BJS Biotechnologies xxsealer User manual

PCR plate heat sealer with programmable

temperature and dwell

User Manual

This Manual Copyright © 2014 BJS Biotechnologies

Page | 2

All rights reserved. No part of this manual may be reproduced, stored in

a retrieval system, or transmitted, by any means or in any form, without

the prior permission of BJS Biotechnologies Ltd (BJS Bio).

The information contained in this manual is subject to change without

notice. BJS Bio

assumes no responsibility for any errors that may

appear in this or related documentation.

Document: XP-5003-01-1

Revision: 1.0 Jan 2014

xxpress® xxplates, and xxsealer are the brand names for BJS

Biotechnologies own range of PCR thermal cycler products and

accessories. For further details please visit our web site.

www.xxpressPCR.com

All sales and technical enquiries should be addressed to:

BJS Biotechnologies Ltd

65 Bideford Avenue

Perivale

Greenford

Middlesex

UB6 7PP

United Kingdom

+44 (0)203 021 3750

sales@xxpressPCR.com or support@xxpressPCR.com

XXSEALER USER MANUAL - 1.0

Page | 3

Contents

1Glossary of Terms and Abbreviations .....................................................4

2Symbols Used in this Instruction Manual ................................................5

3Unit Description.......................................................................................6

4Technical Specification............................................................................9

5Safety Precautions and Limitations of Use............................................10

6Unit Installation......................................................................................14

7Unit Operation .......................................................................................16

7.1 User Display and Controls.....................................................................16

7.2 Operating the Controls of the xxsealer..................................................17

7.3 Performing an xxplate Sealing Operation..............................................18

7.4 Switching Off the Audible Alert..............................................................20

8Maintenance and Servicing...................................................................21

8.1 Replacing the Unit Fuse........................................................................21

8.2 Over Temperature Safety Cut-out.........................................................22

8.3 Routine Cleaning and Inspection ..........................................................22

8.4 Decontamination Procedure..................................................................23

8.5 Transportation and Storage...................................................................23

9Warranty and Returns ...........................................................................25

10 Product Disposal ...................................................................................26

Tables

Table 1: Advisory Symbol Meanings.............................................................5

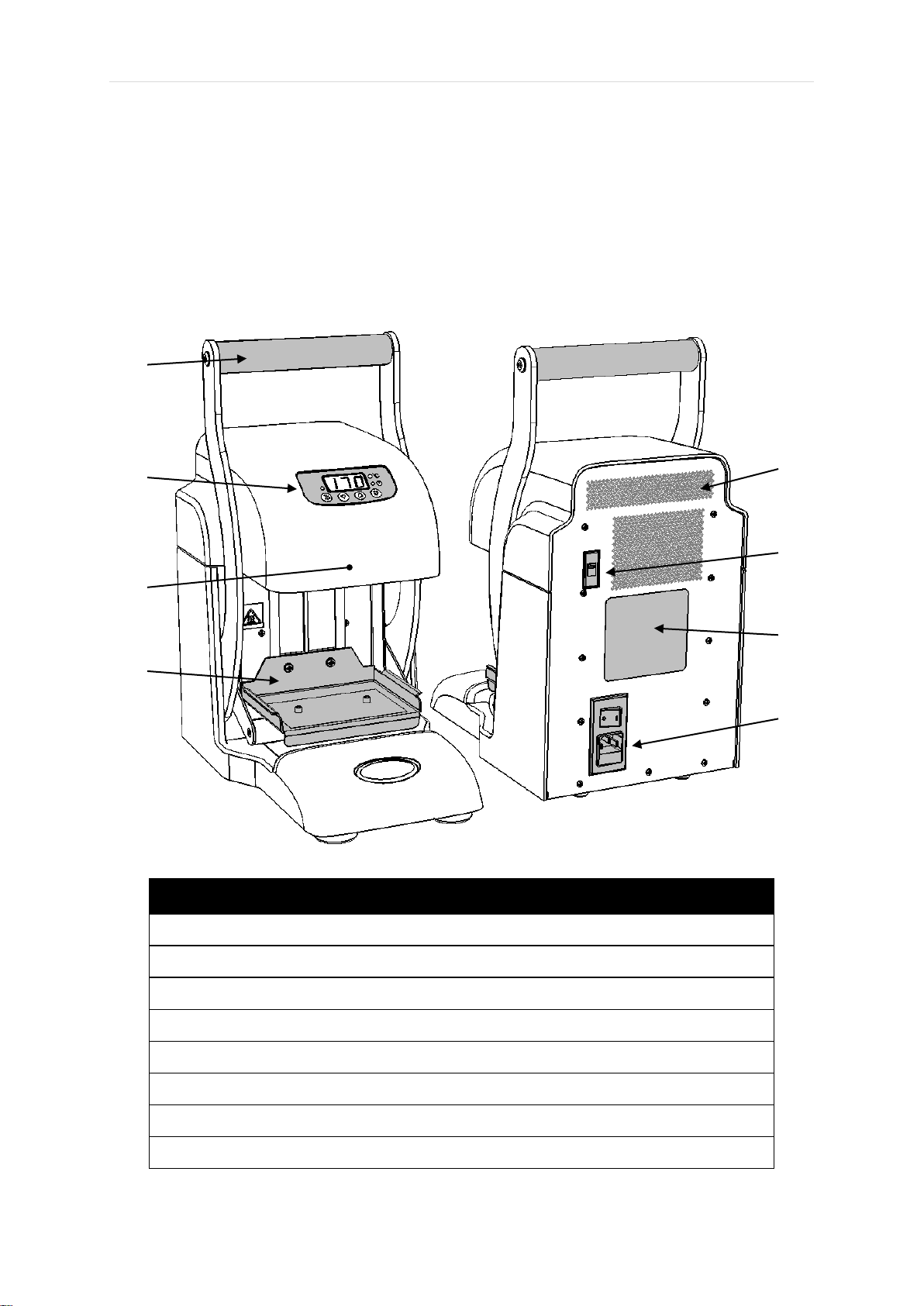

Table 2: Unit Features.....................................................................................6

