Allstate 788.94492 Use and care manual

OPERATING

INSTRUCTIONS

AND

PARTS

LIST

FOR

MOTOR SCOOTER

MODEL

NUMBER 788.94492

--,

This is

the

Model

Number

of

your

Allstate Motor Scooter. It will

be

found

on

a

plate

fastened

on

the

outside

of

the

hinged

door

under

the

seat. Always

mention

this

number

when

communicating

with

us regarding

the

Scooter,

or

when

ordering

repair

parts.

,..---

HOW

TO ORDER REPAIR PARTS

All

parts

listed herein

may

be

ordered

through

any

Sears

retail

or

mail

order

store. In ordering

parts

by

mail from

the

mail

order

store

which

serves

the

territory

in

which

you live, Selling Prices

will

be

furnished

on

request

or

parts

will

be

shipped

at

prevailing prices

and

you will

be

billed accordingly.

WHEN

ORDERING REPAIR PARTS, ALWAYS GIVE

THE

FOLLOWING INFORMATION:

1.

The

Part

Number

in this List.

2.

The

Part

Name

in this List.

3.

The

Model

Number

of

the

item.

This list is valuable. It will

assure

your

being

able to

obtain

proper

parts

service

at

all times.

We

suggest you

keep

it

with

other

valuable papers.

SEARS, ROEBUCK

AND

CO.

Scooterworks

USA

5410

Damen

Ave

Chicago IL 60625

888-96-VESPA

\\W\\'

.scoote

1'\\'01'

ks.

COI11

';

OPERATING

INSTRUCTIONS

AND

PARTS

LIST

FOR

'.

HOW

TO

ORDER

REPAIR

PARTS

MOTOR

SCOOTER,

wHEN

ORDERING REPAIR PARTS. ALWAYS GIVE THE

FOL-

LOWING

INFORMA

nON:

1.

-

The

Part

Number

in

this

List.

2. -

The

Part

Name

in

this List.

S

3.

-

The

Mo~e\,Number

of

the

item

.

r-----~MODEL

NUMBER

788.94492------,

"

This

is

th;;

Model

Number

of

your

Allstate

Motor

sc~'

er.

It

will

be

found

on

a

plate

fastened

on

the

outside

of

the

hing,

door

under

the

seat.

Always

mention

this

number

when

comm

'cating

with

us'regarding

the

Scooter.

or

when

ordering

parts.

~

"'"r'"

:

'I

!

',-'

/

~ll:~~.

~',AIi

parts

listed

herein

may

be

ordered

thr'ough

al'ly

Sears

retail

or

',I~'

'mqu

order

store.

In

ordering

parts

by

mail

from

the

mail

order

store

.

~',:.

w~ch

serves

the

territory

in

which

you

live.

Selling

Prices

will

be

..

.

ftIhushed

on

request

or

parts

will

be

shipped

at

,prevailing

prices

and

you

will

be

billed

accordingly.

'..

'I

".

/

..

"

.,

.

"'J~

I

..-'

...

.

):

~

.

This

list

is

valuable.

It

will

assure

,your

being

able

to

obtain

proper

parts

service

at

all

times.

We

suggest

you

keep

it

with

other

valuable

papers.

SEARS,

ROEBUCK

AND co.

'.

,

./

,I

Location

01

serial

Number

Fig. 1 -

ALLSTATE"

Cruisaire

•Motor

Scooter

WARNING

-2-

In

order

to

keep

your

ALLSTATE

Scooter

in

per-

fect

running

condition

and

not

to

void

the

guarantee,

always

have

your

machine

repaired

at

a

Sears,

Roe-

buck

and

Co. Store.

Special

care

should

be

taken

in

regard

to

the

fuel

mixture

which

should

be

regular

gasoline

and

oil of

the

make,

grade

and

in

the

amount

prescribed

in

this booklet.

Ethyl

gasoline

should

never

be

used.

Do

not

use

Allstate

compounded

motor

oil

or

other

Premium

Heavy

Duty

Motor

Oil

with

deter-

gents.

The

inexperienced

operator

should

exercise

caution

in

applying

front

wheel

brake,

to

avoid

locking.

THROTTLE

CONTROL

GRIP

FILLING

CAP

CHOKE

KICKSTARTER

FUEL

COCK

SHUTIER

OF

CAAME

SWITCH,

HORN

BUTTON.

EARTH

CONTACT

GEAR

SHIFT-CLUTCH

CONTROL

HORN

,,

..

'--

REAR

BRAKE

PEDAL

FRONT

BRAKE

LEVER

Fig.

2 -

Controls

of

Allstate

Scooter

MAIN

SPECIFICATIONS

Frame.

-Of

pressed

and

spot-welded

steel

sheet,

with

stream-lined

monocoque-type

structure.

Suspension.

-

Front

wheel:

coil

spring.

Rear

wheel:

coil

spring

and

coaxial

hydraulic

shock

absorber.

Engine.

-Two-stroke, flat

cast

iron

cylinder

and

cast

aluminum

alloy

cylinder

head.

Fuel

conSUmption:

(Gasoline

-oil

mixture)

Max.

speed

Wheelbase

.

Max.

width

on

handlebars

Max.

length

of

the

'scooter

.

Max.

height

Ground

clearance

Turning

circle.

.

Weight

(unladen)

Displacement.

Bore

....

Stroke . . .

Effective

power

at

5000

rpm

Compression

ratio

.

.118

miles

per

gal.

46.6

m.p.h.

45.6 in.

31

in.

66

in.

37

in.

8.6

in.

59

in.

189 Ibs.

1'23.67

cc. (7.48 cu.

in.)

S4

mm. (2.12 in.)

54

mm. (2.12 in.)

4.5 HP.

6.5:

1

Transmission.

-

Directly

from

engine

to

rear

wheel

through

clutch,

cushion

drive

and

gear

box

.

Starting.

-By

means

of

kickstarter,

right

hand

side

of scooter.

Gear

box.

-

3-speed

drive

with

mesh

gears

in

oil

bath:

Its

two-cable

control

is

coupled

with

that

of

the

clutch,

on

left

hand

side

of

handlebars.

Clutch. -

Wet

type;

steel

plates

with

cork

inserts.

Ignition. -By

flywheel

magneto.

Lighting

and

hom.

-By

flywheel

magneto,

teeding

both

head

lamp

(two-beam).

tail

lamp,

horn

and

stop

light.

Brakes. -

EXPanding

type.

Front

brake:

control

lever

on

right

hand

side

of

handlebars.

Rear

brake:

control

pedal

on

right

hand

side

of

floorboard.

Wheels.

-Of

pressed

steel

sheet,

interchangeable

and

easily

removable.

since

they

are

assembled

in

an

automobile-like

system.

Tires:

dia.

3.50 X8in.

Fuel

tank. -

Total

capacity:

2.17

gals.;

Reserve:

0.4 gals.;

Three-way

cock:

copen,.

- c

closed»

-

"reserve,.

-3-

_~

...

,~

_1

..

__

OPEN

SPEEDOMETER

HOUSING

/

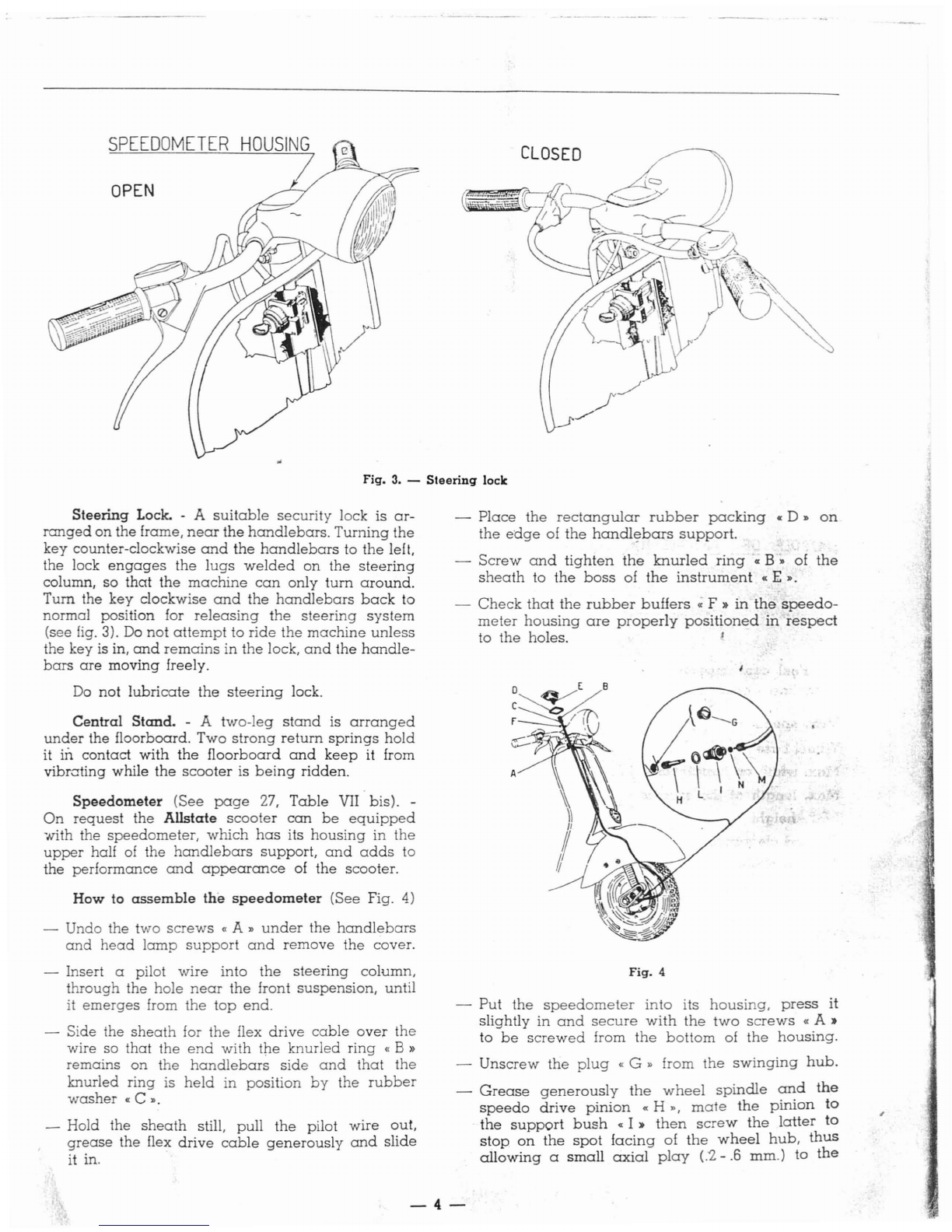

Fig. 3. -

Steering

lock

CLOSED

Steering

Lock. - A

suitable

security

lock is

ar-

ranged

on

the frame,

near

the

handlebars.

