Allstate 788.94493 User manual

OPERATING

INSTRUCTIONS

AND

PARTS

LIST

FOR

MOTOR SCOOTER

,..-----

MODEL NUMBER 788.94493

This is

the

Model

Number

of

your

Allstate

Motor

Scooter.

It will

be

found

on

a

plate

fastened

on

the

outside

of

the

hinged

door

under

the

seat. Always

mention

this

number

when

communicating

with

us regarding

the

Scooter,

or

when

ordering

repair

parts.

,..----

HOW

TO

ORDER REPAIR PARTS

All

parts

listed

herein

may

be

ordered

through

any

Sears

retail

or

mail

order

store. In

ordering

parts

by

mail

from

the

mail

order

store

which

serves

the

territory

in

which

you

live, Selling Prices

will

be

furnished

on

request

or

parts

will

be

shipped

at

prevailing prices

and

you will

be

billed accordingly.

WHEN

ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION:

1.

The

Part

Number

in

this List.

2.

The

Part

Name

in this List.

3.

The

Model

Number

of

the

item.

This list is valuable. It will

assure

your

being

able

to

obtain

proper

parts

service

at

all times.

We

suggest

you

keep

it

with

other

valuable

papers.

SEARS, ROEBUCK

AND

CO.

Scooterworks USA Inc.

5709

N.

Ravenswood

Chicago,

IL

60660

ph: 773.271.4242

fx:

773.271.5012

fii.

I - AllSTATE: •

Cruiaaire.

Motor

Scooter

Location

0/.

aerial

Number

Location

0/'

engine

Number

WARNING

In

order

to

keep

your

ALLSTATE

Scooter

In

perlect

runnmg

condillon

and

not to void

the

guarantee.

always

have

your

machme

repaired

at

a

Sers.

Roebuck

and

Co. Store.

Special

care

should

be

taken

in

regard

to

the

fuel

mixture which

should

be

regular

gasoline

and

.)Ij

of

the

make.

grade

and

1''1

the

amount

prescnbec

in this

booklet.

Ethyl

gasoline

ahould

never

be

used.

Do

not

use

Allatate

compounded

motor

oil

or

other

Premium

::

~

-'-.

Duty

Motor

Oil

with

detergents.

The

inexpenenced

operator

should

exercise

co

lIar.

m

applymg

front

wneel

brake.

to aVOid locklni;;

Fii.

2 .

Controla

0/

AUatate

Scooter

1.

Gear

change

tWlslgnp

with

c!u::n

control

lever·

2.

front

brake

lever·

3

Throllie

control

gnp.

(.

Light

and

dim.

mer

switch

-

5.

front

b-ake

,awl'

- 6

Rear

brw

pedal

-

7.

KJc:ltstarter • 8

Gem

.hilter

-

9.

Rear

brake

Jaws

-

10.

Clutch

•

11.

Carburellor.

au

cleaner

.

12.

Choke

control

lever

-

13.

fuel

cock

-3-

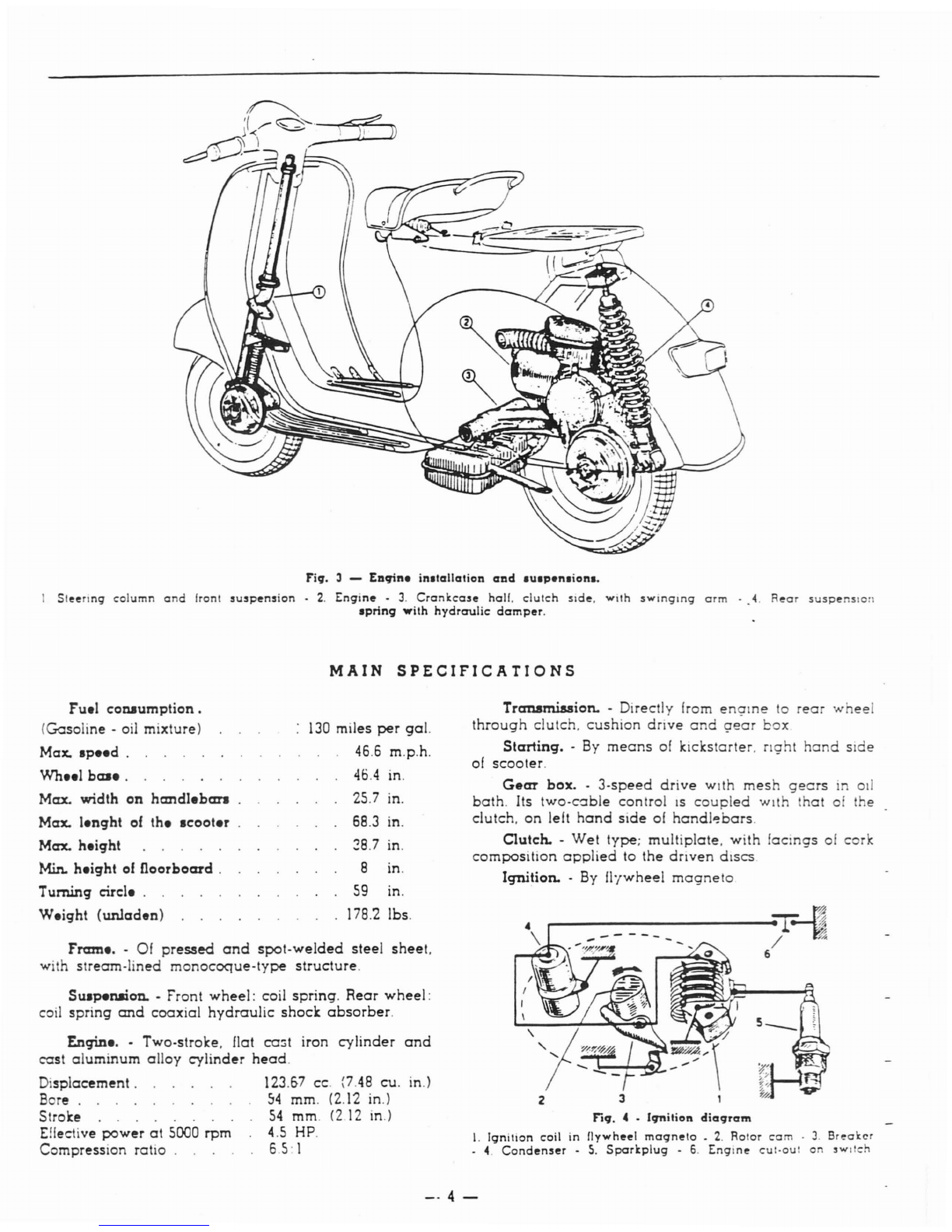

Fiq.

3 -

EDqine

inalallation

aDd

auapenaiona.

I

Sl~~rtng

column

and

front

!u!p~n!ion

•

2.

Engin~

•

3.

Crankca!~

hall.

clutch

sld~.

wIth

sWinging

arm

-

4.

R~ar

susp~nslon

apring

with

hydraulic

damp~r.

MAIN

SPECIFICATIONS

Fram

•.•

Of

pressed

and

spot.welded

steel

sheet.

with

stream-lined

monocoque-type

structure.

Suapenaion. •Front

wheel:

coil

spring.

Rear

wheel:

coil

spring

and

coaxial

hydraulic

shock

absorber.

Engin

•.•

Two-stroke. flat co:;t iron

cylinder

and

cast

aluminum

alloy

cylinder

head.

Displacement.

123.57 cc. (7.48 cu. in.)

Bore.

54

mm. (2.12 in.)

Stroke

54

mm. (2.12 in.)

Effective

power

at

5000 rpm 4.5

HP.

Compression ratio .6.5: I

Fuel

conaumption.

(Gasoline·

oil mixture)

Max.

speed.

Wheel

ba

...

Max.

width

on

handleban

Max.

lenght

of

the

scooter

Max.

height

Min.

height

of

floorboard.

Turning circl

•.

W.ight

(unladen)

130

miles

per

gal.

46.6 m.p.h.

40.4

in.

25.7 in.

68.3 in.

28.7 in.

8in.

59

in.

178.2 lbs.

Transmission.

-Directly [rom

enarne

to

rear

wheel

through

clutch.

cushion

drive

and

ge'ar

box

Starting.

-

By

means

of kickstarter.

nght

hand

Side

of

scooter.

Gear

box.

-

3-speed

drive

with

mesh

gears

in od

bath.

Its two-c::Ible control

IS

coupled

with

that

of the

clutch.

on

left

hand

side

of

handl~bars.

Clutch. -

Wet

type;

multiplate.

with

facrngs of corle

composition

applied

to

the

dnven

dISCS

Iqnition. -

By

fl'lwheel

magneto

...------------erJ~

/~

6

Fiq.

4 -

(qnilion

diaqram

I.

Ignition

coil

in

f1ywh~~1

magn~lo

_

2.

Rolor

cam

.

3.

Br~akcr

4.

Cond~n!~r

-

5.

Sporkplug

-

6.

