Allis-Chalmers AD 30 User manual

t>

,

J

'\

l·

l~~

I~

j...

1\

II

FOREWORD

This book is written for the purpose of giving the operator

essential information regarding 'the day-to-day care,-lubrica-

tion and adj'l:1.stmentof the gra der, Economicaloperation'will

be ensured if these instructions' are followed.' .' ,

The instructions given i'nth

i

s book cover' the operation of tlie

I~llis-Chalmers" Models AD-30 and AD-40 Motor Graders ..'

close adherence to these instructions ~ill result in many hours

of trouble-free operation a,nda longer .operating life for the unit.

If II' ".

Many owners of :Allis-Chalmers equipment employ the Dealerts

·.Service Department for all work other than routine care and

adjustments. This practice is .encouraged as our dealers aj-e

\ kept well informed by the factory regarding advanced methods

of servicing ''Allis-Chalmers''.products, and are equipped to

render satisfactory service. ' .

*

**

All photographs shown throughout this manual 'a-re of the Model

AD-40 Motor Grader, unless otherwise stated. (Model AD-3,O

Motor Grader similar.)

,

,

ADJUSTMENTS

Ball

&

Socket Joints

Circle Guide ••

Clutch Brake. ~ ••

Clutch Linkage ...

'Control Shaf t.B'rak e

Engine Control.

Governor

Parking Brake.

Power 'I1ake-Off Chain.

Power Take-Off Drive Hou s

i

ng

Steering Mechanism.'

'Tandem Drive Chain:

Valves • " ••• " •

'Wheel Brakes .•.

Worm Shaft Bearing

Air Cleane.r ••.••..

Air Pre-Cleaner • ~ • . • '.

Avoid Unnecessary Engine Idling

Ball

&

Socket Joint Adjustment

Batteries ••• ' .•••••.•.

Circle Guide Adjustment ..

Clutch Brake Adjustment •.

Clutch Linkage Adjustment .

Cold Weather Engine Primer

Cold Weather Operation ..•

'Contr~ls

&

Instruments, Operating

Control Shaft Brake Adjustment.

Cooling System, Engine

Description, General. ~

Driving Instructions

Electrical System

Generator

.

,

.

ENGINE

Controls, Adjustment

Cooling System" . • •

Idj ing , Unnecessary

Lubrica tion System '.•

Serial Number. :' •

Starting

Stopping

INDEX

45

45

39

38

46

34

36

43

47

47

44

48

32

40

46

Equipment, Special

Fuel Storage

Fuel System.

General Description

General Specifications

Generator

&

Batteries

Governor Adjustment.

Grader Operation, General Information

Grader Serial Number .

Information on 'Grader Operation.

Injector Equalizing

Injector Timing.. •

Instruments" Operating.

Lubricants, .Spec

if

i

cat i.ons

Lubrication System, Engine

Operating Controls

Parking Brake Adjustments

Periodic Lub r

i

cat

i

on and

Preventive Maintenance Service

Power Take-Off Chain Adjustment

Powe r Take-Off Drive Belt Adjustment

Preparing Grader for Use .•

Preparation of Grader for Storage

Preventive Se rvice

Routine Service.

28

28

16

45

30

45

39

38

18

18

12

46

20

3

16

29

29

SERIAL NUMBER

Engine

Grader

Special Equipment

Specifications, General

Specification of Fuel Oil

Specification of Lubricants

Steering Mechanism Adjustment

Starting

&

Stopping of Engine.

Tandem Drive <7;hainAdjustment

Tires

&

Wheels.

Valve Adjustment.

Wheel Brakes .••

Wheels

&

Tires ..