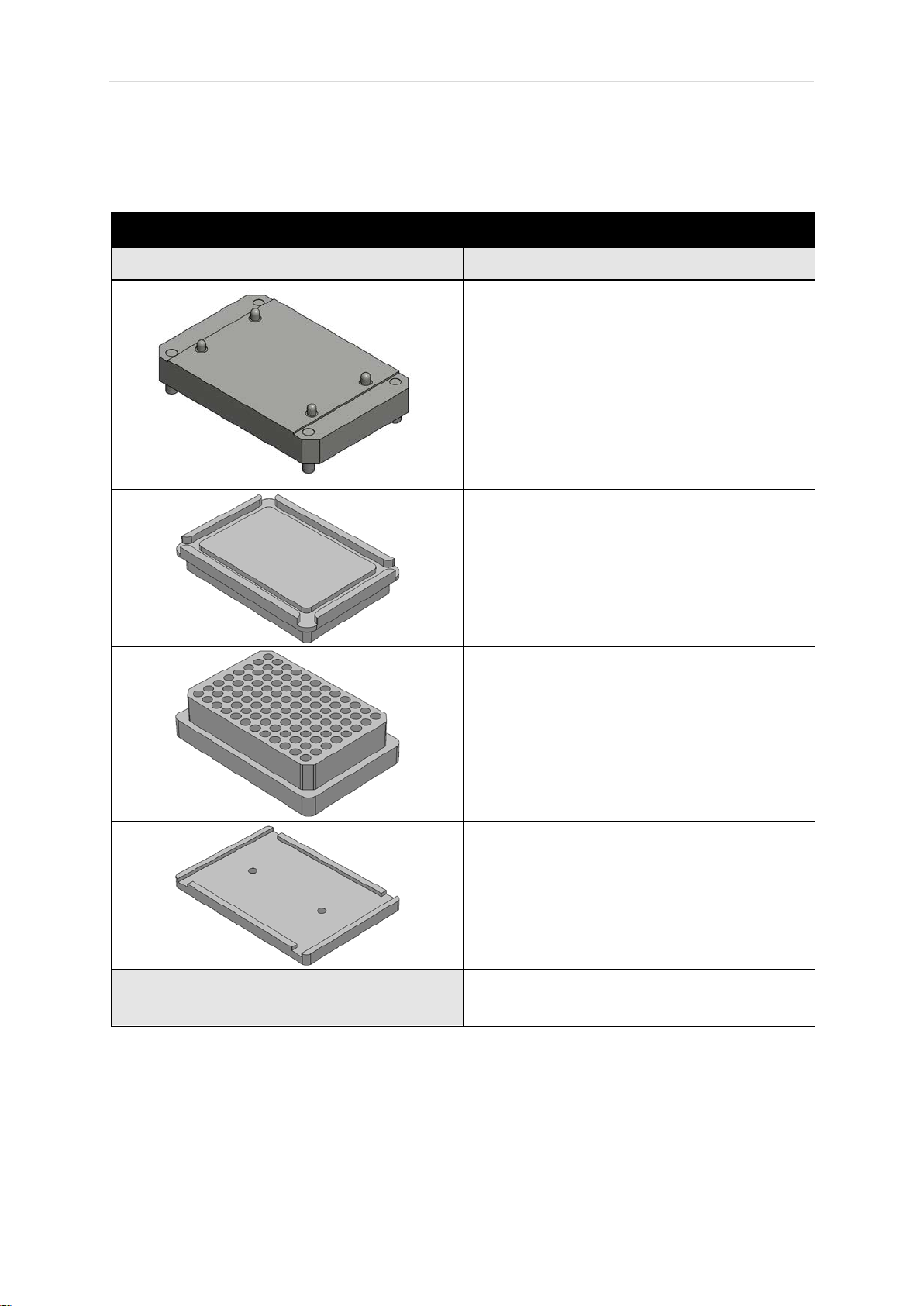

Table 3: Plate and Adaptor Block Types.......................................................7

Table 4: Recommended Film and Foil Types ...............................................8

Table 5: Mains Voltage Selection.................................................................14

Table 6: User Buttons and Status LEDs......................................................16

XXSEALER USER MANUAL - 1.0

Page | 4

1 Glossary of Terms and Abbreviations

ANSI

BJS Bio

American National Standards Institute

BJS Biotechnologies Limited, UK Company

Number 02959160

Deepwell Plate Plate with an SBS footprint featuring 48, 96 or

384 wells with a larger volume than microplates

DWP

Deepwell plate

EMC

Electro-Magnetic Compatibility

Microtitre Plate Plate with an SBS footprint featuring 24, 48, 96

or 384 wells

MTP

Microtitre plate

PCR

Polymerase Chain Reaction

PPE

Personal Protective Equipment

SBS

Society for Bio molecular Screening

Semi-skirted PCR

Plate PCR plate with an outer surrounding half edge

Skirted PCR Plate PCR plate with an outer surrounding edge

Un-skirted PCR

Plate PCR plate without an outer surrounding edge

Well

xxplate

A single sample cavity in a Microtitre plate,

PCR plate or Deepwell plate

BJS Bio PCR test plate for the xxpress real-

time thermal cycler. Available in 24, 54, and 96

well formats.

XXSEALER USER MANUAL - 1.0

Page | 5

2 Symbols Used in this Instruction Manual

The following advisory symbols are used in this manual.

