70-0070-00 Nip Wheel Caster 1

2 70-0071-00 Nip Wheel Block 1

3 70-0072-00 Nip Wheel 2

4 70-0073-00 Nip Wheel T-Hinge 1

5 80-0165-00 Shoulder Screw, 1/4" x 5/8" x #10-24 2

680-0188-00 Set Screw, SSS #10-32 x 1/4" 1

784-0065-00 Red #10-32 Thumb Screw 1

884-0161-00 E-Clip, 1/4" Shaft, .025" Thick 4

984-0272-00 Mylar Velvet 1

54

1

7

6

2

8

3

9

Bri-Lin Corporation

16 Amarosa Drive

Rochester, NH 03868

B

L

DRAWING TITLE

PART # REVISION DRAWN BY

DRAWING # SCALE DRAWING DATE

18-0105-00

MD-0105-00

A

1/11/2005

MATERIAL

FINISH

UNLESS OTHERWISE SPECIFIED

ALL DIMENSIONS ARE IN INCHES

TOLERANCES:

ANGLES 1

1 PLACE DECIMALS .05

2 PLACE DECIMALS .010

3 PLACE DECIMALS .005

4 PLACE DECIMALS .0005

1:3

THIS DOCUMENT AND THE DATA DISCLOSED HERIN OR

HEREWITH IS NOT TO BE REPRODUCED, USED OR DISC-

LOSED IN WHOLE OR IN PART TO ANYONE WITHOUT THE

PERMISSION OF BRI-LIN CORPORATION

NOTE: Static Brush Part #55-0388-00 not shown

Figure 13: Nip Wheel

a) Removal

•Disconnect the power cord from the machine.

1. Remove both the side covers.

2. Remove the x-tie screws from both side frames.(See Figure 19)

3. Slide the nip wheel assembly out of the front of the machine.

b) Installation

Installation is the reverse of the removal.

c) Adjustment

Note: The nip wheel should be adjusted every time a new fold or

form is used that yields a different final size.

1. Set the form with desired fold onto the conveyer so that it is

touching the edge of the roll.

2. Adjust the nip wheel so that it is ½” from the other side of the

folded form. (See Figure 14)

Figure 14: Nip Wheel Adjustment

Folded

Form

Roll

Nip

Wheel

NIP WHEELS MAY NOT BE

WHITE

16

6. Conveyor

Figure 15: Extended Conveyor

6.1. Extended Conveyor Belts

Note: Only the 7K Plus is equipped with the extended conveyor, the 7K is equipped with the standard conveyor which

does not contain the additional conveyor table and belts.

a) Removal

•Disconnect the power cord from the machine.

1. Remove the E-clips on both the idler shafts (8x).

2. Remove the springs from both idler shafts.

Note: Different size springs are used for the intermediate idler shaft and for the final idler shaft.

3. Remove the feet from the final idler shaft.

4. Slide and orient the final idler shaft in table slot to allow for removal and slide the shaft out of the table.

5. Remove the extended conveyor arm from one side of the

extended conveyor.

6. Slide and orient intermediate idler shaft in the table slot

to allow for remove and then slide it out of the table.

7. Remove the conveyor belts.

b) Installation

1. Place the conveyor belts around the rolls on both

conveyor tables.

2. Place the extended table near the conveyor table and

insert the intermediate shaft into the table, making sure

Figure 16: Conveyo

r

17

that the belts for the extended conveyor are on the pulleys.

3. Reattach extended conveyor arm.

4. Orient the shaft such that the bore for the spring is aligned with the notch for the spring, insert springs.

5. Insert E-Clips onto the intermediate idler shaft (4x).

6. Place and hold the final idler rollers inside the extended conveyor belt.

7. Slide the final idler shaft in place.

8. Insert E-Clips (4x).

9. Orient the shaft such that the bore for the spring is aligned with the notch for the spring, insert springs.

10. Reattach the feet so that the conveyor table sits evenly.

7. Wiper

3

2

1

Bri-Lin Corporation

16 Amarosa Drive

Rochester, NH 03868

B

L

DRAWING TITLE WIPER ASSEMBLY

PART # REVISION DRAWN BY

DRAWING # SCALE DRAWING DATE

18-0219-00

MD-0219-00

A

1/11/2005

AAS

MATERIAL

FINISH

UNLESS OTHERWISE SPECIFIED

ALL DIMENSIONS ARE IN INCHES

TOLERANCES:

ANGLES 1

1 PLACE DECIMALS .05

2 PLACE DECIMALS .010

3 PLACE DECIMALS .005

4 PLACE DECIMALS .0005

1:1.5

THIS DOCUMENT AND THE DATA DISCLOSED HERIN OR

HEREWITH IS NOT TO BE REPRODUCED, USED OR DISC-

LOSED IN WHOLE OR IN PART TO ANYONE WITHOUT THE

PERMISSION OF BRI-LIN CORPORATION

ITEM PartNo DESCRIPTION QTY.

