Allstate 788.94370 Use and care manual

OPERATING INSTRUCTIONS

AND

PARTS LIST

FOR

OT

SC

OTE

MODEL NUMBER 788.94370

This

is

the

Model

Number

of

your

Allstate

Motor

Scooter.

It

will

be

found

on

a

plate

fastened

to

the

chassis

under

the

fuel

cock.

Always

mention

this

number

when

communicating

with

us

regarding

the

Scooter,

or

when

ordering

repair

parts.

HOW

TO ORDER REPAIR PARTS

All

parts

listed

herein

may

be

ordered

through

any

Sears

retail

or

mail

order

store.

In

ordering

parts

by

mail

from

the

mail

order

store

which

serves

the

territory

in

which

you

live,

Selling

Prices

will

be

furnished

on

request

or

parts

will

be

shipped

at

prevailing

prices

and

you

will

be

billed

accordingly.

WHEN

ORDERING

REPAIR PARTS, ALWAYS GIVE

THE

FOLLOWING INFORMATION:

1.

The

Part

Number

in

this

List.

2.

The

Part

Name

in

this

List.

3.

The

Model

Number

of

the

item.

This

list is

valuable.

It will

assure

your

being

able

to

obtain

proper

parts

selvice

at

all

times.

We

suggest

you

keep

it

with

other

valuable

papers.

ScootelWorks USA Inc.

5709

N.

Ravenswood

Chicago,

IL

60660

ph: 773.271.4242

fx:

773.271.5012

EARS, EB cA

O.

gs to

19ine

ss

of

lders

rpm

wi h

ance

",ind,

scoo-

nor-

f

be

Fig. 1 •

Sun

Motor

Scooter

WARNING

,-----------.'

-'-

Fig. 2 .

location

of

.erial

number

Serial

numbers

are

preceded

by

prefixes:

VMA

1

T,

for

frame;

VMA

1M,

for

engine.

~

on

nbed

gear

seful

that

;ome

from

lrbu-

)wn-

use

stion

form

in

e

in

et

or

he

he

and

)ion

en-

order

to

keep

your

scooter

in

perfect

running

condi-

on

and

not

to

void

the

guarantee,

always

have

your

achine

repaired

at

a

Seras,

Roebuck

and

Co.

Store.

pecial

care

should

be

taken

with

regard

to

the

fuel

ixture

which

should

be

regular

gasoline

and

oil

of

e

make,

grade

and

in

the

amount

prescribed

in

this

ooklet.

Ethyl"

gasoline

should

never

be

used.

Do

not

use

Allstate

compounded

motor

oil

or

other

Praemium

Heavy

Duty

Oil

with

detergents.

The

inexperienced

operator

should

exercise

caution

in

applying

front

wheel

brake,

to

avoid

locking.

Fig. 3 -

Control.

of

Sean

Scoot..r

1.

Gear

chanC)<'

two

>tg"p

with

clutch

control

leve'

.

2.

Front

brake

lever

.

J.

Throttle

con·

trol

grip

-

~.

L'Qht

and

dim-

mer

switch

.S.

Front

brake

jaws.

-

6.

Reor

bra'e

pedal

-

7.

Kic

starter

-

•.

Gear

selec-

tor

-

9.

Reer

brake

jews.

10.

Clutch.

11.

Carburetor,

air

cleaner.

12.

Storter

push

pull

rod

-13_

fuel

cock.

-

14.

Knob

for

locking

tilting

sad-

dle

- 1

S.

Lever

for

removing

engine

flap.

-3-

.

--_.-.

-'-'-'"

,

r----

I

/

\.

;'

----?....,P'""

.---_.

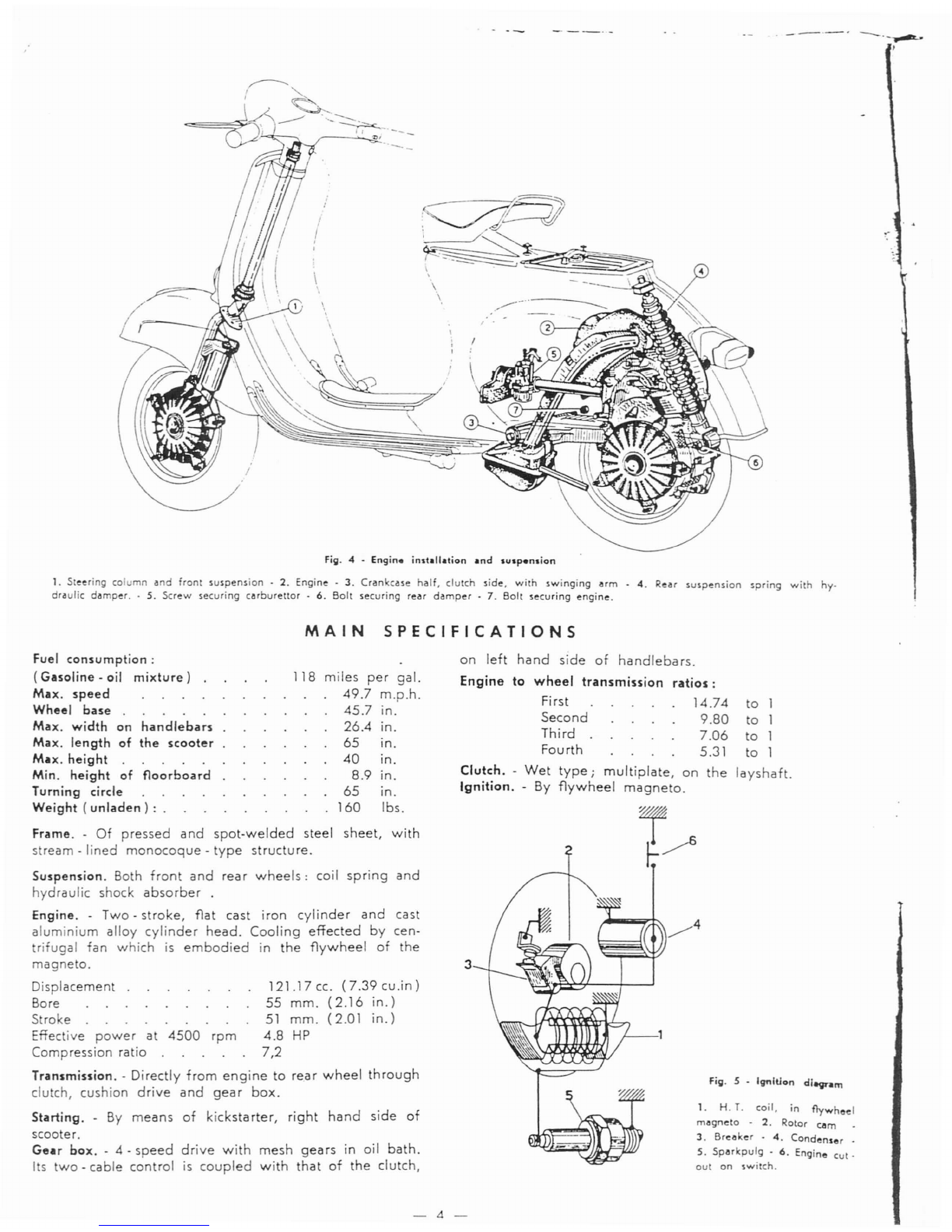

Fig. 4 -

Engin.

installation

and

IUlp.olio"

1. Steering column

and

front

suspension·

2.

Engine·

3.

Crankcase

half.

clutch

side.

with

swinging

arm

.

4.

Rear

suspension

spring

with

hy.

draulic

damper

..

5.

Screw

securing

carburettor

.

6.

Bolt

securing

rear

damper.

7.

Bolt

securing

engine.

MAIN

SPECIFICATIONS

Frame. -

Of

pressed

and

spot-welded

steel

sheet,

with

stream

-

lined

monocoque

-

type

structure.

Suspension.

Both

front

and

rea r

wheels:

coil

spring

and

hydraulic shock

absorber

.

Engine. -Two -

stroke,

flat

cast

iron

cylinder

and

cast

aluminium

alloy

cylinder

head.

Cooling

effected

by

cen-

rifugal

fan

which

is

embodied

in

the

flywheel

of

the

magneto.

Displacemen

121.17

cc.

(7.39

cu .in )

Bore

55

mm.

(2.16

in.)

Stroke

51

mm.

(2.01

in.)

Effective

power

at

4500

rpm

4.8

HP

Compression

ratio

7,2

Transmission. -Directly

from

engine

to

rear

wheel

through

clutch,

cushion

drive

and

gear

box.

Starting. -

By

means

of

kickstarter,

right

hand

side

of

scooter.

Gear

box.

- 4 -

speed

drive

with

mesh

gears

in oil

bath.

I s

two

-

cable

control

is

coupled

with

that

of

the

clutch,

Fill· 5 • IgnltJon

di-vnm

1. H.

T.

coil. in

flywheel

magneto

•

2.

Rotor

cam

3.

Breaker

-

4.

Condenser

.

5.

Sparkpulg

.

6.

Engine

cut-

out

on

switch.

to

1

to

1

to

1

to

1

layshaft.

3

on

left

hand

side

of

handlebars.

