Allstate 788.94495 Use and care manual

--I

OPERATING

INSTRUCTIONS

AND

PARTS

LIST

FOR

MOTOR SCOOTER

r------MODEL

NUMBER

788.94495------

This

is

the

Model

Number

of

your

Allstate

Motor

Scooter.

It

will

be

found

on

a

plate

fastened

to

chassis

under

the

fuel

cock.

Always

mention

this

number

when

communicating

with

us

regarding

the

Scooter.

or

when

ordering

parts.

HOW

TO

ORDER REPAIR PARTS

All

parts

listed

herein

may

be

ordered

through

any

Sears

retail

or

mail

order

store.

In

ordering

parts

by

mail

from

the

mail

order

store

which

serves

the

territory

in

which

you

live.

Selling

Prices

will

be

furnished

on

request

or

parts

will

be

shipped

at

prevailing

prices

and

you

will

be

billed

accordingly.

WHEN

ORDERING REPAIR PARTS. ALWAYS GIVE THE

FOL-

LOWING

INFORMATION:

1.

-

The

Part

Number

in

this

List.

2. -

The

Part

Name

in

this

List.

3. -

The

Model

Number

of

the

item.

This

list

is

valuable.

It

will

assure

your

being

able

to

obtain

proper

parts

service

at

all

times.

We

suggest

you

keep

it

with

other

valuable

papers.

...

co.

AND

.

Printed

in U.S.A.

ROEBUCK

SEARS,

F-1716

I

11-=-1

=============================================-.~

I

821762

1

INTRODUCTION

This

model

of

motor

scooter

has

a

new

and

modern

type

of

engine

in

which

the

distribution

is

realised

by

the

crankshaft

(rotary

valve

di-

stribution).

The

carburettor,

installed

on

the

crankcase,

is in

direct

communication

with

the

pre-compres-

sion

chamber

in

corrispondence

to

the

external

diameter

of

one

of

the

crankshaft

flywheels

(see

fig. 11):

the

periphery

of

the

flywheel

rotates

very

close

to

the

crankcase,

without

touching

it;

a

portion

in

the

periphery

of

said

web

is

ground

off,

and

controls

the

fuel flow to

the

pre-com-

pression

chamber,

thus

acting

as

a

rotary

valve.

The

recess

on

the

web

periphery

has

been

shaped

in

such

a

way

as

to

give

the

maximum

volumetric

efficiency,

an

asymmetrical

distribution

diagram

being

achieved.

It

must

be

noted

that

crankweb

and

crank-

,

case

are

kept

gas

tight

by

'the

film of oil

which

forms

between

them

and

not

by

direct

contact;

in this

way

the

system

is

not

subject

to

wear

by

friction,

as

is

usually

the

case

with

similar

devices.

The

intake

pipe

is

very

short; it is

therefore

only

the

carburettor

which

slows

down

the

flow

of

fresh

charge

to the

engine.

The

advantages

oJ

a

correct

feeding

system

are

therefore

clear;

more

power

with

low

revs,

and

so

a

more

elastic

engine.

The

intake

pipe

leads

therefore

into

the

pre-compression

chamber

and

the fresh

charge

contacts

directly

the

con.

rod

big

end;

in this

way

the

bearings

are

so

efficiently

lubricated

as

to

permit

reduci<1g,

the

percentage

of

oil in

the

gasoline

(2"10).

The

improvement

which

the

rotary

valve

brings

to

the

thermo-dynamic

performance

of

the

engine

can

be

appreciated

by

considering

the

flatness

of

the

power

curve;

this,

as

is

well

known,

makes

the

engine

capable

of

functioning

on

a

wide

rpm

range

and

of

adjusting

itself

automa-

tically,

with

slight

variation

of

speed,

to

all

forms

or

resistance

which

the

scooter

must

overcome

(head

wind,

gradients

etc.).

The

proverbial

climbing

ability

of

this

motor

scooter

is

enhanced

in

this

model.

All

gradients

normally

encountered

on

main

roads

can

easily

be

climbed

in

3rd

gear,

even

with

two

people

on

board;

any

slope

can

be

climbed

at

speed

in

2nd

gear,

while

the

1st

gear

gives

initial

acce-

leration

and

is

particularly

useful

on

bad

surfaces

and

side

roads.

Another

advantage

of

the

rotary

valve

is

that

it

eliminates

back

pressure,

i.

e.

prevents

some

of

the

fresh

fuel from

being

pushed

back

from

the

pre-compression

chamber

towards

the

carburetttor

and

wasted,

at

the

beginning

of

the

dovrnward

stroke

of

the

piston.

Engine

performance

is

also

improved

by

the

adoption

of a

spherical

headed

piston

and

a

com-

bustion

chamber

on

the

cylinder

head

of a

special

form

which

gives

rise

to

higher

turbulence,

thus

resulting

in

higher

compression

ratio

and

thence

increase

in

both

specific

power

and

out-put.

Finally

the

carburettor,

which

is

housed

in

the

air

cleaner,

is

similar

to

those

used

in

the

car

industry,

with

plate-shaped

slide

valve

and

immersed

jets: this

has

reduced

fuel

consumption

and

improved

the

general

performance

of

the

engine.

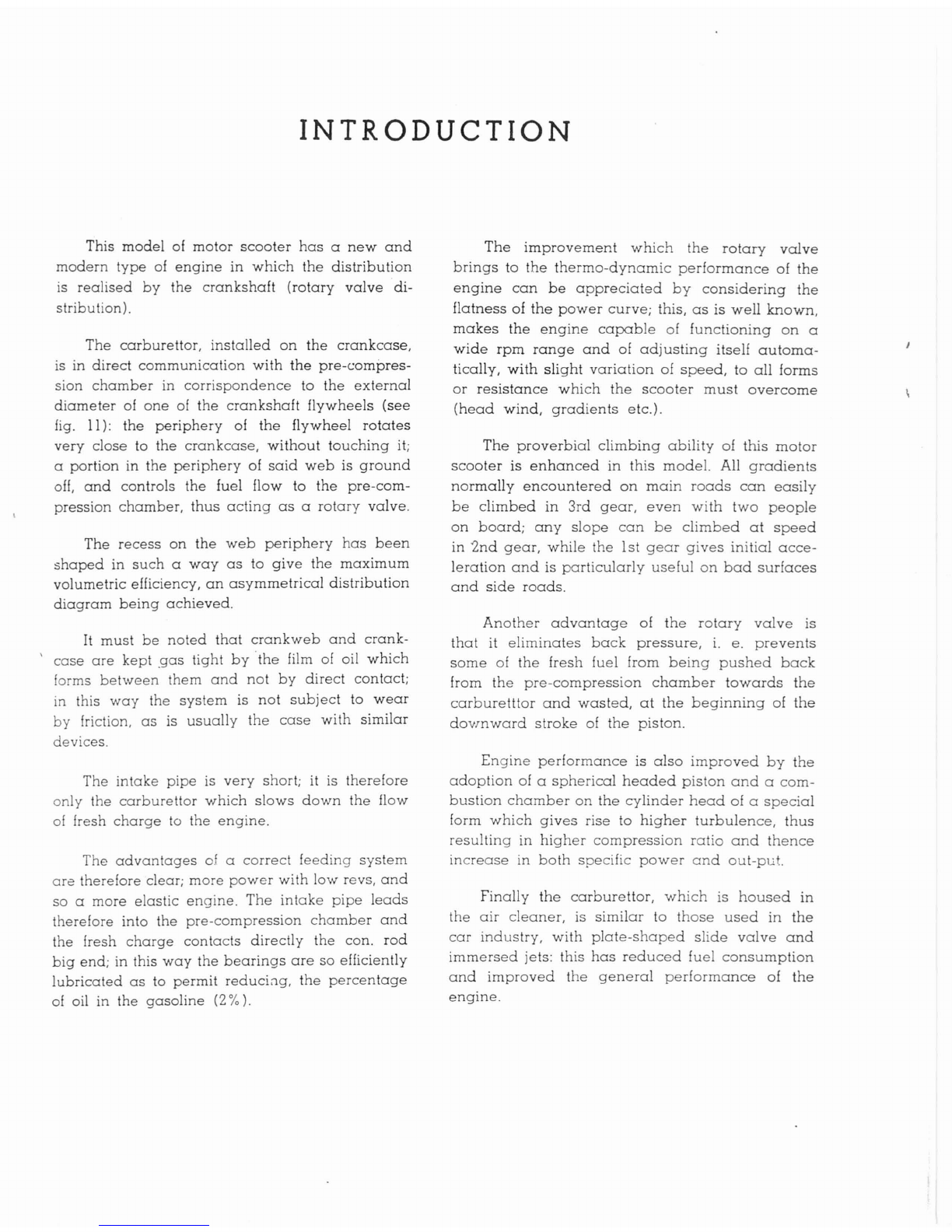

fig.

1 -

ALLSTATE.

Cruisaire.

Motor

Scooter

WARNING

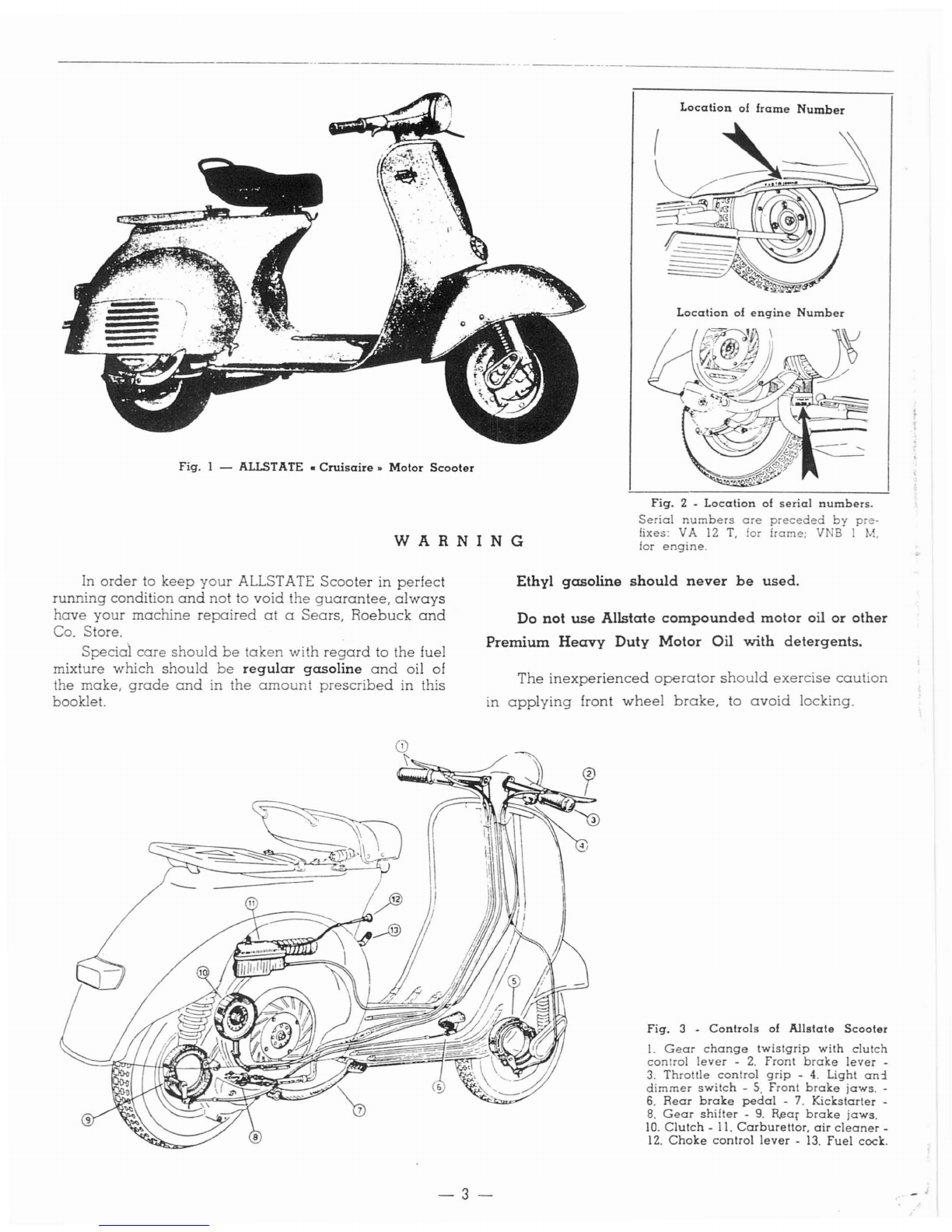

Location

of

frame

Number

Location

of

engine

Number

fig.