Turning

the

key counter-clockwise

and

the

handlebars

to

the

left,

the lock

engages

the

lugs

welded

on

the

steering

column,

so

that

the

machine

can

only

turn

around.

Turn the

key

clockwise

and

the

handlebars

back

to

normal position for

releasing

the

steering

system

(see

fig.

3). Do

not

attempt

to

ride

the

machine

unless

the key is in,

and

remains

in

the

lock,

and

the

handle-

bars

are

moving

freely.

Do

not

lubricate

the

steering

lock.

Central

Stand.

- A

two-leg

stand

is

arranged

under

the floorboard.

Two

strong

return

springs

hold

it

in

contact

with

the

floorboard

and

keep

it from

vibrating

while

the

scooter

is

being

ridden.

Speedometer

(See

page

27,

Table

VII

bis). -

On

request

the

Allstate

scooter

can

be

equipped

"With

the

speedometer,

which

has

its

housing

in

the

upper

half of the

handlebars

support,

and

adds

to

the

performance

and

appearance

of

the

scooter.

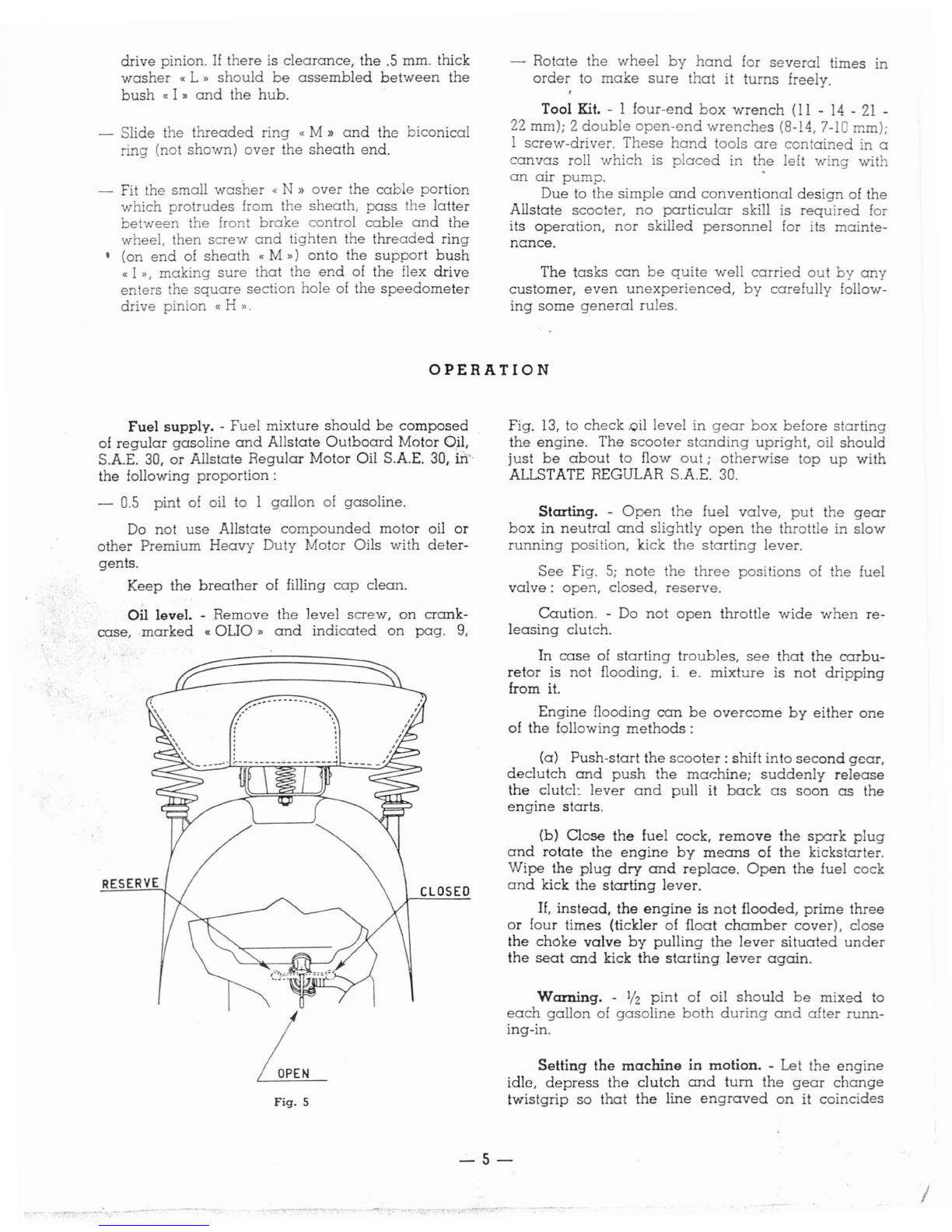

How

to

assemble

the

speedometer

(See Fig.

4)

-Undo the two

screws

«

A"

under

the

handlebars

and

head

lamp

support

and

remove

the

cover.

-Insert apilot

wire

into

the

steering

column,

through

the

hole

near

the

front

suspension,

until

it

emerges

from

the

top

end.

-Side the

sheath

for

the

flex

drive

cable

over

the

wire so

that

the

end

with

the

knurled

ring

«B»

remains

on

the

handlebars

side

and

that

the

knurled ring is

held

in

position

by

the

rubber

washer

«C

».

-Hold the

sheath

still,

pull

the

pilot

wire

out,

grease

the

flex

drive

cable

generously

and

slide

it in.

-

Place

the

rectangular

rubber

packing

«D"

on

the

edge

of

the

handl~bars

support.

-

Screw

and

tighten

the

knurled

ring

«B"

of

the

sheath

to

the

boss

of

the

instrument

«E".

-

Check

that

the

rubber

buffers

« F »

in

the

speedo-

meter

housing

are

properly

positioned

in

respect

to

the

holes. '

,.I

'J

Fig.

4

-

Put

the

speedometer

into

its

housing,

press

it

slightly in

and

secure

with

the

two

screws

«A,.

to

be

screwed

from

the

bottom

of

the

housing.

-

Unscrew

the

plug

«G»

from

the

swinging

hub.

-

Grease

generously

the

wheel

spindle

and

the

speedo

drive

pinion

«H

",

mate

the

pinion

to

the

support

bush

«I»

then

screw

the

latter

to

stop

on

the

spot

facing

of

the

wheel

hub,

thus

allowing

a

small

axial

play

(.2

-.6

mm.)

to

the

-4-

drive

pinion. If

there

is

clearance,

the

.5

mm. thick

washer

«L»

should

be

assembled

between

the

bush

«I»

and

the

hub.

-Slide the

threaded

ring

«M»

and

the

biconical

ring

(not

shown)

over

the

sheath

end.

-Fit the

small

washer

«N»

over

the

cable

portion

which

protrudes

from the

sheath,

pass

the

latter

between

the

fron

brake

control

cable

and

the

wheel,

then

screw

and

tighten

the

threaded

ring

,(on

end

of

sheath

«M")

onto

the

support

bush

«

1",

making

sure

that

the

end

of

the

flex

drive

enters

the

square

section

hole

of

the

speedometer

drive

pinion

«H

».

-

Rotate

the

wheel

by

hand

for

several

times

in

order

to

make

sure

that

it

turns

freely.

,

Tool Kit. -1

four-end

box

wrench

(11

-

14

-

21

-

22

mm); 2

double

open-end

wrenches

(8-14,

7-10

mm);

1

screw-driver.

These

hand

tools

are

contained

in a

canvas

roll

which

is

placed

in

the

left

wing

with

an

air

pump.

'

Due

to

the

simple

and

conventional

design

of

the

Allstate

scooter,

no

particular

skill is

required

for

its

operation,

nor

skilled

personnel

for its

mainte-

nance.

The

tasks

can

be

quite

well

carried

out

by

any

customer,

even

unexperienced,

by

carefully

follow-

ing

some

general

rules.

OPERATION

Fuel

supply.

-

Fuel

mixture

should

be

composed

of

regular

gasoline

and

Allstate

Outboard

Motor Oil,

S.A.E.

3D,

or

Allstate

Regular

Motor Oil S.A.E.