Engine

to

wheel

transmission

ratios:

First

14.74

Second

9.80

Third

7.06

Fourth

5.31

Clutch.

-

Wet

type;

multiplate,

on

the

Ignition.

-

By

flywheel

magneto.

118

miles

per

gal.

49.7

m.p.h.

45.7

in.

26.4

in.

65

in.

40

in.

8.9

in.

65

in.

160

Ibs.

Fuel

consumption:

(Gasoline -oil

mixture)

Max.

speed

Wheel

base

.

Max.

width

on

handlebars

Max.

length

of

the

scooter

Mu.

height

Min.

height

of

floorboard

Turning circle

Weight

(unladen)

:

-4-

F

,\

I

r

Lubrication. -

By

the

oil in

fuel

mixture

for

piston,

cylinder,

wrist

pin,

can.

rod,

crankshaft,

main

bea-

ring

flywheel

side.

The

clutch,

the

main

bearing

clutch

-

side

and

gear

box

operate

in oil

bath.

Carburettor.

-

With

float

-

chamber

(see

fig.

11).

Air

goes

to

the

car-

burettor

through

a

large

silencing

chamber

with

filter

(air

cleaner).

Model

.af

carburet

or:

Dell'Orto

SHB

16/16

-

Venturi

16

mm.

(0."

630)

-

Main

jet

74/100

(0."0291

)

Idler jet

42/100

<0".0163)

-

Air

vent

for

main

jet

140/100

(0."

0550)

-

Mixer

175/100

(0."069)

-

Air

vent

to

idler

jet

130/100

(0."051)

Starter

jet

50/100

(0."0197).

Feeding.

-Fuel

feed

to

the

ca

rbu-

rettor

is

provided

for

by

gravity

(see

fig.

11)

with

gasoline-oil

mixture.

~

Fuel·~nk.

Total

capaciy:

1.5

gals.;

Reserve:

1/4

gal.;

Three

-

way

cock:

"open"

-«

closed"

-«

reserve

".

Muffier. -

Expansion

and

absorption

combined

type.

H

..

ndleb

..

rs. -

Pressure

die

cast

in

light

alloy

and

designed

so

as

to

house

both

headlamp

and

speedometer.

All

the

control

cables

and

electrical

wires

to

this

group

are

con-

cealed

therein.

(See

fig.

3).

Steering

column.

-

The

steering

column

bears

the

hand-

lebars,

clamped

on

its

top

end,

and

the

front

wheel

swinging

hub,

pivoted

at

its

bottom

end

through

a

stub

axle.

Lighting

and

horn.

-

By

flywheel

magneto,

feeding

both

head

lamp

(two

-

beam),

tail

lamp,

horn

and

stop

light

(see

fig.

8).

Brakes. -

Expanding

type

.

Front

brake:

control

lever

on

right

hand

side

of

handle-

bars.

Rear

brake:

control

pedal

on

right

hand

side

of

floor-

board.

The

rear

brake

jaws

are

hinged

on

independent

pivots.

Wheels.

-

Of

pressed

steel

sheet,

intechangeable

and

easily

removable,

since

they

are

assembled

in

an

auto-

mobile

-like

system.

Tires:

dia.

3.50

x

lOin.

Steering

Lock. - A

suitable

security

lock is

arranged

on

the

frame,

near

the

handlebars.

Turn

the

handlebars

to

the

left,

then

rotate

the

key

and

push

inwards,

so

that

it

thrusts

the

sliding

bar

against

the

steering

column.

To

ease

the

insertion

of

the

sliding

bar

into

the

hole

of

the

steering

column,

slightly

turn

the

fig.

6 .

s.rtion

of

engine

1. Air

cleaner

and

carburettor

-

2.

Piston

.

J.

Crankshaft

-

~.

Clueth

S.

Mainshaft

.

6.

Gear

shifter

.

7.

Flywheel

magneto

a.

Kickstarter

9.

Crankcase

half,

clutch

side,

with

swinging

arm.

handlebars

from

the

limit

stop

clockwise.

When

the

hand-

lebars

are

locked

the

key

will

now

spring

back

to

its

original

position

and

can

then

be

withdrawn.

To

release

the

handlebars,

insert

the

key

in

the

lock,

turn

fig.

7 -

S-.:urity

lod,

1.

Normal

position.

2.

Closed

Not.

.The

arrows

indicate

the

operation

to

be

carried

out

for locking

(

J)

and

for

unlocking

(2).

-5-

_.

__

..

_

r-"

.•

0.1

__

""

~

........

,

'-VIII

lllC::

IICIIUICUd(~

in

he normal

position.

The

key

can

be

extracted

from

the lock

even

if

the

handlebars

are

free.

Do

not

lubricate

he

steering

lock.

Central

Stand.

- A

two

-

legged

stand

is

arranged

un-

der

the

floorboard.

A

strong

return

spring

holds

it

in

contact

with

the

floorboard

and

keeps

it

from

vibrating

while

the

scooter

is

being

ridden.

Tool Kit. - 1

box

wrench

(11

-17

-

21

mm.);

2

single

open

-

ended

wrench

(/

-8

mm.);

1

screw

-

driver.

These

hand

tools

are

contained

in aroll

which

is

placed

in

the

tool

box.

Speedometer.

-

The

speedometer

has

its

housing

in

the

middle

of

the

handlebars

and

adds

to

the

perfor-

mance

and

appearance

of

the

scooter.

Accessories

(See

specific

Table

of«

Parts

List

»).

-

On

re-

quest

the

Sears

scooter

can

be

equipped

with

the

spare

wheel

and

bracket,

and

rear

pillion

seat.

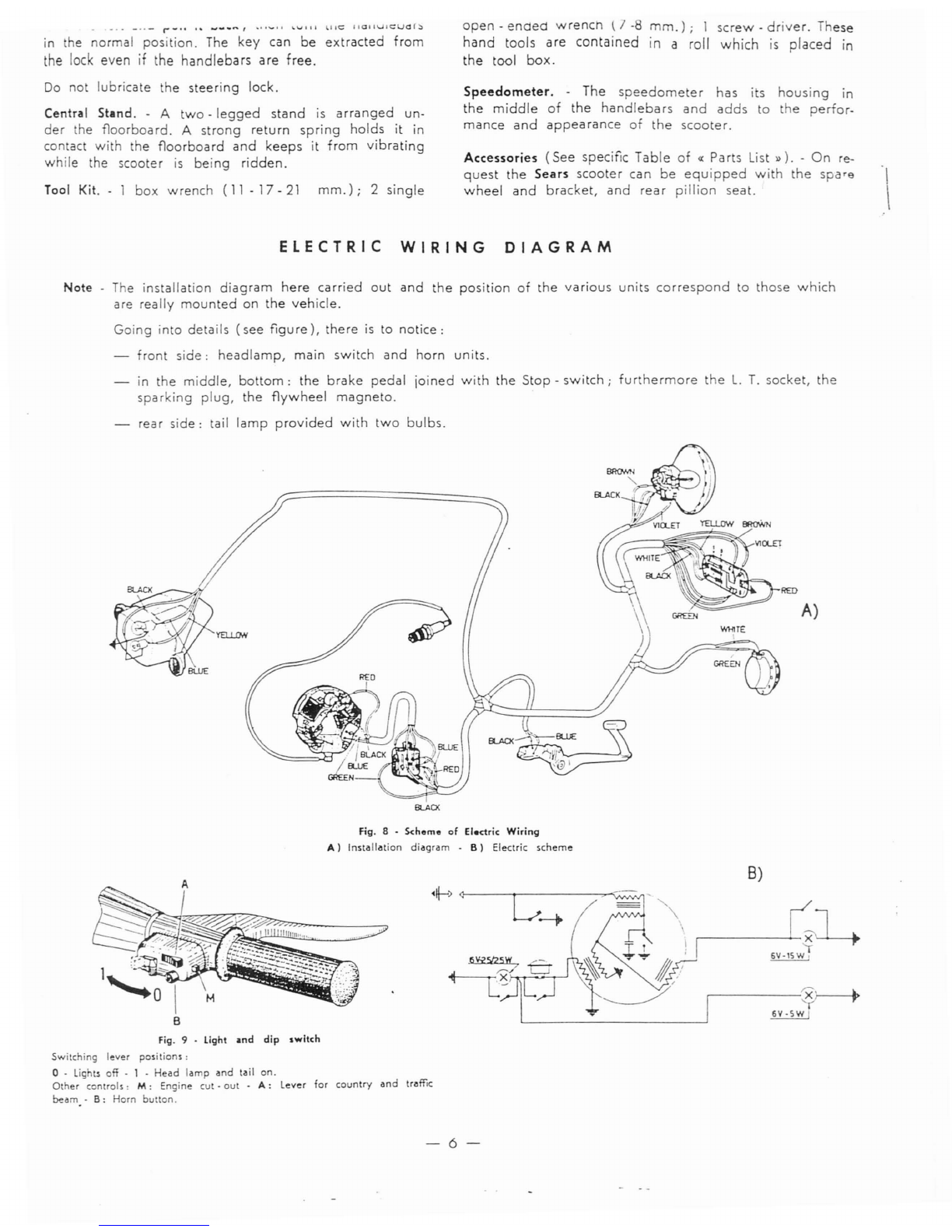

ELECTRIC

WIRING

DIAGRAM

Note -The

installation

diagram

here

carried

out

and

the

position

of

the

various

units

correspond

to

those

which

are

really

mounted

on

the

vehicle.