2 -

Location

of

serial

numbers.

Serial

numbers

are

preceded

by

pre-

fixes: VA

12

T.

for

frame;

V

18

I

M.

for

engine.

In

order

to

keep

your

ALLSTATE

Scooter

in

perfect

running

condition

and

not

to

void

the

guarantee,

always

have

your

machine

repaired

at

a

Sears,

Roebuck

and

Co. Store.

Special

care

should

be

taken

with

regard

to

the

fuel

mixture

which

should

be

regular

gasoline

and

oil of

the

make,

grade

and

in

the

amount

prescribed

in this

booklet.

Ethyl

gasoline

should

never

be

used.

Do

not

use

Allstate

compounded

motor

oil

or

other

Premium

Heavy

Duty

Motor

Oil

with

detergents.

The

inexperienced

operator

should

exercise

caution

in

applying

front

wheel

brake,

to

avoid

locking.

fig.

3 -

Controls

of

Allstate

Scooter

1.

Gear

change

twistgrip

with

clutch

control

lever

-

2.

Front

brake

lever

-

3.

Throttle

control

grip

-

4.

Light

an:!

dimmer

switch

-

S.

Front

brake

jaws.

-

6.

Rear

brake

pedal

-7.

Kickstarter

-

8.

Gear

shifter

-

9.

R,ear

brake

jaws.

10.

Clutch

-

11.

Carburellor.

air

cleaner

-

12.

Choke

control

lever

-

13.

fuel

cock.

-3-

Fig.

4 -

Engine

installation

and

suspensions.

!.

Steering

column

and

front

suspension

-

2.

Engine

-

3.

Crankcase

half.

clutch

side,

with

swinging

arm

-

4.

Rear

suspension

spring

with

hydraulic

damper.

MAIN

SPECIFICATIONS

Frame.

-Of

pressed

and

spot-welded

steel

sheet,

with

stream-lined

monocoque-type

structure.

Suspension.

-Front

wheel:

coil

spring.

Rear

wheel:

coil

spring

and

coaxial

hydraulic

shock

absorber.

Engine. -Two-stroke, flat

cast

iron

cylinder

and

cast

aluminium

alloy

cylinder

head.

Cooling

effected

by

centrifugal fan.

Displacement

123.4

cc.

(7.53

cu. in.)

Bore.

.

52.5

mm. (2.06 in.)

Stroke

57

mm.

(2.24

in.)

Effective

power

at

5000

rpm

4.6 HP.

Compression ratio . 7 : 1

Transmission. -Directly from

engine

to

rear

wheel

through

clutch, cushiOn

drive

and

gear

box.

Starting.

-By

means

of kickstarter,

right

hand

side

of

scooter.

Fuel

consumption:

(Gasoline -oil mixture)

Max.

speed.

Wheel

base.

Max.

width

on

handlebars

Max.

length

of

the

scooter

Max.

height.

Min.

height

of

floorboard

.

Tuming

circle .

Weight

(unladen)

130

miles

per

gal.

46-.6

m.p.h.

46.4 in.

25.7

in.

68.2 in.

38.7

in.

8in.

59

in.

182

Ibs.

Gear

box.

-

3-speed

drive

with

mesh

gears

in

oil

bath.

Its

two-cable

control

is

coupled

with

that

of

the

clutch,

on

left

hand

side

of

handlebars.

Engine

to

wheel

transmission

ratios:

First

12.2

to 1

Second

7.6

to

1

Third.

4.85

to 1

Clutch.

-

Wet

type;

multiplate,

with

facings

of

cork

composition

applied

to

the

driving

discs.

Ignition.

-

By

flywheel

magneto.

.--------/-1

6

3

Fig.

5 -

Ignition

diagram

1.

Ignition

coil

in

flywheel

magneto

_

2.

Rotor

cam

-

3.

Breaker

_

4.

Condenser

-

S.

Sparkplug

-

6.

Engine

cut-out

on

switch.

-4-

Lubrication. -By oil

the

in fuel mix-

ture for piston, cylinder, wrist pin, con.

rod,

cranshaft,

main

bearings.

Both

clutch

and

gear

box

operate

in oil

bath.

Carburettor. -With

float-chamber

(see

fig.

11);

air

cleaner

mounted

on

the

engine. Air

goes

to

the

carburettor

through

a

large

inlet

tube

and

asilenc-

ing

chamber

with filter

having

incor-

porated

choke

valve.

Model of

carburettor:

Dell'Orto SI

20/15 B - Venturi

15

mm

(0".59) -

Main

jet 82/100

(0".03.2.3)

-

Idler

jet

42/100

(0".0163) -Air-vent for

main

jet

100/100

(0".0394) -Air hole

on

mixer

top

150/100

(0".059) -Mixer

type

E

2.

-Air-vent to

idler jet 160/100 (0".063) -

Spray

nozzle

200/100 (0".0788) -

Float

chamber

fuel

level 20.5 ±1mm. (0".87) -Oil

recovery

vent 50/100 (0".0197).

Feeding. -

Fuel

feed

to

the

carburettor

is

provided

for

by

gravity

(see fig. 11)

with

gasoline-oil

mixture.

Fuel tank. -Total

capacity:

2,03 gals.;

Reserve:

,-.J

1/

3.

gal.

;

Three--way

cock:

«

open»

-«

closed»

-

«reserve»

Muffler. -

Expansion

and

absorption

combined

type.

Handlebars. -

Consisting

of

two

arms

in

steel

tube,

clamped

in a

support

which

is fixed to

the

steering

column. The

central

part

of

handlebars

is

completed

by

two shells in

pressed

steel

sheet.

The

headlamp

is installed therein. All control

cables

and

electric

wires,

to

be

connected

to

the

handlebars,

are

concealed

inside it.

Steering column. -The

steering

column

bears

the

handlebars,

clamped

on

its

top

end,

and

the

front

wheel

swinging

hub,

pivoted

at

its

bottom

end

through

a

stub

axle.

Lighting

and

hom.

-By flywheel

magneto,

feeding

both

head

lamp

(two-beam),

tail

lamp,

horn

and

stop

light (see

fig.

9).

Brakes. -

Expanding

type.

Front

brake:

control

lever

on

right

hand

side

of

handlebars.

Rear

brake:

control

pedal

on

right

hand

side

of

floorboard.

Wheels.

~

Of

pressed

steel

sheet,

interchangeable

and

easily

removable,

since

they

are

assembled

in

an

automobile-like

system.

Tires:

dia. 3.50 x8in.

Steering Lock. -A

suitable

security

lock is

arranged

on

the frame,

near

the

handlebars.

Turning

the

key

counter-clockwise

and

the

handlebars

to

the

left,

the

lock

engages

the

lugs

welded

on

the

steering

column,

so that the

machine

can

only

turn

around.

Turn

the

key

clockwise

and

the

handlebars

back

to

normal

position

for

releasing

the

steering

system

(see

Fig. 7). Do

not

attempt

to ride the

machine

unless

the

key

is in,

and

re-

mains

in

the

lock,

and

the

handlebars

are

moving

freely.

5

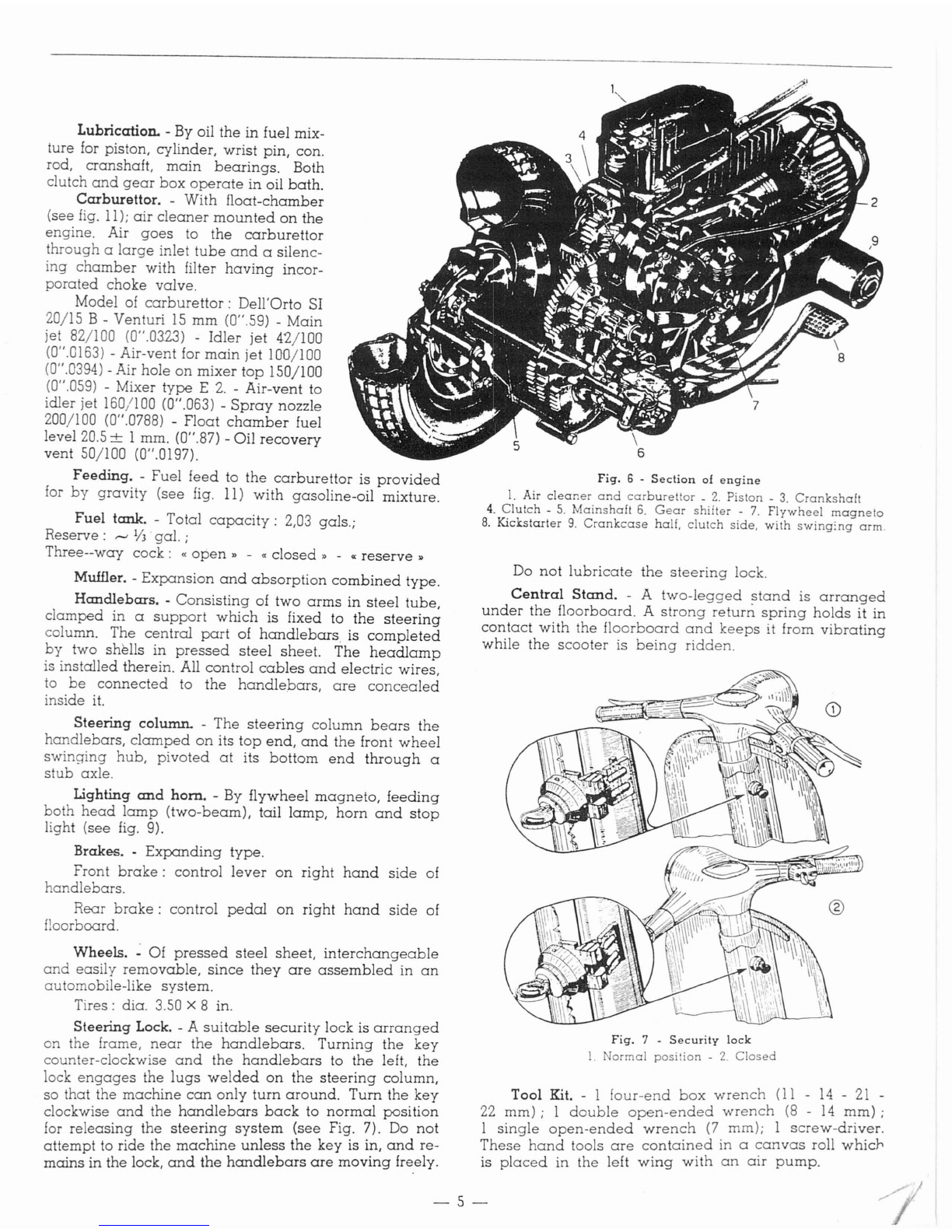

Fig.