3D,

m"

the

following

proportion:

-

0.5

pint

of oil to 1

gallon

of

gasoline.

Do

not

use

Allstate

compounded

motor

oil

or

other

Premium

Heavy

Duty

Motor Oils

with

deter-

gents.

Keep

the

breather

of filling

cap

clean.

Oil level. -

Remove

the

level

screw,

on

crank-

case,

marked

«OUO»

and

indicated

on

pag.

9,

CLOSED

L

Fig.

5

Fig.

13,

to

check

.oil

level

in

gear

box

before

starting

the

engine.

The

scooter

standing

upright,

oil

should

just

be

about

to flow

out;

otherwise

top

up

with

ALLSTATE REGULAR S.A.E.

30.

Starting.

-

Open

the

fuel

valve,

put

the

gear

box

in

neutral

and

slightly

open

the

throttle in

slow

running

position, kick

the

starting

lever.

See

Fig.

5;

note

the

three

positions

of

the

fuel

valve:

open,

closed,

reserve.

Caution.

-Do

not

open

throttle

wide

when

re-

leasing

clutch.

In

case

of

starting

troubles,

see

that

the

carbu-

retor

is

not

flooding,

i.

e.

mixture

is

not

dripping

from it.

Engine

flooding

can

be

overcome

by

either

one

of

the

following

methods:

(a)

Push-start

the

scooter:

shift

into

second

gear,

declutch

and

push

the

machine;

suddenly

release

the

clute!:

lever

and

pull

it

back

as

soon

as

the

engine

starts.

(b)

Close

the

fuel

cock,

remove

the

spark

plug

and

rotate

the

engine

by

means

of

the

kickstarter.

Wipe

the

plug

dry

and

replace.

Open

the

fuel

cock

and

kick

the

starting

lever.

If,

instead,

the

engine

is

not

flooded,

prime

three

or

four

times

(tickler of

float

chamber

cover),

close

the

choke

valve

by

pulling

the

lever

situated

under

the

seat

and

kick

the

starting

lever

again.

Warning.

-

112

pint

of oil

should

be

mixed

to

each

gallon

of

gasoline

both

during

and

after

runn-

ing-in.

Setting

the

machine

in

motion.

-Let

the

engine

idle,

depress

the

clutch

and

tum

the

gear

change

twistgrip

so

that

the

line

engraved

on

it

coincides

-5-

.'

- - _

...

J

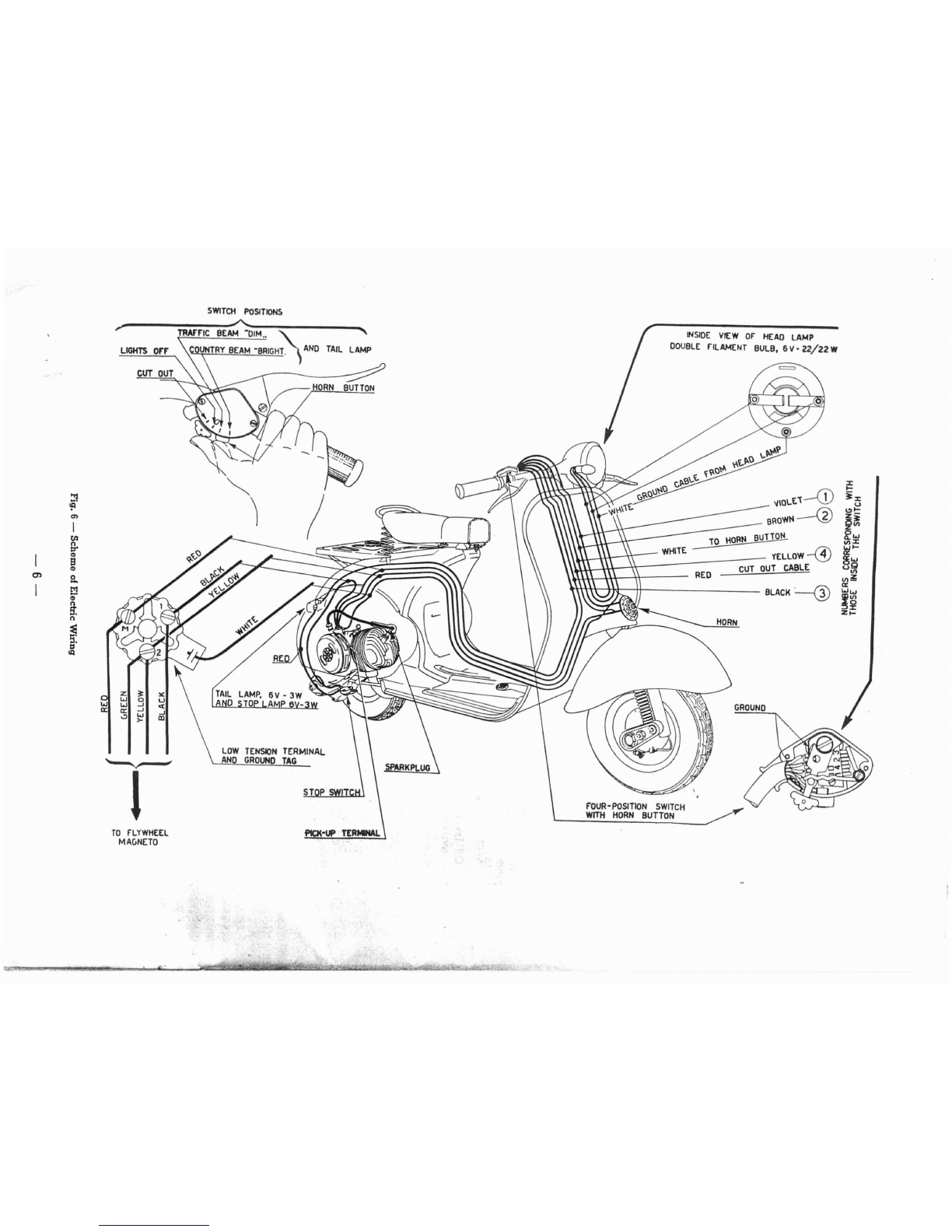

INSIDE

VIEW

OF"

HEAD

LAMP

DOUBLE

F"ILAMENT

BULB,

6V'

22/22W

HORN

BUTTON

LOW

TENSION

TERMINAL

AND

GROUND

TAG

CUT

OUT

SWITCH

POSITIONS

.-

..A...-~--~----_

,

TRAffiC

BEAM

"DIM

"\..

'

LIGHTS

orr

,\CO~TRY

BEAM

·B~IGH1.

)

AND

TAIL

LAMP

TO

F"LYWHEEL

MAGNETO

'--v--'

1

~

~

x

~\O\.E1-CD

~

~

1ix

~

u

BROWN-@

C)~

en

2~

I

en

BuTiQN f

....

n

'l'ELLOW-@

j:

l:l"

WHITE

Itil

B

til

CUT

OUT

CABLE

uQ

til

en

2-

RED

tIl~

I

!.'!l

BLACI<~

a:

........

til

~~

S:

z~

n

~

tl

lQ

with

the

number

1

(lst

gear)

engraved

on

handlebars

(see Fig. 7).

Now

let

in

the

clutch

gently,

while

open-

ing

the

throttle

gradually

to

set

the

machine

in

motion.

Gear

change.

-After

reaching

the

required

speed

in

1st

gear,

close

quickly

the

throttle,

depress

the

Fig.

7

clutch

and

tum

the

gear

change

twistgrip

so

that

the

engraved

line

is

opposite

number

2

(2nd

gear);

let

in

the

clutch

and

open

the

throttle

gradually.

Repeat

this

procedure

for

changing

into

3rd

gear.

For

changing

down,

close

the

throttle,

depress

the

clutch

and

tum

the

gear

change

twistgrip

to

the

required

position.

When

you

reduce

the

speed

of

your

machine,

change

down

with

no

delay.

Do

not

tum

the

gear

change

twistgrip

while

the

engine

is

not

running.

Fig.

8

As

soon

as

gear

change

troubles

arise,

parti-

,,1/

cularly

when

the

control

becomes

hard,

customers

should

have

their

machines

adjusted

at

a

Sears

Roebuck

and

Co.

store.

Tires. -

The

wheels

are

interchangeable,

i.

e.

they

can

be

assembled

either

in

front

or

rear,

pro-

vided

of

course

that

they

are

enflated

to

pressures

respectively

hereunder

prescribed.

When

aflat

tire

is

to

be

replaced,

unscrew

the

four

nuts

which

secure

the

wheel

to

its

flange,

pull

wheel

sideways

off

the

studs

(see

Fig. 8),

repair

it

or

replace

with

spare

wheel.

To

remove

the

tube,

deflate

it

first,

then

sepa-

rate

the

felloe from

the

ring

by

unscrewing

the

nuts

which

join

them

(see

Fig. 9).

Tire

pressure

should

be

18

psi

on

rear

wheel,

11

psi

on

front

wheel.

If

the

Allstate

is

ordinarily

ridden

by

both

driver

and

passenger,

the

pressure

of

the

rear

tire

should

be

28 psi.

Fig.

9

Stopping

the

engine.

-

Push

the

switch

lever

all

the

way

to

the

left;

fuel

vapors

remain

in

the

cylinder

in

this

way,

and

the

next

start

will

be

much

easier.

Brake

adjustment.

-

Brakes

are

properly

ad-

justed

if:

-

the

wheel

rotates

freely

when

respective

control

lever

or

pedal

are

in

resting

position;

-

the

braking

action

starts

as

soon

as

respective

controls

are

operated.