Going

into

details

(see

figure),

there

is

to

notice:

front

side:

headlamp,

main

switch

and

horn

units.

in

the

middle,

bottom:

the

brake

pedal

joined

with

the

Stop

-

switch;

fur

hermore

the

L.

T.

socket,

the

sparking

plug,

the

flywheel

magneto.

rear

side:

tail

lamp

provided

with

two

bulbs.

A)

8LACX

Fig. 8 • S<:heme

of

Electric

Wiring

A)

Installation

diagram

.

B)

Electric

scheme

B)

Fig. 9 .

light

.nd

dip

switch

Switching

lever

positions:

o -

lights

off • 1 .

Head

lamp

and

tail

on.

Other

controls:

HI:

Engine

cut·

out

-

A:

Lever

for

country

and

traffic

beam.

-

B:

Horn

button.

-6-

OPERATION

Fuel

supply

..

Fuel

mixture,

both

during

and

after

run-

ning

in, should be

composed

of

regular

gasoline and

pure

mineral

oil

SAE

30 at

2%,

i.

e.:

-

~,~

pint

of

oil to 1

'l~

gal-

lons

of

gasoline.

When using pre -

diluted

or

additive

oils,

or

oils

for

out-

board

motors,

mix

'l~

pint

of

oil

per

gal.

Keep the

breather

of

filling

cap clean.

Oil

level.

-Remove the level

screw, on crankcase,

marked

«

OLIO»

as

indicated

on Fig.

20, to check

oil

level

in

gear

box

before

sta

rting

the en-

gine.

The

scooter

standing

upright,

oil should just be

about

to

flow

out;

otherwise

top

up

with

ALLSTATE

REGULAR

S.

A.

E.

30.

Fig.

10

• F

..

ding

circuit

1. Fuel

COC'(

lever:

A)

Reserve.

B)

Open.

C)

Closed

-

2.

Throllie

slide

set

screw·

J.

Idling

adjuster

-

4.

Idling

iet

-

5.

Starter

valve

-

6.

Air

vent

for

idling

ie -7. Air

cleaner

-

8.

Air

vent

for

main

jet -

9.

Starter

jel

-

10.

Float -

11.

Mai:1

jet -

12.

Throllie

slide

-

13.

Inlet

port

-

14.

Transfer

ports

.

15.

Exhaust

duct.

Fig.

11

-

Oper.tiona

to corry

out

for

rtarting

the

engine

·1

~

.\

A:

open

the

fuel

cock.

B:

seleCI •

neutral.

-

c:

operate

starter.

push

pull

rod

(with

cold

engine)

0:

throllie

centrol

grip

in

idling

pNition

-

E:

depr~..

the

kickst.rter

.nd

turn

grip

cD.

by

short

strokes.

-7-

Running.

in. -

Important

rules

to

be

followed

while

run-

ning

-

in

(600

miles):

Do

not

insist

by

fully

opening

out

the

throttle.

Change

oil

in

the

gear

box

and

check

that

nuts

and

bolts

are

not

slack

after

the

first

600

miles.

Starting

..

Open

the

fuel

valve,

put

the

gear

box

in

neutral

and

slightly

open

the

throttle

in

slow

running

position,

kick

the

starting

lever.

With cold

engine,

operate

starter

push

pull

rod.

Push

said

rod

back

as

soon

as

the

engine

fires.

See

Fig.

10;

note

the

three

positions

of

the

fuel

valve:

open,

closed,

reserve.

Clution.

-Do

not

open

throttle

wide

when

releasing

clutch.

In

case

of

starting

troubles,

due

to

engine

being

flooded

(unvaporized

fuel

mixture

has

reached

the

cylinder

and

combustion

becomes

therefore

very

difficult),

proceed

according

to

either

one

of

the

following

methods:

a)

Push -

start

the

scooter:

shift

into

second

gear,

de-

clutch

and

push

the

machine;

quickly

release

the

clutch

lever

and

pull

it

back

as

soon

as

the

engine

starts.

b)

Close

the

fuel

cock,

remove

the

spark

plug

and

rotate

the

engine

by

means

of

the

kickstarter.

Wipe

the

plug

dry

and

replace.

Open

the

fuel

cock

and

kick

the

starting

lever.

For

access

to

the

engine

and

remove

the

spuk.

plug,

rotate

the

lever

fig. 3 - n.

14,

then

take

off

the

engine

flap.

Extract

the

spark.

plug,

using

the

box

wrench.

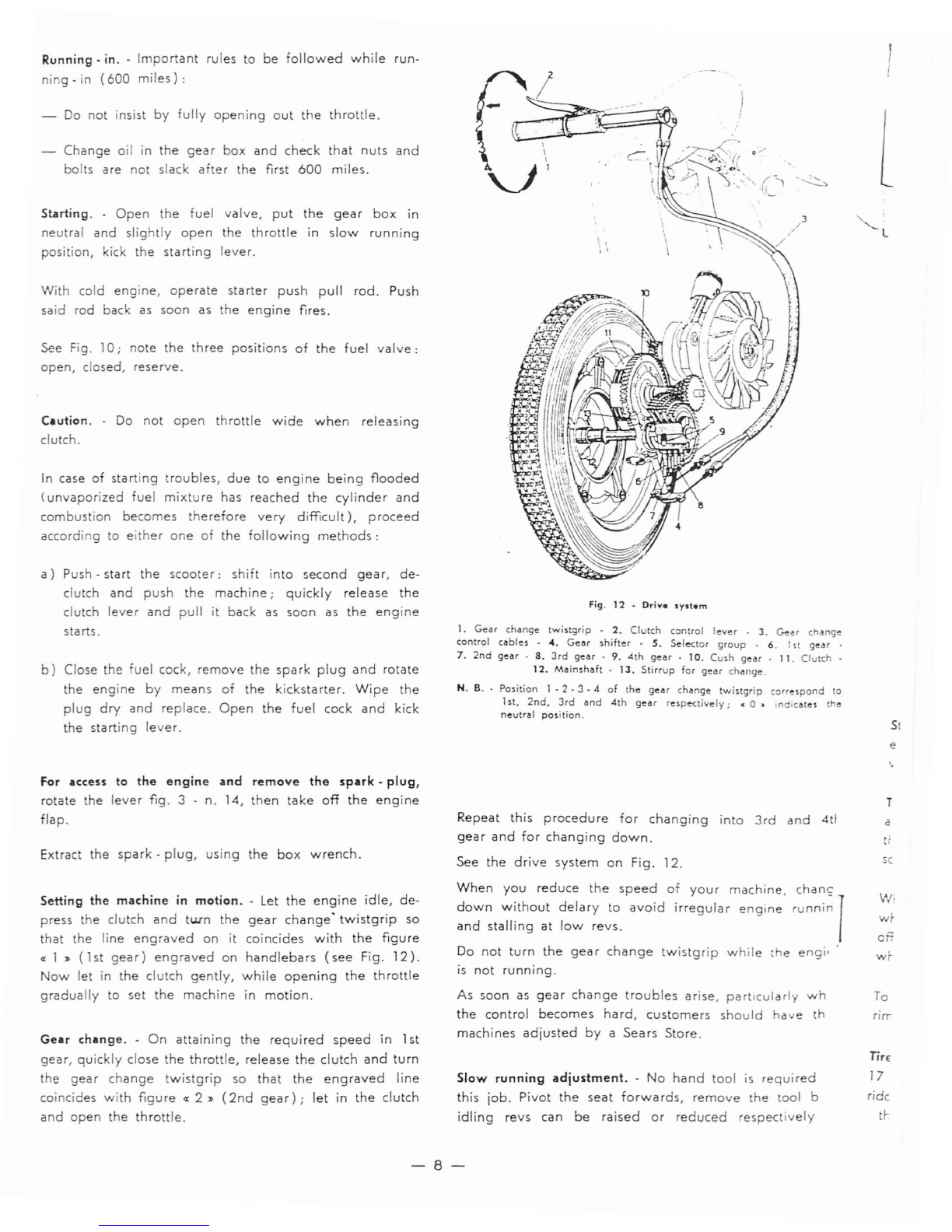

Fig.

12

-

Drive

system

I.

Gear

change

twistgrip

.

2.

Clutch

control

lever

-

3.

GeO'

change

control

cables

-

...

Gear

shifter

-

S.

Sele<tor

group

-

6.

I H

gear

7.

2nd

gear

-

8.

3rd

gear·

9.

4th

gear

-

10.

Cush

gear.

11.

Clutch

_

12.

Mainshaft

-

13.

Stirrup

for

gear

change.

N. B. -

Position

I - 2 - 3 -

<I

of

the

gear

change

twistgrip

correspond

to

1

st,

2nd.

3rd

and

4th

gear

respe<tively;

<0>

Indicates

the

neutrlll position.

Repeat

this

procedure

for

changing

into

3rd

and

4tl

gear

and

for

changing

down.