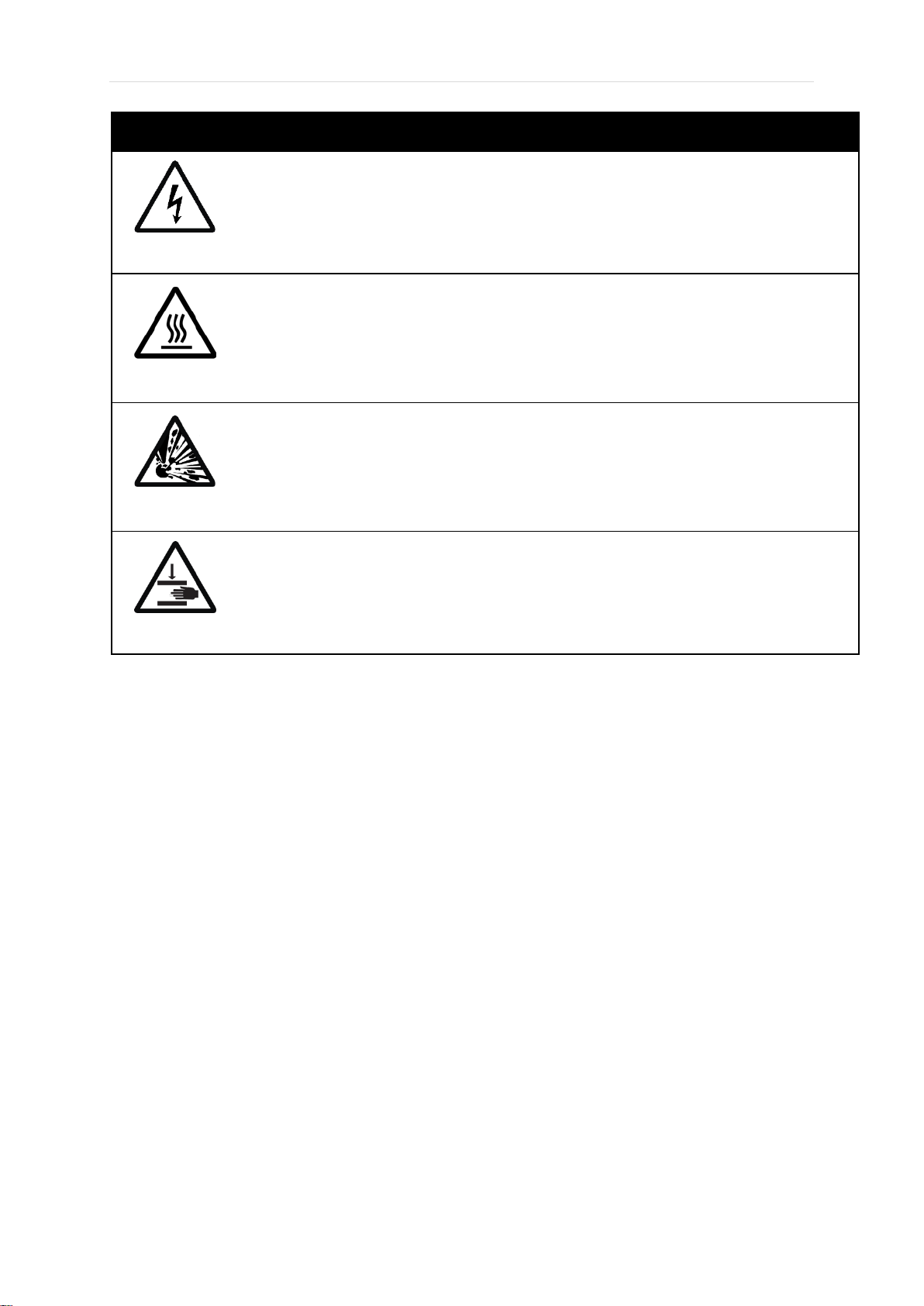

Table 1: Advisory Symbol Meanings

DANGER

Indicates a Risk of Electric Shock which could, if not

avoided, result in serve injury or death.

DANGER

Indicates a Burn Hazard which could, if not avoided,

result in serve injury or death.

DANGER

Indicates a Risk of Explosion which could, if not

avoided, result in serve injury or death.

WARNING

Indicates a hazardous situation which could, if not

avoided, result in serve injury or death; or severely

damage the unit.

CAUTION

Indicates a hazardous situation which could, if not

avoided, result in minor or moderate injury; or degrade

or impair the functionality of the unit.

CAUTION

Indicates a Risk of Crush hazard due to moving parts

which could, if not avoided, result in minor or moderate

injury.

Advisory note or other useful information.

NN Refer to “Section NN” for more details.

XXSEALER USER MANUAL - 1.0

Page | 6

3 Unit Description

The xxsealer provides a safe and controlled method for sealing plastic

sample plates to protect the samples from evaporation and contamination

during the heating and cooling of a PCR process. The sealer is adjustable

for both the sealing time and temperature, and gives a visual countdown

display during the sealing process for consistent results.

The unit has the following external features:

Table 2: Unit Features

Seal Activation Handle

7.2

User Interface Display and Control Buttons

7.1

Heater Plate (Internal)

7.1

Adaptor Block Carrier

Table 3

Rear Ventilation Holes

5

Mains Voltage Selector

5

Product Information Label

4

Power Inlet, On/Off Switch and Fuse Holder

5

XXSEALER USER MANUAL - 1.0

Page | 7

The xxsealer unit is designed to be used with a range of sample plates

and consumables – some of which are listed below:

Table 3: Plate and Adaptor Block Types

Adaptor Block Type

Suitable Plate Types

BJS xxplate

(Suitable for 24, 54, and 96 well

xxplates)

96 Well Microtiter Plate

384 Well Microtiter Plate

PCR 96 Well Skirted Plate

PCR 96 Well Semi-skirted Plate

PCR 96 Well Un-skirted Plate

Deepwell Plates

Plate Material Types

Polypropylene, Polyethylene or

Polystyrene

Other specialist adaptor plates may be available at request. Please

contact your distributor for details.

XXSEALER USER MANUAL - 1.0

Page | 8

Table 4: Recommended Film and Foil Types

Films

Clear Polyester/Polypropylene

Laminate

Clear Polymer

Thin Clear Polymer

Foils

Foil Polypropylene Laminate

Foil Laminate

Foil

Note:

The only film approved for use with xxplates is the BJS Bio’s xxplate

sealing film. Part number HS-3001-01-1.