-7-

/

"T

CJutch

leyer:

~ine

side

BClutch lever

on

handlebars

Fig.

12

Wrong

play

in

the

control

may

cause

the

clutch

plates

burning

out

even

i.n

normal

riding

conditions.

The

cable

is

to

be

tensioned

or

loosened,

as

the

case

may

be,

so

that

control

lever

(B),

on

handle-

bars,

makes

a

stroke

of 2

mm.

(.078")

before

lever

(C),

on

engine,

starts

moving.

Adjustment

of

clutch

control.

-

Adjustment

of

clutch

control

is

achieved

operating

on

adjusting

nut

(A),

screwed

to

the

engine

braket

(see

Fig. 12),

by

means

of

open

end

wrench

15655

in

the

tool

roll.

Slow

running

adjustment.

-

No

hand

tool

is

re-

quired

for this

job;

idling

revs

can

be

raised

by

simply

tightening

the

screw

which

presses

on

car-

buretor

cover

and

vice-versa.

Fig.

10

c

Fig.

11

s::::>

sS~

a

tr

7

2

?5

'

~

~

ups,

\

I:;

~:

!

1I1i"!

I

~

sp

7

I:D

These

conditions

are

achieved

adjusting

the

cobles

by

means

of

screws

indicated

with

an

arrow

in Figs.

10

and

11.

-8-

MAINTEN

ANCE

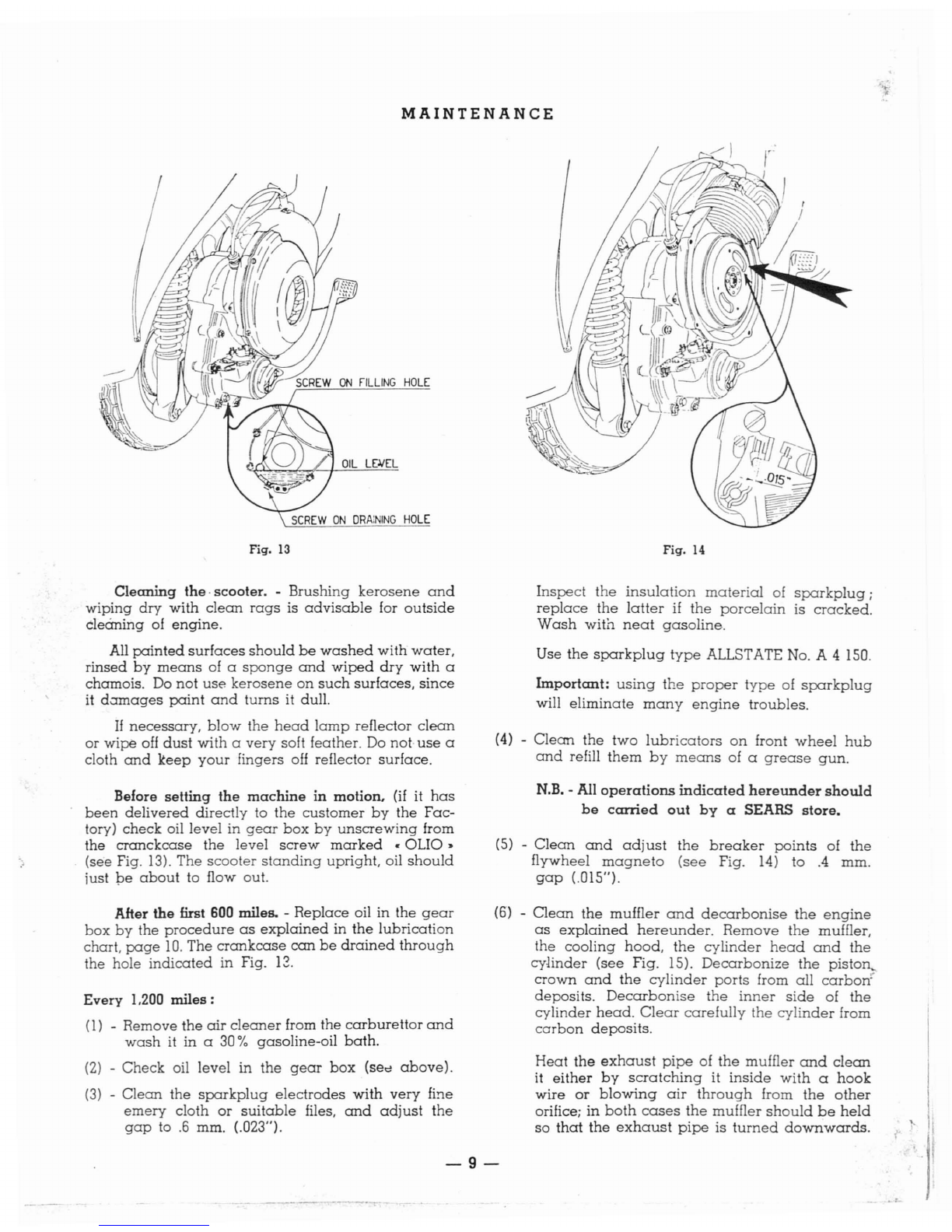

Fig.

13

Cleaning

the·

scooter.

-

Brushing

kerosene

and

wiping

dry

with

clean

rags

is

advisable

for

outside

cleaning

of

engine.

All

painted

surfaces

should

be

washed

with

water,

rinsed

by

means

of a

sponge

and

wiped

dry

with

a

chamois. Do

not

use

kerosene

on

such

surfaces,

since

it

d.:rrnages

paint

and

turns

it

dull.

If

necessary,

blow

the

head

lamp

reflector

clean

or

wipe

off

dust

with

a

very

soft feather. Do not·

use

a

cloth

and

keep

your

fingers

off

reflector

surface.

Before

setting

the

machine

in

motion,

(if

it

has

been

delivered

directly

to

the

customer

by

the

Fac-

tory)

check

oil

level

in

gear

box

by

unscrewing

from

the

cranckcase

the

level

screw

marked

•

OLIO

~

(see Fig.

13).

The

scooter

standing

upright,

oil

should

just

be

about

to flow out.

After

the

first

600

miles. -

Replace

oil in

the

gear

box

by

the

procedure

as

explained

in

the

lubrication

chart,

page

10.

The

crankcase

can

be

drained

through

the hole

indicated

in Fig.

12.

Every

1.200

miles:

(l)

-Remove

the

air

cleaner

from

the

carburettor

and

wash

it

in

a

301"0

gasoline-oil

bath.

(2) -

Check

oil

level

in

the

gear

box

(sec

above).

(3) -

Clean

the

sparkplug

electrodes

with

very

fine

emery

cloth

or

suitable

files,

and

adjust

the

gap

to

.6

mm. (.023").

Fig.

14

Inspect

the

insulation

material

of

sparkplug;

replace

the

latter

if

the

porcelain

is

cracked.

Wash

with

neat

gasoline.

Use

the

spark

plug

type

ALLSTATE No. A4150.

Important:

using

the

proper

type

of

sparkplug

will

eliminate

many

engine

troubles.

(4) -

Clean

the

two

lubricators

on

front

wheel

hub

and

refill

them

by

means

of a

grease

gun.

N.B.

-All

operations

indicated

hereunder

should

be

carried

out

by

aSEARS

store.

(5)

-

Clean

and

adjust

the

breaker

points

of

the

flywheel

magneto

(see

Fig.

14)

to

.4

mm.

gap

(.015").

(6) -

Clean

the

muffler

and

decarbonise

the

engine

as

explained

hereunder.

Remove

the

muffler,

the

cooling

hood,

the

cylinder

head

and

the

cylinder

(see

Fig. 15).

Decarbonize

the

piston~

crown

and

the

cylinder

ports

from

all

carbon!'

deposits.

Decarbonise

the

inner

side

of

the

cylinder

head.

Clear

carefully

the

cylinder

from

carbon

deposits.

Heat

the

exhaust

pipe

of

the

muffler

and

clean

it

either

by

scratching

it

inside

with

a

hook

wire

or

blowing

air

through

from

the

other

orifice;

in

both

cases

the

muffler

should

be

held

so

that

the

exhaust

pipe

is

turned

downwards.

-9-

-

----

.'~

Fig.

15

LUBRICATION CHART FOB

~ATE

PART

TO

BE

OPERATION

TIM

E

TYPE

OF

LUBRICANT

LUBRICATED

Engine

Mix

gasoline

with

the

following

amount

of At

each

refilling of

the

fuel

Allstate

Regular

SAE

30

or

lubricating

oil :

tank

Allstate

Outboard

Motor

Oil

-

0.5

pint

of oil to I

gallon

of

gasoline.

Gear

Box

W=

up

the

engine

and

drain

off

all

oil. After

the

first

600

miles

Pour

some

fresh

oil

in

and

run

the

engine

for afew

seconds.

Drain

again

and

refill

with

Allstate

Regular

SAE 30

new

oil

(see

page

9

and

Fig. 13).

Refill

with

new

oil to

011

level

hole.

Every

1200

miles

Front

wheel

hub

Lubricate

with

grease

gun.

Every

1200

miles

High

Pressure

::hassis

Grease

Joints

on

brake

controls

Grease.

Every

1200

miles

Allstate

all-purpose

Gear

Ratchet

quadrant

Lubricator

SAE

140

of

gear

shifter

Shock-absorber

Change

oil.

Only

when

the

shock-absorber

Allstate

Shock

is

out

of

order

Absorber

Fluid

Control

cables

Clean

and

lubricate.