See

the

drive

system

on

Fig.

12.

l

S(

e

T

a

sc

Slow

running

adjustment.

-

No

hand

tool

is

requi

red

this

job.

Pivot

the

seat

forwards,

remove

the

tool b

idling

revs

can

be

raised

or

reduced

respec

ively

Do

not

turn

the

gear

change

twistgrip

while

the

engi'

is

not

running.

As

soon

as

gear

change

troubles

arise,

particularly

wh

the

control

becomes

hard,

customers

should

have

th

machines

adjusted

by

a

Sears

Store.

Setting

the

machine

in

motion

..

Let

the

engine

idle,

de-

press

the

clutch

and

tum

the

gear

change'

twistgrip

so

that

the

line

engraved

on

it

coincides

with

the

figure

"1,,

(1st

gear)

engraved

on

handlebars

(see

Fig.

12).

Now

let

in

the

clutch

gently,

while

opening

the

throttle

gradually

to

set

the

machine

in

motion.

Gear

change.

-

On

attaining

the

required

speed

in 1st

gear,

quickly

close

the

throttle,

release

the

clutch

and

turn

the

gear

change

twistgrip

so

that

the

engraved

line

coincides

with

figure"

2"

(2nd

gear);

let

in

the

clutch

and

open

the

throttle.

When

you

reduce

the

speed

of

your

machine,

down

without

delary

to

avoid

irregular

engine

and

stalling

at

low

revs.

chane

,uooi~

)

W,

wI-

on

wI-

To

rirr

Tire

17

ridc

tl-

-8-

simply

tightening

or

slackening

the

adjuster

screw

..

A

)}

fig. 13

(i.

e.,

n. 2, Fig.

10).

This

screw

controls

the

throttle

slide

valve.

On

the

carburettor

body

is

a

spring

-

loaded

screw

("

C

})

fig. 13,

i.

e.,

n. 3fig.

10)

that

controls

the

flow

of

car-

burettor

air

through

the

duct

from

the

idling

jet,

and

consequently

the

idling

revs.

We

recommend

that

custo-

mers

refrain

from

re -

setting

this

screw

(and

the

set

screw"

B

",

fig.

13,

provided

for

adjusting

the

throttle

cable

play)

unless

absolutely

necessary

or

during

di-

smantling

and

re -

asembling

operations

that

should,

any-

way,

be

entrusted

to a

Sea

rs

Store.

- 9 -

.\

Ii

(

front)

wh

••

1

Fig.

'4

.

Dismantling

th.

I

ii'

/

I~

;./

----_._------

o

o

~.

When

aflat tire

is

to

be

replaced,

unscrew

the

five

nuts

which

secure

the

wheel

to

its

flange,

pull

wheel

sideways

off

the

studs

(see

Fig. 14 L

repai

rit

or

replace

with

spa

re

wheel.

Tire pressure

should

be

22,5

7

23,5

psi

on

rear

wheel,

17

.7

18 psi

on

front

wheel.

If

the

scooter

is

ordinarily

ridden

by

both

driver

and

passenger,

the

pressure

of

the

rear

tire

should

be

33

7

35,5

psi.

Fig.

13

-

Acce.s

to

cilrburettor

~nd

ilir

d

••

ner

lillY_

To

remove

he

tube,

first

deflate,

then

separate

the

wheel

rims

by

unscrewing

the

nuts

which

join

them

(see

Fig.

15).

Tires. -The

wheels

are

interchangeable,

i.

e.,

they

can

be

assembled

either

in

front

or

rear,

provided

of

course

that

hey

are

inflated

to

pressures

respectively

hereunder

pre-

scribed.

Stopping

the

engine.

Select

in "

neutral

)},

then

push

the

earthing

button.

This will

leave

the

cylinder

full

of

fuel

vapours,

and

the

next

start

will

be

much

easier.

Fig.

15

.

Removing

the

inner

tube

Brake

adjustment.

-Brakes

are

properly

adjusted

if:

the

wheel

rotates

freely

when

respectively

control le-

ver

or

pedal

are

in

resting

position;

the

braking

action starts as

soon

as

respective

con-

trols

are

operated.

Fill.

16

-Brolce

adjustment

These conditions

are

achieved

adjusting

the

cables

by

means

of

screws

indicated

with

an

arrow

in

Fig. 16.

Adjustment

of

clutch

control.

-

Adjustment

of

clutch con-

trols

is

achieved

operating

on

adjusting

nut

(a),

screwed

to

the

engine

sti

rrup

(see

Fig.

17).

The

cable

is

to

be

tensioned

or

loosened,

as

the

case

may

be

so

that

c'ontrol

lever,

on

handlebars,

makes

a

stroke

of 2mm.

(0.078")

before

lever

(b),

on

engine

starts

moving.

Wrong

play

in

the

control

may

cause

the

clutch

plates

burning

out

even

in

normal

running

conditions.

Fill·

17

•

Adjustment

of

clutch

contTol

a

MAINTENANCE

Cleaning

the

scooter.

-

Brushing

kerosene

and

wiping

dry

clean rags

is

advisable

for

external

cleaning

of

engine.

All

painted

surfaces

should

be

washed

with

water,

rinsed

by

means

of

a

sponge

and

wiped

dry

with

a

chamois.

Do

not

use

kerosene

on

such

surfaces,

since

it

damages

paint

and

turns

it

dull.

If

necessary,

blow

the

head

lamp

reflector

clean

or

wipe

off

dust

with a

very

soft

feather.

Do

not

use

acloth

and

keep

your

fingers

off reflector

surfaces.

Before

setting

the

mllchine

in

motion,

(if

it

has

been

delivered

directly

to

the

customer

by

the

Factory)

check

oil level in

gear

box

by

unscrewing

the

level

screw

mar-

ked

«

OLIO,.

from

the

crankcase

(see

Fig.

20).

The

scoo-

ter

standing

upright,

oil'

should

just

be

about

to

flow

out.

After

the

first

600

miles.

-

Replace

oil in

the

gear

box

by

the

procedure

as

explained

in

the

lubrication

chart,

page

12.

The

crankcase

can

be

drained

through

the

hole

indicated

in Fig.

20.

\.

I

-10-

Every

2.500

miles:

--

I

1)

Check

oil

level

in

the

gear

box

(see

on

pages

10-

12)

.

2)

-

Grease

all joints

on

the

brake

controls

and

the

gear

shifter.

3)

.

Clean

the

sparkplug

electrodes

with

very

fine

emery

cloth

or

suitable

files,

and

adjust

the

gap

to

0.6

mm.

(0.023"

).

Inspect

the

insulation

material

of

sparkplug;

re-

place

the

latter

if

the

porcelain

is

cracked.

Wash

with

neat

gasoline.

Use

the

sparkplug

type

Marelli

CW

240

N;

Bosch

W

240

T

1;

Champion

L

86;

AC

42

F.

Important:

using

the

proper

type

of

sparkplug

will

eliminate

many

engine

troubles.

4)

-Pivot

the

seat

forwards,

remove

the

tool

box

and

the

choke

control

cable,

then

dismount

the

fuel

tap

rod

(fig.

13, D -

E);

next

unscrew

the

wing

-

nuts

«F

J)

(fig.

13)

and

remove

air

cleaner.

Extract

the

filter,

wash

in

gasoline

and

if

possible

air

blast

dry.

5)

-

Remove

the

rubber

plug

of

front

suspension

and

refill

·with

grease

the

concerning

housing.

6)

-

Clean

the

lubricators

on

front

wheel

hub

and

refill

them

by

means

of

a

grease

gun.

N.

B.

-All

operations

indicated

hereunder

should

be

carried

out

by

aSEARS

store.

7)

-

Lubricate

the

speedometer

drive

pinion

and

flex

drive.

8)

-

Decarbonize

the

engine

as

explained

hereunder.

Remove

the

carburettor

(screw

n.

5,

fig.

4),

the

rear

wheel,

the

muffler,

release

the

rear

damper

unit

(n.

6,

fig.

4).

then

rotate

the

engine

downwards:

remove

the

cooling

hood,

the

cylinder

head

and

the

cylinder

(see

Fig.

18).

Decarbonize

the

piston

crown

and

the

cylinder

ports

from

all

carbon

de-

posits.

Decarbonize

the

inner

side

of

the

cylinder

head.

Carefully

clear

the

cylinder

carbon

deposits.

Heat

the

exhaust

pipe

of

the

muffler

and

clean

it

either

by

scraping

internally

with

a

hooked

wire

or

blowing

air

through

from

the

other

orifice;

in

both

cases

the

muffler

should

be

held

so

that

the

exhaust

pipe

is

turned

downwards.

Fig.

19

•

Breaker

points

A)

Max.

gap

of

breaker

points

cA.

should

be

0.011".0.019"

Every

5.000

miles:

3)

Change

the

oil in

the

gear

box,

as

stated

on

page

12.

4)

-

Grease

the

felt

wich

lubricates

the

cam

of

flywheel

magneto

(by

a

Sea

rs

Store).

In

case

of

shock

-

absorber

troubles,

overhaul

or

simply

clean

the

assembly

and

change

oil.