Engin~

CUI-OU!

on

!wl!ch

-·4-

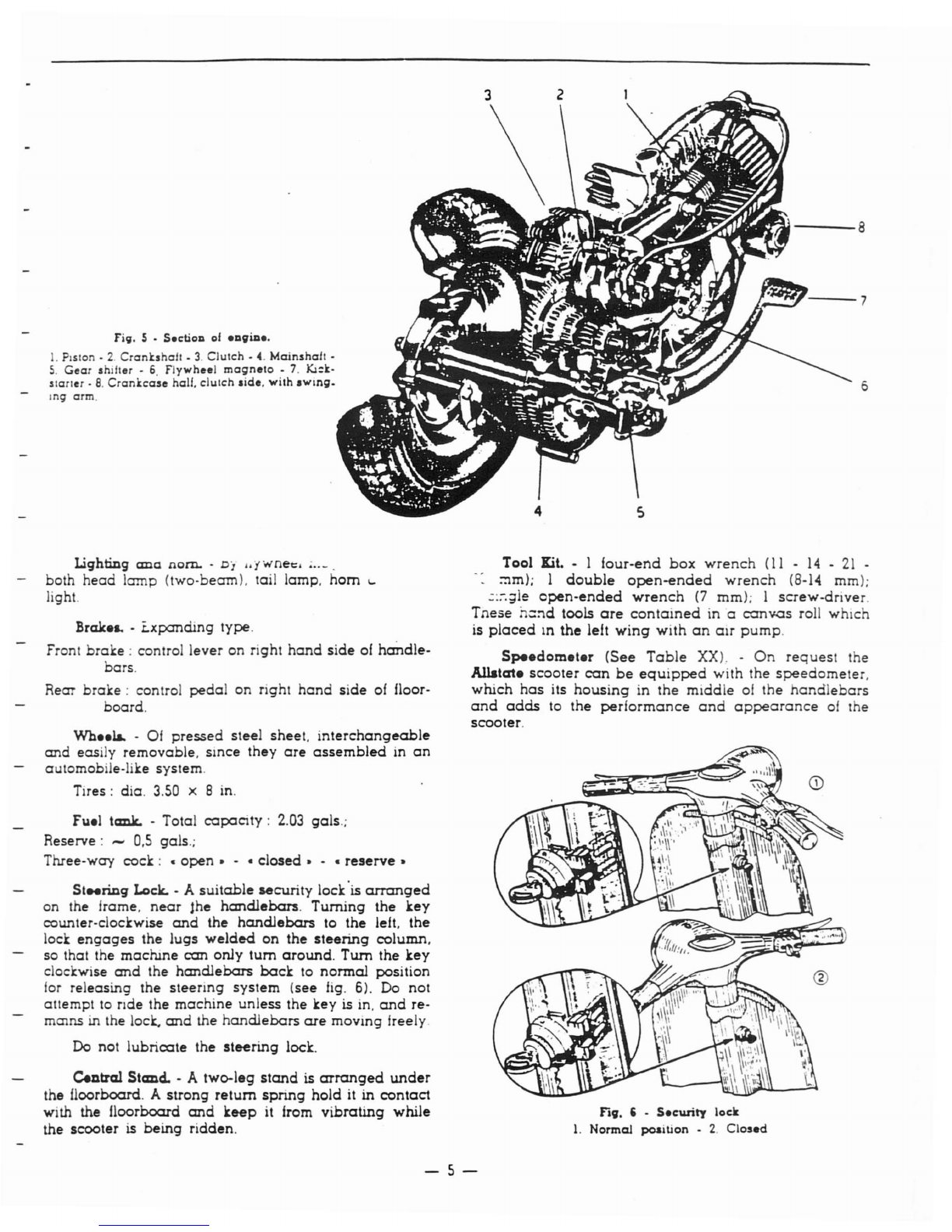

Fi9. 5 • S.c:tiOD

01

.DgiD

••

.

PIston·

2.

Cranbhafl

•

3.

Clutch

-

4.

Mainshafl

•

5.

Gear

shifter·

6.

Flywheel

magneto.

7.

Kl:k-

starter·

8.

Crankcase

hall.

clutch

aide.

with

aWing.

Ing

arm.

Lighting

ana

nom.

-

0]

••

fwnet.

;

..

_.

both

head

lamp

(two-beam). tail lamp.

hom

'-

light.

Brake&.

-Lxpanding type.

Front

brake:

control lever on right

hand

side

of

handle-

bars.

Rear

brake:

control

pedal

on right

hand

side

of floor·

board.

Wh

••

1&.

•01

pressed

steel sheet.

interchangeable

and

easily removable. since they

are

assembled

in

an

automobile-like system.

Tires: dia.

3.50

x 8 in.

Fuel tank. -Total

copacity:

2.03

gals.;

Reserve: -

0,5

gals.;

Three-way

cock:

copen.

- c closed

•.

c

reserve.

St

..

ring

Lock. -A

suitable

security

lock'is

arranged

on the lrame.

near

Jhe

handlebars.

Turning

the

key

counter-clockwise

and

the

handlebars

to the left. the

lock

engages

the

lugs

welded

on

the

steering

column.

so that the

madune

can

only

tum

around.

Tum

the

key

clod:wise

and

the

handlebars

beck

to

normal

position

lor releasing the

steering

system

(see

fig.

6). Do not

attempt to

TIde

the

machine

unless the key is in.

and

re-

mams

in the lock.

and

the

handlebars

ere

moving Ireely.

Do

not

lubricate

the

steering

lock.

Central

Stand.

- A two-leg

stand

is

arranged

under

the floorboard. A

strong

return

spring

hold

it

in

contact

with the floorboard

and

keep

it

from

vibrating

while

the scooter is

being

ridden.

---8

·r.r..~---7

6

Tool Kit. • 1

lour-end

box

wrench

(11

-

14

•

21

.

~m);

1

double

open-ended

wrench

(8-14 mm);

.:::-.;lle

open-ended

wrench

(7

mm); I

screw-driver.

Tnese

n::'ld

tools

are

contained

in a

canvas

roll

which

is

placed

In

the

left

wing

with

on

air

pump.

Speedometer

(See

Table

XX). -

On

request

the

Allatate

scooter

con

be

equipped

with the

speedometer.

which

has

its

housing

in

the

middle

of

the

handlebars

and

odds

to the

performance

and

appearance

01

the

scooter.

Fig. , -

Security

lock

1.

Normal

position

-

2.

Closed

-5-

r

2

~

-rr

~

I)

~

-.tt

-.rT

ftUJIIII -

l1li

~

i

tB

y•

~"

: 3

I

\

L-.T1Ul[

•

",

;

15--r.-+

;-7

'--

.:.'-.",J

'

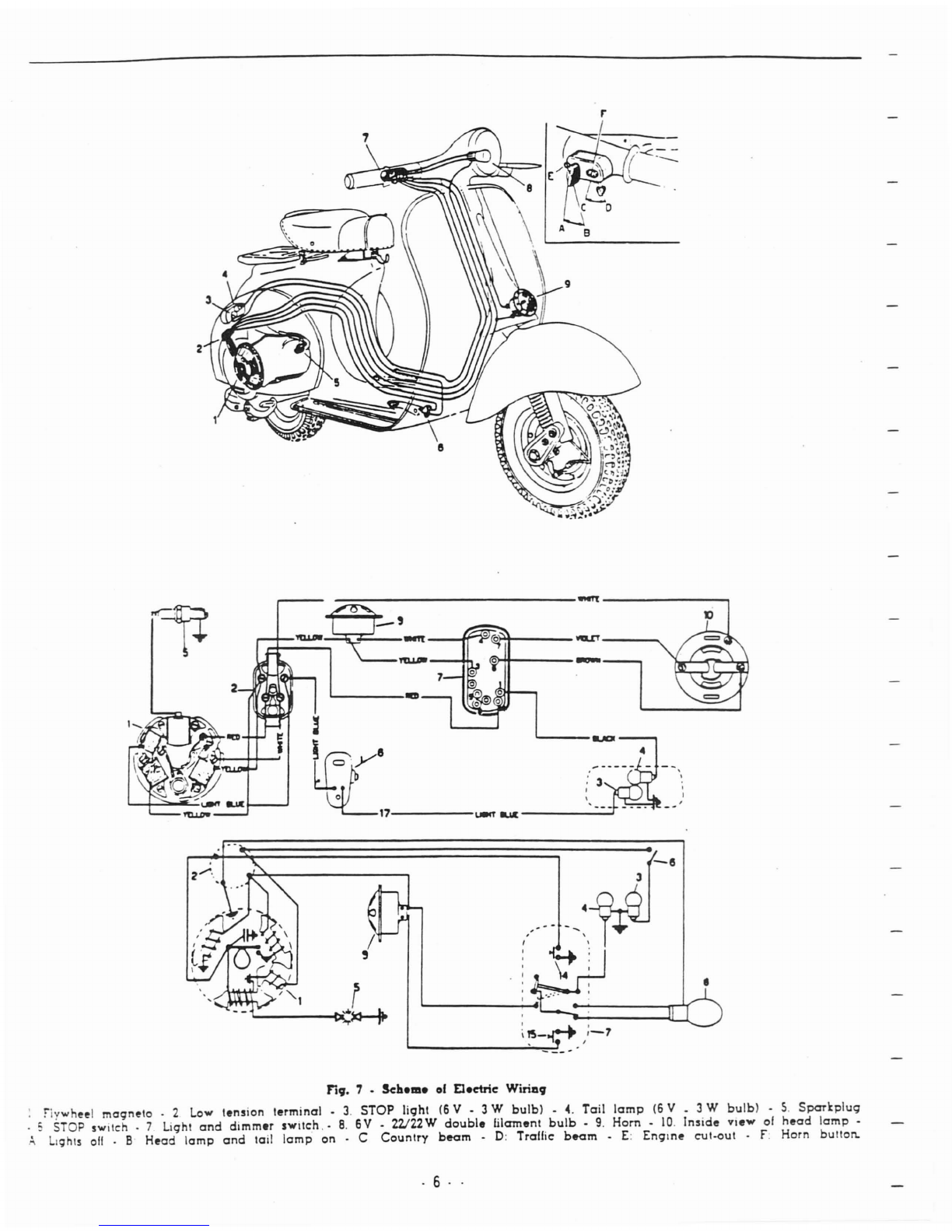

Fiq. 7 • Scheme

01

Eleetric

Wirillq

:

fiywh~~1

magn~lo

. 2 Low tltnsion

lltrminal

•

3.

STOP

light

(6

V • 3 W

bulb)

•

4.

Tail

lamp

(6

V • 3 W

bulb)

•

5.

Sparkplug

. 5 STOP

switch.

7Light

and

dimmer

SWitch

.•

8.

6V

.

W22W

double

filament

bulb·

9.

Hom·

10.

Inside

view

of

hltad

lamp

•

.

~

LIghts

011

•BHltad

lamp

and

tail

lamp

on

. C

Country

bttam

•

D:

Traffic

bttam

•

E:

Englnlt

cut-out

.

f.

Horn

bullon.

. 6

..