6 -

Section

of

engine

1.

Air

cleaner

and

carburet

tor _

2.

Piston

-

3.

Crankshaft

4.

Clutch

-

5.

Mainshaft

6.

Gear

shifter

-

7.

Flywheel

magneto

8.

Kickstarter

9.

Crankcase

half.

clutch

side,

with

swing:ng

arm.

Do

not

lubricate

the

steering

lock.

Central Stand. -A

two-legged

:;tand

is

arranged

under

the

floorboard.

A

strong

return

spring

holds

it in

contact

with

the

floorboard

and

keeps

it from

vibrating

while

the

scooter

is

being

ridden.

Fig.

7 -

Security

lock

1.

Normal

position

-

2.

Closed

Tool

Kit.

- I

four-end

box

wrench

(II

-

14

-

21

-

22

mm);

1

double

open-ended

wrench

(8

-

14

mm);

1

single

open-ended

wrench

(7

mm); 1

screw-driver.

These

hand

tools

are

contained

in a

canvas

roll

which

is

placed

in

the

left

wing

with

an

air

pump.

Accessories (See

Table

XX).

-

On

request

the

Allstate scooter

can

be

equipped

with

the

spare

wheel

(and

bracket)

and

speedometer.

Spare

wheel

and

bracket (see fig. 8). -The

wheel

bracket

sheet

steel pressing,

can

be

secured

to

the

scooter frame

behind

luggage

carrier

(see

Table

XX,

c

Spare

parts

list

.).

It is very

robust

and

simple

and

holds

the

wheel

in

such

aposition

where

it is

easily

accessible.

Speedometer. -The

speedometer

has

its

housing

in the middle

of

the

handlebars

and

adds

to the

per-

formance

and

appearance

of the scooter.

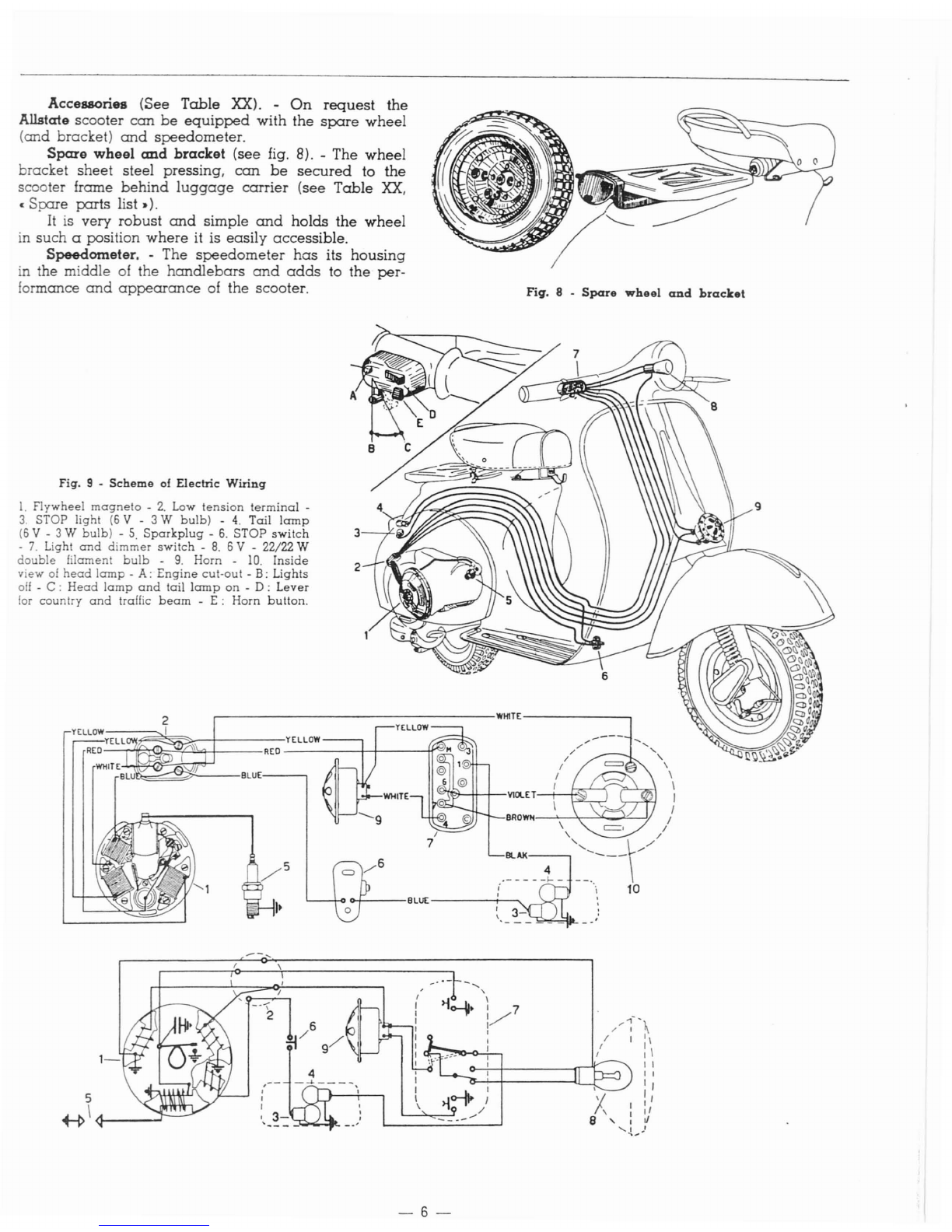

Fig.