These

operations

should

be

carried

out

by

your

SEARS

store.

Fig. 18 •

Cleaning

the

cylinder

heed,

cylinder

and

piston

Clean

the

breaker

points.

In

order

to

avoid

ignition

troubles

or

abnormal

running,

have

the

breaker

points

adjusted

in a

Sears

store;

the

gap

should

not

be

more

than

0.011"-0.019"

(see

Fig.

19)

and

the

points

should

begin

to

open

when

the

current

in

the

primary

ignition

circuit

has

attained

its

peak

value.

Grease

the

control

cables.

1)

-

2)

-

I

11....

Disuse:

1)

In

such

a

case,

cleaning

the

scooter

throughly

is

advisable.

2)

-With

engine

not

running

remove

the

spark

-

plug,

next

introduce

10

-"-

15 cc.

of

Allstate

-

Regulu

Oil

SAE

30

or

Allstate

Outboard

Motor

Oil

through

the

threaded

hole

of

the

latter.

Then

operate

the

kickstarter

three

or

four

times.

3)

-Rest

the

floorboard

on

two

wooden

blocks

in

order

to

take

the

weight

off

the

tyres.

4)

-Drain all

fuel

from

both

tank

and

carburettor.

5)

-

Grease

all

unpainted

metal

parts.

-

11-

LUBRICATION

CHART

PAlT

TO

s.e

OPERATION

T I

III

E

TYPf

OF

LUBlICANT

LUBllCATtD

Engine Mix

gasoline

with

the

following

amount

At

each

refilling

of

the

fuel

Non

-

detergent

SAE

30

of

lubricating

oil:

tank.

MOTOR

Oil

- %

pint

of

oil to 1

y~

gall.

of

gasoline.

N.

B.

-

With

pre-diluted

or

additive

oils,

mix

%

pint

of

oil to

each

gallon

of

gasoline.

Gear

Box

Warm

up

the

engine

and

drain

off

oil.

After

the

fi

rst

600

miles

Allstate

Regular

SAE

30.

Pour

some

fresh

oil in

and

run

the

en-

and

every

5000

miles.

gine

for

a

few

seconds.

Flush

and

refill

with

new

oil

(about

8.5

oz.).

Refill

with

new

oil

to

oil

level

hole.

Every

5000

miles.

Front

wheel

hub

Speedometer

lubricate

with

grease

gun.

Every

2500

miles.

High

Pressure

Chassis.

flex

drive

and

pinion

Joints

on

brake

Grease.

Every

2500

miles.

Allstate

all -

purpose

controls

Gear

lubricator

~AE

140.

Ratchet

qua-

Grease.

Every

2500

miles.

Allstate

all -

purpose

drant

of

gear

Gear

lubricator

SAE

140.

shifter

Control

cables

Clean

and

lubricate.

Every

5000

miles.

Allstate

all -

purpose

Gear

lubricator

SAE

140.

Felt

of

flywheel

Small

spot

of

grease

on

the

felt.

Every

5000

miles.

Allstate

Bearing

Grease.

cam

Shock-a

bsorbe

rs

Change

oil.

Only

when

the

shock

-

ab-

Allstate

Shock

Absorber

sorber

is

out

of

order.

Fluid.

ENGINE

LUBRICATED

BY

MIXTURE

ALLSTATE

REGULAR

SAE

30

/.

OR

ALLSTATE

OUTBOARP

M;;OR

~i

~~

Fig.

20

-

lubrication

scheme

1.

Filling

hole

-

2.

Draining

hole

-

12-

HIGH

PRESSURE

CHASSIS

GREASE

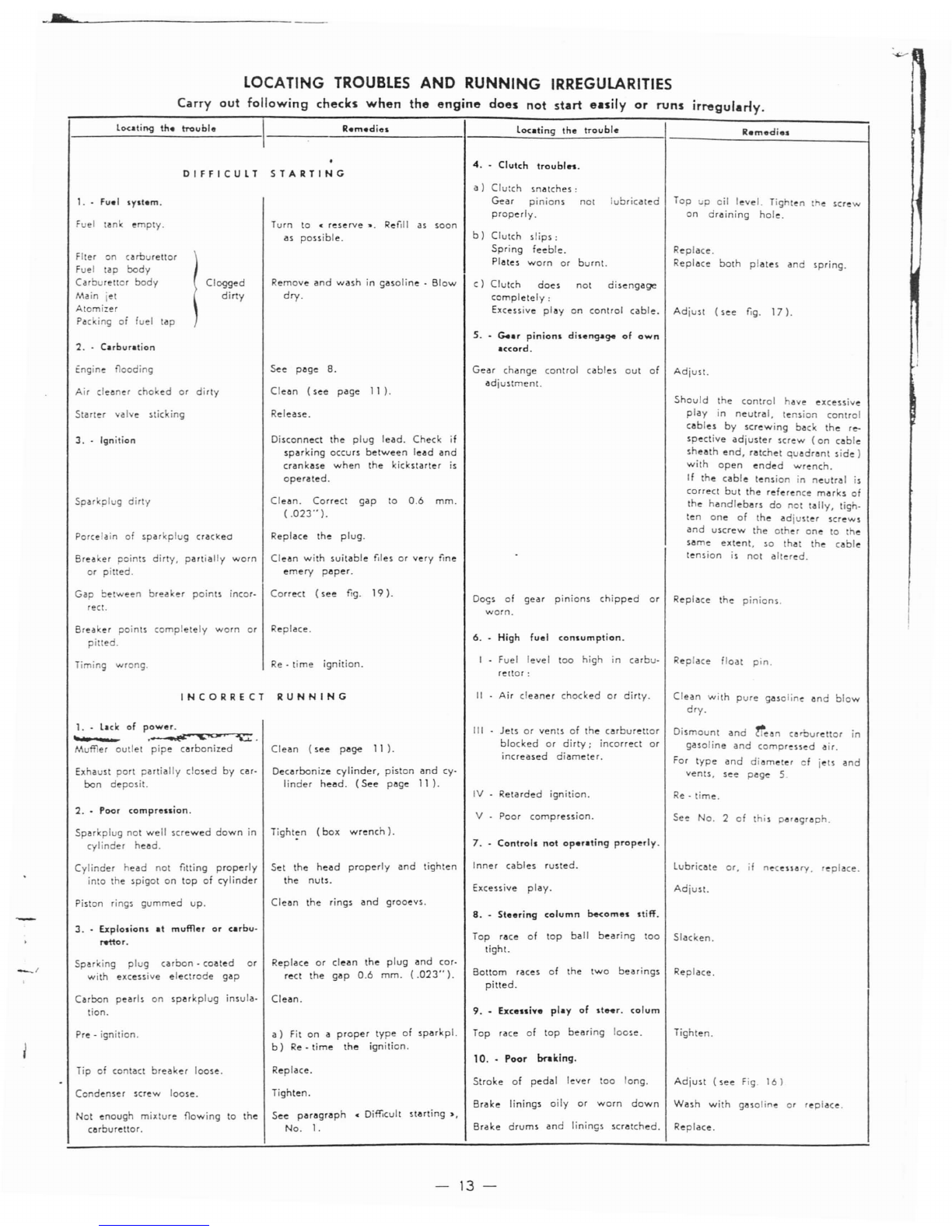

LOCATING

TROUBLES

AND

RUNNING IRREGULARITIES

Carry

out

following

checks

when

the

engine

does

not

start

easily

or

runs

irregulany.

louting

the

lToubl.

I

Remedies

louting

the

troubl.

Remedie.

1------.:..------

------------I-----.:..::.=..:~~....:.--.:.~---I-----------_l

4

..

Clutch

troubln.

DIFFICULT

STARTING

c)

Clutch

does

not

disengage

completely:

Excessive

play

on

control

cable.

Adjust

(see

fig.

17).

Fuel

tanl<

empty.

Flter

on

c.roureltor

Fuel

tap

body

Carbureltor

body

Main

jet

Atomizer

Pac

ing

of

fuel

tap

2.

-

Cubuntion

Clogged

dirty

Turn

to

c

reserve

-,

Ref.1I

as

soon

as

possible.

Remove

and

wash

in

gasoline·

Blow

dry.

a)

Clutch

snatches:

Gear

pinions

not

lubricated

properly.

b)

Clutch

slips:

Spring

feeble.

Plates

worn

or

burnt.

s.

-

c..r

pinions

disenCJ-I94

of

own

accord.

Replace.

Replace

both

plates

and

spring.

tngine

flooding

Air

c1e.ner

choked

or

dirty

Starter

valve

sticking

3.

-

Ignition

Spar

plug

dirty

Porcelain

of

sparkplug

crackee

Bre.ker

points

dirty.

partially

worn

or

pilted.

See

page

B.

Clean

(see

page

II).

Release.

Disconnect

the

plug

lead.

Check

if

sparking

occurs

between

lead

and

crankase

when

the

kickstarter

is

operated.

Clean.

Correct

gap

to

0.6

mm.

(.023·'

).

Replace

the

plug.

Clean

with

suitable

f,les

or

very

fine

emery

paper.

Gear

change

control

cables

out

of

adjustment.

Adjust.