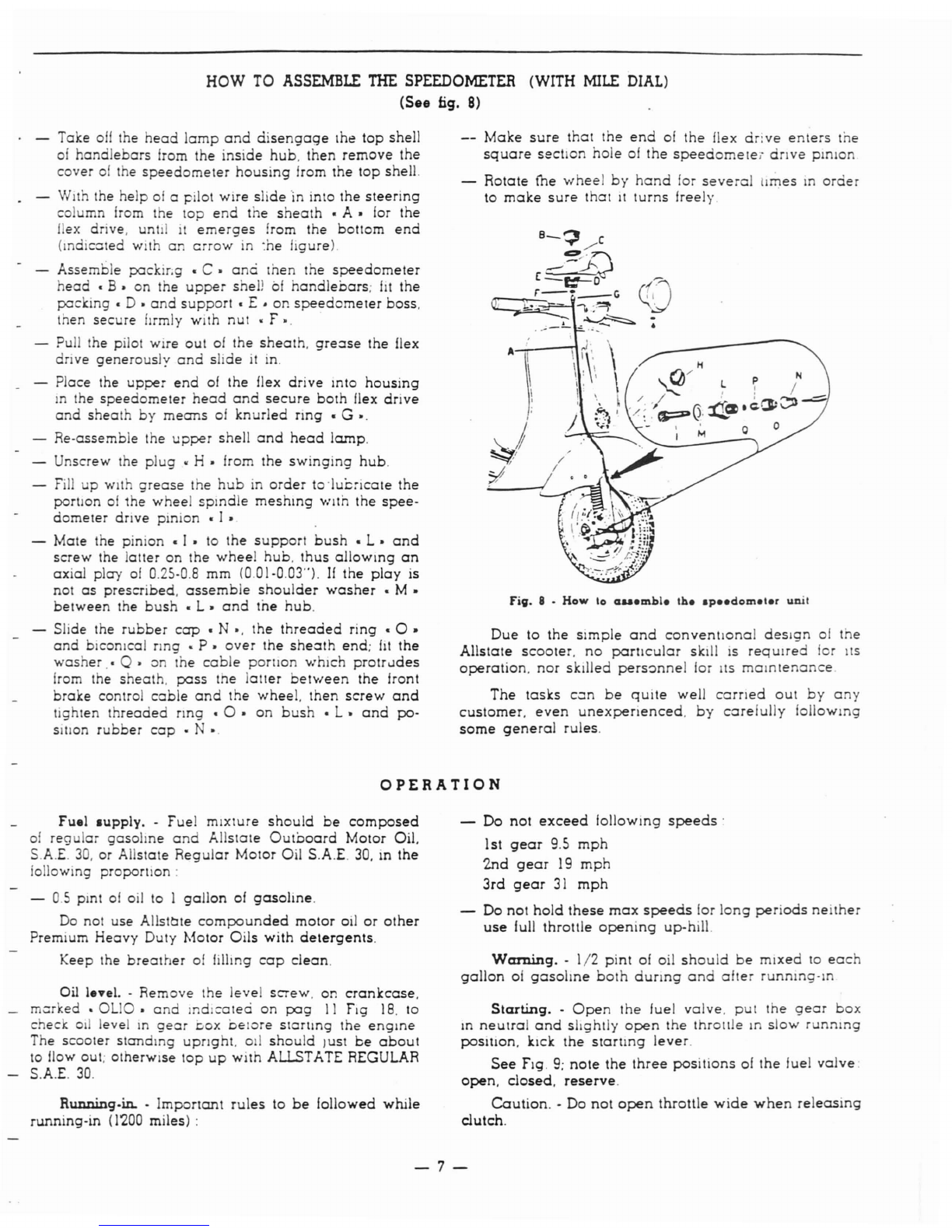

HOW

TO

ASSEMBLE

THE

SPEEDOMETER

(WITH

MILE

DIAL)

(See fig.

8)

Take

011

the

head

lamp

and

disengage

Ihe

top

shell

of

handlebars

from the

inside

hub,

then

remove

the

cover

of

the

speedomeler

housing

from

the

top

shell.

-WIth the

help

of

apilot

wire

slide

'in

into the

steering

co umn from the

100

end

the

sheath

•

A.

for

the

fex drive. unt

it

'emerges

from the bottom

end

(mdic:Jled with

an

crrow

in

:he

figure).

Assemble packir;g •

C.

ana

Ihen the

speedometer

head.

B.

on

the

upper

sheD

of

handlebars;

fIt

the

packing.

D •

and

support.

E •

on

speedometer

boss,

then

secure

fJrmly with

nut

• F •.

Pull the pilot wire

out

of

the

sheath,

greose

the flex

drive

generously

and

slide

it

in.

-Place the

upper

end

of

the flex

drive

mto

housing

mthe

speedometer

head

and

secure

both

flex

drive

and

sheath

by

means

of

knurled

ring

• G

'.

Re-assemble the

upper

shell

and

head

lamp.

Unscrew the

plug

•H• from the

swinging

hub.

Fill

up

with

grease

the

hub

in

order

to'luc:lcate

the

portion

of

1he

wheel

spmdle

meshing

...

nth

the

spee-

dometer

drive pinion • I •

-Mate the pinion • I • to

the

support

bush

• L •

and

screw

the

latter

on

the

wheel

hub,

thus

allOWing

an

axial

play

of

0.25-0.8

mm

(0.01-0.03"). If the

play

is

not

as

prescribed.

assemble

shoulder

washer

• M •

between

the

bush

•

L.

and

toe

hub.

-Slide the

rubber

cap

• N

'.

the

threaded

ring

•0 •

and

biconlcal ring •

p.

over

the

sheoth

end;

fit

the

washer

.•

Q.

on the

cable

portIon

which

protrudes

from the

sheath,

pass

the

latter

between

the

front

brake

control

cable

and

the

wheel.

then

screw

and

tighten

threaded

nng

•

O.

on

bush

•

L.

and

po-

SItion

rubber

cap

• N

'.

Make

sure

that

the

end

of the flex

drive

enters

the

square

sect

on

hole

of

the

speedometei

dnve

pinion

Rotate

fne

wheel

by

hand

for

several

times

In

order

to

make

sure

that

It

turns

freely

Fig.

8 • How

'0

cu

...

mel.

lb.

ap

••

dom.'.r

unit

Due

to

the

Simple

and

conventional

deSign

of

the

Allstate

scooter,

no

particular

skill

IS

requITed for

ItS

operation,

nor

skilled

pers~nnel

lor

ItS

maintenance.

The

tash

con

be

quite

well

carned

out

by

any

customer.

even

unexpenenced.

by

core/ully

follOWing

some

general

rules.

OPERATION

Fuel

lupply.

-Fuel mIxture

should

be

composed

of

reg

lar

gasohne

and

Allstate

Outboard

Motor Oil.

S.A.E.

30.

or Allstate

Regular

Motor Oil S.A.E. 30. in

the

following

proportion:

-

0.5

pmt

of

oil to I

gallon

of

gasoline.

Do

not use AllsttIte

compounded

motor

oil

or

other

Premium

Heavy

Duty Motor

Oils

with

detergents.

Keep the

breather

of

filling

cap

clean.

Oil level. -Remove the level

screw,

on

crankcase,

mer

ked •

OLIO,

and

mdlcateci

on

pag

II Fig

18.

to

check

01

level

10

gear

DO>:

belore

slartlng

the

engine

The

scooter

standing

upnght.

011

should

Just

be

about

to flow out; otherWise

top

up

with

ALLSTATE REGULAR

S.A.E.

30.

Running.in. -

Important

rules

to

be

followed

while

running-in

(1'200

miles) :

-Do

not

exceed

follOWing

speeds'

1st

gear

9.5

mph

2nd

gear

19

mph

3rd

gear

31

mph

Do

not

hold

these

max

speeds

for

long

periods

neither

use

full throttle

opening

up-hill.

Warning.

-

1/2

pint

of oil

should

be

mixed

10

each

gallon

of

gasoline

both

dunng

and

after

running-In

Starting.

-

Open

the

fuel

valve,

put

the

gear

box

m

neulral

and

shghlly

open

the

throllJe

In

slow

running

poSItiOn, kick

the

slartlng

lever.

See

Fig.

9;

note

the

three

positions

of

the

fuel

valve.

open,

closed.

reserve.

Caution.

-Do

not

open

throttle

wide

when

releasing

clutch.

-7-

In

case

of

starting troubles,

see

that the

carburetor

is

not flooding, i. e. mixture is not

dripping

from it.

Engine flooding

can

be overcome

by

either

one

of

the following

methods:

(a) Push-start the scooter: shift into

second

gear,

declutch

and

push

the machine;

suddenly

release

the

clutch lever

and

pull

it

back

as

soon

as

the

engine

start::.

(b) Close the fuel cock, remove the

spark

plug

and

rotate the engine

by

means

01

the !tickstarter. Wipe the

plug dry

and

replace.

Open

the fuel cock

and

!tick the

starting lever.

If,

instead. the

engine

is not flooded. close the

choke valve

by

pulling the lever

situated

under

the

seat

and

kick

the starting lever

again.

Setting the

machin.

in

motioD. •Let the

engine

idle,

depress the clutch

and

tum

the

gear

change

twistgrip

so that the line

engraved

on

it

coincides with the

num-

ber 1(lst

gear)

engraved

on

handlebars

(see Fig. 11).

Now

let in the clutch gently, while

opening

the throttle

gradually

to

set the machine in motion.

~.~

~

J

"

•.

I .