Worm Shaft Bearing Adjustment

34

20

16

26

6

15

15

*

*

r

*

51

9

22

3

4

29

36

17

6

17

34

33

12

7

26

12

43

9

4-7

47

12

50

9

10

,'_

51

4

8

7

44

15

48

,I

48

32

40_

'4$

46

r

GENERAL DESCRIPTION

CONTROL LEVERS

...J

f·

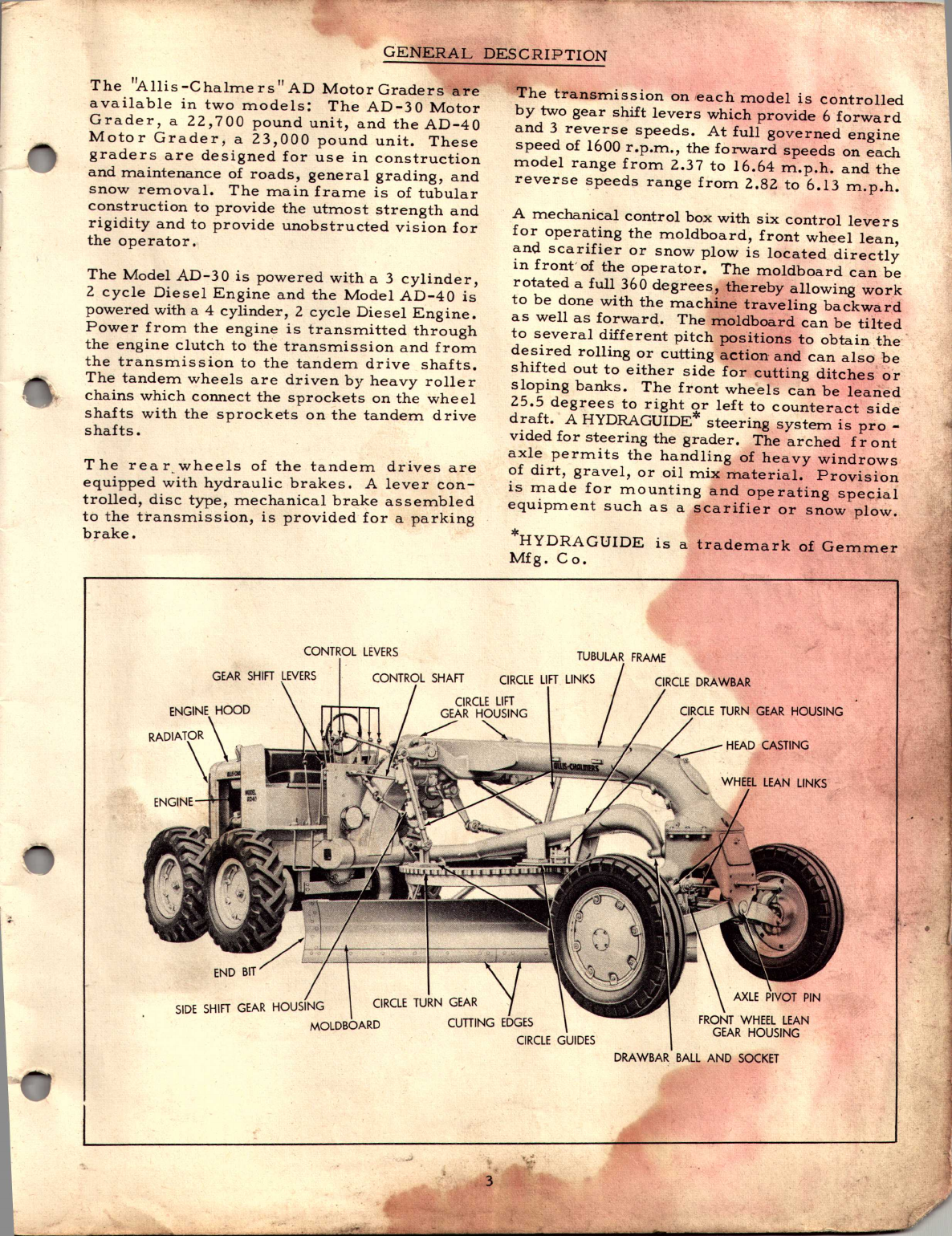

The ''Allis -Chalme rs

If

AD Motor Graders are

available in two models: The AD-30 Motor

Grader, a 22,700 pound unit, and the AD-40

Motor Grader, a 23,000 pound unit. These

graders are designed for use in construction

and maintenance of roads, general grading, and

snow removal. The main frame is of tubular

construction to provide the utmost strength and

rigidity and to provide unobstructed vision for

the operator.