XXSEALER USER MANUAL - 1.0

Page | 9

4 Technical Specification

Model Type

Model Name

Model No

xxsealer

VTS-953-A

Physical Unit Properties

Dimensions (W x D x H)

Weight (without adaptor)

220 mm x 325 mm x 425 mm

7.2 kg

Mains Supply

Power Cord Rating

Inlet Module Type

Supply Voltage Selections

Supply Frequency Range

Power Consumption

Fuse Ratings and Sizes

IEC C13, 3-Core, 5A min

IEC C14, DPST, Single Fuse

115 110 to 120 VAC ±10%

230 220 to 230 VAC ±10%

50 to 60 Hz ±5%

350 W max

115 T3.15AH 250V 20x5mm

230 T1.6AH 250V 20x5mm

Operating Environment

Temperature Range

Relative Humidity Range

Maximum Operating Altitude

+18 to +30 °C

20% to 80% non-condensing

2200 m above sea-level

Storage and Transportation

Temperature Range

Relative Humidity Range

-10 to +50 °C

20% to 95% non-condensing

Sealing Parameters

Temperature Range

Timer Range

Audible Alert

125 to 200 °C in 1 °C steps

1.0 to 9.0 seconds in 0.5 second steps

On or Off

XXSEALER USER MANUAL - 1.0

Page | 10

5 Safety Precautions and Limitations of Use

It is essential that all users of this equipment have fully read and

understood the following safety precautions and limitations of use before

installing or operating the xxsealer unit.

IMPORTANT

WARNING

The protection provided by this equipment may be impaired if

it is not used in a manner described in this manual.

WARNING

It is essential that the user of this equipment is aware of the

potential hazards associated with the unit and its accessories.

All

operators should be familiar with the safety precautions and

warnings given in these instructions before attempting to

operate the unit.

Improper use of this unit or its accessories may impair their

functionality and invalidate the manufacturer’s warranty.

Unit Handling Precautions

CAUTION

Care should be taken not to drop the unit or subject it to rough

physical handling, both during normal use and during

transportation and storage.

WARNING

The unit should be held by the handle when being lifted or

moved. Do not lift the unit by any other part of the casework.

Care should be taken when lifting the unit due to its weight.

CAUTION

Care should be taken not to knock the LED display.

Do not use excessive force when pressing the control buttons

or operating the seal activation handle.

XXSEALER USER MANUAL - 1.0

Page | 11

Unit Installation and Operating Environment

DANGER

WARNING

The xxsealer unit is designed for indoor laboratory use only.

The acceptable operating temperature range is 18ºC to 30ºC,

with a relative humidity of 20% to 80% non-condensing, at a

maximum altitude of 2200m above sea level.

If the unit is stored in conditions outside of these ranges, it

must be left to stand unpowered until it has acclimatised to

within these environmental limits before being powered.

DANGER

Use only the AC mains power cord provided with the unit or as

specified Section 4.

The unit must be connected to a suitably earthed mains

supply, with appropriate earth-leakage and over-current

protection.

WARNING

Always ensure that the mains power connector is securely

inserted into the rear of the unit, and any excess power cord

does not pose a potential trip or pull hazard.

DANGER

Do not operate the unit in any area which is, or has been, or is

thought to have been exposed to explosive or flammable

gases, vapours or liquids.

WARNING

The unit must be installed and operated on a solid, stable and

level working surface; ensuring that the ventilation holes at the

rear of the unit are not obstructed.

XXSEALER USER MANUAL - 1.0

Page | 12

General Operating Precautions

DANGER

Ensure that the power is switched off at both the AC mains

supply outlet and at the back of the unit before inserting or

removing the mains power cord.

DANGER

The heater plate can reach temperatures of 200ºC and will

remain hot for a considerable time after being turned off.

Extreme care must be taken not to touch the heater plate as it

will cause a serve burn injury.

DANGER

The unit is intended for use with plates containing biological

samples only.

Never use the unit to seal any explosive, volatile or highly

reactive substances or chemicals.

CAUTION

There is a possible finger crush hazard due to the moving

parts of the handle and plate carrier.

Care should be taken when operating the handle.

XXSEALER USER MANUAL - 1.0

Page | 13

Unit Maintenance and Serviceability

DANGER

WARNING

There are no user or operator serviceable parts inside the unit.

Do not remove the unit casework.

Removal of the unit's casework will void the manufacturer’s

warranty and may expose the user to a Risk of Electric Shock

resulting in serious injury or death.

DANGER

Once installed, the externally accessible unit fuse will only

blow under a fault condition. This fuse should only be changed

after the unit has been thoroughly inspected by a qualified

engineer. See Section 8.1 for details.

DANGER

Always switch off the unit and disconnect the power cord

before performing any cleaning or decontamination procedure.

If liquid is spilt into or over the unit, switch off and disconnect

the power from the AC mains outlet before attempting to deal

with the spillage.

CAUTION

Ensure that the heater plate has cooled down to room

temperature before performing any cleaning operation and

before moving or storing the unit.

CAUTION

The use of harsh chemicals and cleaning agents may damage

the unit and degrade its performance.

Always follow the cleaning and decontamination procedures

specified in Sections 8.3 and 8.4 of this instruction manual.

CAUTION

Do not autoclave any part of the unit or its accessories.

XXSEALER USER MANUAL - 1.0

Page | 14

6 Unit Installation

Before installing the xxsealer unit, please check that the delivery is

complete and that the unit and any accessory parts are intact and free

from any signs of transportation damage. Also ensure that all external and

internal packaging has been removed from the unit before installation.

Please retain all packaging for future transportation and

storage of the unit and its accessories.

The xxsealer unit should be installed in a location which meets the

following requirements:

•Safe and suitable operating environment (see Section 5)

•Solid, stable, level working surface

•At least 10cm clearance around the unit to adjacent objects and

walls

•Earthed AC mains power connection (see Section 4)

WARNING

Please also observe and abide by the Unit Installation and

Operating Environment safety precautions and preconditions

listed in Section 5.

It is important the check that the Mains Voltage Selector switch on the rear

of the unit has been set to the correct position for the desired operating

voltage, and the correct value of fuse has been fitted (see Table 5).

Table 5: Mains Voltage Selection

Operating Voltage

110 to 120 VAC

220 to 230 VAC

Voltage Selection

See Section 3 for

switch location ()

on unit rear panel.

115

230

Fuse Rating

3.15AH

1.6AH

XXSEALER USER MANUAL - 1.0

Page | 15

WARNING

Ensure that the correct fuse type has been fitted in the mains

inlet fuse holder

for the desired voltage selector switch value.

See Table 5 for details.