Every

1800

miles

Allstate

all-purpose

Gear

Lubricator

SAE

140

Felt of fiywheel

Small

spot

of

grease

on

the

felt.

Every

1800

miles

Allstate

Bearing

Grease

cam

Every 1,800 miles. -

Grease

the

felt which

lubri-

cates

the

cam

of flywheel

magneto.

In

case

of

shock-absorber

troubles,

overhaul

or

simply

clean

the

assembly

and

change

oil.

These

operations

should

be

carried

out

by

your

SEARS store.

Disuse :

(1) -In

such

a

case,

cleaning

the

scooter

thoroughly

is

advisable.

(2)

-

Start

the

engine

and

run

it

at

low

revs

in

neutral.

Pump

60

cc. of

Allstate

Regular

Oil

SAE

"30

or

Allstate

Outboard

Motor

Oil

through

hole

in

the

air

cleaner

into

the

carburettor

intake,

by

means

of

an

oiler.

(3)

-Rest

the

floorboard

on

two

wooden

blocks

in

order

to

take

the

weight

off

the

lyres.

(4)

-

Drain

all

fuel from

both

tank

and

carburettor.

(5)

Grease

all

unpainted

metal

parts.

-10

-

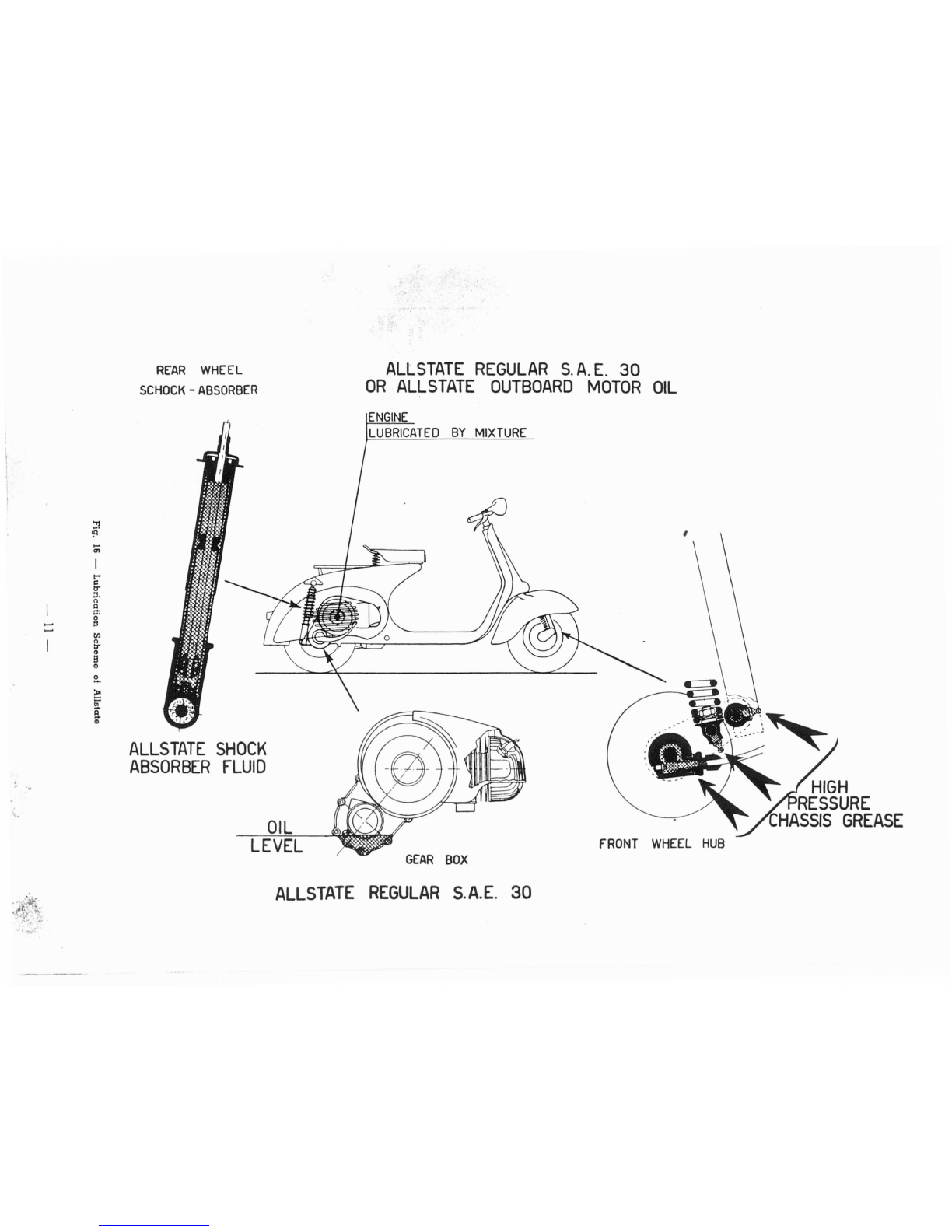

REAR

WHEEL

SCHOCK

-

ABSORBER

ALLSTATE

REGULAR

S.

A.

E.

30

OR

ALLSTATE

OUTBOARD

MOTOR

OIL

,

'.

,

<.

:!l

'f-l

....

m

t"'

~

tr'

::I.

n

I:l

1::".

.......

0

.......

I::l

til

n

:r

t)

B

CD

a.

~

in'

R

~

ALLSTATE

SHOCK

ABSORBER

FLUID

OIL

LEVEL

ENGINE

LUBRICATED

BY

MIXTURE

GEAR

BOX

fRONT

WHEEL

HUB

HIGH

RESSURE

CHASSIS

GREASE

:~.~~

.}

ALLSTATE

REGULAR

S.A.E.

30

LOCATING

TROUBLES

AND RUNNING IRREGULARITIES

Carry

out following checks

when

the

engine

does

not start easily

or

runs

irregularly.

~~

.-'

/..-'-

Adjust

(see

Figs.

10

and

11.

page

8).

Wash

with

gasoline

or

replace.

Replace

Replace

Tighten

Slacken

Lubricate

or,

if

necessary,

re-

place

Adjust

Re-time

See

No. 2of

this

paragraph

Fit

proper

jet

(.80 mm.)

Release

Clean

with

pure

gasoline

and

blow

dry,

Dip

the

metal

wadding

into

a39%

gaso-

line-oil

bath

" .

Release

operating

and

lubri-

cating

the

lever

on

the

bacl:

of

the

cleaner

case

Replace

Clean

or

replace

both

needle

and

float

chamber

cover

Replace

the

selector

Replace

the

pinions

Adjust

Replace

Replace

Replace

both

plates

and

springs

See

paragraph

•Difficult

start-

ing"

No. I

Turn

convex

face

towards

spring

cups.

Top

up

oil

level.

Tighten

the

screw

on

drainin

=1

hole.

Adjust

Tighten

the

screws

Replace

ReJ?~ace

.F

r-

,,~

Excessive

play

8

••

Steerinq

column

becomes

stili

Top

race

of

top

ball

bearing

too

tight

Bottom

races

of

the

two

bea-

rings

pitted

9

.•

Excessivo

play

of

steering

column

Top

race

of top

bearing

loose

10

••

Poor

bralring

Stroke

of

pedal

or

lever

too

long

Brake

linings

oily

or

worn

down

Brake

drums

and

linings

scrat-

ched

IV

-

Diameter

of

main

jet

ori-

fice

wrong

or

increased

V -

Retarded

ignition

VI

-

Poor

compression

7. -

Control.

not

operating

pro-

perly

Inner

cables

rusted

III

-

Flap

of

choke

valve

sticl:-

ing

in

closed

or

partially

closed

position

6

••

High

fuel

consumption

I -

Fuel

level

too

high

in

car-

burettor:

a)

Tickler

sticking

in

de-

pressed

position

bl

Float

perforated

c)

Float

needle

valve

not

properly

fitting

into

its

seating

II

-Air

cleaner

chol:ed

or

dirty

Not

enough

mixture

Dowing

to

the

carburettor

4.

•

Clutch

troubles

a)

Clutch

snatches:

Convex

steel

plates

wrongly

assembled

Gear

pinions

not

lubricated

properly

b)

Clutch

slips:

Springs

feeble

Plates

with

cork

-ii'lllerts

worn

or

burm

c)

Clutch

does

not

disengage

completely:

'

Excessive

play

on

conlrol

cable

Excessive

convexity

of

steel

plates.

S

••

Gear

pinions

disenllalle

of

own

accord

Gear

change

control

cables

out

of

adjustment

Gear

shifter

loose

on

crankcase

Spring

of

stirrup

broken,

feeble

or

missing

Excessive

play

between

ac-

tuating

arm

and

gear

shift

flange

or

wrong

positi?ning

of

the

arm.

Selector

arms

chamfered

Dogs

of

gear

pinions

chipped

or

worn

Tip of

contact

breaker

loose

Condenser

screw

loose

Clean

Replace

or

clean

the

plug

and

correct

the

gap

to 6mm.

(.023")

Replace

Clean

the

rings

and

grooves

Tighten

(21

mm

box

wrench)

Set

the

head

properly

and

tighten

the

nuts

Replace

Re-time

ignition

Replace

RUNNING

Clean

(see

page

9)

Replace

the

packing

between

pipe

and

cylinder.

Tighten

the

nuts

on

cylinder

studs.

Decarbonize

cylinder,

piston

and

cylinder

head

Replace

Disconnect

the

plug

lead.

Check

if

sparking

occurs

between

lead

and

crankcase

when

the

kicks

tarter

is

operated.