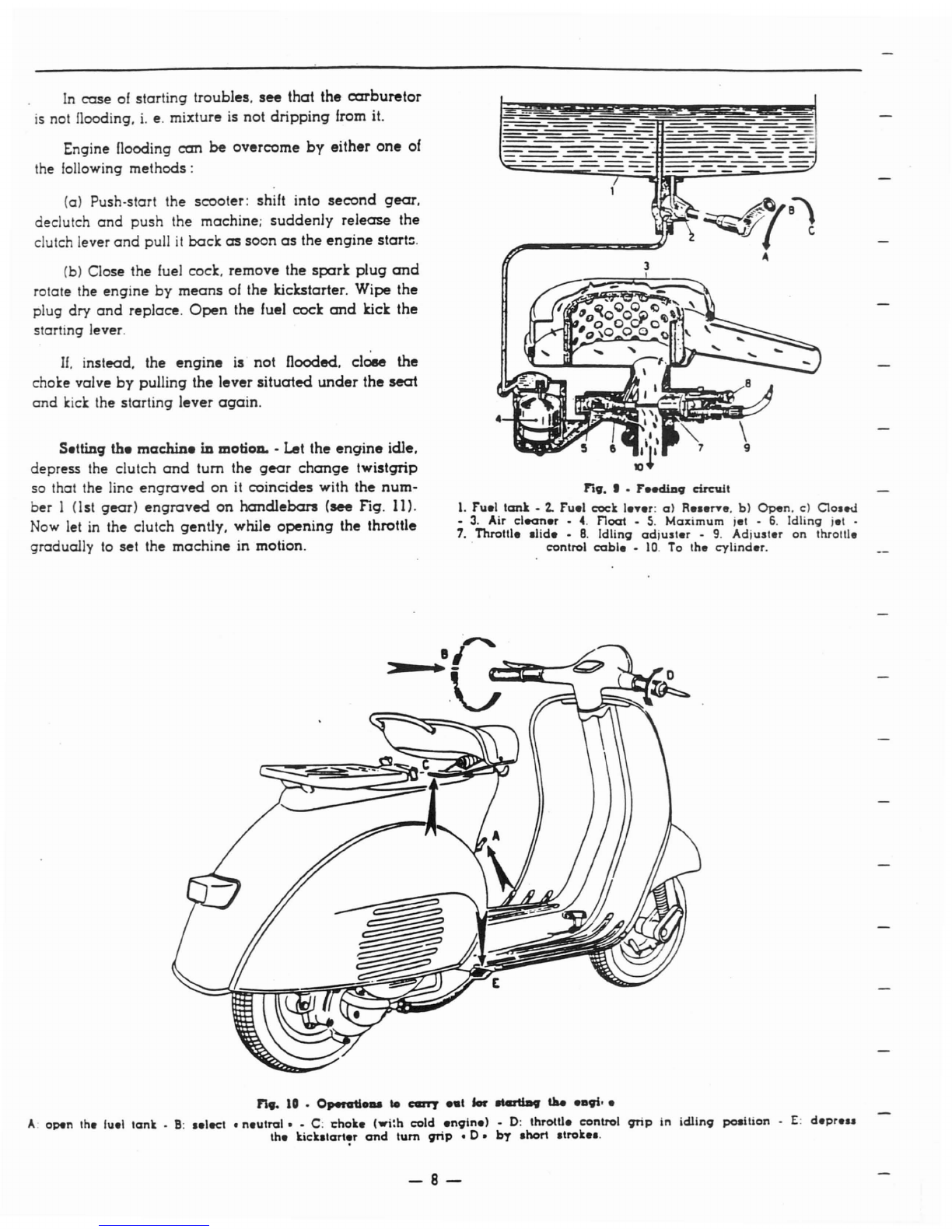

FeediD.

c:ircW1

1.

Fuel

tank

•

2..

Fuel

coc:k le'l'er:

a)

ReserYe,

b)

Open,

c)

Closed

•

3.

Air

cleaner

-

4.

Float

-

5.

Maximum

iet -

6.

Idling

jet -

7.

Throttle

slide

•

8.

Idling

adjuster

-

9.

Adjuster

on

throttle

control

cable

-

10.

To

the

cylinder.

"

••

10

•

Openrtlo_

..

carr

..

I

lor

atcatmv

tIM ealli· e

A:

open

the luel

lank

_

B:

selecl

•

neutral

••

C:

choke

(wi:h

cold

enqine)

•

0:

throtUe

control

qrip

In ic:lllnq

position

-

E:

depre

..

the

kicltstart!r

and

tum

qrip

•

D.

bT

short

slrokes.

-8-

G.ar

change

••

Alter

reaching

the

required

speed

in

1st

gear, close quickly the throttle,

depress

the clutch

and

tum

the

gear

change

twistgrip

so

that

the

engraved

line is opposite

number

2(2nd

gear)

let in the clutch

and

open the throttle gradually.

Repeat this procedure lor

changing

into 3rd

gear.

(See Drive system on

fig.

11

l.

For changing down. close the throttle.

depress

the

clutch

and

tum

the

gear

change

twistgrip to the requi-

red position.

Fi9.

11

•Dri

..

IYllelll

I.

Gear

change

twillgrip

•

2..

Clutch

cantrol

lever

•

3.

Gear

change

conlrol

cablel

-

Gear

.hiller

•

5.

Selector

Ilem

-

6.

S.lector

•

7.

lit

gear

pinion.

8.

2nd

\lear

pinion

-

9.

3rd

\lear

pinion •

10.

Mainshall -

II.

Cuah

gear

•

12..

Clutch.

N.B.

-

POI

IlionI

1·2·3

of

the

gear

cban\le

twUl\lrip

correlpond

10

III.

2nd

and

3ro:!

\lear

relpeeuvely;

•

C.

indJcatel

the

neutral polilion.

When you reduce the

speed

of

your

machine.

chan-

ge

down with no delay.

Do

not

tum

the

gear

change

twistgrip while

the

en-

gine ia not running.

AI

.oon

as

gear

change

trouble.

ariMo

particularly

when

the control

become.

hard.

cuatome,..

should

haYe

their

machin..

adjusted

at

a

Sears

Roebuck

and

Co•

•tore.

Fig. 12 -DiamaDtliD, U.e troDI

wll

..

L

Tir

...

-The

wheels

are

interchangeable.

i.

e. they

can

be

assembled

either

in (ront

or

rear.

provided

oi

.

course

that

they

are

enflated

to

pressures

respecltvely

hereunder

prescribed.

When

aflat tire

is

to be

replaced.

unscrew

the

lour

nuts

which

secure

the

wheel

to its flange. pull

wheel

sideways

off

the

studs

(see

fig.

12),

repair

it

or

replace

with

spare

wheel.

To

remove

the

tube,

deflate

it

itrst.

then

separate

the

felloe from

the

ring

by

unscrewing

the

nuts

which

join

them

(see

fig.

l~).

Tire

pressure

should

be

18

psi

on

rear

wheel.

11

psi

on

front

wheel.

If

the

Allstate is

ordinarily

ridden

by

both

driver

and

passenger,

the

pressure

01

the

rcer

tire

should

be

28

psi.

StoppiDg

the

en~.

-

Push

the

cut-out

button

(see

fig.

7.

letter

"E

..

);

fuel

vapors

remain

in the

cylmder

in

this

way,

and

the

next

start

will be

much

easier.

-9-

Brake

adju.tment.

-Brakes

are

properly

adjusted

if:

-the wheel rotates freely

when

respective control

lever or

pedal

are

in resting position;

-the braking action startS

as

soon

as

respective

controls

are

operated.

These conditions

are

achieved

adjusting

the

cables

by

means

of

screws indicated with

an

arrow

in Fig.

14.

®

fill.

14

•Brake ad!llStIDe"

Adju.tment

of clutch controL -

Adjustment

of

clutch

controls is

achieved

operating

on.

adjusting

nut

(aJ.

screwed

to

the

engine

braket

(see Fig. 15).

by

means

of

open

end

wrench

82199 in the tool roll.

a

fiV.

15

•

Ad!uatmeat

of

dutch

coatrol

0)

A.djustlng

nul

-b)

Clutch

leyer.

engine

side

The

cable

is

to

be

tensioned

or

loosened.

as

the

case

may

be.

so

that

control lever.

on

handlebars.

makes

a

stroke

of 2mm.

(0.078")

before

lever

(b).

on

engine.

starts

moving.

Wrong

play

in the control

may

cause

the clutch

plates

burning

out

even

in

normal

riding

conditions.

MAINTENANCE

Slow

running

adjwatm.nL -

No

han'" tool is

required

for

this job; idling revs

can

be

raised

by

simply tighten.

ing the screw which

presses

on

carburetlor

cover

and

vice-versa.

Cleaning the

scoot.r.

-Brushing

kerosene

and

wiping dry with

dean

rags

is

advisable

for

outside

cleaning

of

engine.

All

painted

surfaces

should

be

washed

with

water.

rinsed

by

means

of

a

sponge

and

wiped

dry

with a

chamois.

Do

not use kerosene

on

such

surfaces.

since

it

damages

paint

and

turns

it

dull.

If

necessary.

blow

the

head

lamp

reflector clean

or

wipe

oil

dust

with a

very

soft feather.

Do

not

use

a

cloth

and

keep

your

fingers oil refiector

surface.

Befor

...

tting

the

mac:hiD.

in

motion.

(if

it

has

been

delivered

directly to the

customer

by

the

Factory)

check

oil level in

gear

box

by

unscrewing

from

the

cranckase

the

level

screw

marked

•

OUO.

(see

Fig.

181.

The

scooter

standing

upright. oil

should

just

be

about

to

now

out.

AJter

the

tint

600

mil...

-

Replace

oil in the

gear

box

by

the

procedure

as

explained

in the

lubrication

chart.

page

11.

The

crankcase

can

be

drained

through

the

hole

indicated

in

Fig.

18.

10

-

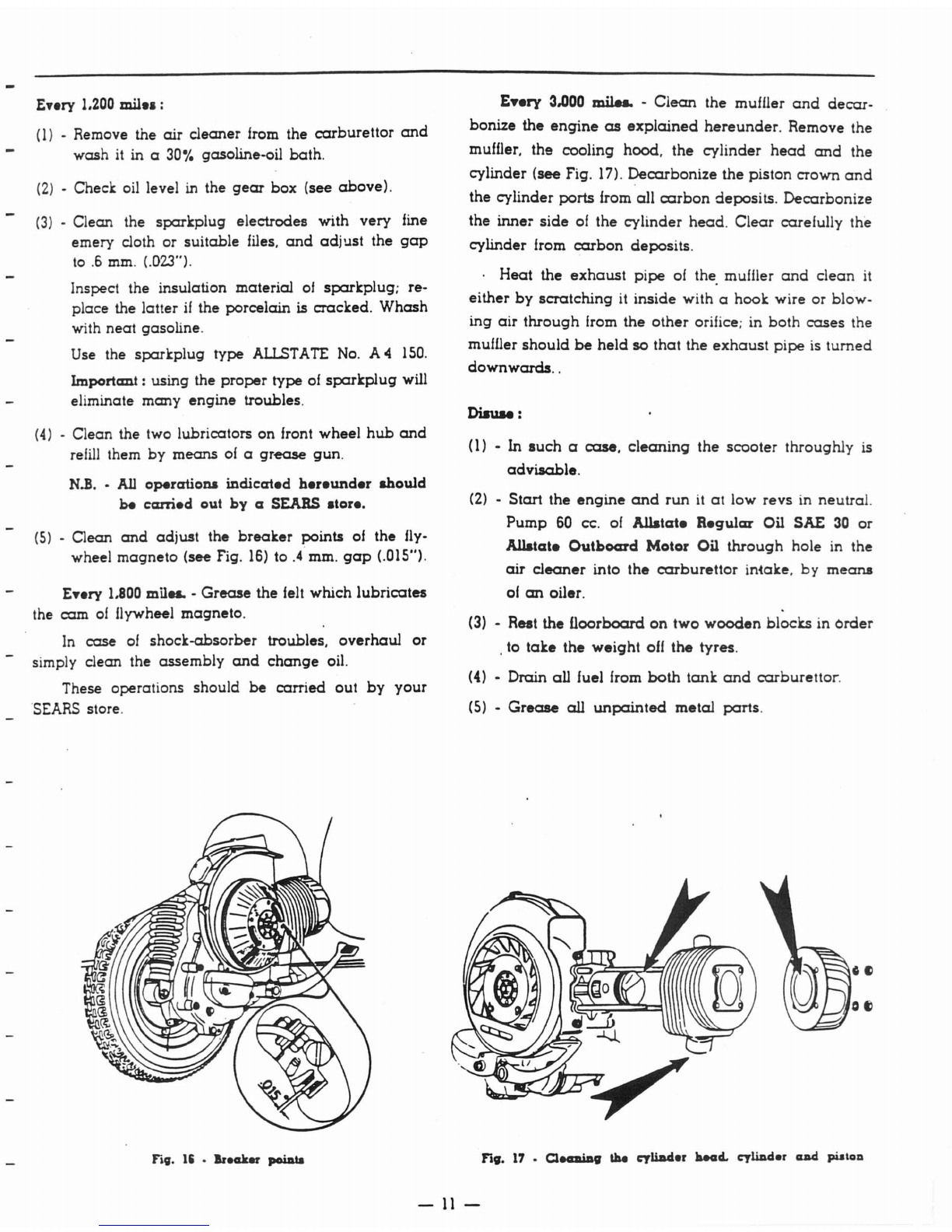

Eury

1.200

mil

••

:

(1)

-Remove the

air

cleaner

from the

carburettor

and

wash

it in a

30~.

gasoline-oil bath.

(2) -Check oil level in the

gear

box (see

above).

(3) •Clean the

sparkplug

electrodes with

very

fine

emery cloth or suitable files.

and

adjust

the

gap

to

.6

mm. (.023").

Inspect the insulation material

of

sparlcplug; re-

place the latter

if

the porcelain

is

cracked.

Whash

with

neat

gasoline.

Use the

sparkplug

type

AllSTATE

No.

A4

ISO.

Important:

using the

proper

type

of

sparkplug

will

eliminate

many

engine

troubles.

(4) •Clean the two lubricators

on

front wheel

hub

and

refill them

by

means

of

agr-ease gun.

NoB.

•

All

operatioDa indicated

hereunder

ahould

be

carried out

by

aSEARS atore.

(5)

•

Clean

and

adjust

the

breaker

points

of

the fly-

wheel

magneto

(see Fig.

16)

to

.4

mm.

gap

(.015").

Eury

1.800

mil

...

-

Grease

the felt which

lubricates

the cam

of

Ilywheel magneto.

In

case

01

shoclc-absorber troubles,

overhaul

or

simply clean the

assembly

and

change

oil.

These operations

should

be

carried

out

by

your

'SEARS

store.

Fig.

15

•

Ir.aker

poiAta

Enry

3.000

milu.

-

Clean

the muffler

and

decar-

bonize the

engine

as

explained

hereunder.

Remove the

muffler. the cooling hood. the

cylinder

head

and

the

cylinder (see Fig.

17).

Decarbonize

the piston crown

and

the cylinder ports from

all

carbon

deposits.

Decarbonize

the inne:-

side

of

the

cylinder

head.

Clear

carefully the

cylinder from

carbon

deposits.

.

Heat

the

exhaust

pipe

of

the. muffler

and

clean

it

either

by

scratching

it

inside

with ahook wire

or

blow-

ing

air

through

from the

other

orifice; in

both

cases

the

muffler

should

be

held

so

that

the

exhaust

pipe

is

turned

downwards

..

Diauu

:

(l)

•

In

such

a

case,

cleanin9

the

scooter

throughly is

advisable.

(2) •

Start

the

engine

and

run

it

at

low

revs

in neutral.

Pump

60

ce.

of

Allatate

aegular

Oil SAl:

30

or

Allatate

Outboard

Motor Oil

through

hole in the

air

cleaner

into

the

carburettor

iniake.

by

meana

01

an

oiler.

(3)

•Rest the

floorboard

on

two

wooden

blocks in Order

.to

take

the

weight

off

the

tyres.

(4)

•Drain all fuel from

both

tanlc

and

carburettor.

(5)

•

Grease

all

unpainted

metal

parts.

Fig.

17

•

Q.-iDlJ

the

cyliDd.r

laeacL

cyliDd.r

cuad

pUlOD

-

11

-

LUBRICATION CHART FOR AIJ.STATE

PART

TO

BE

I

OPERATION

TI

ME

TYPE

OF

LUBRICANT

LUBRICATED I

Enqine

,Mix

qasoline

'With

the

followinq

amount

of

At

each

rdfillinq of

the

fuel

Allstate

Regular

SAE

30

or

lubricatinq

oil:·

tank

Allstate

Outboard

Motor Oil

i-

0.5

pint

of oil

to

I

qallon

of

qasoline.

Gear

Box

I

Warm

up

the

engine

and

drain

off

all

oil. After

the

first 600

miles

IPour

some

fresh oil in

and

run

the

engine

lor

a

lew

seconds.

Dram

again

and

refill

with

Allstate

Regular

SAE

30

ne";

oil.

Refill with

new

oil to oil levcl hole.

Every

1200

miles

front

wheel

hub

Lubricate

with

grease

gun.

Every

1200

mlles

Hiqh

Pressure

Chassis

Grease

Joints on

brake

I

Grease.

Every

1200

miles

Allstate

all

-

purpo.e

control.

I

Gear

Lubricator

SAE

140

Shock·absorber

Change

oil.

Only

when

the

shock-absorber

Allstate

Shock

is

out

of

order

Absorber

nuid

I.

Control

cables

C1l1OTl

and

lubricate.

Every

1800

mil.s

Allslate

all

-

purpose

Gear

Lubricator

SAE

140

fell

01

nywheel

Small

of

grtMIse

on

the

fel:!.

i

Every

11m

miles

Allstate

BtMJring

Grease

spot

I

cam

I

Ratchel

quadrant

Grease.

Every

1800

miles

Allstate

all

-

purpose

01

qear

.hiller

II

Gear

Lubricator

SAE

140

I

["&II(

U8IIUTtO

IU.S

Taft

IlGULU

SA(

JO

(lit

aLL)

Tift

OY!'IOA!!Q

Ml)!pI!

ill.

Fi,.

II

•Lulniccrtioll

acbellle

I. Filling

hole

-

2.

Draining

hole

-

12-

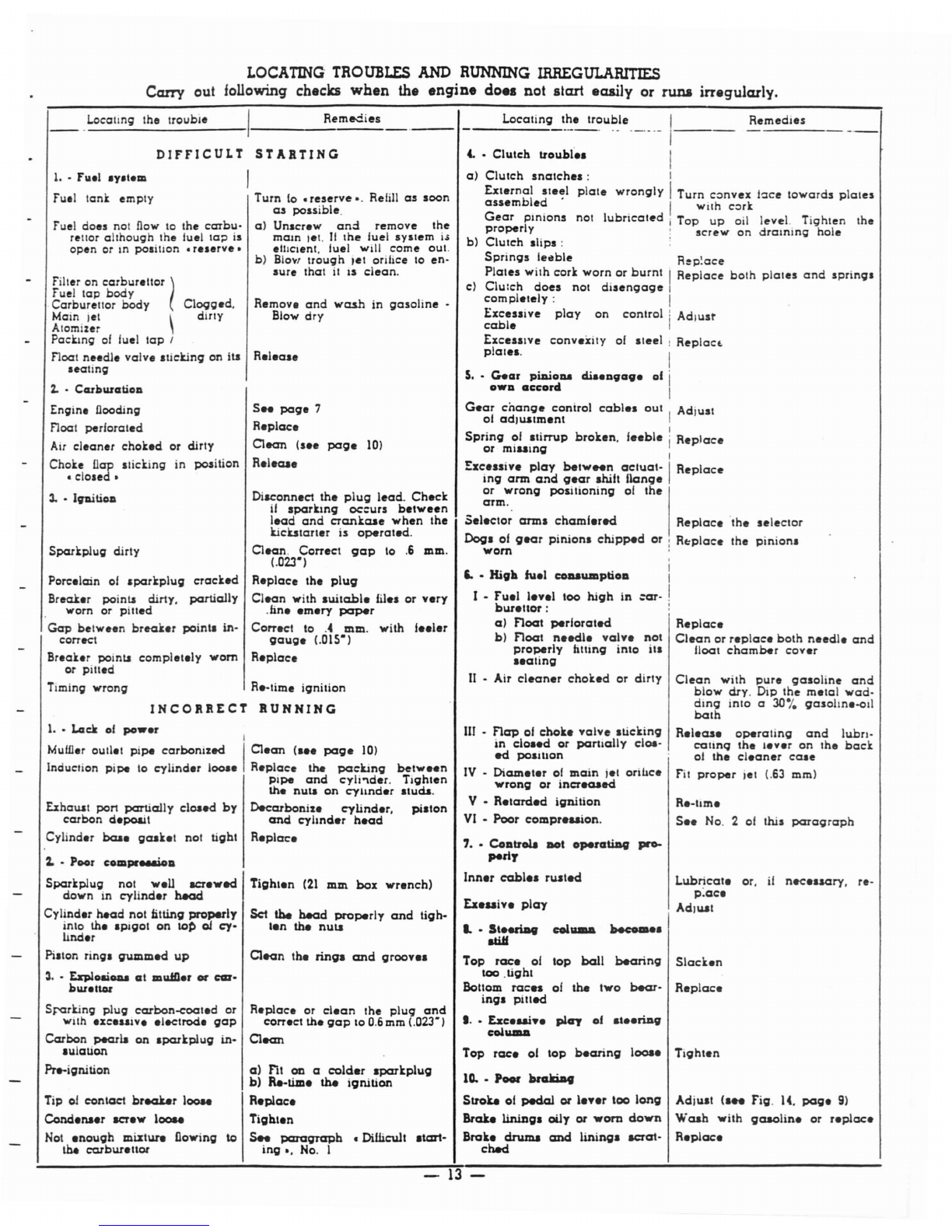

LOCATING TRO

UBLES

AND RUNNING IRREGUlARITIES

Carry out following checks

when

the

engine

do

••

not start easily or runa irregularly.

INCORRECT

BUNNING

DIF'FICULT

STARTING

R.-hm.

S..