8 -

Spare

wheel

and

bracket

.--------------------

WHlTE------_

9

BRDWII---"---',-"",--,,"--J/

~l*-4+--+--V1OLET-I--~

2

o-I----BLut

----.-.---...

~~~~---BLUE-----,

2

YELLOW~U;;p~I~~_t-

_

YELL YELLOW

REO---r-~I"0~~~+---

REO

-----+-1------1(;:

Fig. 9 -

Scheme

of Electric

Wiring

1.

Flywheel

magneto

-

2.

Low

tension

terminal

-

3.

STOP light

(6

V - 3 W

bulb)

-

4.

Tail

lamp

(6

V - 3 W

bulb)

-

5.

Sparkplug

-

6.

STOP

switch

-

7.

Light

and

dimmer

switch

-

8.

6 V - 22/22 W

double

filament

bulb

-

9.

Horn -

10.

Inside

view

of

head

lamp

-A:

Engine

cut-out

-

B:

Lights

off

- C :

Head

lamp

and

tail

lamp

on

-

D:

Lever

lor

country

and

traffic

beam

-

E:

Horn

bulton

.

5

~\<1----I-

-6-

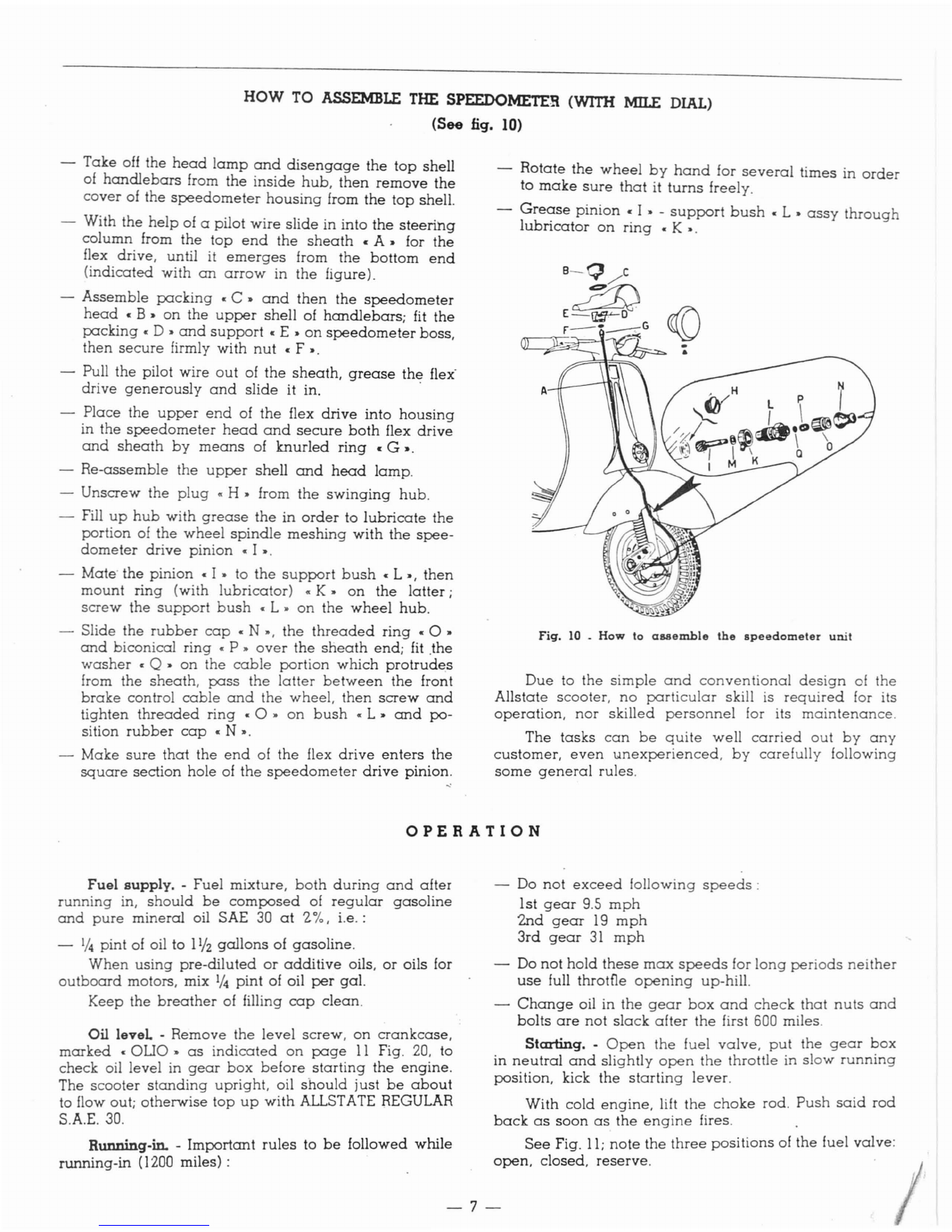

HOW

TO

ASSEMBLE

THE

SPEEDOMETER

(WIm

MILE

DIAL)

(See fig. 10)

-

Take

off

the

head

lamp

and

disengage

the

top

shell

of

handlebars

from

the

inside

hub,

then

remove

the

cover

of the

speedometer

housing

from

the

top

shell.

-With

the

help

of apilot

wire

slide

in

into

the

steerihg

column

from

the

top

end

the

sheath

cA.

for

the

flex drive, until it

emerges

from

the

bottom

end

(indicated

with

an

arrow

in

the

figure).

-

Assemble

packing

c

C.

and

then

the

speedometer

head

c

B.

on

the

upper

shell

of

handlebars;

fit

the

packing

cD.

and

support

c E •

on

speedometer

boss,

then

secure

firmly

with

nut

c F •.

-Pull

the

pilot

wire

au

tof

the

sheath,

grease

the

flex'

drive

generously

and

slide

it in. .

-

Place

the

upper

end

of

the

flex

drive

into

housing

in

the

speedometer

head

and

secure

both

flex

drive

and

sheath

by

means

of

knurled

ring

c G •.

-

Re-assemble

the

upper

shell

and

head

lamp.

-

Unscrew

the

plug

«H.

from

the

swinging

hub.

-Fill

up

hub

with

grease

the

in

order

to

lubricate

the

portion

of the

wheel

spindle

meshing

with

the

spee-

dometer

drive

pinion

c I •.

-Mate'

the

pinion

c

I.

to

the

support

bush

c L

.,

then

mount

ring

(with

lubricator)

«K.

on

the

latter;

screw

the

support

bush

c

L.

on

the

wheel

hub.

-

Slide

the

rubber

cap

eN.,

the

threaded

ring

cO.

and

biconical

ring

c P •

over

the

sheath

end;

fit

.the

washer

cQ •

on

the

cable

portion

which

protrudes

from the

sheath,

pass

the

latter

between

the

front

brake

control

cable

and

the

wheel,

then

screw

and

tighten

threaded

ring

cO.

on

bush

«L.

and

po-

sition

rubber

cap

eN

•.

-

Make

sure

that

the

end

of

the

flex

drive

enters

the

square

section

hole

of

the

speedometer

drive

pinion.

-

Rotate

the

wheel

by

hand

for

several

times

in

order

to

make

sure

that

it

turns

freely.

-Grec:zse

pinion

c I • -

support

bush

c L •

assy

through

lubncator

on

ring

«K

•.

B-Q

C

z1;)

E--=u¥O

.

r-·~G

:

Fig.

10 .

How

to

aaaemble

tbe

speedometer

unit

Due

to

the

simple

and

conventional

design

of

the

Allstate

scooter,

no

particular

skill is

required

for its

operation,

nor

skilled

personnel

for its

maintenance.

The

tasks

can

be

quite

well

carried

out

by

any

customer,

even

unexperienced,

by

carefully

following

some

general

rules.

OPERATION

Fuel

supply.

-

Fuel

mixture,

both

during

and

after

running

in,

should

be

composed

of

regular

gasoline

and

pure

mineral

oil SAE

30

at

1.

':I.,

i.e.:

-1/

4pint of oil to 11

12

gallons

of

gasoline.

When

using

pre-diluted

or

additive

oils,

or

oils for

outboard

motors, mix 1/

4

pint

of oil

per

gal.

Keep

the

breather

of filling

cap

clean.

Oil

level

-

Remove

the

level

screw,

on

crankcase,

marked

«OUO"

as

indicated

on

page

11

Fig.

20,

to

check

oil level in

gear

box

before

starting

the

engine.

The

scooter

standing

upright,

oil

should

just

be

about

to flow out;

otherwise

top

up

with

ALLSTATE REGULAR

S.A.E.30.

Running-in. -

Important

rules

to

be

followed

while

running-in

(1200 miles) :

Do

not

exceed

following

speeds:

1st

gear

9.S

mph

2nd

gear

19

mph

3rd

gear

31

mph

-Do

not

hold

these

max

speeds

for

long

periods

neither

use

full throtfie

opening

up-hill.

-

Change

oil in

the

gear

box

and

check

that

nuts

and

bolts

are

not

slack

after

the

first 600 miles.

Starting.

-

Open

the

fuel

valve,

put

the

gear

box

in

neutral

and

slightly

open

the

throttle in

slow

running

position,

kick

the

starting

lever.

With

cold

engine,

lift

the

choke

rod.

Push

said

rod

back

as

soon

as

the

engine

fires.

See

Fig.

lI;

note

the

three

positions

of

the

fuel

valve:

open,

closed,

reserve.

7-

Caution.

-Do not

open

throttle

wide

when

releasing

clutch.

In

case

of

starting

troubles.

due

to

engine

being

flooded

(unvaporized

fuel

mixture

has

reached

the

cylinder

and

combustion

becomes

therefore

very

dif-

ficult).

proceed

according

to

either

one

of

the

following

methods:

f(

a)

Push-start

the

scooter:

shift into

second

gear,

1[1

declutch

and

push

the

machine;

quickly

release

the

clutch lever

and

pull

it

back

as

soon

as

the

engine

starts.

b) Close the fuel cock.

remove

the

spark

plug

and

;~

rotate the

engine

by

means

of

the

kickstarter.

Wipe

the

[

plug

dry

and

replace.

Open

the

fuel cock

and

kick

the

,.

starting

lever.

Fig.

11

•

Feeding

circuit

1.

Fuel

cock

lever:

A)

Reserve,

B)

Open,

C)

Closed

-

2.

Float

_

3.

Air

cleaner

-

4.

Choke

lever

-

5.

Set

screw

for

throttle

slide

_

6.

Throttle

slide

-

7.

Air

vent

for

main

jet

-

8.

Hole

on

mixer

top

_

9.

Mixer -

10.

Main

jet

-

II.

Idling

jet

-

12.

Air

vent

for

idling

jet -

13.

Plug

for

inlet

hole

for oil: for

laying

up

-

14.

Idling

adjuster

-

15.

Intake

port

-

16.

Transfer

ports

-

17.

Exhaust

duct.

B~

Z

.!

!V

Fig.

12 _

Operations

to

carry

out

for

starting

the

engine

A:

open

the fuel

cock

_ B :

~elect

•

neutral.

-

C:

choke

(with

cold

engine)

-

D:

throttle

coritrol

grip

in

idling

position

-

E:

depress

the

kicks

tarter

and

turn

grip

•

D.

by

short

strokes.

-8-

-9-

.=---'