Clean.

Correct

gap

to

.6

mm.

(.023")

Replace

the

plug

Release

the

lever

Clean

with

suitable

files

or

very

fine

emery

paper

Correct

to

.4

mm.

with

feeler

gauge

(.015·)

Turn

to

vertical

position

Release

by

1lepressing

the

tickler

Replace

Clean

(see

page

9)

Release

Remove

and

wash

in

gasoline

-

Blow

dry

See

page

5

Release

Turn

to •

reserve..

Refill

as

soon

as

possible.

a)

Depress

the

tickler

until

some

fuel

drips

out,

or

b)

unscrew

and

remove

the

main

jet.

If

the

fuel

system

is

efficient, fuel

wil1

come

out.

c) Blow

trough

jet

orifice to

ensure

that

it

is

clean.

Clogged,

dirty

Locating

the

trouble

1

R_em_e_di_·e_s

II

Loc_ati_·n_

g

_t_h_e_lro_ub_I_8

1.

R_e_m_edi_'e_s

1

D

IFF

I C U L T S

TAR

TIN

GPre-i\1nition

a)

Fit

on

a

colder

sparkplug

b)

Re-time

the

ignition

Replace

Tighten

Exhaust port

partially

closed

by

carbon

deposit

Cylinder

base

gasket

not

tight

2.

-Poor

compression

Sparkplug

not

well

screwed

down

in

cylinder

head

Cylinder

head

not fitting

pro-

perly

into the

spigot

on

top

of

cylinder

Head

gasket

not light

Piston rings

gummed

up

3.

•Explosions

at

muffler

or

carburettor

Sparkinq

plug

carbon-coated

or

with

excessive

electrode

gap

Carbon

pearls

on

sparkplug

insulation

Breaker

points

completely

worn

or

pitted

Timing

wrong

Pick-up

terminal

cracked

INCORRECT

1.

-Lack

of

power

Muffler outlet

pipe

carbonized

Induction

pipe

to

cylinder

loose

Sparkplug

dirty

Porcelain

of

sparkplug

cracked

Switch

lever

jammed

in

•

cut

out.

position

Breaker

points dirty,

partially

worn or

pitted

Gap

between

breaker

points

incorrect

2.

-

Carburation

Enqine

flooding

Tickler sticking

in

depressed

position

Float

perforated

Air

cleaner

choked

or

dirty

Choke

flap sticking

in

position

•

closed.

Carburettor

assembly

mounted

at

an

angle

3. -Ignition

I. •

Fuel

syslem

Fuel

tank

empty

Fuel

does

not

Dow

10

the

car-

burettor

although

the

fuel

lap

is

open.

or

in

porq,ion

•

reserv"

-

Filter

on

carburettor

Fuel

tap

body

Carburettor

body

Main

jet

Atomizer

Hose

between

fuel

tap

and

carbu-

rettor

Float

needle

valve

sticking

on

its

seating

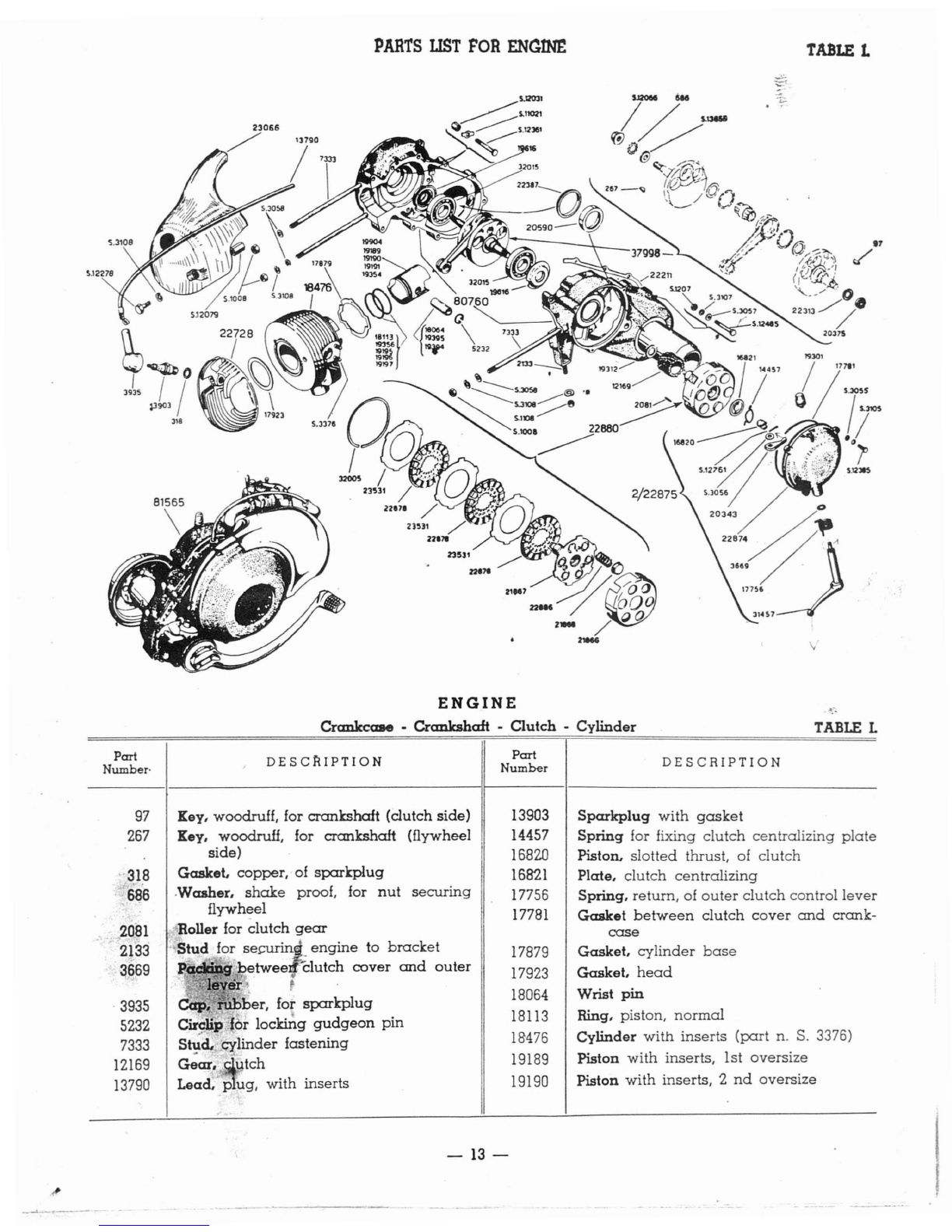

PARTS

UST

FOR

ENCIN£

TABLE

L

ENGINE

Crankccate •

Crankshaft

-

Clutch

-

Cylinder

TABLE

L

Part

DESC~IPTION

Part

DESCRIPTION

Number·

Number

97

Key, woodruff, for crankshaft (clutch side) 13903

Sparkplug

with

gasket

267 Key, woodruH, for crankshaft (flywheel 14457

Spring

for fixing

clutch

centralizing

plate

side) 16820 Piston.

slotted

thrust, of

clutch

318

Gasket.

copper, of

sparkplug

16821

Plate,

clutch

centralizing

686 .Washer,

shake

proof, for

nut

securing

17756 Spring,

return,

of

outer

clutch

control

lever

flywheel

17781

Gasket

between

clutch

cover

and

crank-

2081

.Roller for clutch

gear

case

2133

Stud

for

se~'

engine

to

bracket

17879

Gasket,

cylinder

base

3669

~betwee

clutch

cover

and

outer

17923

Gasket,

head

':~)iY~

.18064 Wrist

pin

-

3935

Cap,

rllbber,

for

sparkplug

18113 Ring, piston,

normal

5232 Circlip

lor

locking

gudgeon

pin

7333

stid.

Cylinder

fastening

18476 Cylinder

with

inserts

(part

n.

S.

3376)