No. 2of lhis

paragraph

AdilUt (a

..

Fig.

14.

page

9)

Wash

with

gaaolin.

or

r.plac.

R.plac.

Clean

with

pure

gasoline

and

blow

dry.

DIp

the

m.tal

wad-

ding

inlo

a30%

gasolln,-011

bath

R.l.as.

operating

and

lubn-

callnq

the

I.v.r

on

lhe

back

o(

the

c1.aner

eale

fit

proper

jet

<.63

mm)

Replac.

Clean

or

r.plae.

both

needle

and

floal

chamber

cov.r

I

I

:ar.

!

Lubricat.

or,

if

nec.asary,

re-

p:ac.

AdllUt

become.

I

col_

4.

•

Clutch

trouh!'

••

Locating

the

trou~_le'

__

'_I

Remedies

I

a)

Clutch

snatchel:

I

Ext.rnal

steel

plate

wrongly

I

Turn

convex

bee

towards

plates

assembled

. . IWilh

cork

Gear

pinions

not

lubrlcaled

j

Top

up

oil

level.

Tighten

the

properly

,

screw

on

draining

hole

bl

Clutch

llips:

Springs

leable

Rep~ace

Plates

with

cork

worn

or

burnt

Replace

both

plales

and

springs

c)

Clu:ch

does

not

disengage

compl.lely

:

ExceSlive

play

on

control

Adjust

cable

ExceSilve

conv.xity

of

Ileel

Replact.

plat.l.

tx.uiv.

play

50

•

High

ha.l

COIIaWDplioD

I •

Fu.l

l.v.l

too

high

in

bur.llor:

a)

noat

perlorated

b)

noat

n.edl.

valve

not

properly

hlling

into

ill

••

ating

II

•Air

cleaner

chok.d

or

dirty

S

••

GaClr

piDiolU

cli

••

1l9C19.

of

OWIl

a~~orci

Gear

cnange

conirol

cabl.1

out

Adiusl

01

ad,lUtm.nt

Spring

of .tilT\lp

broken,

le.bl.

Replace

or

miumg

Exc.ssive

play

belw

..

n

actuat-

Replace

ing

ann and

g.ar

ahift

llanoe

or

wrong

positioning

of

the

arm.

Sel.ctor

annl

chaml.red

Replace

'lhe

selector

Dog.

of

g.ar

pinionl

chipped

or

:

R~plac.

the

pinionl

worn

'

7

••

CoDuola

_t

opeJ'ClUD9

pro-

peri,

Inn.r

cabl..

rlUted

m •

nap

of

choke

valve

lticking

in

cloa.d

or

partially

c1e.-

ed

polltlOn

IV

-

Diam.t.r

of

main

j.l

orihce

wrong

or

increaaed

V •

R.tard.d

ignition

VI

•

Poor

compr.uion.

...

SteeriD9

atiJf

Top

rac.

of

top

ball

bearing

Slack.n

too

.tight

Bottom

rac..

of

the

two

~-

Replac.

ing.

pitted

1

Q.

•

p_

bralI:iD9

Stroke

of

~

or

l.ver

too

1000g

Brake

lininga

oily

or

wom

down

Brait.

cirwna and

lininga

aerat-

checl

I

..

Eac.ui..

play

of

....

riDg

collUDD

Top

rac.

01

top

bearing

loos.

Tighten

Remedies

R.-time

ignition

S

..

page

7

R.plac.

Clean

(s.e

page

10)

R.I.cae

R.I.a.e

Turn

(0

•

reserve

•.

Refill

as

soon

as

possible.

aJ

Unscr.w

and

remove

the

mam

,et.

II

Ihe

luel

system

i~

elhclent, tuel will

come

out.

b)

B10."

Irough

,et

orifice 10

en-

sure

that

it

IS

clean.

Remove

and

wash

in

gasoline

-

Blow

dry

Diaconn.ct

Ihe

plug

lead.

Check

if

sparking

oc:urs

b.tween

lead

and

erankcae

when

Ihe

kicutart.r

is

operat.d.

Clean.

Correct

gap

10

.6

mm.

(.023-)

Replace

th.

plug

Clean

with

.uitabl.

file.

or

v.ry

.tin

••

m.ry

paper

Correct

10

.4

mm.

with

I

••

l.r

gaug.

(.OlS-)

R.place

Tight.n

(21

mm

box

wr.nch)

Clean

the

ringa

and

groov

..

Set

the

bead

properly

and

tigh·

t.n

the

nUll

R.p1ace

or

c1.an

the

plug

and

corr.ct

th.

gap

to

0.6

mm <.023-)

Clean

0)

FIt

CD

a

cald.r

aparkplug

b)

Re·tim.

the

ignition

R.p1ac.

Tigbl.n

Ie

s..

paragrapb

•Dillieu1t

atart·

ing.,

No. I

Locallng the

trouble

1

••

F'lIel

.y.lem

fu.1

tank

empty

fuel

does

not now to Ihe

cClTbu-

rettor

all

hough

the

luella;)

is

open

or

In

position

•

r.serve

•

filler

on

carburetlor

(

fuel

tap

body

Carburettor

body

Clogg.d,

Main lei \

diTlY

Atomizer

Packing

of

fuel

tap

I

float

needle

valve

sticking

on

ill

seating

1.

•CMkllUCltiOIl

Engin.

llooding

float

perforated

Air

cleaner

chok.d

or

dirty

Choke !lap

Iticking

in

position

•

closed.

3.

•

lpi

tiOll

Sparkplug

dirly

Pore.lain

of

lparkplug

crack.d

Break.r

poi

nil

dirty,

partially

worn or

pitted

Gap

betw.en

break.r

poinl.

in·

correct

Br.ak.r

points

complet.ly

worn

or

pitl.d

Timing

wrong

1

.•

Lack

of

pow.r

I

Muli.r

outl.1

pipe

carbonized

I

C1.an

(I"

page

10)

Induction

pipe

10

cylind.r

loose

Replace

the

packJng

betw

••

n

Pipe

and

cyli"\d.r.

Tlghlen

lb.

null

on

CYllnd.r

Iluda.

Deearbonize

cylind.r,

pi.ton

and

cyllnd.r

head

R.plac.

Exhauat port

partially

closed

by

carbon

d.poait

Cylind.r

ba..

gcak.t

not

tight

Sr-arking

plug

carbon-eoat.d

or

wllh

'XC'Sll'r'

.leclrod.

gap

Carbon

peoria

on

.parkplug

in·

'1Ilation

Pre-ignition

Tip

01

~ntact

break.er

100M

Cond.naer

aer.w

100M

Nol

.nough

mixture

Dowing

the

earbur.lIor

1. •

P_r

~omJWeouiclia

Spark

plug

not

w.ll

aer.wed

down

in

cylind.r

beacI

Cylind.r

head

not

titting

properly

into th

••

pigot

on

tot>

01

cy.

lmd.r

Pi.ton

rings

gummed

up

3

.•

Exploaiou

ClI

.WIl.r

or

car·

bllT.llol

-

13-

-14-

-i

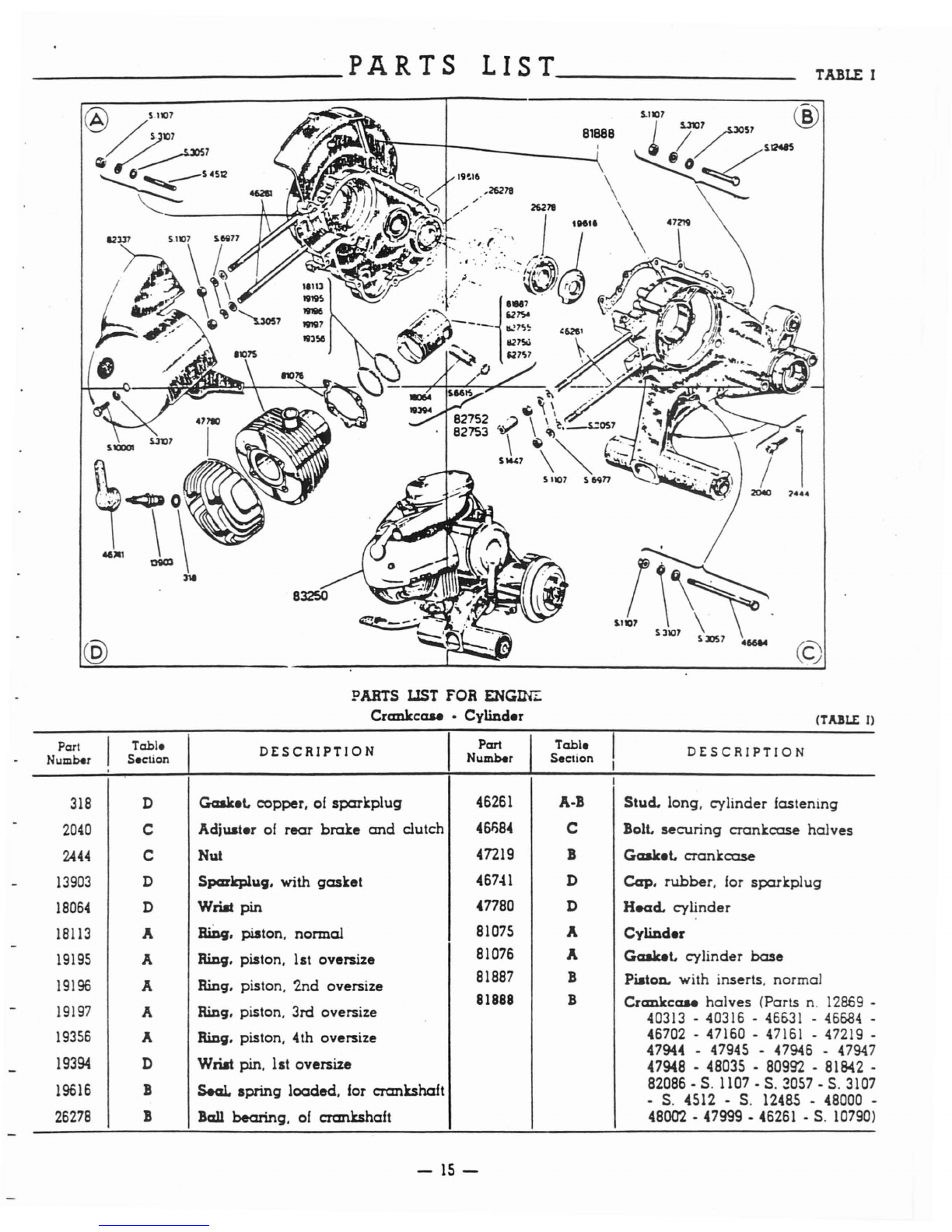

_________

p

ART

S

LIS

T _

TABLE

I

@

19~16

,26278

PARTS IJST

fOR

ENG~

Crankcase

-Cylinder

(C)

(ToUU:

l)

Part I

Table

DESCRIPTION

IPart

Table

I

DESCRIPTION

Number Section

Nwnber

Section

,I

I

318

DGaaket. copper,

of

sparkplug

46261

A-B

Stud.

long, cylinder fastening

2040

CAdjuster

of

rear

brake

and

clutch

45$)84

CBolt.

securing

crankcase

halves

2444

C

Nul

47219

BGaalcet.

crankcase

13903

DSparkplug.

with

gasket

.(6741

D

Cap.

rubber.

for

sparkplug

18064

DWriat

pin

"n80

D

Head.

cylinder

18113

A

~.

piston. normal

81075

A

Cylinder

19195

ARing. piston.