1. Remove the AC plug

from the power inlet

module

2. Use a small flat bladed

screwdriver to carefully

pull out the fuse holder

3. Fit the correct fuse in the

far position only

4. Push the holder back

into the inlet mode

Install and test the xxsealer unit using the following procedure:

1) Place the unit on the suitably selected working surface (as

specified above), ensuring that the ventilation holes on the

rear of the unit are not obstructed.

2) Connect the unit to the AC mains power outlet using the

mains power cord supplied or as specified in Section 4.

3) Switch the mains power on at supply outlet first, and then

switch the unit on using the power switch located at the rear of

the unit.

4) Check that the unit is stable and safe by performing a trial

sealing operation, as described in Section 7.2.

DANGER

If the unit has been stored in a cool environment, it must be

left to stand unplugged until it has acclimatised to the new

room temperature before being powered.

XXSEALER USER MANUAL - 1.0

Page | 16

7 Unit Operation

WARNING

Please ensure that you have read and fully understood all of

the Safety Precautions and Limitations of Use listed in

Section 5 before attempting to operate the xxsealer unit.

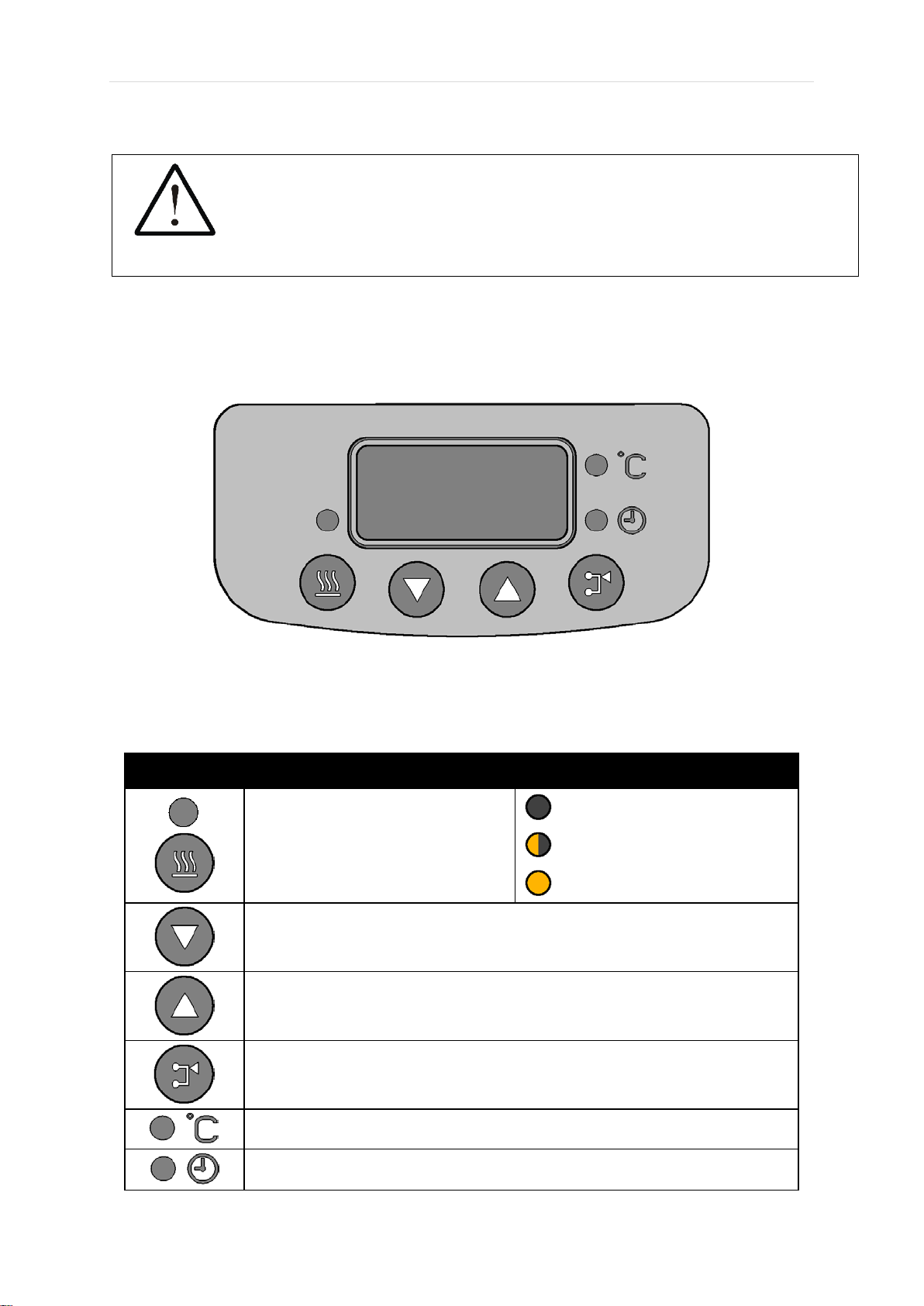

7.1 User Display and Controls

The unit’s user interface consists of a large 3-digit LED display, four

control buttons and three status indicator LEDs.

The LED display shows the current temperature or sealing time set-point

(depending on the mode). The button and LED functions are listed in

Table 6.

Table 6: User Buttons and Status LEDs

Heater Status LED

HEATER On/Off Button

Off – Heater Turned Off

Flashing – Warming Up

On – Unit Ready For Use

DOWN Button

UP Button

MODE Select Button

Temperature Mode LED

Timer Mode LED

XXSEALER USER MANUAL - 1.0

Page | 17

7.2 Operating the Controls of the xxsealer

When the unit is switched on, it recalls the last sealing operation settings

and the displays the sealing temperature or time (depending on the

display mode), and automatically restores the heater on/off state.

Pressing the MODE button toggles the LED display between the plate

heater Temperature set-point in degrees centigrade and the seal Timer

setting in seconds.

The sealing temperature is set by pressing the MODE button to illuminate

the Temperature LED ( ) then using the UP and DOWN buttons to

set the temperature in the range 125 to 200 ºC in 1ºC steps.