,

--,

--'\

Fig.

14 -

Drive

system

1.

Gear

change

twistgrip

-

2.

Clutch

control

lever

-

3.

Gear

change

control

cables

_

4.

Gear

shifter

-

S.

Selector

stem

-

6.

Selector

-

7.

1st

gear

-

8.

2nd

gear

-

9.

3rd

gear

-

10.

Mainshaft

•

I!.

Cush

gear

•

12.

Clutch.

N.B.

-

Positions

1-2-3 of

the

gear

change

twistgrip

correspond

to

1st,

2nd

and

3rd

gear

respectively;

«0.

indicates

the

neutral

position.

Do

not

turn

the

gear

change

twistgrip

while

the

engine

is

not

running.

As

soon

as

gear

change

troubles

arise,

~ticularly

when

the

control

becomes

hard,

customers

should

have

their

machines

adjusted

by

a

Sears

Store.

Slow

running

adjustment.

-No

hand

tool is

requir-

ed

for this job.

Idling

revs

can

be

raised

or

reduced

respectively

by

simply

tightening

or

slackening

the

knurled

slotted

screw

on

air

cleaner

steel

sheet

cover

(No.5.

Fig.

II).

This

screw

controls

the

throttle

slide

valve.

The

adjuster

screw

for

the

throttle

control

cable

is

installed

on

the

air

cleaner

case.

This

screw

is

to

be

reset

only

when

necessary

and

while

dismantling

and

re-assembling.

Opposite

to

said

adjuster

screw

there

is

on

the

air

cleaner

case

a

plugged

hole

for

access

to

another

screw

(spring

loaded);

see

Fjg.

II

No, 14.

This

screw

controls

the

flow of

carburated

air

through

the

duct

from

the

idling

jet.

and

consequently

the

idling

revs.

We

recommend

that

customers

refrain

from

re

Fig.

13

•

Engine

bonnet

removal

1.

Engine

bonnet

blocking

lever

-

2.

Front

pivot -

3.

Fixing

hool::

-

4.

Hooked

pivot

and

tum

the

gear

change

twistgrip

so

that

the

engraved

line

coincides

with

figure c

2"

(2nd

gear);

let

in

the

clutch

and

open

the

throttle.

Repeat

this

procedure

for

changing

into

3rd

gear

and

for

changing

down.

See

the

drive

!iystem

on

Fig.

14.

When

you

reduce

the

speed

of

your

machine,

change

down

without

delay

to

avoid

irregular

engine

running

and

atallinq

at

low

revs.

For

access

to

the

engine.

take

off

the

engine

cowl-

ing,

then

proceed

as

follows.

-Pull

the

lever

c

1»

(Fig. 13))

and

tum

it

so

as

to

release

it from

bonnet.

Then

move

the

bonnet

slightly

outwards

,until front

pivot

c

'2

»

disengages

from

the

hole

on

the

frame.

Push

the

bonnet

from

the

front

upwards

and

tum

it

(see

position

indicated

by

dotted

line),

thus

releasing

the

fixing

hook

c3»from frame.

-Move

bonnet

outwards

round

its

hooked

pivot

c4»

until

the

latter

disengages

from

the

hole

on

frame.

Thus

the

bonnet

is

removed.

For

re-assembly,

follow

the

reverse

procedure.

Setting

the

machine

in

motion.

•Let

the

engine

idle,

depress

the

clutch

and

tum

the

gear

change

twist-.

grip

so

that

the

line

engraved

on

it

coincides

with

the

figure c

I»

(lst

gear)

engraved

on

handlebars

(see

Fig.

1'4).

Now

let

in

the

clutch

gently,

while

opening

the

throttle

gradually

to"

set

the

machine

in

motion.

Gear

change.

-

On

attaining

the

required

speed

in

1st

gear,

quickly

close

the

throttle,

release

the

clutch

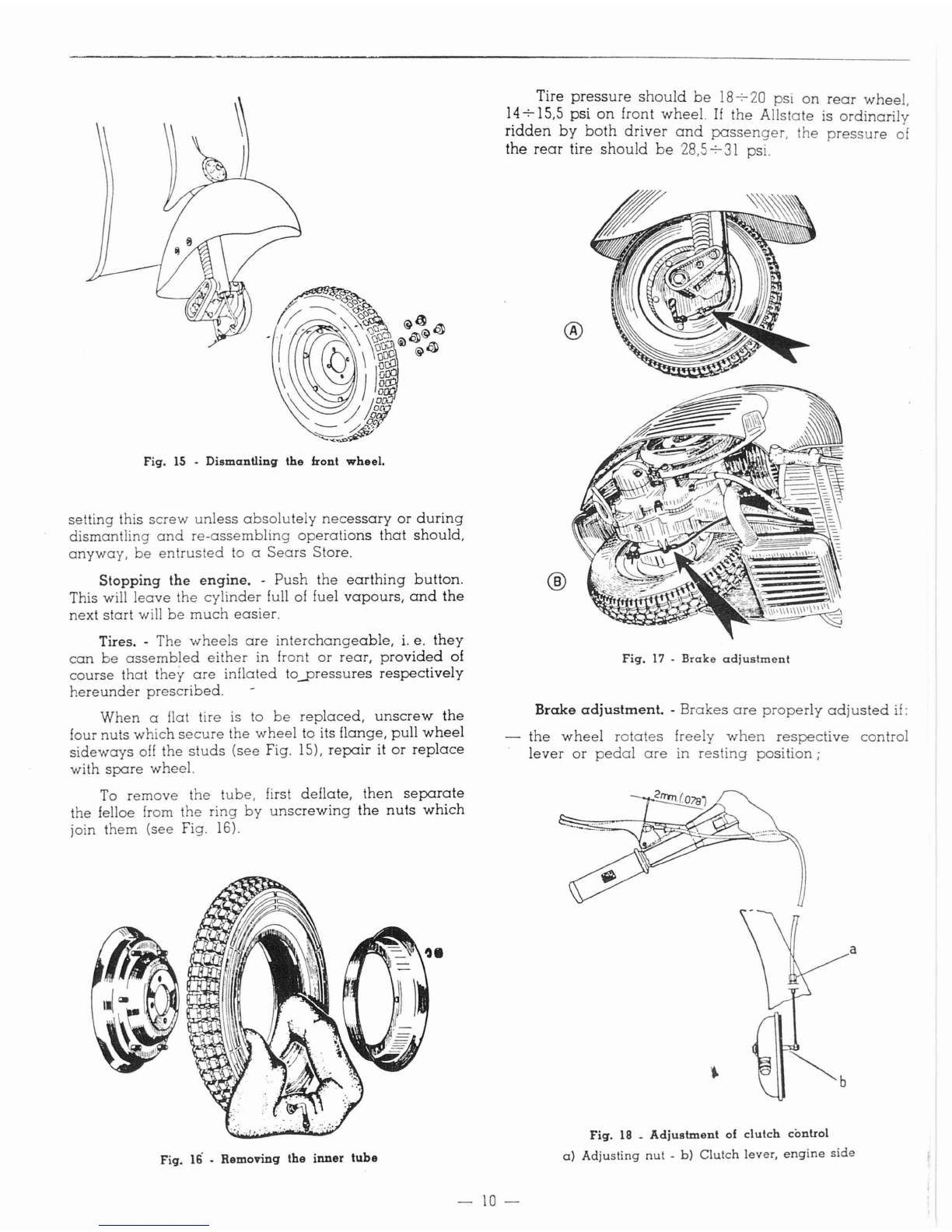

Fig.

15

-

Dismantling

the

front

wheel.

setting this

screw

unless

absolutely

necessary

or

during

dismantling

and

re-assembling

operations

that

should,

anyway,

be

entrusted

to a

Sears

Store.

Stopping

the

engine.

-

Push

the

earthing

button.

This will

leave

the

cylinder

full of fuel

vapours,

and

the

next

start

will

be

much

easier.

Tires. -The

wheels

are

interchangeable,

i.

e.

they

can

be

assembled

either

in front

or

rear,

provided

of

course

that

they

are

inflated

toyressures

respectively

hereunder

prescribed.

When

aflat tire is to

be

replaced,

unscrew

the

four

nuts

which

secure

the

wheel

to its flange,

pull

wheel

sideways

off

the

studs

(see

Fig. 15),

repair

it

or

replace

with

spare

wheel.

To

remove

the

tube,

first

deflate,

then

separate

the felloe from

the

ring

by

unscrewing

the

nuts

which

join

them

(see Fig. 16).

Fig.

16 -

Removing

the

inner

tube

Tire

pressure

should

be

18-;-.20

psi

on

rear

wheel,

14-;-'15,5

psi

on

front

wheel.

If

the

Allstate

is

ordinarily

ridden

by

both

driver

and

passenger,

the

pressure

of

the

rear

tire

should

be

28,5-;-'31 psi.

®

®

Fig.

17

-

Brake

adjustment

Brake

adjustment.

-

Brakes

are

properly

adjusted

if:

the

wheel

rotates

freely

when

respective

control

lever

or

pedal

are

in

resting

position;

a

Fig.

18 _

Adjustment

of

clutch

control

a)

Adjusting

nut

-b)

Clutch

lever,

engine

side

-10-

-the

braking

action

starts

as

soon

as

respective

controls

are

operated.

These

conditions

are

achieved

adjusting

the

cables

by

means

of

screws

indicated

with

an

arrow

in

Fig.

17.

Adjustment

of

clutch

control. -

Adjustment

of

clutch

controls is

achieved

operating

on

adjusting

nut

(a),

screwed

to the

engine

bracket

(see

Fig.

IB).

by

means

of

open

end

wrench

82199

in

the

tool roll.

The

cable

is to

be

tensioned

or

loosened,

as

the

case

may

be

so

that

control

lever,

on

handlebars,

makes

a

stroke

of 2mm.

(O.07B")

before

lever

(b).

on

engine,

starts

moving.

Wrong

play

in

the

control

may

cause

the

clutch

plates

burning

out

even

in

normal

riding

conditions.

MAINTENANCE

Every

5.000

miles:

In

case

of

shock-absorber

troubles,

overhaul

or

simply

clean

the

assembly

and

change

oil.

These

operations

should

be

carried

out

by

your

SEARS store.

(B) -

Clean

the

muffler

and

decarbonize

the

engine

as

explained

hereunder.

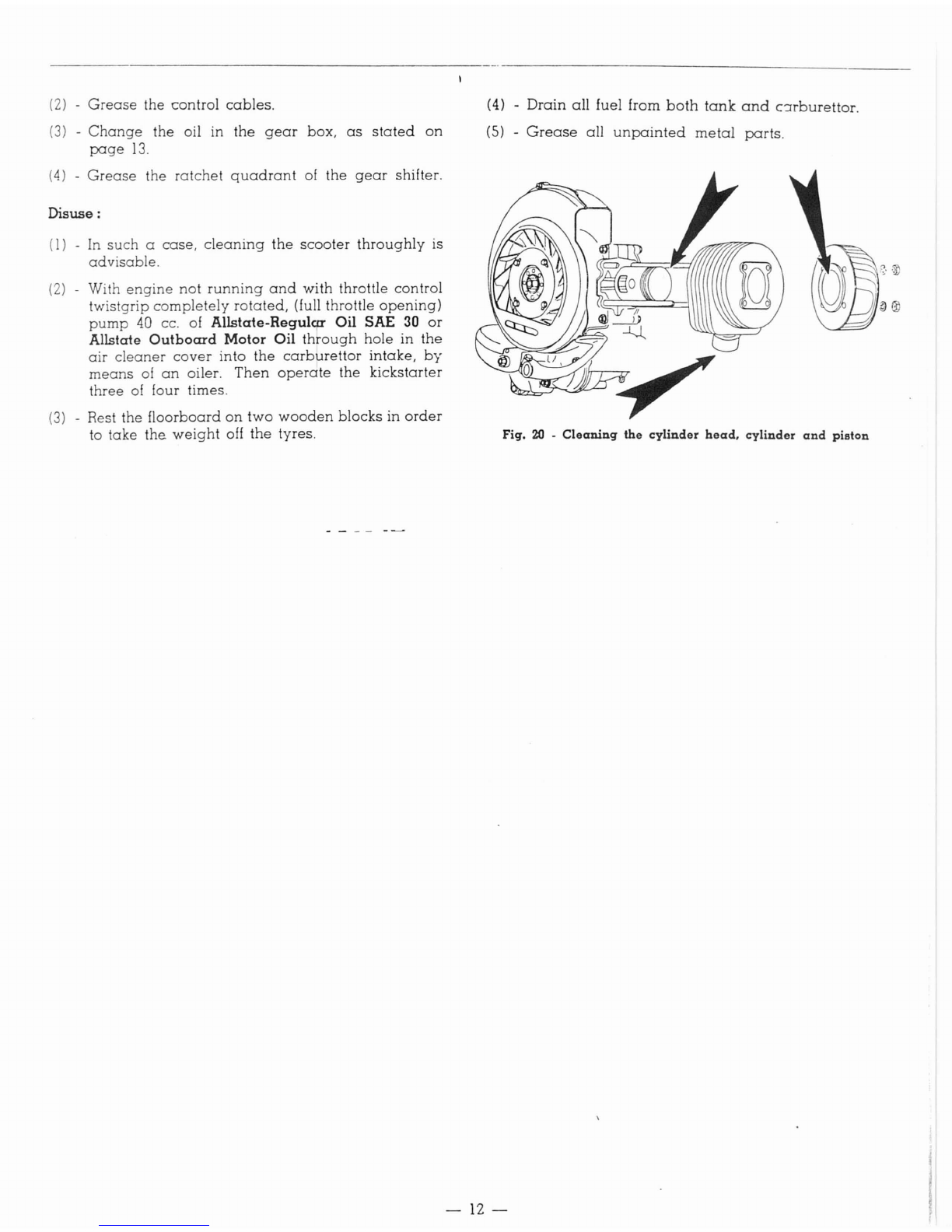

Remove

the

muffler,

the

cooling

hood,

the

cylinder

head

and

the

cylinder

(see

Fig. 20).

Decarbonize

the

piston

crown

and

the

cylinder

ports

from

all

carbon

deposits.

Decar-

bonize

the

inner

side

of

the

cylinder

head.

Care-

fully

clear

the

cylinder

carbon

deposits.

Heat

the

exhaust

pipe

of

the

muffler

and

clean

it

either

by

scraping

internally

with

a