1st

oversize

81076

AGaalcet. cylinder

base

19196

ARing. piston.

2nd

oversize

81887

BPiston. with inserts, normal

81888 B

Crankcase

halves

(Parts

n.

12869

-

19197

ARing, piston.

3rd

oversize

40313

.

40316

.

46&31

-

46684

-

19356

ARing. piston.

4th

oversize

46702

.

47160

-

47161

-

47219

.

47944

.

47945

-

47946

-

47947

19394

D

Wn.t

pin, lst oversize

47948

-

48035

-

80992

.

81842

-

19616

B

Seal.

spring

loaded,

for crankshaft

82086

-

S.

1107.

S.

~057

-

S.

3107

-

S.

,(512

-

S.

12485

.

48000

-

26278

BBall

bearing.

of

crankshaft

48002

.

47999

-

46261

.

S.

10790)

-

15-

Part. li.t

for

eaqiDe -Crankr:a.e •Cylinder •Continued

Part Table I

DESCRIPTION

Part

Table

I

DESCRIPTION

Number Section Number Section

82237

AHood. cooling

S.

1107

A-B-C Nut. for locking

cylinder

head

and

82752

CPiston. with

standard

wrist pin

crankcase

halves

(Parts

n.

180&4

-

81887

-

S.

6611)

S.

3057 A·B·C

Waaher.

plain

82753

CPiston. with wrist pin.

1st

oversize

S.

3107 A·B·C·D

Washer.

spring

(Parts

n.

180&4

-

92754

-

S.

60

11

)S.

1-447

CNut.

spacer,

hood

fixin9

82754

BPiston. with inserts, 1st oversize

S.

4512

A

Stud.

securing

cranxcose.

halves

gz755

BPiston. with inserts. 2nd oversize

S.

6615

CCirc:lip. for locking

gudg~on

pin

82756

BPiston. with inserts, 3rd oversize

S.

6977

A·C

Washer.

spring

S.

10001

D

Screw.

hood

fixing

82757

BPiston. with inserts, 4th oversize S.

12485

BBolt. short,

securing

crCJ'!.ki:ase hal-

83250

DEngine. g.a.

ves

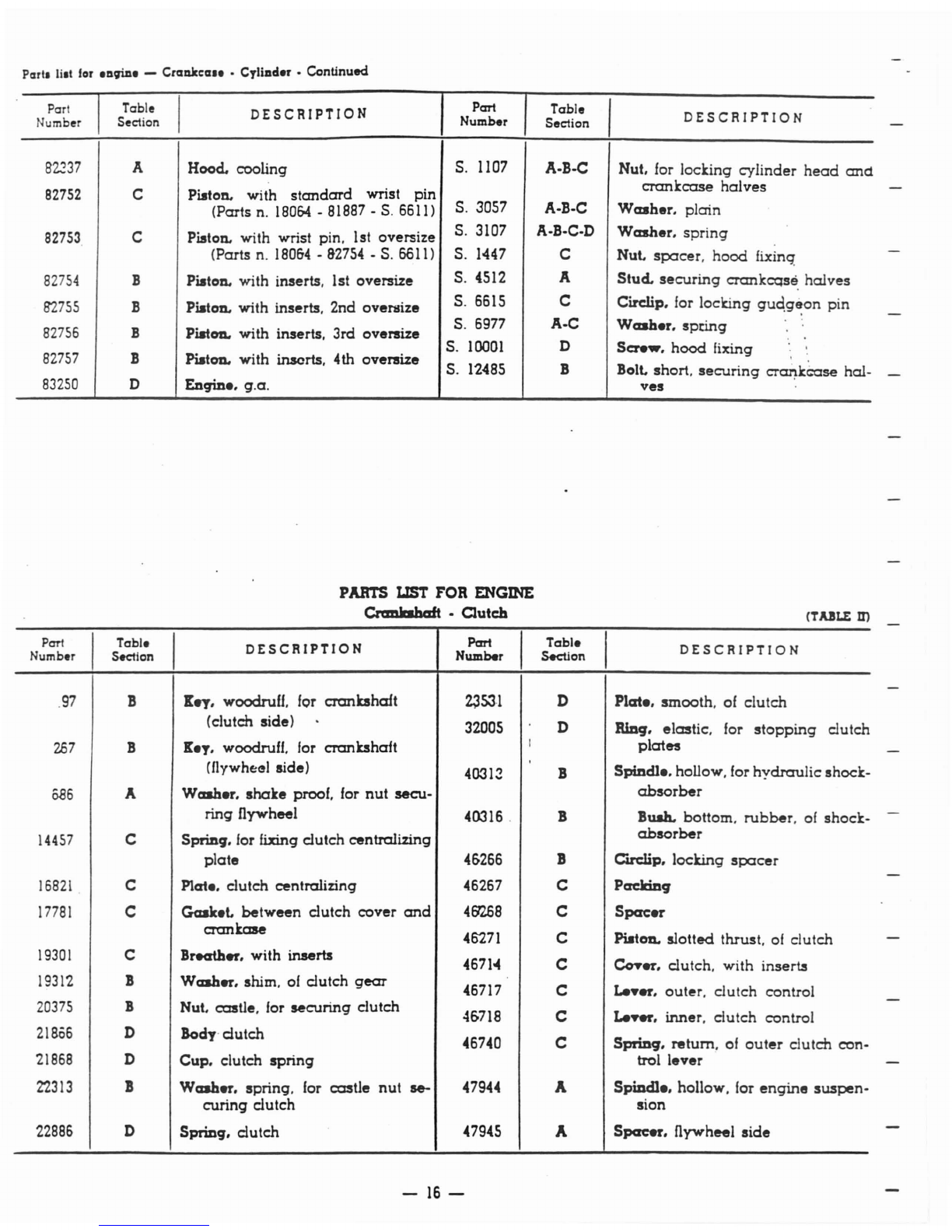

PARTS LIST

FOR

ENGINE

Cnmlrehaft -Clutch

(T.uLE

m

Pan

ITable I

DESCRIPTION

Part I

Table

I

DESCRIPTION

Number

s.ctlon

Number Section

.97

B

X..,.

woodruU, for crankshaft

~53'}

DPlcrte. smooth. of

clutch

(clutch side) 32005 D

RlDq.

elastic. for

stopping

clutch

267

BXey. woodruff, for crankshaft I

plates

(flywhe<!1

side) 40312 BSpindle. hollow, for

hydraulic

shock-

686

AWasher.

shake

proof. for

nut

se<:u-

absorber

ring flywheel 40316 .BBush. bottom,

rubber,

of

shock-

14457

CSpring. for fixing

dutch

centralizing

absorber

plate

4&266

BCirclip. locking

spacer

16821

CPlate. clutch centralizing 46267 C

Packing

17781

CGasket.

between

dutch

cover

and

45'258

C

Spacer

crankaae

46271

CPiston. slotted thrust.

of

clutch

19301

CBreather. with

inserts

467104

C

Co?er.

dutch,

with inserts

19312

B

Washer.

shim.

of

dutch

gear

46717 CLe"er.

outer,

dutch

control

20375

BNut. castle. for

securing

clutch

4&718

C

Le~.

inner,

dutch

control

21856

DBody·

dutch

46740 CSPfiD9. return.

of

outer

dutch

con-

21868

DCup. clutch

spring

trol

lever

22313

B

Washer.

spring, for

castle

nut

se- 47944 A

Spindle.

hollow, for

engine

suspen-

curing

clutch

sian

22886

DSpring.

dutch

47945 A

Spacer.