Should

the

control

have

excessive

play

in

neutral,

tension

control

cables

by

screwing

back

the

re-

spective

adjuster

screw

(on

coble

sheath

end,

ratchet

quadrant

side)

with

open

ended

wrench.

If

the

cable

tension

in

neutral

is

correct

but

the

reference

marks

of

the

handlebars

do

not

tally,

tigh-

ten

one

of

the

adjuster

screws

and

uscrew

the

othe

r

one

to

the

same

extent,

so

that

the

cable

tension

is

not

altered.

Gap

between

breaker

points

incor-

Correct

(see

fig.

19).

reet.

Breaker

points

completely

worn

or

Replace.

pilted.

Do<;s

of

gear

pinions

chipped

or

Replace

the

pinions.

worn.

6.

High

fuel

consumption_

Timing

wrong.

Re·

time

ignition.

I

Fuel

level

too

high

in

carbu-

Replace

float

pin.

rettar:

INCORRECT

1. .Lick

of

power.

t

LL

.~"''''''''''~fC)O:>r'-:I-u.:~

_

Mu

er

outlet

pipe

carbonized

Exhaust

port

partially

closed

by

car-

bon

deposit.

RUNNING

Clean

(see

page

11 ).

Decarbonize

cylinder,

piston

and

cy-

linder

head.

(See

page

11).

II

Air

cleaner

chocked

or

dirty.

III

Jets

or

vents

of

the

carburettor

blocked

or

dirty;

incorrect

or

increased

diameter.

IV

Retarded

ignition.

Clean

with

pure

gasoline

and

blow

dry.

Dismount

and

"e~n

cerburettor

in

gasoline

and

compressed

air.

For

type

and

diameter

of

jets

and

vents.

see

page

5

Re

-

time.

2

.•

Poor

comprenion.

Sparkplug

not

well

screwed

down

in

Tight:n

(box

wrench).

cylinder

head.

V

Poor

compression.

7.

Controls

not

operlting

properly.

See

No.

2

of

his

paragraph.

Cylinder

head

not

fitting

properly

into

the

spigot

on

top

of

cylinder

Piston

rings

gummed

up.

Set

the

head

properly

and

tighten

the

nuts.

Clean

the

rings

and

grooevs.

Inner

cables

rusted_

Excessive

play.

8

.•

Steering

column

b-e<omes

1tiff.

Lubricate

or,

if

ne"

..

ary.

replace.

Adjust.

3

.•

Explosions

at

muffler

or

carbu.

rettor.

Top

race

of

top

ball

bearing

lOO

Slacken.

tight.

Sparl<ing

plug

carbon

-

coated

with

excessive

electrode

gap

or

Replace

or

clean

the

plug

and

cor·

rect

the

gap

0.6

mm.

(.023··).

Bottom

races

of

the

two

bearings

pitted.

Replace.

Carbon

pearls

on

sparkplug

insula-

Clean.

tion.

9

.•

Excessive

plly

of

steer.

cofum

Pre·

ignition.

Tip

of

contact

breaker

loose.

Condenser

screw

loose_

a)

Fit

on

a

proper

type

of

sparkp!.

Top

race

of

top

bearing

loose.

b)

Re·

time

the

ignition.

10

.•

Poor

braking.

Replace.

Stroke

of

pedal

lever

too

long.

Tighten.

Tighten.

Adjust

(see

Fig.

16)

Not

enough

mixture

flowing

to

the

carburettor.

See

paragraph

cDifficult

starting"

No.1.

Brake

linings

oily

or

worn

down

Wash

with

gasoline

or

replace.

Brake

drums

and

linings

scratched.

Replace.

-

13-

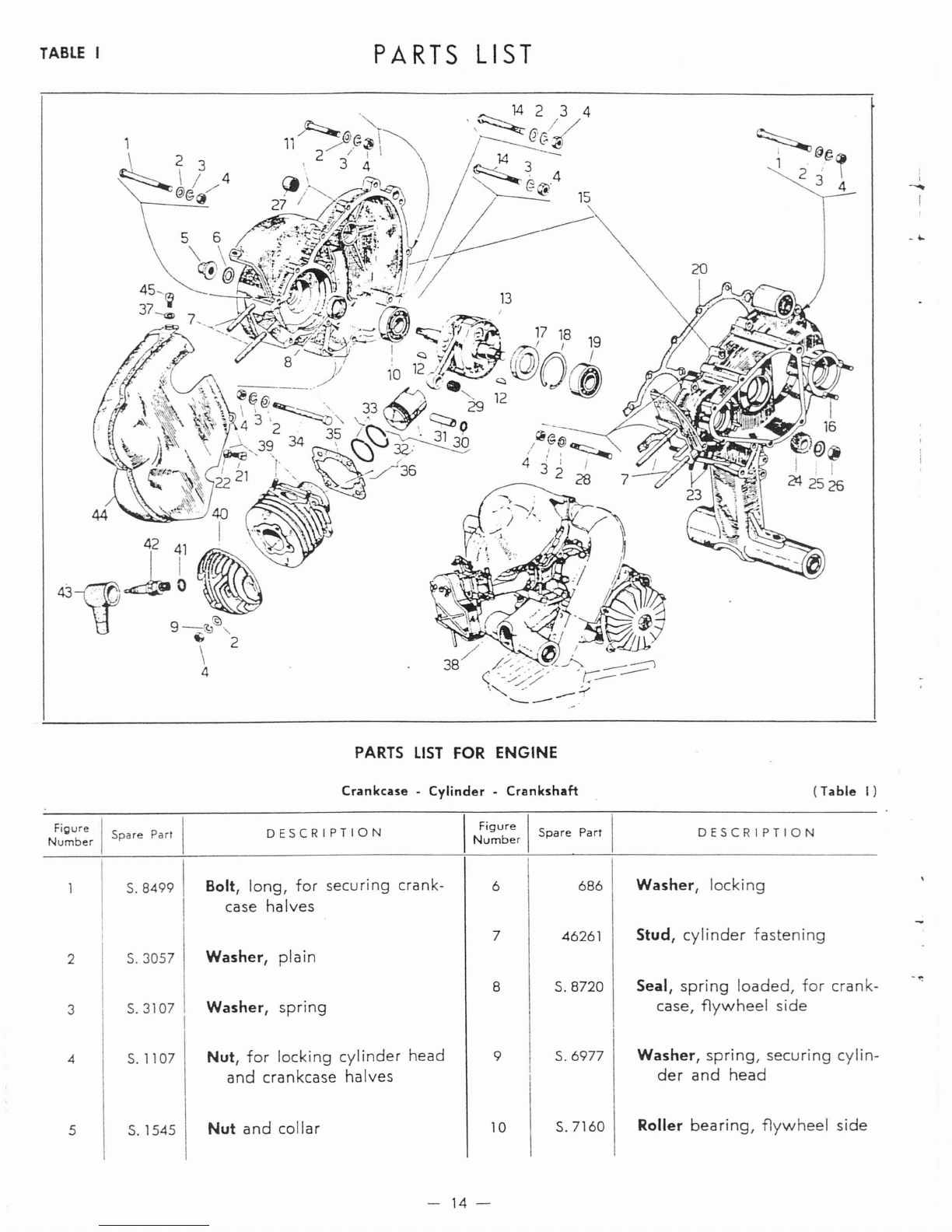

TABLE

I

PARTS

LIST

14

2 3 4

"~

14

3

~

, 4

~

PARTS

LIST

FOR

ENGINE

Crankcase -

Cylinder

-Crankshaft

20

(Table

I)

i

-...

Figure

I I

Number

Spare

Part

S.8499 1

DESCRIPTION

Bolt,

long,

for

securing

crank-

case

halves

I

Figure

I I

Number

Spare

Part

6

686

DESCRIPTION

Washer,

locking

2

3

4

5

S.

3057

S.3107

S.1107

S.1545

Washer,

plain

Washer,

spring

Nut,

for

locking

cylinder

head

and

crankcase

halves

Nut

and

collar

7

8

9

10

46261

S.

8720

S.6977

S.7160

Stud,

cylinder

fastening

Seal,

spring

loaded,

for

crank-

case,

flywheel

side

Washer,

spring,

securing

cylin-

der

and

head

Roller

bearing,

flywheel

side

-

14-

12

267,

Key

Figu,,, I

Number

I

11

..

,,,

Parr

I

S.8420

'

DESCRIPTION

Bolt,

short,

securi

ng

Li

Gn

r,,,

"

lOA

halves

I

Figure

I

Spare

Part

I

Number

I

17

I

91356

DESCRIPTION

Piston, 1st

o/s,

wrist

pin

(with

parts

Figs.

30

-31 -

33)

.

'-

I

-<-.

'

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

111311

S.8421

110699

S.456

S.8731

S.6647

S.7125

110711

2856

110720

S.584

111666

S.1821

S.1510

S.7188

S.4515

a)

93233

S.6615

111307

111308

Crankshaft, g. a.

(with

part.

Fig.

29).

Bolt,

securing

crankcase halves

Crankcase, g. a.

(With

parts

Figs. 1 - 2 - 3 -

4 - 11 - 14 -

20

-34

T.

I;

56

T.

II;

21

T.