12169

Gear,

~utCh

19189 Piston

with

inserts, 1st

oversize

13790

Lead,

pug,

with inserts 19190 Piston

with

inserts, 2

nd

oversize

-13-

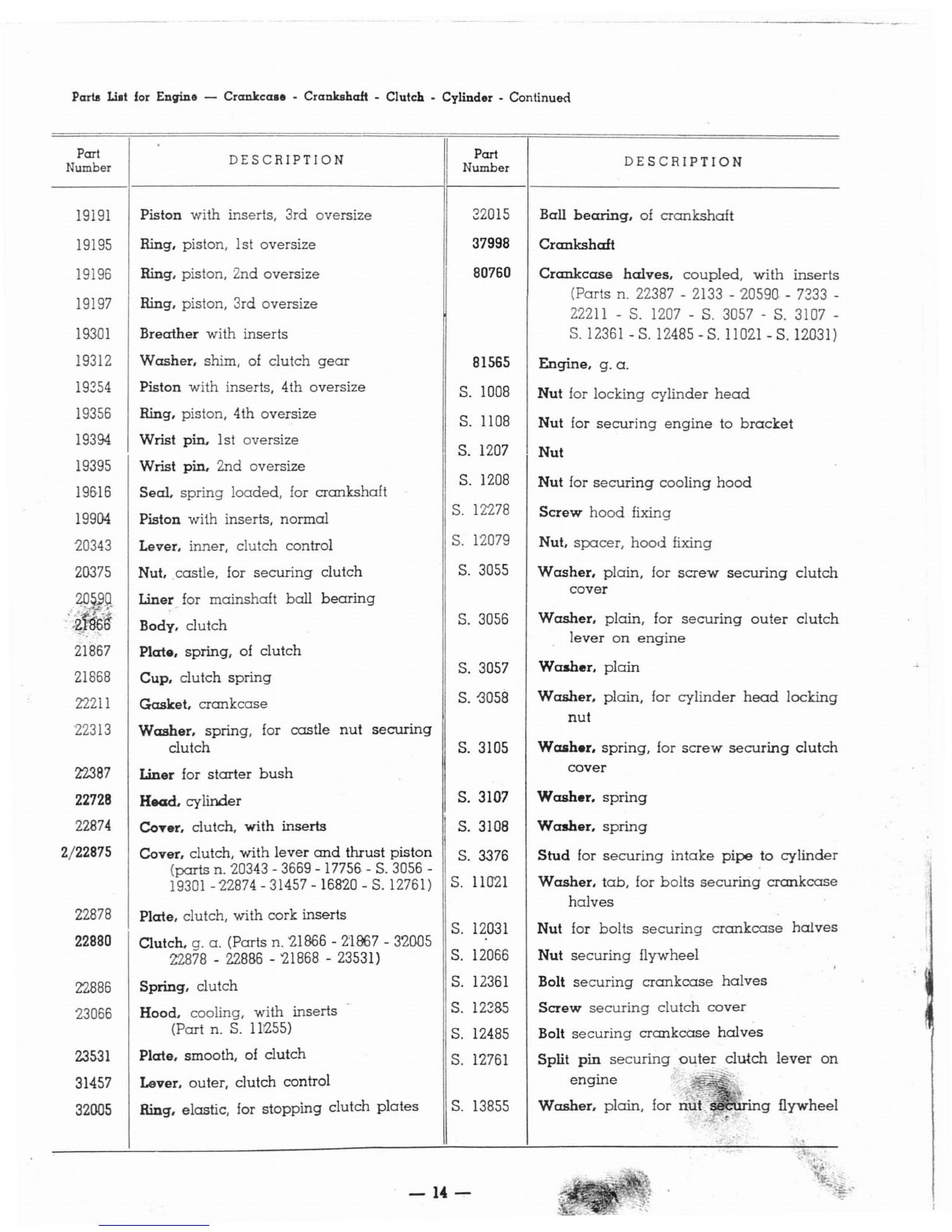

Pam

List

for

Engine -

Crankcase

-Crankshaft -Clutch •Cylinder -Continued

gflywheel

Part

Number

19191

19195

19196

19197

19301

19312

19354

19356

19394

19395

19&16

19904

20343

20375

49

Jlg

'iW9~

21867

21868

22211

'22313

22387

22728

22874

2/22875

22878

22880

22886

23066

23531

31457

32005

DESCRIPTION

Piston

with

inserts, 3rd oversize

Ring, piston, 1st oversize

Ring, piston, 2nd oversize

Ring, piston, 3rd oversize

Breather

with inserts

Washer.

shim,

of

clutch

gear

Piston with inserts, 4th oversize

Ring, piston, 4th oversize

Wrist pin, 1st oversize

Wrist pin, 2nd oversize

Seal.

spring

loaded,

for

crankshaft

Piston with inserts,

normal

Lever, inner, clutch control

Nut

•.

castle, for

securing

clutch

Liner for

mainshaft

ball

bearing

Body. clutch

Plate,

spring, of

clutch

Cup,

clutch

spring

Gasket,

crankcase

Washer,

spring, for

castle

nut

securing

clutch

Liner for

starter

bush

H.ad,

cylinder

CoTer, clutch,

with

inserts

Cover, clutch,

with

lever

and

thrust

piston

(parts

n. 20343 -3669 -17756 -

S.

3056 -

19301

-22874 -31457 -16820 -S. 12761)

Plate, clutch,

with

cork inserts

Clutch. g.

a.

(Parts n.

'21866

-

2'1967

-32005

22878 -

228B6

-'21868 -23531)

Spring, clutch

Hood. cooling, with inserts

(Part n.

S.

111255)

Plate,

smooth, of clutch

Lever. outer, clutch control

Ring, elastic, for

stopping

clutch

plates

Part

Number

32015

37998

80760

81565

S.

1008

S. 1108

S.

1207

S. 1208

S.

12278

S.

12079

S.

3055

S. 3056

S. 3057

S.

<3058

S. 3105

S. 3107

S. 3108

S. 3376

S.

110'21

S.

12031

S. 12066

S.

12361

S.

123B5

S. 12485

S.

12761

S.

13855

DESCRIPTION

Ball

bearing,

of

crankshaft

Crankshaft

Crankcase

halves,

coupled,

with

inserts

(Parts n. 22387 -2133 -20590. -7333 -

22211

-S. 1207 -S. 3057 -S. 3107 -

S.

12361

-S. 12485 -S.

11021

-S. 12D3l)

Engine.

g.

a.

Nut

for

locking

cylinder

head

Nut

for

securing

engine

to

bracket

Nut

Nut

for

securing

cooling

hood

Screw

hood

fixing

Nut.

spacer,

hood

fixing

Washer,

plain,

for

screw

securing

clutch

cover

Washer,

plain.

for

securing

outer

clutch

lever

on

engine

Washer.

plain

Washer,

plain,

for

cylinder

head

locking

nut

Wcuher,

spring,

for

screw

securing

clutch

cover

Washer.

spring

Washer,

spring

Stud

for

securing

intake

pipe

to

cylinder

Washer,

tab,

for

bolts

securing

crankcase

halves

Nut for

bolts

securing

crankcase

halves

Nut

securing

flywheel

Bolt

securing

crankcase

halves

Screw

securing

clutch

cover

Bolt

securing

crankcase

halves

Split

pin

securing

ou,ter

~utch

lever

on

engine

;

i' ,-"

Washer,

plain,

for

nu(

-14-

PARTS

UST

FOR

ENGINE

Gear

Box -

Brake

-Kiclaltarter -

Ventilator

-

flywheel

Magneto

TABLE

n.

39486

TABLE

IL

-;:

.

Part

DESCRIPTION

Pcut

DESCRIPTION

Number

Number

603

Screw

for

securing

coils

2210

Spring

for

starter

bush

619

Washer,

plain,

for

screw

securing

coil

2442

Nut for

securing

wheel

622

Washer,

shim,

of

breaker

2852

Screw,

long,

for

securing

fan

casing

624

Nut

2856

Screw,

short,

for

securing

fan

casing

625

Fork.

spring

2946

Screw

for

securing

fan

casing

cover

662

Terminal

3213

Screw

securing

condenser

and

felt

blade

674

Circlip for flywheel

extraction

7153

Seal,

rubber,

for

starter

bush

2021

Screw

for

joining

brake

drum

to

flange

7562

Ball

bearing,

inner,

of

mainshaft

2098

Split

pin

°for

locking

castle

nut

2148

Ring,

threaded,

for locking

mainshaft

ball

10260

Seal,

felt, of

starter

assembly

bearing

10788

Cable,

earth,

with

terminal

2195

Washer,

seal

locking I

11451

Spring,

return,

of

kickstarter

-

15-

PARTS

UST

•

Continued

ENGINE

Gear

Box

•Brake •Kickstarter -Ventilator -Flywheel

Magneto

,

.'

Part

Number

12501

14501

14651

15907

16351

16416

16417

16418

16419

16420

16421

17821

17824

17800

17887

17888

18106

18206

18445

~

18446

18447

a)

18558

18619

18620

18941

a)

19611

a)

20-321

a)

20322

a)

20323

a)

20324

20841

21148

a)

21898

21900

21931

22538

22539

22792

23g'22

DESCRIPTION

Ball

bearing,

outer,

of

mainshaft

Terminal

Stem,

selector

Flange,

female spline, with inserts

Drum,

rear

brake

Breaker

with

platinum

point

Axle,

breaker

Gusset,

contact

Ring,

insulating

Cam

Blade, felt, with

inserts

Selector,

gear

Gear,

2nd

speed

Layshaft

Spring

of

cush

drive

Gear,

outer

of

cush

drive

Seal,

spring-loaded,

of

mainshaft

Bush, slotted,

with

bronz~

liner

Gear,

low

speed

Ratchet,

starter

Circlip

retaining

shoulder

washer

Washer,

shoulder, normal,

of

gear

pinions

Drive, cushion, g.

a.

(parts

n. 17887 -17888

-

186'20

-

S.

10776 -31157)

Gear,

multiple

Condenser

Gear,

high spet::a

Washer,

shoulder, 1st oversize (.088")

Washer,

shoulder,

2nd

oversize (.096")

Washer,

shoulder,

3rd

oversize

(.104")

Washer,

shoulder, 4th oversize (.112")

Coil, ignition

Circlip

Mainshaft

Mainshaft, g.

a.

(parts

n.

S.

13768 -

21931

-

18447

-

1&558

-

17821

-21898 -16451)

Bush,

guide,

of

selector

stem

Fan

Casing

fan

Bush.

starter

Stator

with

inserts

(part

n. 16417)

Part

Number

25707

25710

25711

25741

25755

30412

31157

32494

39486

80019

80429

81568

S. 1209

S. 2314

S. 3055

S.

3103

S.

3105

S.

3105

S. 3109

S. 3110

bis

S. 6037

S.

1~7'

S. 10776

S. 11004

S.

11010

S.

12263

S.

12331

S."

12322

S. 12488

S.

13768

S.

13800

S.

13801

S. 13815

S. 13824

DESCRIPTION

Stator.

g.

a.