Likewise, the sealing time is set bypressing the MODE button to illuminate

the Timer LED ( ) then using the UP and DOWN buttons to set the

time in the range 1 to 9 seconds in 0.5 second steps.

Pressing the HEATER button toggles the plate heater between on and off.

When the Heater LED is flashing, the heater is onand theplate is warming

up, which will normally take about 10 minutes.

Once the Heater is on the LED display shows the current temperature or

sealing time set-point (depending on the mode).

When the heater plate is up to temperature (within 2ºC of the set-point)

the Heater LED will remain constantly on, and the xxsealer is ready to

begin sealing.

The operator may set a precise temperature and seal time for the sealing

operation. Sealing is initiated by pulling the handle down, which raises the

sample plate into contact with the heater plate. The unit detects when the

sample plate is correctly positioned and starts a countdown timer. When

the display reads zero, the operator moves the handle back to its upmost

position, which moves the sample plate away from the heater plate. The

sample plate is then manually removed for storage or further processing.

XXSEALER USER MANUAL - 1.0

Page | 18

7.3 Performing an xxplate Sealing Operation

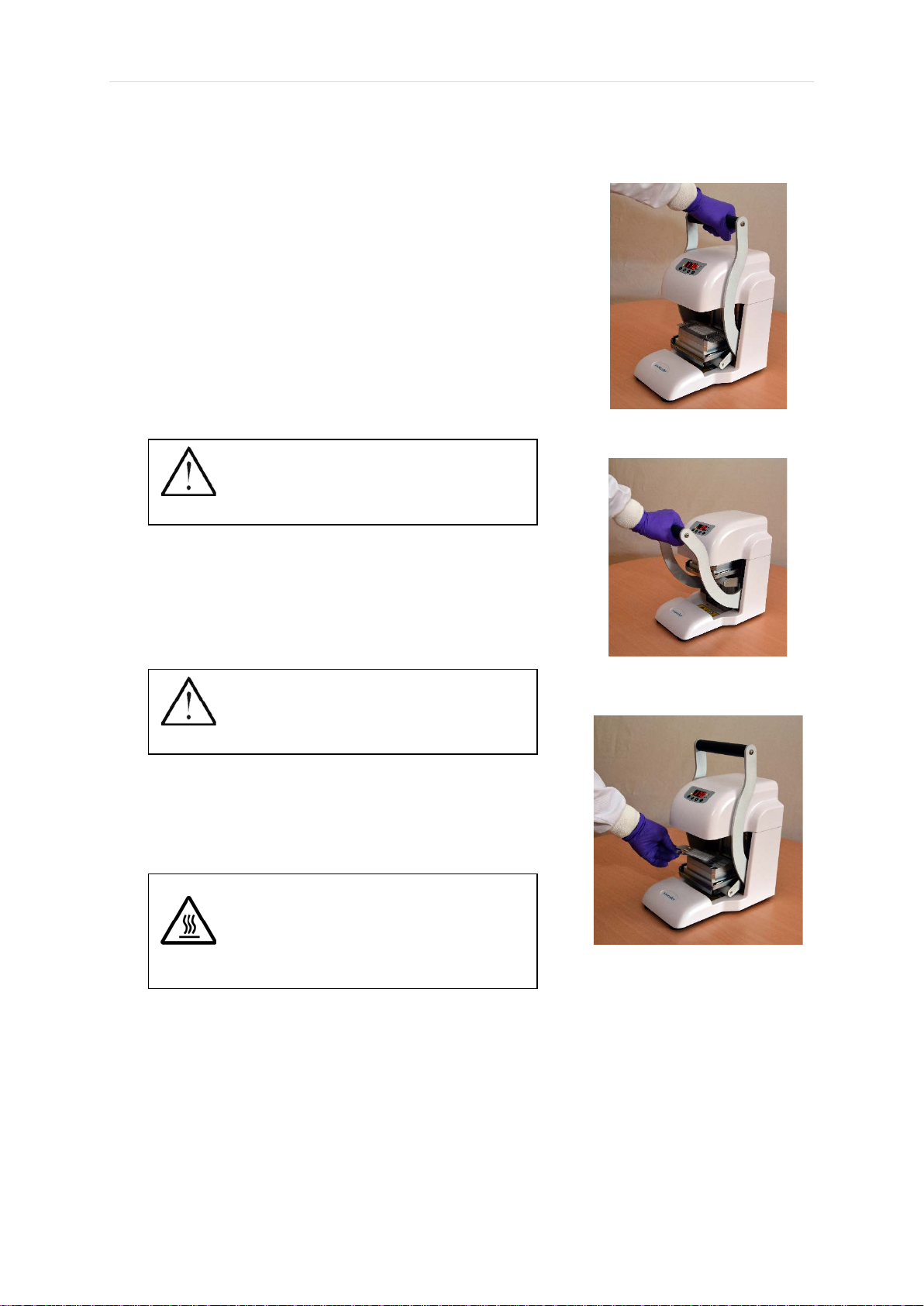

A typical operating sequence to seal an xxplate is:

1) Switch the unit on and set the sealing time to 1.5 seconds and the

heater plate set-point temperature to 170ºC (using the method

described above). These are the recommended setting for the

xxplate film.

2) If necessary, press the HEATER button to turn the heater on.

3) Allow sufficient time for the unit to reach temperature (the Heater

LED will stop flashing and remain constantly on).

4) Fit the BJS xxplate Adapter Block into the PCR 96 Well Skirted

Plate Adapter Block (both provided with the xxsealer) and locate

in the Adapter Block Carrier

5) Load the xxplate onto the xxplate Adapter Block locating it onto

the sprung pins. It should sit flat on the adapter block.

And add the sealing film on top, the correct way up.

WARNING

Care should be taken not to touch

the surface of the heater plate whilst

loading the sample plate.

XXSEALER USER MANUAL - 1.0

Page | 19

6) Grasp the handle with one or two hands, as

appropriate, and pull the handle forward

and down to raise the plate carrier until the

sample plate contacts the heater plate.

7) When correct sealing pressure is achieved,

an audible alert will sound (if enabled – see

Section 7.4) and the timer will start counting

down from the set value. When zero

seconds is reach, the display will flash and

the audible alert sound.