hooked

wire

or

blowing

air

through

from

the

other

orifice; in

both

cases

the

muffler

should

be

held

so

that

the

exhaust

pipe

is

turned

downwards.

Clean

the

breaker

points.

In

order

to

avoid

ignition

troubles

or

abnormal

running,

have

the

breaker

points

adjusted

in a

use

Sears

stores;

the

gop

should

not

be

more

than

0.011 "-0.01

9"

(see

Fig.

19)

and

the

points

should

begin

to

open

when

the

current

in

the

primary

Ignition

d,cuH

has

allalned

ils

peak

value.

/

Fig.

l~

-

Breaker

points

•Max.

gap

of

breacker

points

should

be

a

all"

-D.OI

g"

(l)

-

-

11

-

Cleaning

the

scooter.

-

Brushing

kerosene

and

wiping

dry

with

clean

rags

is

advisable

for

external

cleaning

of

engine.

All JXlinted

surfaces

should

be

washed

with

water,

rinsed

by

means

of a

sponge

and

wiped

dry

with

a

chamois. Do

not

use

kerosene

on

such

surfaces,

since

it

damages

JXlint

and

turns

it dull.

II

necessary,

blow

the

head

lamp

reflector

clean

or

wipe

off

dust

with

a

very

soft feather. Do

not

use

a

cloth

and

keep

your

fingers off reflector

surface.

Before

setting

the

machine

in

motion,

(if

it

has

been

delivered

directly

to

the

customer

by

the

Factory)

check

oil level in

gear

box

by

unscrewing

from the

cranckase

the level

screw

marked

«OLIO»

(see

Fig. 21).

The

scooter

standing

upright,

oil

should

just

be

about

to

flow out.

After

the

first 600 miles. -

Replace

oil

in

the

gear

box

by

the

procedure

as

explained

in

the

lubrication

chart, JXlge

13.

The

crankcase

can

be

drained

through

the hole

indicated

in Fig.

21.

Every

2.500

miles:

(l)

-Remove

the

air

cleaner

from the

carburettor

and

wash

it in a

30

'Yo

gasoline-oil

bath.

(2) -

Check

oil level in

the

gear

box

(see

above).

(3) -

Grease

all joints

on

the

brake

controls.

(4) -

Clean

the sJXlrkplug

electrodes

with

very

fine

emery

cloth

or

suitable

files,

and

adjust

the

gap

to

0.6

mm. (0.023").

Inspect

the

insulation

material

of

sJXlrkplug; re-

place

the

latter

if

the

porcelain

is

cracked.

Wash

with

neat

gasoline.

Use the sJXlrkplug

type

Marelli

CW

230

A-

T;

Marelli

CW

225

N-T;

Morelli

CW

225

A-T;

Bosch

W

225

Tl;

Champion

L.

86;

AC

43

F;

KLG F

70

or

F

75.

Important:

using

the

proper

type

o[

sparkplug

will

eliminate

many

engine

troubles.

(5)

-

Grease

the felt

which

lubricates

the

cam

of

fly-

wheel

magneto.

(6)

-

Clean

the

two

lubricators

on

front

wheel

hub

and

refil

them

by

means

of a

grease

gun.

N.B.

-All

operations

indicated

hereunder

should

be

carried

out

by

aSEARS

store.

(7)

-

Lubricate

the

speedometer

drive

pinion

and

flex

drive

(if

mounted).

(2)

-

Grease

the control

cables.

(3) -

Change

the oil in

the

gear

box,

as

stated

on

IXIge

13.

(4)

-

Grease

the

ratchet

quadrant

of

the

gear

shifter.

Disuse:

(l)

-

In

such

a

case,

cleaning

the

scooter

throughly

is

advisable.

(2)

-With

engine

not

running

and

with throttle control

twistgrip

completely

rotated,

(full throttle

opening)

pump

40 cc. of Allstate-Regulca Oil SAE

30

or

Allstate Outboard Motor Oil

th~ough

hole in

the

air

cleaner

cover

into

the

carburettor

intake,

by

means

of

an

oiler.

Then

operate

the

kickstarter

three

of

four times.

(3)

-Rest the

floorboard

on

two

wooden

blocks

in

order

to

take

the

weight

off

the

tyres.

(4) -

Drain

all

fuel from

both

tank

and

clrburettor.

(5) -

Grease

all

unpainted

metal

parts.

~::

Fig.

20

.

Cleaning

the cylinder

head.

cylinder

and

piston

-

12-

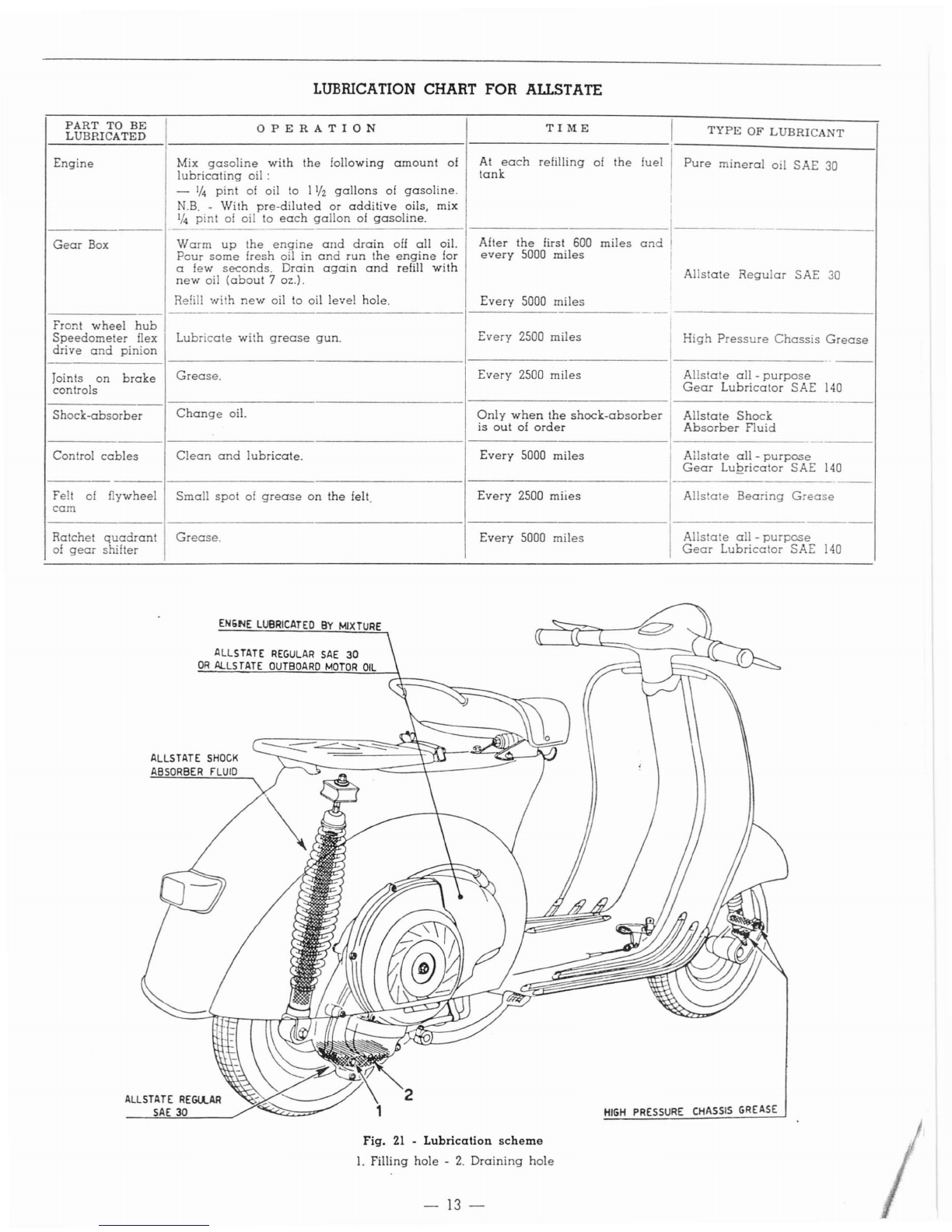

LUBRICATION

CHART

FOR

ALLSTATE

PART

TO

BE

OPERATION

TI

ME

I

TYPE

OF

LUBRICANT

LUBRICATED

Engine

Mix

gasoline

with

the

following

amount

of

At

each

refilling of

the

fuel I

Pure

mineral

oil SAE

30

lubricating

oil:

tank

-

'/4

pint

of

oil to

l'h

gallons

of

gasoline.

N.B.

-

With

pre-diluted

or

additive

oils, mix I

I

'/4

pint

of

oil to

each

gallon

of

gasoline.

I

----------

Gear

Box

Warm

up

the

engine

and

drain

oll

all

oil. After

the

first 600

miles

and

Pour

some

fresh oil in

and

run

the

engine

for

every

5000

miles

I

afew

seconds.

Drain

again

and

refill

with

Allstate

Regular

SAE

new

oil

(about

7oz.).

30

Refill

wi

h

new

oil to oil

level

hole.

Every

5000

miles

-

Front

wheel

hub

Speedometer

flex

Lubricate

with

grease

gun.

Every

2500

miles

High

Pressure

Chassis

Grease

drive

and

pinion

-

---

Joints

on

brake

Grease.

Every

2500

miles

Allstate

all

-

purpose

controls I

Gear

Lubricator

SAE

140

Shock-absorber

Change

oil.

Only

when

the

shock-absorber

Allstate

Shock

is

out

of

order

Absorber

Fluid

Control

cables

Clean

and

lubricate.

Every

5000

miles

Allstate

all

-

purpose

Gear

LUQricator SAE

140

--

Felt of flywheel

Small

spot

of

grease

on

the

felt.

Every

2500

miies

Allstate

Bearing

Grease

cam

Ratchet

quadrant

Grease.

Every

5000

miles

Ails a e

all

-

purpose

of

gear

shifter

Gear

Lubricator

SAE

140

EN6NE

LUBRICATED

BY

MIXTURE

ALLSTATE

REGULAR

SAE

30

OR

ALLSTATE

OUTBOARD

MOTOR

OIL

ALLSTATE

SHOCK

ABSORBER

FLUID

2

Fig.

21

-

Lubrication

scheme

1.

Filling

hole

-

2.

Draining

hole

-

13-

HIGH

PRESSURE

CHASSIS

GREASE

LOCATING

TROUBLES

AND RUNNING IRREGULARITIES

Carry

out

following checks

when

the

engine

does

not

start

easily

or

rWlS

irregularly.

Remedies

Locating

the

trouble

I'

1----=----------

------------

Locating

the

trouble

---

----------------

I

Remedies

-

--------------

I

--

DIFFICULT

STARTING

3,

-

Ignition

Sparkplug

dirty

Choke

flap

sticking

in

position

«

closed.

Replace

Replace

both

plates

and

springs

Replace

the

selector

Replace

the

pinions

Should

the

control

have

exces-

sive

play

in

neutral,

tension

control

cables

by

screwing

back

the

respective

adjuster

screw

(on

cable

sheath

end,

ratchet

quadrant

side)

with

an

8

mm

open

ended

wrench.

If

the

cable

tension

in

neutral

is

correct

but

the

reference

marks

of

the