flywheel

side

-

16-

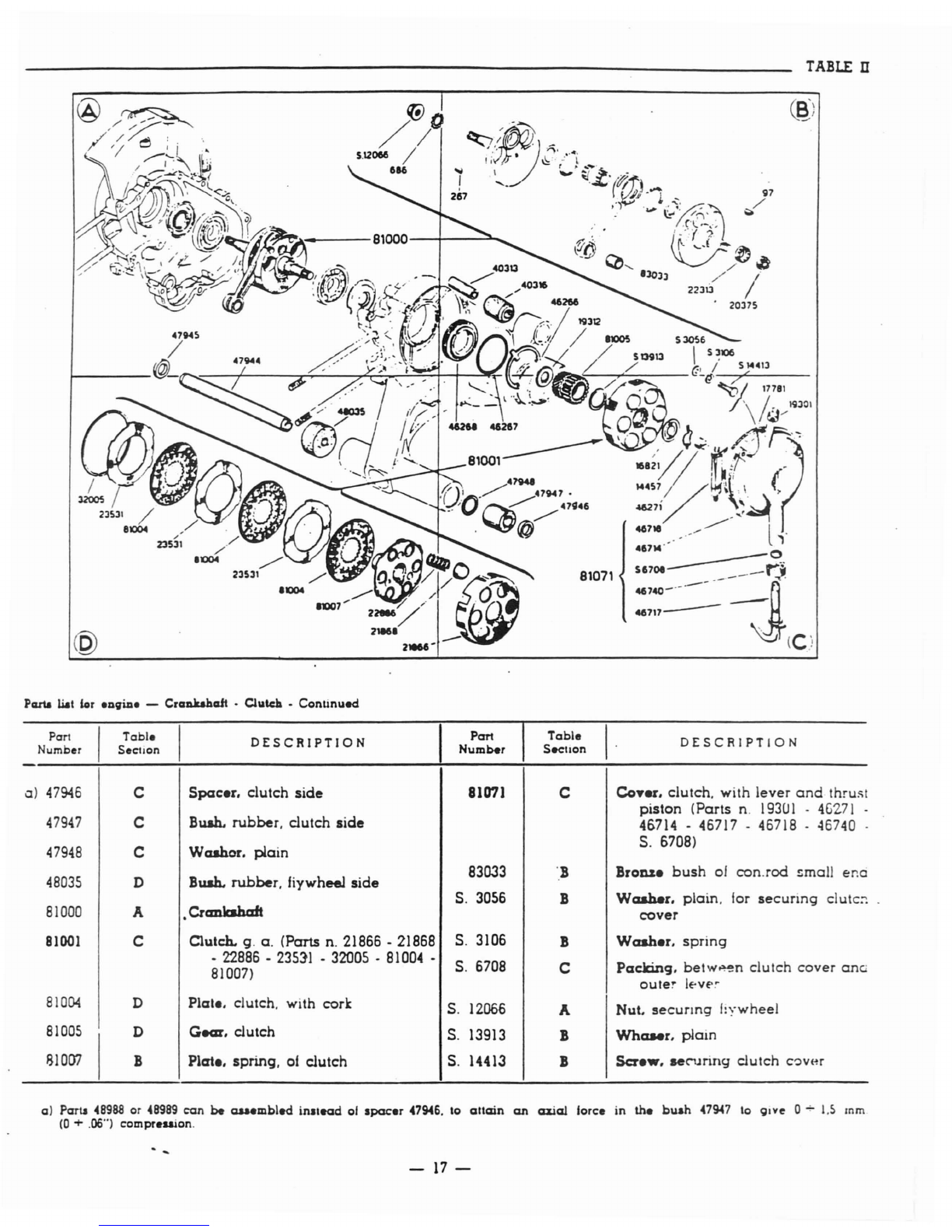

TABLE n

@

46717

Pcuta llat

for

engine

-Crankahcdt •

C!utdl

•

Continued

Part I

Table

I

DESCRIPTION

Part

Table

I·

DESCRIPTION

Number Seclion

Number

Seellon

0)

47946

C

Spacer.

clutch

side

81071 C

Coyer.

clutch. with

lever

and

thru>il

47947

CBush.

rubber.

clutch

side

piston

(Parts

n.

193U

I -

4G271

-

46714

•

46717

-

46718

•

46740

47948

CW

ashor.

~ain

S.

6708)

48035

DBush.

rubber.

fiywheel

side

83033

·.B

Bron1e

bush

of

con.rod

~mall

er.a

S.

3056

B

Washer.

plain.

for

secunng

clute::

81000

A•

Crcmlcsh

aft

cover

81001

CClutch. g.

a.

(Parts n.

21866

-

21868

S.

3106

B

Washer.

spring

•

22886

-

23511

-

32005

-

81004

•

S.

6708

C

Padting.

betw~n

clutch

cover

COG

81007)

outer

IE-Vf'o

81004

DPlale. clutch. with cork

S.

1206£

ANut.

secunng

f:ywheel

81005

I

D

Gear.

clutch

S.

13913

B

Whaaer.

plain

g10D?

BPlate. spring.

of

clutch

S.

14413

B

Scre

••

sec-uring

clutch

C::lver

a)

Parts

48988

or

4B9B9

can

be

auembled

inllead

of

lpacer

47946.

\0

attain

an

axial

lorce

in

the

buah

47947

\0

91ve

0.;-

1.5

mm

(0

+.06") cOlIlpreuion.

-17-

--------------------------------

__

TABLEm

(J;;)/

snw

:D

PARTS LIST FOR ENGINE

Gear

box

•Rear

wh

..

1Dange (TABLE III)

Part I

Table

DESCRIPTION

Part

Table

I

DESCRIPTION

Number Seclion

Number

Section

61

AClip. spring, lor

brake

jaws

12869 B

Screw.

for

dust

cover

2021

ASc:rew. lor joining

brake

drum

to

17821

DSelector.

gear

flange

a)

17B24

CGear. 2nd

speed

2035

B

LiDk.

brake

19H7 CClJ'Clip.

retaining

shoulder

washer

2036

BBolt. for securing

cable

to

brake

a)

18558

C

Washer.

shoulder.

normal.

of

gear

links pinions

2082

BPin. for

rear

brake

links

a)

19611

CG.a:r. 3rd

speed

2098

ASplit pin.

for

locking castle

nut

a)

20321

C

Washer.

shoulder. 1st oversize

2442

ANut.

for

securing

wheel

a)

20322 C

Washer.

shoulder

2nd oversize

7563

ABall

bearing

of

mains

haft

a)

20323 C

Washer.

shoulder

3rd oversize

7884

B

Arm.

rear

brake

control

a)

20324 CWhaMr.

shoulder

4th oversize

7886

A

Pad

23831

ADrum.

rear

brake

a)

Th.

total

axial

plOT

of

the

auembly

·of the 3

gear

pinion.

in

respect

to

their

Hat

mu.l

be

contained

between

.006"

and

.olr.

Shoulri this

play

exceed

.aid

toleraneell. the

nonnal

.houlder

wa.h.r

mu.t

be

replaced

br

another

with

proper

o.e~ize.

--

18-

PcutI llal lor

eniine

-

Gear

box·

Rear wheel ilanve •

ConLlnu~d

MaiDahaft. g.a. (Parts

n.

17821

-

18447

_

18558-

46605

_

47190

_

S.

13815

82085

•

S.

13768)

ParI

Number

25990

46605

46688

46696

46099

46700

46702

46803

47190

a)

48349

81'229

820S(

ITable

Seclicn

A

C

A

A

A

A

B

B

C

C

A

C

DESCRIPTION

Spring. return,

of

brake

jaws

Stem. selector

Ring. locking ball

bearing

Axl..

cam.

of

rear

brake

S.aL

spring

-

loaded

of

mainshaft

Circlip

Duat cover

Deneetor

Bush. guide,

01

selector stem

Gear.

low

speed

Jaw.

rear

brake.

with lining

IPari

Number

a)

82085

82120

S.

1207

S.

2314

S.

3110

bis

S.

3204

S.

~208

S.

13768

Tabl..

Section

D

A

B

A

A

B

B

C

A

DESCRIPTION

Mainahaft

Flange.

female spline, with inserts

Nut.

on

bolt

securing

brake

links

Nut. castle, for

securing

wheel

flange

Washer.

spring,

for

nut

securing

wheel'

Split pin.

on

pin for

brake

links

Split pin. for

cam

axle

Washer.

tab,

on

selector

stem

Waaher.

plain,

for

nul

securing

wheel flange.

a) The

IOlal

axial

play

ol the

auembly

01

the

3

gear

pinion.

in

relpect

to

their

aeal

mlal

be

contained

belwHn

.006"

and

012".

Should thil

play

exc:oed

laid

toleranc

..

,the normal

lhoulder

'Wasber mUlt

be

replacod

by

another

'With

proper

overl11e.

PARTS

LIST

FOR ENGINE

Cuah

gear

•

Kicbtarter

(TABLE:

JV)

Pan

ITable I

DESCRIPTION

Part I

Table

I

DESCRIPTION

Number Section INumber Section

2457

DBoller. for multiple

gear

483«7

CGear. multiple

17887

C

Spring.

of

cuah

drive

48348

C

Gear.

starting

17888

C

Gear.

outer,

of

c:u.sh

drive

81842

ARoller

31157

C

Washer.

plate,

of

cush drive

springs

82086

A

Cage.

roller

bearing

3'2494

DBall

bearing,

01

multiple

gear

82128

BKic:katarter

46618

DLayabaft

83014

COri..... cushion. g.a. (Parts

n.

17887

-

46631

B

Plug

17888

-

311S7

-

48347

-

S.

10776)

'{67'42

CBuJfer. for

starting

sector

S.

1209

DNut. for

securing

layshaft

47160

ARaee. roller

bearing

of

mainshaft

S.

3057

B

Waabar.

plain.

01

kickstarter

47161

A

Washer.

shoulder, roller

bearing

S.

3109

D

Washer.

sprin';l. for

nut

securing

layshalt

47'218

ASpring. return,

of

kickstarter

S.

57'23

ARiTet.

se=U1

ing

pr:Iwl

47226

B

Scre

••

securing

kickstarter

S.

6637

DCirclip. lor locking multiple

gear

47996

DSector. starting, with

parts

47998

-

ball

bearing

S.

S723

S.6721 B

Packing

47998

APcrwl

S.

10776

CBiTet. for

securing

plate

washer

47999

CBlad•• long, for starting

sector

S.

10790

C

Bi

....t. for

securing

blades

.{8000

CBlade. short, for

starting

sector

S.

12824

D

Waaber.

plain,

for

nut

securing

48002

C

Pad.

blades

layahaft

-

19-

________________________________

TABLE

IV

__

82128

@

47996

Sll637

.I

PARTS LIST

FOB

ENGINE

FlTWb

..

l

Magneto

•Fcm

5.1)77'&

{

@

©

(TULE

V)

Part I

Tabl.

I

DESCRIPTION

Part I

Tabl.

I

DESCRIPTION

Number Section Number Section

603

0Screw. for

securing

coils 16416 CBreaker.

with

platinum

point

619

0

Washer.

plain. for

securing

coils 16417 CAxle.

breaker

622

C

Washer.

shim. of

breaker

16418 C

Guaet.

contact

624

CNut 16419 CRiD9.

insulating

16420 CCam

625

CFork

spring

16421

0

Blade

felt.

with

inserts

662

"'-0

TermiDal 46750 0

Condenser

6'74

BCarclip. for flywheel

extraction

46075

...

Cam

2856

BSc:rew. long. for

securing

fan

cas-

46764

...

Cable.

earth.

with

terminal

ing

cover

46766

...

Grommet

2946

B

Scre~.

short. for

securing

fan

cas-

47191

...

Flywh

..

L

with

inserts

(Parts

n.

6562

ing cover •46675 -S.

IOnS)

3213

cSc:rew.

securing

condenser

and

felt 47576 BFcm

blade

47sn

Beo..r. fan

casing

65~

B

Washer.

plain.

of

com

82150

...

Coil

ignition. g.

a.

(Parts

n.

82852 -

1,(501

....

I)

Terminal

4676&

-827(6)

-?f'l

-

Table of contents

Other Allstate Scooter manuals