(parts

n. 603 -619 -622 -

&24

-625 -2213 -16416 -

1&418

-16419

-16420 -

1&4'21

-S. 3103 -S. 3105 -

-

S.

12.331

-

S.

12332 -

S.

13800 -

S.

1380-1

-

18941

-

20841

-10788 -23921 -

2.3922

-25710 -25711)

Coil,

low

tension,.

No.1

Coil,

low

tension,

No.2

Flywheel

with

inserts

Kickstarter

Roller for

multiple

gear

Washer.

plate,

of

cush

drive

springs

Ball

bearing

of

multiple

gear

Cover,

fan

casi!lg

Coil,

low

tension

No. 3

Spacer

between

mainshaft

bail

bearings

Flywheel

magneto,

q.

a.

(parts

·n.

25741 -

27856)

Nut

for

securing

layshaft

Nut,

castle,

for

securing

wheel

flange

W<:rsher.

plain,

for

screw

securing

stator

Washer,

sPr:ing, for felt

blade

Washer,

spring,

for

screw

securing

stator

Washer,

spring,

for

screw

securing

coils

Washer,

spring,

for

nut

securing

layshaft

Washer,

spring,

for

nut

securing

wheel

Circlip for

locking

multiple

gear

ball

bearing

Screw

for

securing

statOl

Rivet for

securing

plate

washers

Washer,

tab,

for

screw

securing

fan

Plate.

tab,

for kicks

tarter

bolts

Screw

securing

fan

Screw

retaining

cables

Screw

securing

blade

with

cam

greasing

felt

Bolt for

securing

kickstarter

Washer.

tab,

on

selector

stem

Washer

for

screw

retaining

cables

Washer.

insulating,

for

screw

retaining

cables

Washer,

plain,

for

nut

securing

wheel

flange

Washer,

plain,

for

nut

securing

layshaft

..

.

bl

of

t~

3

gear

pinions

In

respect

to

their

seat

must

be

contmned

between

.OOS"

and

.016".

(a) The

total.axlal

play

of

the

~dsseml

Y

th

normal

shoulder

washer

must

be

rep1a.

ced

by

another

with

proper

oversize.

Should

this

play

exceed

SOl

to

erances,

e

-16-

PARTS UST FOR ENGINE

Carburettor .Air

Cle<Dler

.Gear Shifter

TABLE

m.

Part I

DESCRIPTION

Part

DESCRIPTION

Number

Number

397

Packing, oil filling

and

draining

holes

2606

Spring of

throttle

slide

2121

Screw for

securing

gear

shifter

to

crank-

2610

Jet,

maximum

case

2611

Screw,

guide,

for

throttle

slide

2489

Pivot of

roller

carrying

stirrup

2612

Screw,

cable

stretcher

2508

Cap,

rubber,

for

low

tension

socket

2613

Nut,

jam,

of

cable

stretcher

screw

2600

Cap,

fastening,

of fuel

inlet

pipe

2615

Tickler

2601

Packing

of

inlet

pipe

2616

Clip,

tickler

2602

Pipe, fuel

inlet

Spring,

tickler

2603

Filter, fuel,

with

inserts

2617

2604

Screw for

securing

float.

chamber

cover

2618

Cover,

float

chamber

fo

-

17-

J

.,

PAllTS

US!

-

Continued

ENGINE

Carburettor

-Air

Cleaner

-

Gear

Shifter

Part

Number

2619

2620

2621

2622

2623

2748

2990

2990

4475

12080

12358

13&30

13883

13885

13990

13991

14142

14231

14233

14236

14427

14577

15496

HESS

18161

18166

18170

18411

19489

19492

19495

19630

19975

21089

21438

*

22258

DESCRIPTION

Packing

of float

chamber

cover

Float

Valve,

needle,

of float

Screw,

clamp

Clamp

Pivot,

threaded,

for

rocker

Cap,

oil filling

Cap,

oil

draining

Skid,

gear

shifting

Screw,

locking,

for

slotted

bush

Packing

between

cylinder

and

intake

pipe

Nut,

wing,

for

securing

air

cleaner

Stirrup,

roller

carrying,

of

gear

shifter

Pin,

roller

carrying,

of

gear

shifter

Screw,

stop,

of

throttle

slide

Spring

for

stop

screw

of

throttle

slide

Packing

for

air

cleaner

Atomizer

with

idling

jet

Clip for

taper

needle

Plug,

slotted,

for

hook

rod

Terminal,

pick-up

Rocker,

throttle

cable

Shifter,

gear,

g.

a.

(Parts

n.

31517

-

S.

32D6

-

Z2258

-

S.

13010

-

31515

-

S.

3'204

-

-

14883

-

22262

-

'2489

-

13885

-

4475

-

13514)

Cover,

air

cleaner,

with

inserts

Packing

between

air

cleaner

case

and

throttle

cable

support

Stud

for

securing

air

cleaner

to

carburettor

Gauze

in

air

cleaner

Support,

throttle

cable

Support,

throttl~

cable,

with

lever

and

rocker

(parts

n.

13990

-

13991

-

2748

-

S.

3104

-

S.

12012

-

14577

-

18411

-

2613

-

2612)

Slide,

throttle

Cup

for

spring

of

throttle

slide

Rod,

hook,

of

throttle

slide

Deflector,

mud

Needle,

taper

Socket,

low

tension,

for

earth

and

lighting

cables

Quadrant,

ratchet,

of

gear

shifter

Part

Number

22262

22733

24647

24930

2'4931

25897

25898

25900

25901

266&4

266B7

27991

*31514

31515

31517

S.

11-07

S.

3104

S.

3107

S.

3204

S.

3206

S.

12006

S.

12012

S.

12768

S.

12774

*S.13010

S.

13842

S.

13860

S.

14011

S.

14402

DESCRIPTION

Flange,

gear

shift

Pipe,

intake,

with

inserts

Circlip

retaining

float

needle

valve

Cover,

mixing

chamber

Packing

for

hook

:rod

Air

cleaner,

g.

a.

(Parts

n.

18170

-

S.

12'771i

-

18155

-

S.

13860

-

25898

-14N2)

Air

cleaner

with

inserts

Carburettor

with

throttle

cable

support,

rocker

and

studs

(Parts

n.

'25901

-

19489

-18166)

Carburettor,

Dell'Orto

TA

18E

Type

(with-

out

throttle

cable

support,

rocker

and

studs),

g.

a.

(Parts

n.

'2600

-

'2601

-

2602

-

2603

-

2615

-

2616

-2617 -

2604

-

2618

-

2619

-

2620

-

26'21

-

2606

-2623 -

2610

-

2611

-

'26667

-

'24647

-

14231

.

26'22

-

19495

-

2'4931

-24930 -

'26664)

Slide,

throttle,

.g.

a.

(Parts

n.

19492 -21089

-

14233

-

19630

-

14'236)

Body,

carburettor

Plug

on

air

cleaner

Lever,

gear

shifting

Roller,

control,

gear

shift

Spring

of

roller

carrying

stirrup

Nut

securing

intake

pipe

and

mud

deflector

Washer,

spring,

for

rocker

pivot

Washer,

spring,

for

intake

pipe

attachment

Split

pin

on

roller

pin

Split

pin

for

gear

shifting

skid

and

stirrup

pivot

Nut.

jam,

for

screw

locking

slotted

bush

Nut

for

rocker

pivot

Slipt

pin

Split

pin

PilL

taper,

iar

joining

quadrant

to

lever

Washer,

plain,

under

nut

securing

intake

pipe

and

mud

deflector

Washer,

plain

Packing

between

pick-up

terminal

and

crankcase

Screw

on

low

tension

socket

fbd d th th I

ver

31514

and

taper

pin

S. 13010.

C*)

Warning:

The

ratchet

quadrant

22258 of

gear

shl

ter

15

to e

or

ere

toge

er

WI

e

-

18-

--------------------------------

__

TABLE

IV.

81576

SJ20a......

s.Jloe

~

~

~\

.'"

2t~

l3081

....

PARTS

UST

FOR

CHASSIS

Fuel

Tank

-

Saddle

-Tool Box -

Bonnet

TABLE IV

Part

Number

2159

a)

2174

2319

2383

2809

2917

2939

2940

2941

2944

3221

4433

4435

5082

DESCRIPTION

BuHer

Ferrule

Packing

of filler

cap

Washer,

plain,

for

rear

attachment

of

saddle

Spring

for

bonnet

lock

Pivot,

hinge,

of

carburettor

side

shutter

Lever, lock, of tool

box

shutter

Spring

of tool

box

shutter

Pin

for lock

lever

Split

pin,

hinge,

of tool

box

shutter

Strap,

pipe

fastening

Pivot

Screw,

tie, of filler

cap

Rivet for

securing

hinge

of

engine

bonnet

Part

Number

10055

11032

11128

11177

11242

11653

11751

11760

12218

13481

1361-8

128'21

15123

DESCRIPTION

Nut.

wing,

for filler

cap

Rivet for

joining

support

plates

of

saddle

Spring,

return,

of

carburettor

side

shutter

Spring,

wire,

for

bonnet

frame

Plate,

connection

Hook.

purse

.hanging

Beading,

rubber,

for

engine

bonnet

BuHer,

stop,

of

carburettor

side

shutter

Spring

for

supporting

canvas

roll

Hinge

for

engine

bonnet

Pivot

fop

joining

connection

plate

to

saddle

frame

BuHer,

rubber,

for

spring

gusset

Pipe,

rubber,

from fuel

tap

to

carburettor

-19-

Table of contents

Other Allstate Scooter manuals