The Model AD-30.is powered with a 3 cylinder,

2 cycle Diesel Engine and the Model AD-40 is

powered with a 4 cylinder, 2 cycle Diesel Engine.

Power from the engine is transmitted through

the engine clutch to the transmission and from

the transmission to the tandem drive shafts.

The tandem wheels are driven by heavy roller

chains which connect the sprockets on the wheel

shafts with the sprockets on the tandem drive

shafts.

T he rea

l'

wheels of the tandem drives are

equipped v.:ith hydraulic brakes. A lever con-

trolled, disc type, mechanical brake assemb~ed

to the transmission, is provided for a

pa

rking

b~ake.

The transmission on leach model is co'ntrolled

by two gear shift levers which provide 6 forward

and 3 reverse speeds. At full governed engine

speed of 1600r.p.m., the forward speeds on each

model range from 2.37 to 16.64 m.p.h. and the

reverse speeds range from 2.82 to 6.13 m.p.h.

,A mechanical control box with six control levers

for operating the moldboard, front wheel lean,

and scarifier or snow plow is located directly

in front' of the operator. The moldboard can be

rotated a full 360 degrees, thereby allowing

wo

rk

to be done with the machine traveling backw?-r.d

as well as forward. The moldboard can be tilted

to several different pitch positions to obtain the' .

desired rolling or cutting action and can also be

shifted out to either side for cutting ditches' ~'r"

sloping banks. The front wheels can be leaned

25.5 degrees to right or left to counteract side'

draft. A HYDRAGUIDE*steering system is pro _

vided for steering the grader. The arched fr ont

axle permits the handling of heavy windrows

of dirt, gravel, or .oil mix material. Provision

is made for mounting and operating special

equipment such as a scarifier or snow plow.

*HYDRAGUIDE is a trademark of Gemmer

Mfg. Co.

TURN GEAR HOUSING

!'lEAD CASTING

,

.

