1000 Series Ho-Pac

SECTION 3.0

PRINCIPLES OF OPERATION

3.1 Ho-Pac

The Allied Ho-Pac is a high-energy

compaction tool utilizing three compaction

techniques:

• The IMPULSE FORCE generated

by the rotating eccentric mass

vibrates the soil near the base plate

to eliminate voids between material

particles.

• The VIBRATION FREQUENCY

of 2000 r.p.m. provides maximum

effectiveness for the consolidation

and compaction of granular soil

materials.

• The DOWN FORCE of the carrier

provides a preload force to

effectively transfer the vibrating

energy and to compress the

material.

Optimum compaction is usually obtained

with two passes. The duration of the initial

pass is dependent on depth and material.

The second pass may require additional fill

material and Ho-Pac repositioning to

achieve a finished surface.

The Allied Ho-Pac can also be an effective

sheet or pile driver. The Ho-Pac’s

vibration energy is transferred through the

sheet or pile to the soil. Sandy soils and

moist clays are “softened” by the vibration,

which allows the sheet or pile to penetrate

more easily.

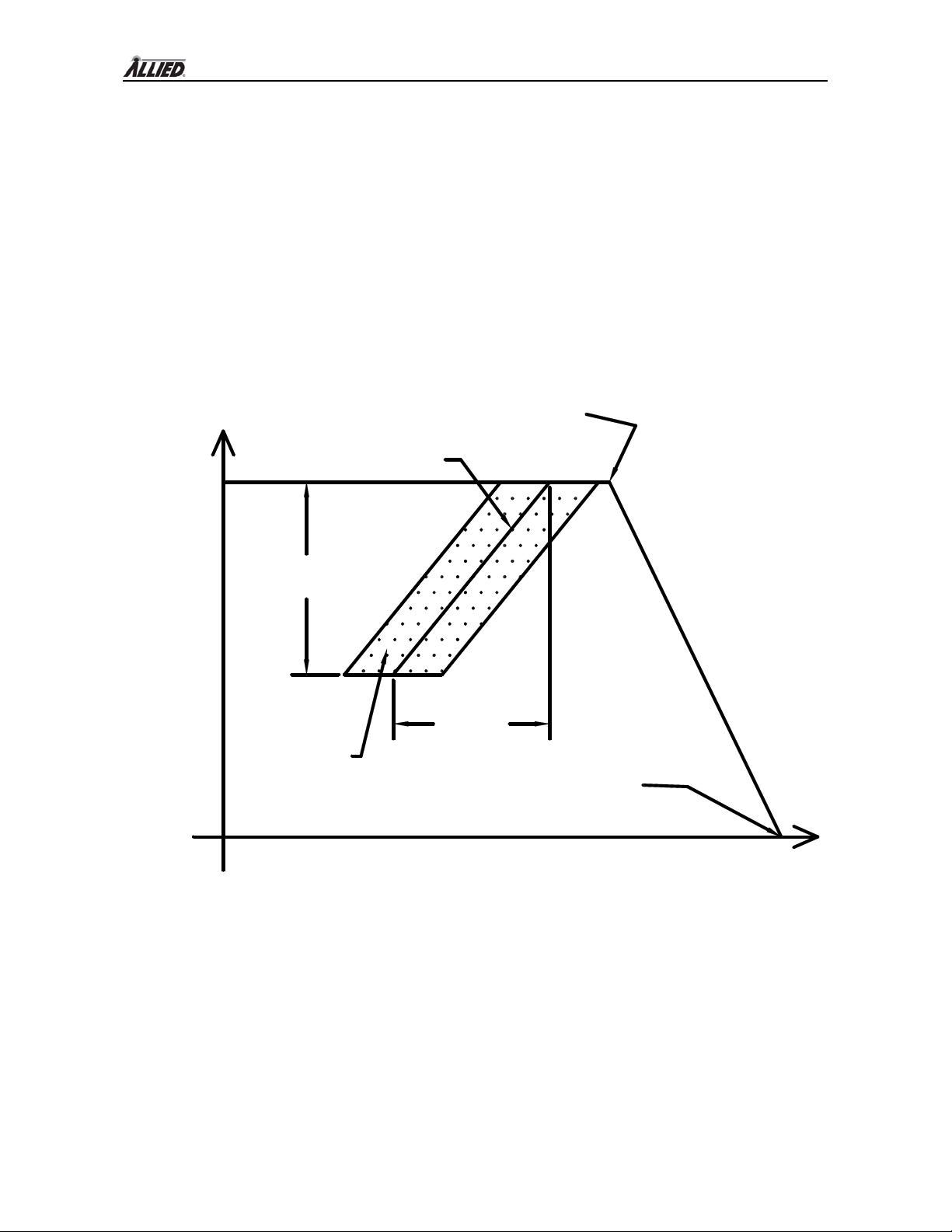

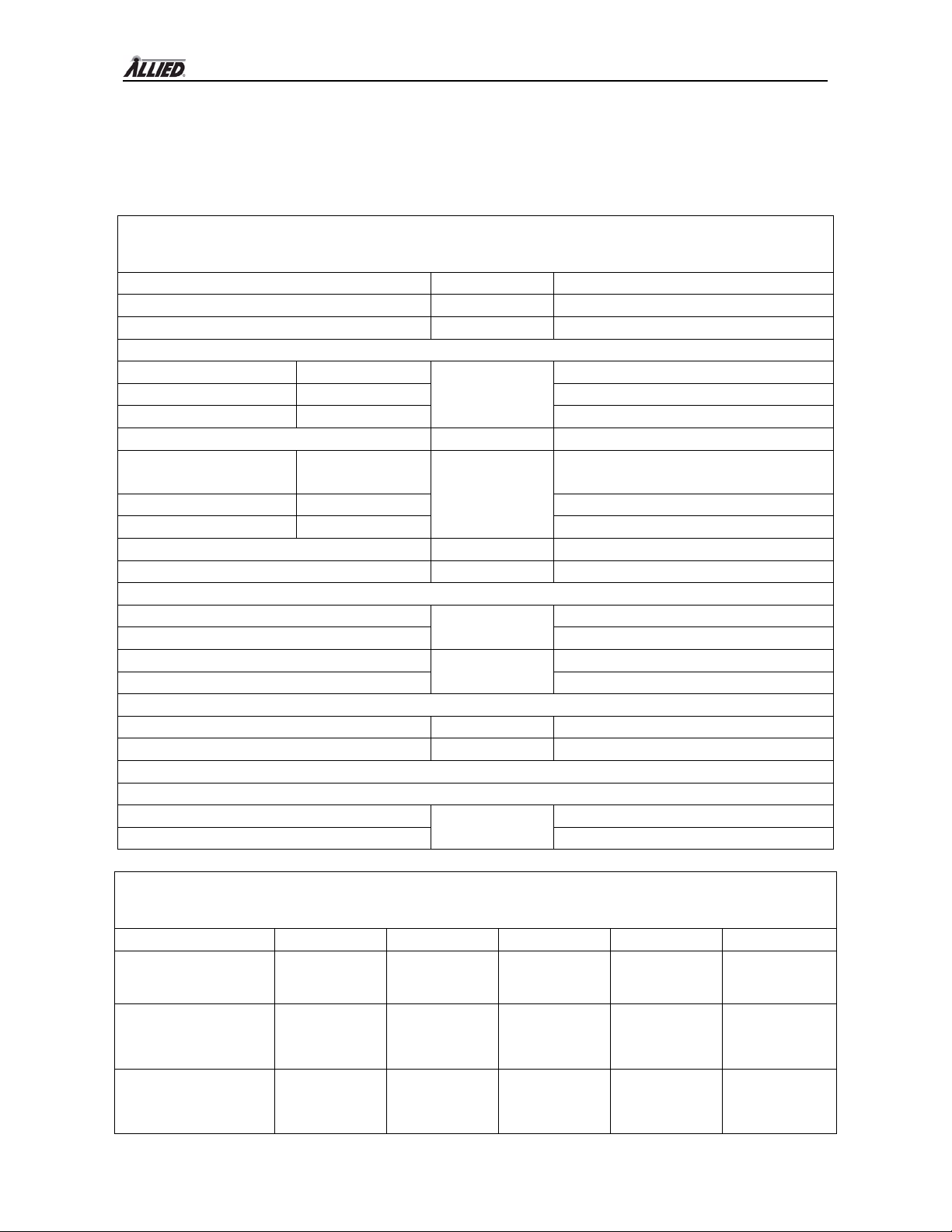

3.2 Hydraulic Installation Definition

Efficient operation, production rates and

service life of Allied attachments depend

on the correct hydraulic oil flow and

pressures. Adjust the carrier's hydraulic

system accordingly during installation and

start-up. Among other important

information, the Allied technical

specifications include Hydraulic Flow,

Operating Pressure, Dynamic Relief

Pressure and Static Relief Pressure. These

parameters are defined as:

• HYDRAULIC FLOW is the

hydraulic oil flow range, minimum

to maximum, necessary for proper

attachment operation. Operating

the attachment outside this range

can result in inefficient operation,

damage to the attachment, or injury

to personnel.

• HYDRAULIC OPERATING

PRESSURE is the average

hydraulic oil pressure measured at

the attachment during operation.

The Hydraulic Operating Pressure

range is the range of pressure

required to operate the attachment

throughout the Hydraulic Flow

range. The Operating Pressure is

not to be used as a relief valve

pressure setting.

• DYNAMIC RELIEF PRESSURE

is the hydraulic oil pressure when

the relief valve starts to open and

divert oil back to the carrier instead

of the attachment. The carrier's

hydraulic system shall be capable

of providing the desired oil flow at

a pressure equal to at least the

dynamic relief pressure. Also it is

very important not to control the oil

flow with the relief valve. This

may cause significant heat

4