CAUTION

Do not to apply more force to the

handle than is necessary to operate

the start switch.

8) Immediately return the handle to its upmost

position to retract the sealed sample plate

from the heater plate.

CAUTION

Failure to release the handle when

sealing is complete could degrade

the sample plate and seal quality.

9) Remove the sealed plate from the unit and

review the seal integrity.

WARNING

The sample plate and film/foil may

remain hot for several seconds after

being removed from the unit.

For optimum performance, the sealing temperature and/or time may need

to be adjusted to best suit the sample plate and film/foil types being

sealed. Various types of plastic sample plate may be loaded onto a plate

carrier and thermal sealed using a suitable foil or clear film. See Section

3 for details.

XXSEALER USER MANUAL - 1.0

Page | 20

7.4 Switching Off the Audible Alert

The unit is fitted with an audible alert which sounds at the beginning and

end of each sealing operation.

If desired, this alert can be turned off (or back on again) using the following

procedure:

1) If necessary, press the MODE button to select the Temperature

LED setting mode.

2) Next, simultaneously press both the HEATER and MODE buttons

together.

3) The display should show “01” or “00”. If it does not, repeat this

procedure from step 1 above.

4) Now press the DOWN button to turn the alert off (display shows

“00”) or the UP button to turn the alert back on (display shows “01”).

5) Finally, press the MODE button to store the new setting.