III;

34 -

35-

36

T.

VIII).

Stud,

securing

flange

for

jaw

Seal,

spring

loaded,

for

crank-

case,

clutch

side

Circlip

Ball bearing, clutch side

Gasket, crankcase

Screw,

securing

cooling

hood

Spacer,

securing

cooling

hood

Stud,

securing

fuel

inlet

joint

Clutch,

drive

gear

Washer,

plain

Nut,

sec.

drive

gear

Roller cage

Stud

Roller cage

Circlip,

for

locking

wrist

pin

Wrist pin,

normal

Piston,

with

standard

wrist

pin

(with

parts

Figs.

30

-

31

-

33)

.

32

32

32

33

33

33

33

33

34

35

36

37

38

39

40

41

42

43

44

45

91357

91358

91359

110651

91368

91369

91370

91371

S.8419

110710

91324

S.3056

150716

S.3918

111446

318

98753

72843

111734

2946

Piston,

2nd

o/s,

wrist

pin

(with

parts

Figs.

30

-

31

-

33)

.

Piston,

3rd

o/s,

wrist

pin

(with

parts

Figs.

30

-

31

33)

.

Piston,

4th

o/s,

wrist

pin

(with

parts

Figs.

30

-

31

33)

.

Ring,

piston,

normal

Ring,

piston,

1st .

o/s.

Ring,

piston,

2nd

o/s.

Ring,

piston,

3rd

o/s.

Ring,

piston,

4th

o/s.

Bolt,

long

Gasket,

cylinder

base

Cylinder piston g.

a.

(with

part

Fig.

32).

Washer,

securing

cooling

hood

Engine, g. a.

Stud,

securing

exhaust

pipe

Head,

cylinder

Gasket,

copper,

of

sparkplug

Sparkplug,

with

terminal

Cap,

rubber,

for

sparkplug

Hood,

cooling

Screw,

hood

fixing

a)

Con -

rods

and

roller

cages

are

subdivided

in 4

categories.

and

the

category

numbe~

is.

marked

on

every

con

-

rod

and

cage.

Assy:

con

-

rod

with

cage

of

the

same

category.

When

ordenng

roller

cages,

always

indiCaTe

the

wanted

caTegory.

-

15-

26

/

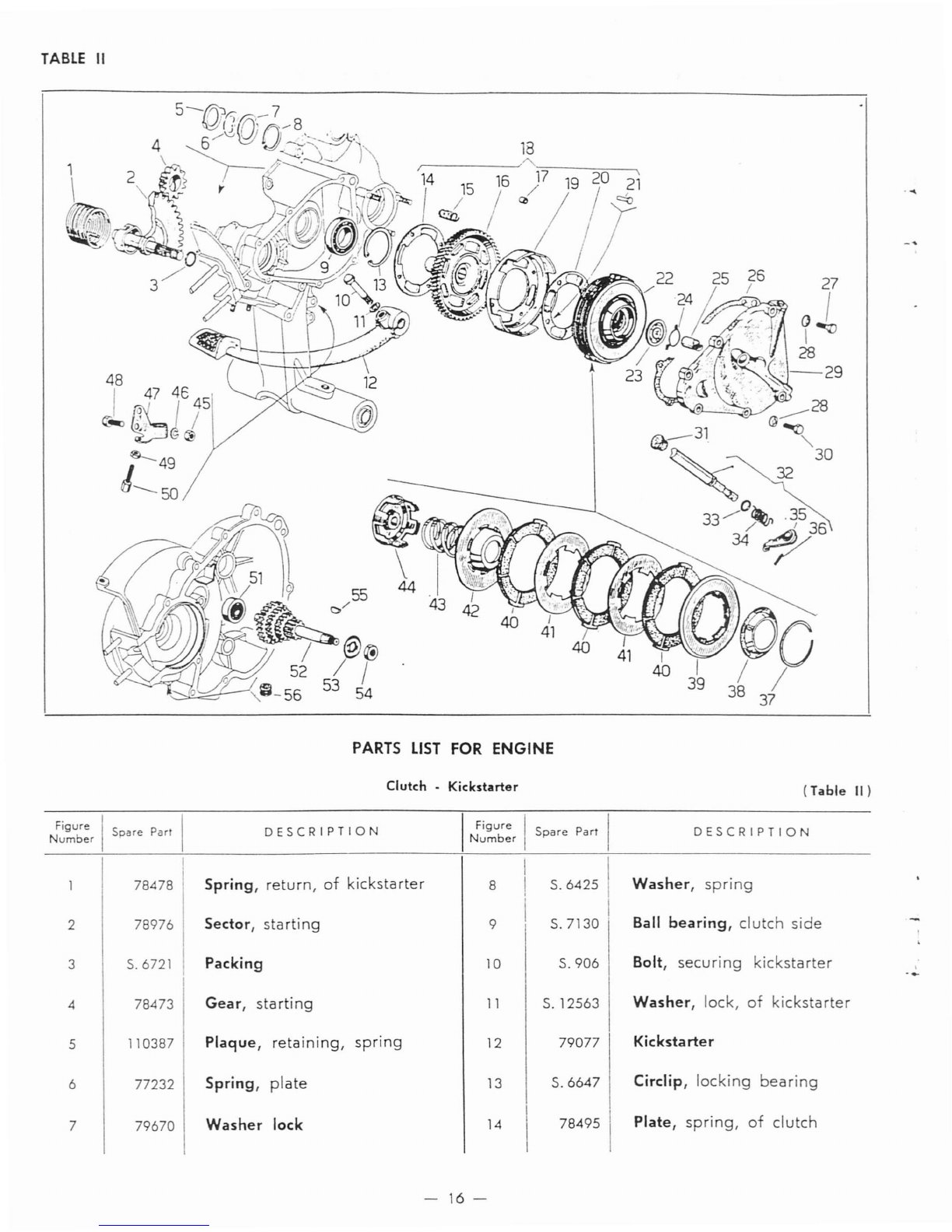

TABLE

II

48

IJ

47

46 45

c~

f!X

I /

~@~

~49

'---50

27

oI

\--V

I

28

:r

.

:-29

~

.....