CIRCLEGUIDES DRAWBAR BALL AND SOCKET

3

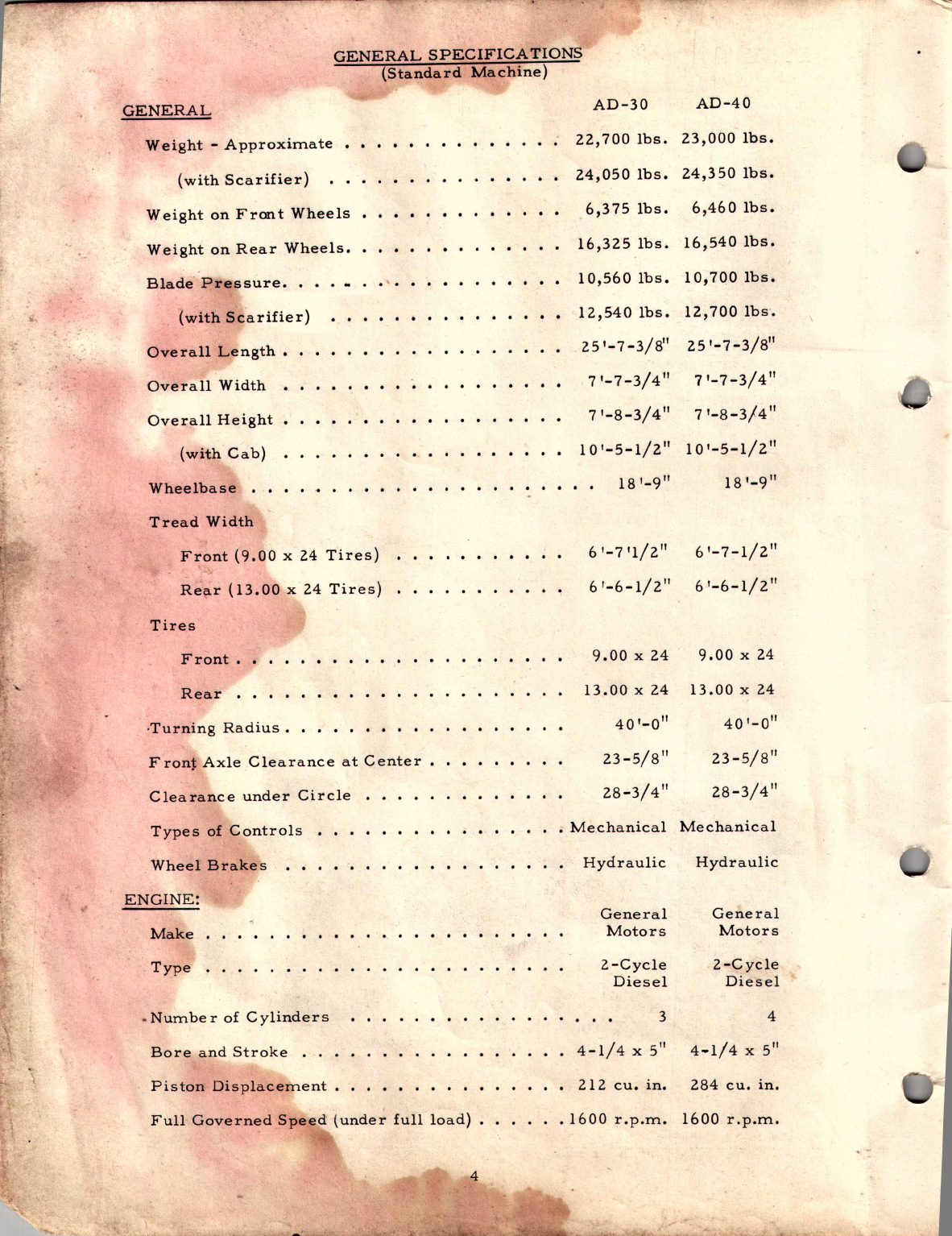

GENERAL SPECIFICATIONS

(Standard Machine)

GENERAL

Weight,.. Approximate • • .

(with Scarifier)

Weight on Front Wheels

.

_

Weight on Rear Wheels•

Blade' Pressure •.•

• .1;,. • •

....

(with Scarifi.er]

,

.'

Overall Length.

'Overall Width

.

..

.

.

.

Overall Height

(with C~b)

Wheelbase .

Tread Width

Front (9.00 x 24 Tires)

;~

Rear (13.00 x'24 Tires)

Tires

Front.

Rear •

_-T'urning Radius.

Front Axle ,Clearance at Center.

Clearance under Circle

Types of Controls

Wheel Brakes

ENGINE:

Make

Type

-Nurnbe

r of Cylinders

Bore and Stroke . . .

Piston Displacement.

Full Governed Speed (under full load)

AD-30 AD-40

22,700 lbs. 23,0001bs.

.

.

.

24,050 lbs, 24,350 lbs ,

6,375 lbs. 6,460 Ibs,

l6,325lbs. l6,540lbs.

10,560 lbs, 10,700lbs.

·12,5-40lbs. l2,700lbs •

25'-7 -3/8" 25'-7-3/8"

7'-7.,.3/4" 7'-7-3/4"

7'-8-3/4" 7'-8-3/4"

10'-5-1/2" 10'-5-1/2"

18'-9" 18'-9"

..

6'-7'1/2" 6'-7-1/2"

6'-6-1/2" 6'-6-1/2"

9.00 x 24 9.00 x 24

13.00 x 24 13.00 x 24

40'-0" 40'-0"

23-5/8" 23-5/8

11

28..;.3/4" 2.8-3/4"

. Me.chanica1

Me c ha n ic a l

Hydraulic Hydraulic

General General

Motors Motors

2-Cycle Z-Cycle

Diesel Diesel

34

4-1/4 x 5" 4-1/4 x 5"

212 cu. in. 284 cu. in.

.1600

rvp.rn ,

1600 r.p.m.

.

-

4

This manual suits for next models

1