XXSEALER USER MANUAL - 1.0

Table of contents

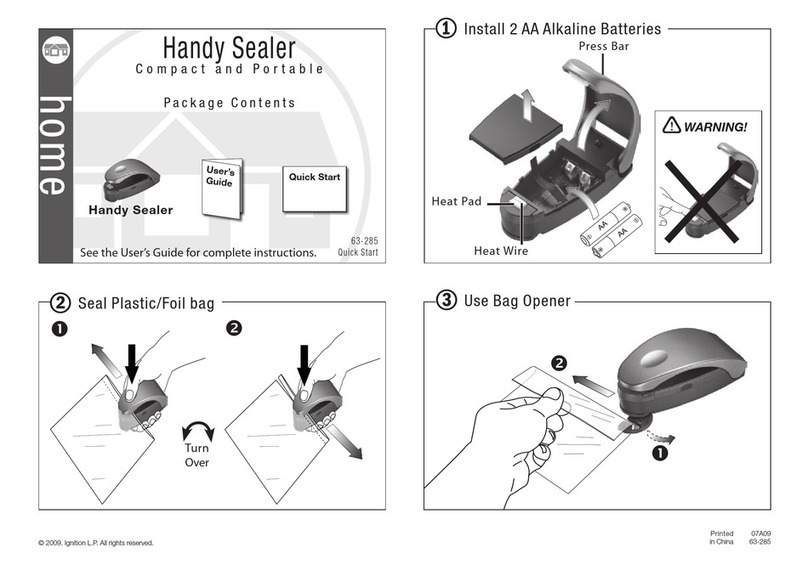

Popular Food Saver manuals by other brands

Radio Shack

Radio Shack 63-285 quick start

Chesterton

Chesterton TwinHybrid 4400H Installation, Operation and Rebuild Instructions

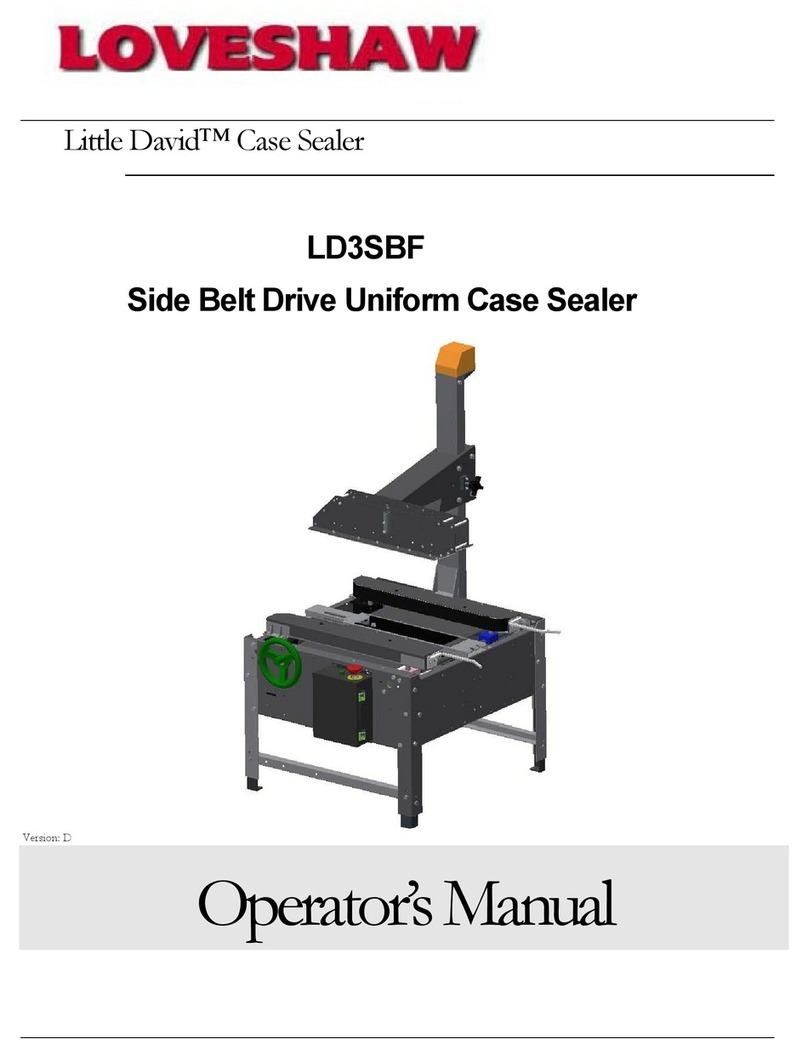

Loveshaw

Loveshaw LD3SBF Operator's manual

Braukmann

Braukmann CASO DESIGN VC200 Original operating manual

SOLIS

SOLIS VAC PREMIUM quick start guide

Biobase

Biobase BK-BTS1 user manual

Craftworx

Craftworx 1A-DS217 instruction manual

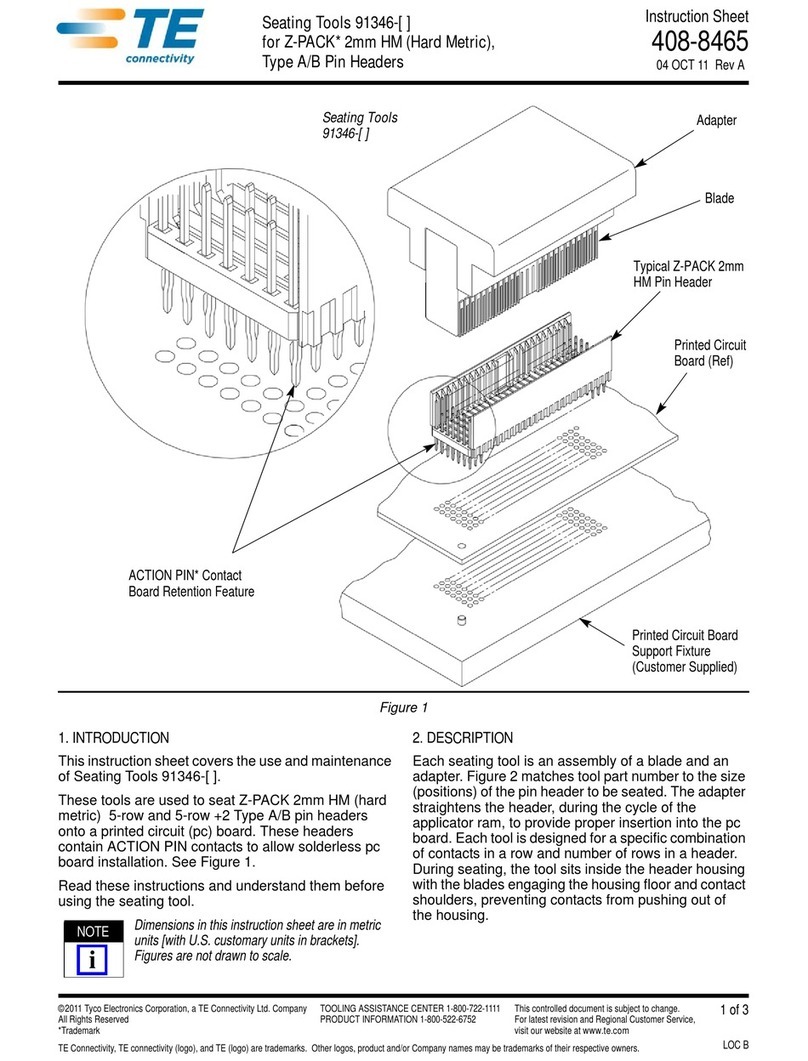

TE Connectivity

TE Connectivity 91346 Series instruction sheet

Cryo Bio System

Cryo Bio System SYMS I user manual

FoodSaver

FoodSaver V5800 Series owner's manual

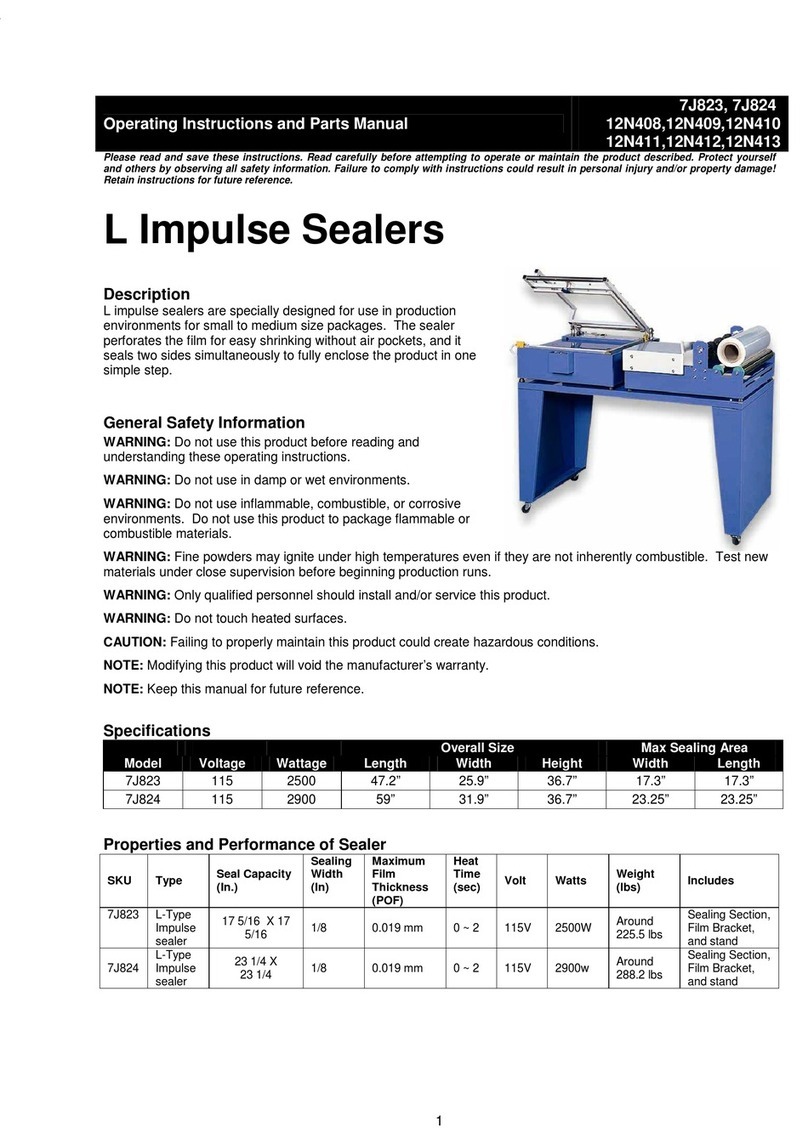

ASAHI

ASAHI HIPPO AS-V-320 user manual

Grainger

Grainger 7J823 Operating instructions and parts manual