handlebars

do

not

tally,

tighten

one

of

the

adjuster

screw

and

unscrew

the

other

one

to

the

same

extent,

so

that

the

cable

ten-

sion

is

not

altered.

feeble

I

Replace

4.

-Clutclh

troubles

a)

Clutch

snatches:

Gear

pinions

not

lubricated

Top

up

oil

level.

Tighten

the

properly

screw

on

draining

hole

b)

Clutch

slips:

Springs

feeble

Plates

worn

or

burnt

c)

Clutch

does

not

disengage

completely:

Excessive

play

on

control

Adjust

(see

fig.

18)

cable

5.

-

Gear

pinions

disengage

of i

own

accord

I

Gear

change

control

cables

out

Adjust

of

adjustment

Spring

of

stirrup

broken,

or

missing

Selector

arms

chamfered

Dogs

of

gear

pinions

chipped

or

worn

Turn

to «

reserve

"Refill

as

soon

as

possible.

Remove

and

wash

in

gasoline

-

Blow

dry

Correct

(see

fig. 19)

Replace

the

plug

Clean

with

suitable

files

or

very

fine

emery

paper

Release

Disconnect

the

plug

lead.

Check

if

sparking

occurs

between

lead

and

crankase

when

the

kicks

tarter

is

operated.

Clean.

Correct

gap

to 0.6 mm.

I

(023")

I

I

See

page

8

I

I

Replace

Clean

(see

page

II)

Clogged

dirty

Porcelain

of

sparkplug

cracked

Breaker

points

dirty,

partially

worn

or

pitted

Gap

between

breaker

points

in-

correct

Engine

flooding

Float

perforated

Air

cleaner

choked

or

dirty

2.

-

Carburation

1.

-

ruel

system

Fuel

tank

empty

Filter

on

carburettor

(

Fuel

tap

body

Carburet

tor

body

Main

jet

\.

Atomizer

Packing

of fuel

tap

I

INCORRECT

RUNNING

Not

enough

mixture

flowing

to

See

paragraph

cDifficult

start-

the

carburettor

ing.,

No. 1

Breaker

points

completely

worn

Replace

or

pitted

i

Timing

wrong

I

Re-time

ignition

1.

-

Lack

of

power

I

Muffler

outlet

pipe

carbonized

I

Clean

(see

page

11)

Exhaust

port

partially

closed

by

,

Decarbonize

cylinder,

piston

and

carbon

deposit

cyhnder

head

Cylinder

base

gasket

not

sealing

Replace

Adjust

(see

Fig.

17)

Wash

with

gasoline

or

replace

Replace

Dismount

and

clean

carburettor

in

gasoline

and

compressed

air.

For

type

and

diameter

of

jets

and

vents,

see

page

5.

Replace

Re-time

See

No. 2of

this

paragraph

Replace

Clean

with

pure

gasoline

and

blow

dry.

Dip

the

metal

wad-

ding

into

a

30'10

gasoline-oil

bath

Lubricate

or,

if

necessary,

re-

place

Adjust

Slacken

Tighten

III

-Jets

or

air

vents

of

the

car-

buret

tor

blocked

or

dirty;

incorrect

or

increased

dia-

meter

IV

Retarded

ignition

V -

Poor

compression.

7

..

Controls

not

operating

pro-

perly

Inner

cables

rusted

6.

-

High

fuel

consumption

I -

Fuel

level

too

high

in

car-

burettor:

Float

perforated

iI

-Air

cleaner

chocked

or

dirty

Excessi

ve

play

8.

-

Steering

column

becomes

stili

Top

race

of

top

ball

bearing

too

tight

Bottom

races

of

the

two

bear-

ings

pitted

9. -

Excessive

play

of

steering

column

Top

race

of

top

bearing

loose

10. -

Poor

braking

Stroke

of

pedal

or

lever

too

long

Brake

linings

oily

or

worn

down

Brake

drums

and

linings

scrat-

ched

a)

Fit

on

a

proper

type

of

spark-

plug

b)

Re-time

the

ignition

Replace

Tighten

Replace

or

clean

the

plug

and

correct

the

gap

to 0.6

mm

(.023")

Clean

Tip of

contact

breaker

loose

Condenser

screw

loose

Pre·ignition

Sparking

plug

carbon-coated

or

with

excessive

electrode

gap

Carbon

pearls

on

sparkplug

in-

sulation

2.

-

Poor

compression

I

Sparkplug

not

well

screwed

Tighten

(21

mm

box

wrench)

down

in

cylinder

head

Cylinder

head

not

fitting

properly

I

Set

the

head

properly

and

tigh-

into

the

spigot

on

top

of

cy-

ten

the

nuts

linder

Piston

rings

gummed

up

I

Clean

the

rings

and

grooves

3.

-

Explosions

at

muller

or

car-

bureltor

-

..

-

14

--

PARTS

LIST

TABLE I

©

~

&\~44

/"',

@2040

S.1~7

5.3t

\

~

s.J057 \ -

46684

26278

87584

87GS5

26rS

~9290

I</~J~

~

:~~,

4661

87422

87423

89671

S.14441

~\~~.

~

~'8

92230

@

PARTS

UST

FOR

ENGINE

Crankcase

-

Cylinder

(TABLE

I)

Part

Number

Table

Section

DESCRIPTION

Part

Number

Table

Section

DESCRIPTION

I

318 D

Gasket,

copper,

of

sparkplug

2/84821 A

Hood,

cooling

2040 C

Adjuster

of clutch 84644 B

SeaL

spring

loaded,

[or

crankcase,

2444 CNut

flywheel

side

86944

B

Piston,

with

standard

wr'st

pin

(with

13903 D

Sparkplug,

with

gasket

2/51992 -

S.

6615)

23823 C

Adjuster

of

rear

brake

87420

B

Piston,

1st

oversize,

with wrist

pin

26278 B

Ball

bearing,

of

crankshaft

(with

2/51992 -

S.

6615)

46261

A-B

Stud,

long,

cylinder

fastening

87421

B

Piston,

2nd

oversize

with wrist

pin

(with

2/51992

-

S.

6615)

46684 CBolt,

securing

crankcase

halves

Piston,

3rd

oversize

with wrist pin

87422

B

46741

D

Cap,

rubber,

for

sparkplug

(with

2/51992

-

S.

6615)

45290 B

Seal,

spring

loaded,

for

crankcase,

87423

B

Piston,

4th

oversize

with wrist pin

clutch

side

(with

2/51992

-

S.

6615)

49502 B

Gasket,

crankcase

8743'2

A

Ring,

piston,

1st

oversize

2/51992 A

Wrist

pin

87433 A

Ring,

piston,

2nd

oversize

52575 ARing, piston,

normal

87434 A

Ring,

piston,

3rd·

~versize

52625 A

Cylinder

-

15

--

Parts

list for

engine

-

Crankcase

-

Cylinder

-

Continued

Part

Number

Table

Section

DESCRIPTION

Part

Number

Table

Section

DESCRIPTION

II

87425 ARing. piston, 4th

oversize

I

IS.

5'21

B

Stud.

for fixing

carburettor

87436 D

Wrist

pin,

1st

oversize

S. 1107 A-B-C

Nut.

for

locking

cylinder

head

and

87437 DI

Wrist

pin,

2nd

oversize

crankcase

halves

87584

B

Crankcase

halves

(Parts

n. 12869 -S. 1207 C

Nut

40313 -40316 -

4626,1

-

46'6-31

-S. 1447 IC

46684 -47160 -47161 -47944 -

Nut.

spacer,

hood

fixing

47945 -47946 -47947 47948 -S. 3057 A-B-C

Washer.

plain

48000 -48002 -48035 -49502 -

51255 -54071 -81842 -a2086 -S. 2107 A-B-C-D

Washer.

spring

87685 -S.

521

-S. 1107 -S. 3057

S.6615

C

Circlip.

for

locking

wrist

pin

-S. 3107 -S. 10790 -S. 11288 -

S. 12485)

S.6977

A-C

Washer.

spring

87685 B

Plug.

on

crankcase,

flywheel

side

S.11288

A

Stud.

securing

crankcase

halves

89120 A