170-0220-00 Felt Holder 1

270-0221-00 Wiper Felt Strip 1

384-0164-00 Black #10-32 Thumb Screw 3

Figure 17: Wiper Assembly

a) Removal

1. Remove all three thumb screws.

2. Slide the wiper assembly off the x-tie and remove from the machine.

3. Inspect the felt wiper, if it is dirty flip over or replace.

b) Installation

1. Slide the wiper assembly in place.

2. Insert the two thumb screws facing out the front of the machine.

3. Adjust the pressure on the roll so the felt is slightly touching. Check that the holder is parallel with the roll.

Note: If the felt is pressing too hard on the roll it can increase the load on the motor and reduce the performance

of the machine. If the felt is not contacting the roll it will not properly clean and can mark up the forms with ink.

4. Insert the last thumb screw into the top of the felt holder.

18

8. Rolls

Note: If roll configuration is different than shown, see addendum

Figure 18: Rolls

a) Removal

•Disconnect the power cord from the machine.

1. Remove the all drive train components. (See Section: 2)

2. Remove the fold trays, simply lift up trays and slide out of chassis.

3. Remove the feed gauge x-tie mounting screws from the drive train side of the chassis. (See Figure 19)

4. Remove the feed table mounting screws from the drive train side of the chassis. (See Figure 19)

5. Remove the feed roller mounting screws from the drive train side of the chassis. (See Figure 19)

6. Remove the conveyor table mounting

screws from the drive train side of the

chassis. (See Figure 19)

7. Remove the nip wheel x-tie mounting

screw from the drive train side of the chassis.

(See Figure 19)

8. Remove the drive motor guards and the

drive motor mounting screws. The drive

motor can be left in the machine.

9. Ensure the electrical side cover is in place

and on a sturdy surface tip the machine so

that the electrical side is face down. Ensure

the drive motor is securely resting and no

wires are being pinched or stretched.

10. Remove the base plate mounting screws

and rear leg from the drive train side frame.

11. Slide the drive train side frame off of the

rolls and remove. SERVICING THE ROLLS

19

12. Inspect the rolls for wear and replace any damaged or worn components.

a)Clean rolls by wiping down with a household cleaner such as OOPS or the equivalent.

b) Installation

1. Installation is the reverse of removal

Figure 19: Side Frame Screws

This view is shown with roller bearings

Note: If Frames are not as shown, see addendum

RollerBearing NeedleBearing

Part # 25-1103-00 Part # 25-0167-00

BEARING IDENTIFICATION

Feed Gauge X-tie

Conveyor Table

Feed Idler Shafts

Rear Motor

Guard

Front Motor Guard

Feed Table

Drive Motor (4x)

Cover (4x)

Nip Wheel X-Tie

20

9. Electrical

Figure 20: Electrical Components (Optional Fuji Drive not shown #29-0697-00)

9.1. Drive Motor

a) Removal

•Disconnect the power cord from the machine

1. Remove both the side covers.

2. Remove the rear motor guard.

a)Unscrew the power switch bracket from the electrical

side frame.

b)Unscrew and remove the rear motor guard.

3. Disconnect the electrical leads from the motor.(See

Appendix)

4. Remove the motor clutch with pulley. (See Section 2.2)

5. Remove the motor mounting screws and slide the

motor from the chassis.

b) Installation Motor Part #30-0658-00

1. Installation is the reverse of the removal.

9.2. Touch Screen

a) Removal

•Disconnect the power cord from the machine.

1. Remove the electrical side cover.

2. Remove the small holding brackets (4x).

3. Unplug the electrical connector from the unit.

4. Remove the touch screen and if faulty replace with a new

unit.

Table of contents

Other Infinity Solutions Food Saver manuals

Popular Food Saver manuals by other brands

Pro-Line Boats

Pro-Line Boats VS-CHD2 user manual

FoodSaver

FoodSaver Vacuum Sealing System user manual

ACME

ACME DSR-220 Operation, parts and safety manual

IPG

IPG INTERPACK USA 2024-BFF Operations manual & parts list

3M

3M 3M-Matic 7000r-I Instructions and parts list

Lava

Lava V.300 Premium operating instructions