Gasket.

cylinder

base

S.

1'2485

BBolt.

short,

securing

crankcase

89871

D.

Engine.

g.

a.

halves

92230 D

Head,

cylinder

S.14441 D

Screw.

hood

fixing

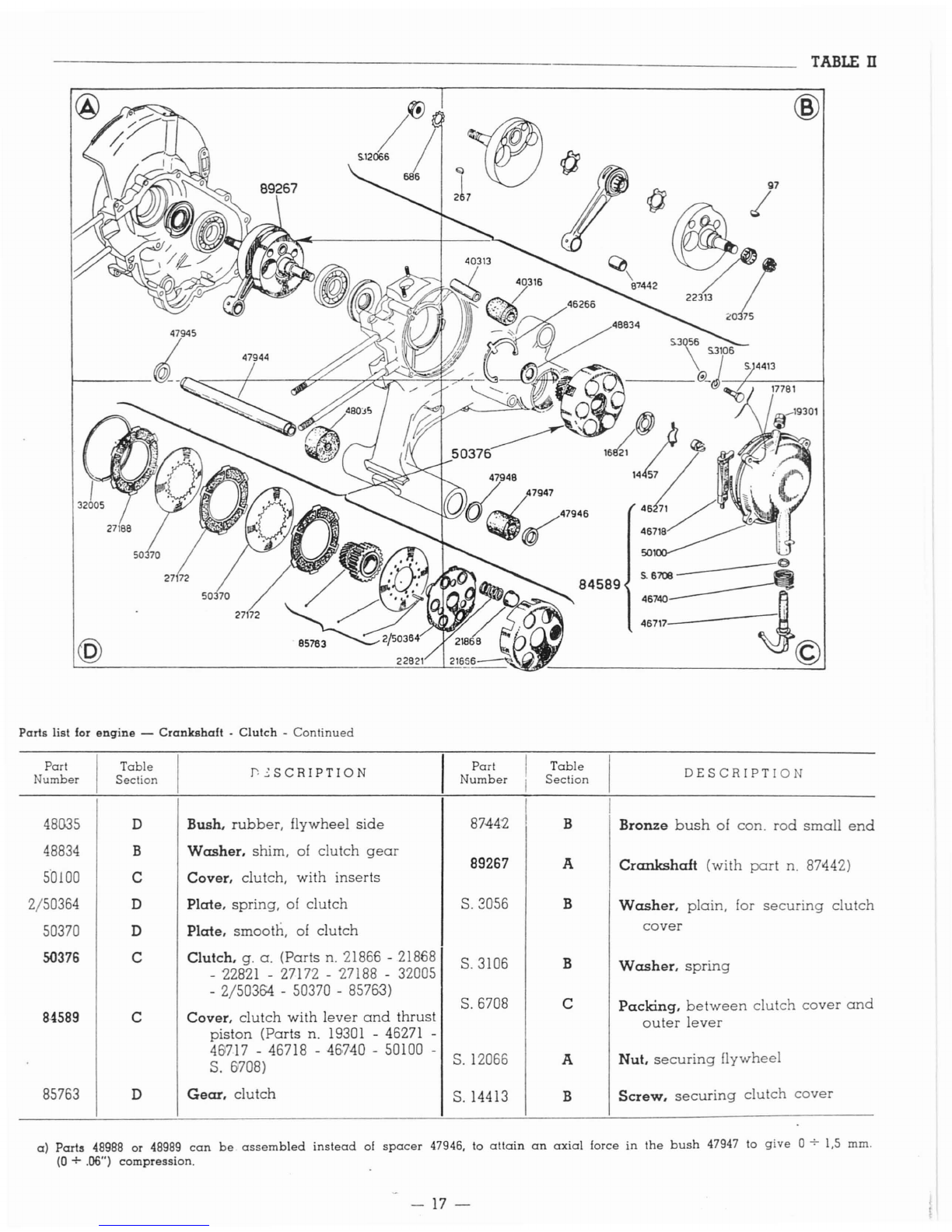

PARTS

UST

FOR

ENGINE

Crankshaft

-

Clutch

(TABLE II)

Washer

spring,

for

castle

nut

se-

curing

clutch

a)

47946

Part'

Number

97

267

686

14457

16821

17781

19301

2G375

21866

21868

22313

22821

27172

Table

Section

B

B

A

C

C

C

C

B

D

D

B

D

D

DESCRIPTION

Key. woodruff. for

crankshaft

(clutch

side)

Key. woodruff, for

crankshaft

(flywheel

side)

Washer.

shake

proal. for

nut

secur-

ing

flywheel

Spring,

for fixing

clutch

centralizing

plate

Plate.

clutch

centralizing

Gasket.

between

clutch

cover

and

crankcase

Breather.

with

inserts

Nut.

castle,

for

securing

clutch

Body

clutch

Cup,

clutch

spring

Spring.

clutch

Plate.

clutch,

with

linings

Part

Number

27188

32005

40313

40316

46266

46271

46717

46718

46740

47944

47945

47947

47948

Table

Section

D

D

B

B

B

C

C

C

C

A

A

C

C

C

DESCRIPTION

Driving

disc,

external,

of

clutch

Ring.

elastic,

for

stopping

clutch

plates

Spindle.

hollow, for

hydraulic

shock-

absorber

Bush.

bottom,

rubber,

of

shock-

absorber

Circlip.

locking

spacer

Piston,

slo

ted

thrus

,of

clutch

Lever.

outer,

clutch

control

Lever.

inner,

clutch

control

Spring,

return,

of

outer

clutch

con-

trol

lever

Spindle.

hollow, for

engine

su-

spension

Spacer,

flywheel

side

Spacer.

clutch

side

Bush.

rubber,

clutch

side

Washer.

plain

-

16-

TABLE

n

@

Paris

lisl lor

engine

-

Crankshaft

-

Clulch

-

Continued

84589

@

Part

Number

Table

Section

r.'::SCRIPTION

Part

Number

Table

Section

DESCRIPTION

I

48G35

D

Bush.

rubber,

flywheel

side

8744:2

B

Bronze

bush

of

can.

rod

small

end

48834

B

Washer.

shim, of

clutch

gear

89267

A

Crankshaft

(with

part

n.

87442)

5'0100

C

Cover.

clutch,

with

inserts

2/50364

D

Plate.

spring,

of

clutch

S.

2056

B

Washer.

plain,

for

securing

clutch

50370

D

Plate.

smooth,

of

clutch

cover

S<l376

C

Clutch.

g.

a.

(Parts

n.

21866

-

21868

S.3106 B

Washer.

spring

-

22821

-

27172

-

27188

-

32005

-

2/503&1

-

50370

-

85763)

S.

6708

C

Packing.

between

clutch

cover

and

84589

C

Cover.

clutch

with

lever

and

thrust

outer

lever

piston

(Parts

n.

19301

-

46271

-

461717

-

46718

-

46·740

-

50100

-

S.

12066

A

Nut.

securing

flywheel

S.

(708)

85763

D

Gear.

clutch

S.14413 B

Screw.

securing

clutch

cover

a)

Parts

48988

or

48989

can

be

assembled

instead

of

spacer

47946, to

attain

an

axial

force

in

the

bush

47947 10

give

0

-;-

1,5

mm.

(0

+.06")

compression.

-

17

-

---------------------------------_

TABLE

ill

@

~~lny{§

~-----:::7/

....

----"'--1)-'O>-\

17'"

B201lS

~sr"'47

47'90

'.1376'

"'"'S

\

@

PARTS

LIST

FOR ENGINE

Gear

box

-Rear

wheel

flange

©

(TABLE

ill)

Part

Number

Table

Section

DESCRIPTION

Part

Number

Table

Section

DESCRIPTION

61

AClip,

spring,

for

brake

jaws

a)

20322 CIWasher,

shoulder

2nd

oversize

2021

AScrew, for joining

brake

drum

to (thickness: 2,35 mm. =0"

.09.2)

flange

a)

20323 CWasher,

shoulder

3rd

oversize

2,442

ANut. for

securing

wheel

(thickness: 2,50 mm. =0".098)

7563 Ball

bearing

of

mainshaft

a)

20324 C

Washer,

shoulder

4th

oversize

A(thickness:

2,&5

mm. =0".104)

7886 A

Pad

23831 A

Drum,

rear

brake

12869 BScrew, for

dust

cover

42043 BArm,

rear

brake

control

17821

DSelector,

gear

42047 BLink,

brake

18447

CCirclip,

retaining

shoulder

washer

42048 BPin, for

rear

brake

links

a)

18558

CWasher,

shoulder,

normaL of

gear

46605 CStem,

selector

pinions

Washer,

shoulder,

1st 46688 A

Ring,

locking

ball

bearing

a)

20321

C

oversize

(thickness: 2,2 mm. =0".086) 46699 A

Seal,

spring

-

loaded

of

mainshaft

a)

The

total

axial

play

01

the

assembly

01

the

3

gear

pinions

in

respect

to

their

seat

must

be

contained

between

.006"

and

.012".

Should

this

play

exceed

said

tolerances,

the

normal

shoulder

washer

must

be

replaced

by

another

with

proper

oversize.

10

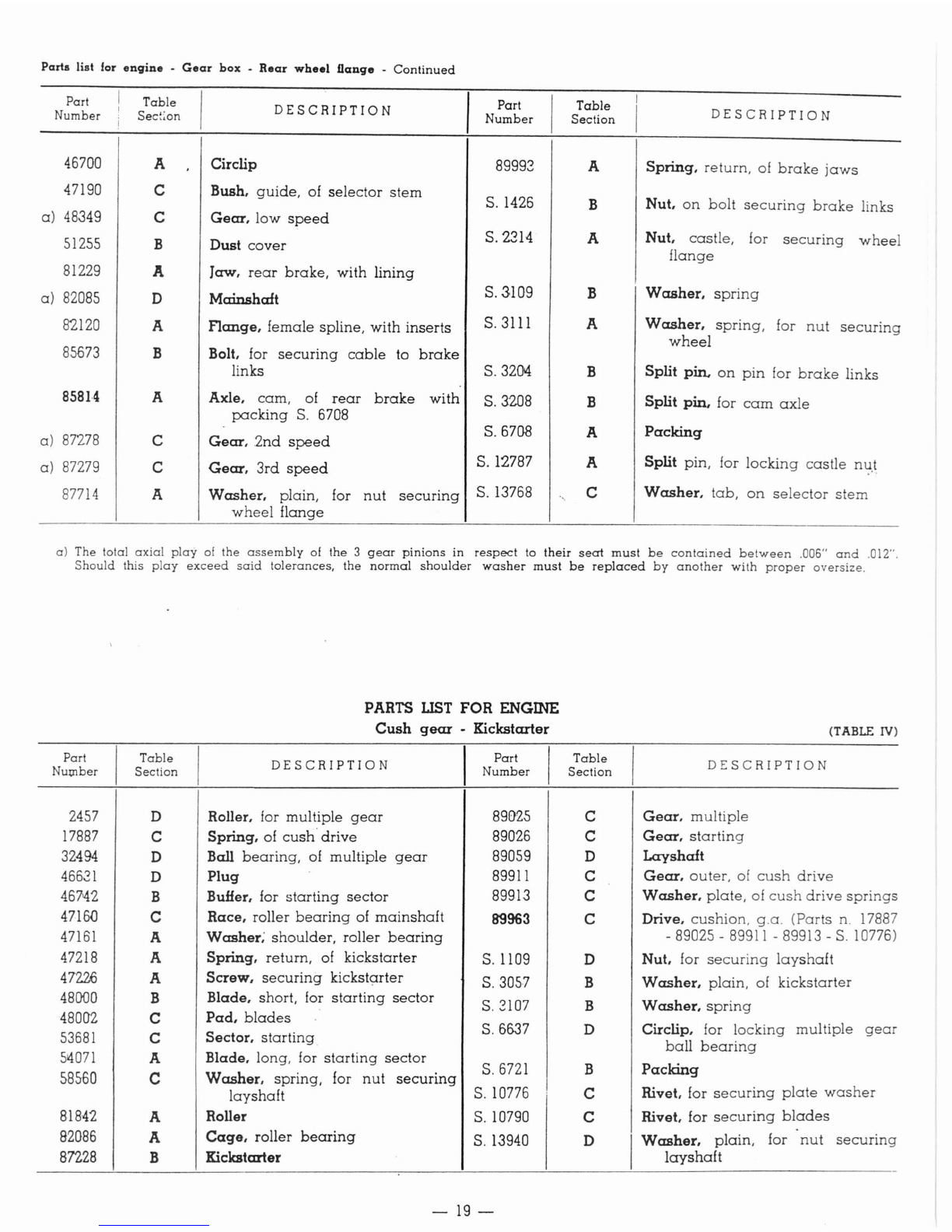

Parts list lor

engine

.

Gear

box

.

Rear

wheel

nange

-

Continued

Part

Number

46700

47190

a)

48349

51255

81229

a)

82085

82120

85073

858J.4

a)

87278

a)

87279

87714

Table

Sec:;on

A

C

C

B

A

D

A

B

A

C

C

A

DESCRIPTION

Circlip

Bush,

guide,

of selector

stem

Gear, low

speed

Dust

cover

Jaw,

rear

brake,

with lining

Mainshaft

Flange, female spline, with inserts

Bolt, for

securing

cable

to

brake

links

Axle,

cam,

of

rear

brake

with

packing

S.

6708

Gear, .2nd

speed

Gear,

3rd

speed

Washer, plain, for

nut

securing

wheel

flange

Part

Number

89993

S.

1426

S.2314

S.3109

S.3111

S.3204

S.3208

S.

6708

S.12787

S. 13768

Table

Section

A

B

A

B

A

B

B

A

A

C

DESCRIPTION

Spring,

return,

of

brake

jaws

Nut,

on

bolt

securing

brake

links

Nut, castle, for

securing

wheel

flange

Washer,

spring

Washer,

spring,

for

nut

securing

wheel

Split Pin.

on

pin

for

brake

links

Split pin, for

cam

axle

Packing

Split pin, for

locking

castle

nl.;!.t

Washer,

tab,

on

selector

stem

a) The total

axial

play

of

the

assembly

of

the

3

gear

pinions

in

respect

to

their

seat

must

be

contained

between

.006"

and

.012".

Should

this

play

exceed

said

tolerances,

the

normal

shoulder

washer

must

be

replaced

by

another

with

proper

oversize.

PARTS

LIST

FOR ENGINE

Cush

gear

-Kickstarter

(TABLE

IV)

Part

Nu~ber

Table

Section

DESCRIPTION

I

Part

Number

Table

Section

DESCRIPTION

2457

DRoller, for multiple

gear

89025 CGear, multiple

17887

CSpring,

of

cush'

drive

89026 CGear,

starting

32494

DBall

bearing,

of multiple

gear

89059 DLayshaft

46631

DPlug

89911

CGear,

outer,

of

cush

drive

467'42

B

BuHer,

for

starting

sector

89913 CWasher,

plate,

of

cush

drive

springs

4716D

CRace. roller

bearing

of

mainshaft

89963

CDrive,

cushion,

g.a.

(Parts n. 17887

47161

AWasher; shoulder, roller

bearing

-89025 -

89911

-89913 -

S.

10776)

47218

ASpring. return,

of