PARTS

LIST

FOR

ENGINE

Clutch

-

Kickstarter

(Table

II)

~~~u~:r

I

Spare

Part

I

DESCRIPTION

I

Figure

I

Spare

ParI

I

DESCRIPTION

Number

78478 Spring,

return,

of

kickstarter

8

S.6425

1Washer,

spring

I

278976 Sector,

starting

9

S.7130

.Ball

bearing,

clutch

side

3S.6721 Packing

10

S.906

Bolt, securi

ng

kickstarter

,

-.-

478473 Gear,

starting

11

S.12563

Washer,

lock,

of

kickstarter

5110387 Plaque,

retaining,

spring

12

79077 Kickstarter

677232 Spring,

plate

13

S.6647

Circlip,

locking

bearing

779670 Washer lock

14

78495\

Plate,

spring,

of

clutch

-

16-

.......

,'

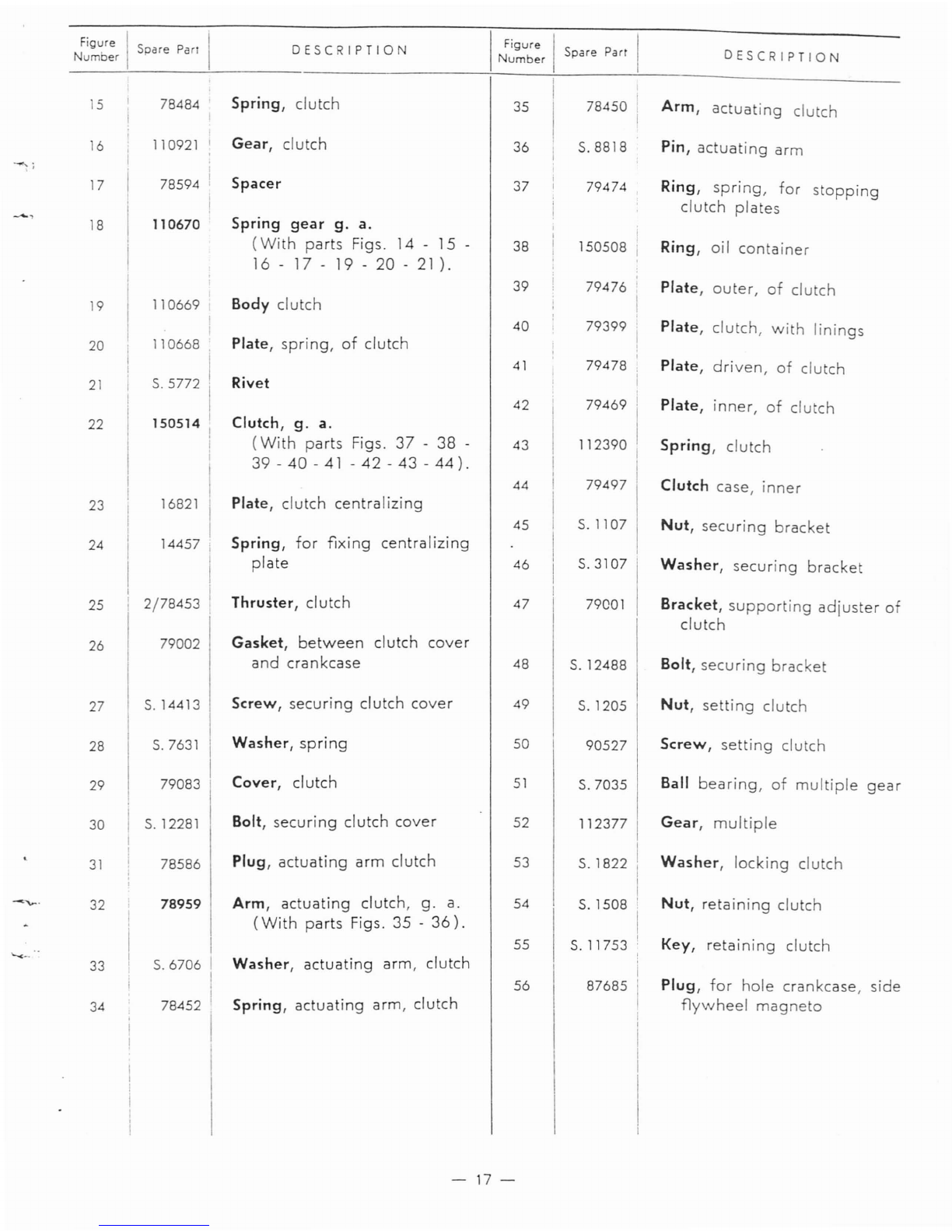

Figure

I

Nb

Spare

Part

urn

er

15

78484

16

110921 t

DESCRIPTION

Spring, clutch

Gear, clutch

I

35 I

36

Spare

Parr

78450

S.8818

DESCRIPTION

Arm,

actuating

clutch

Pin,

actuating

arm

~.

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

78594

110670

110669

110668

S.5772

150514

16821

14457

2/78453

79002

S.14413

S.7631

79083

S.12281

78586

78959

S.6706

78452

Spacer

Spring gear

g.

a.

(With

parts

Figs. 14 -15 -

16 - 17 - 19 -20 -

21

).

Body clutch

Plate,

spring,

of

clutch

Rivet

Clutch,

g.

a.

(With

parts

Figs.

37

-

38

-

39

-

40

-

41

-

42

-

43

-

44).

Plate, clutch centralizing

Spring,

for

fixing centralizing

plate

Thruster, clutch

Gasket,

between

clutch

cover

and

crankcase

Screw,

securing

clutch

cover

Washer,

spring

Cover, clutch

Bolt,

securing

clutch

cover

Plug,

actuating

arm

clutch

Arm,

actuating

clutch, g. a.

(With

parts

Figs. 35 -

36).

Washer,

actuating

arm,

clutch

Spring,

actuating

arm, clutch

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

79474

150508

79476

79399

79478

79469

112390

79497

S.1107

S.3107

79001

S.12488

S.1205

90527

S.

7035

112377

S.1822

S.1508

S.11753

87685

Ring,

spring,

for

stopping

clutch

plates

Ring, oil

container

Plate,

outer,

of

clutch

Plate, clutch,

with

linings

Plate,

driven,

of

clutch

Plate,

inner,

of

clutch

Spring, clutch

Clutch

case,

inner

Nut,

securing

bracket

Washer,

securing

bracket

Bracket,

supporting

adjuster

of

clutch

Bolt,

securing

bracket

Nut,

setting

clutch

Screw,

setting

clutch

Ball

bearing,

of

multiple

gear

Gear,

multiple

Washer, locking clutch

Nut,

retaining

clutch

Key,

retaining

clutch

Plug,

for

hole

crankcase,

side

flywheel

magneto

-

17-

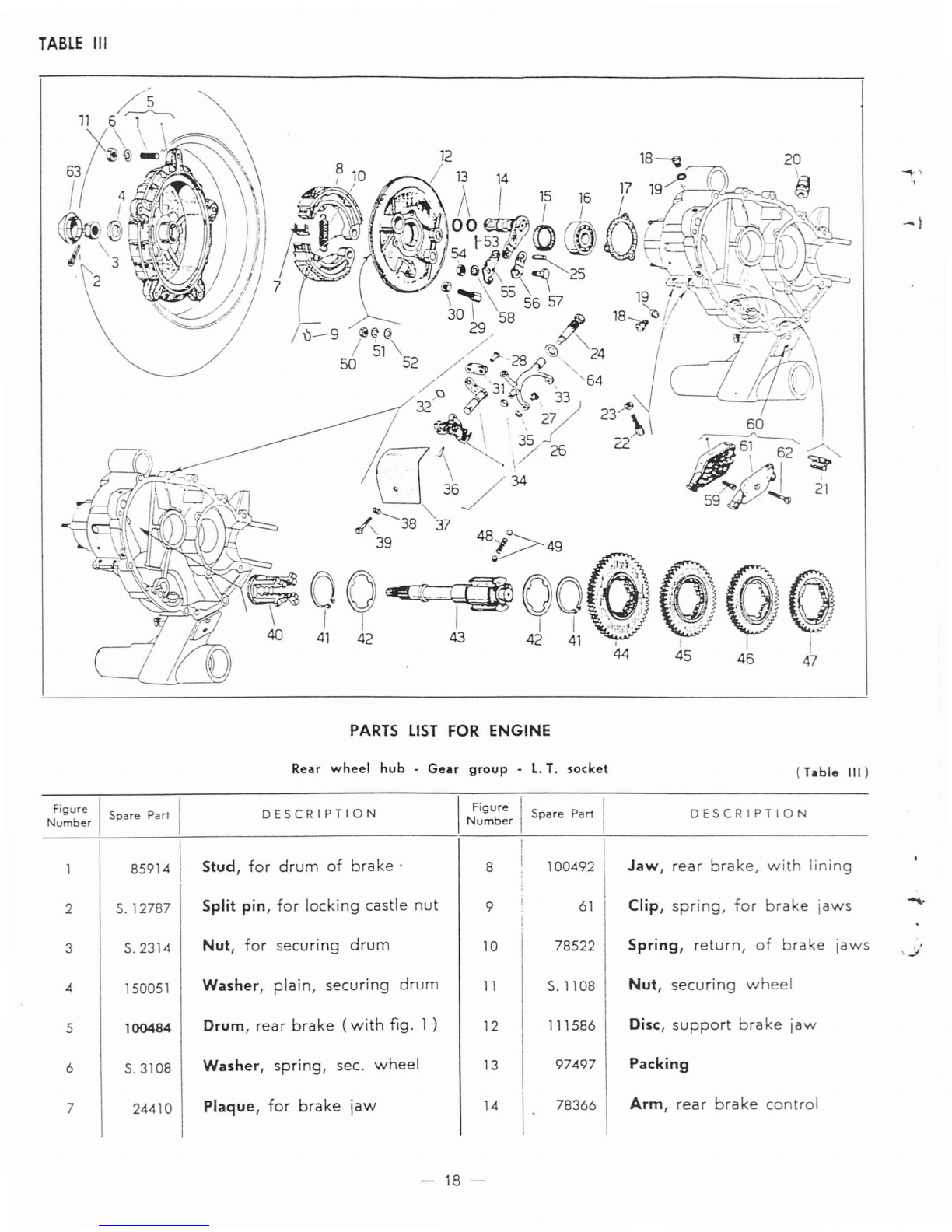

TABLE

III

PARTS

LIST

FOR ENGINE

~,

I

--I

Rear

wheel

hub.

Gear

group·

L.

T.

socket

Figure

II

DESCRIPTION

I

Figure

II

Number

Spare

ParI

Number

Spare

Part

85914 II

100492\

I

Stud,

for

drum

of

brake'

8I

2

5.12787

Split

pin,

for

locking

castle

nut

9

61

3

5.2314

Nut,

for

securing

drum

10

78522

4150051

Washer,

plain,

securing

drum

11

5.1108

5

100484

Drum,

rear

brake

(with

fig.

1)

12

111586

6

5.3108

Washer,

spring,

sec.

wheel

13

97497

724410

Plaque,

for

brake

jaw

14

\.

78366

-

18-

(Table

III)

DESCRIPTION

Jaw,

rear

brake,

with

lining

Clip,

spring,

for

brake

jaws

Spring,

return,

of

brake

jaws

Nut,

securing

wheel

Disc,

support

brake

jaw

Packing

Arm,

rear

brake

control

Figure

Spare

Pan

Number

I

DESCRIPTION

I

Figure

!

Spare

Part

Number

I

DESCRIPTION

15

3/46699

Seal,

spring

-

loaded

of

main-

shaft

41

5.5901

Circlipt

retaining

shoulder

washer

-1

16

17

7563

90899

Ball

bearing

t

clutch

side

Packing

42

42

a)

111996

a)

112008

Washer

t

shoulder,

normal,

of

of

gear

pinions

Washer,

shoulder,

1

st

oversize

18

19

20

2990

Capt

filler, oil

397

Packing

t

for

cap

19301

Breather

42

42

42

a)

112009

Washer

t

shoulder,

2nd

oversize

a)

112010

Washer

t

shoulder,

3rd

oversize

a)

112011

Washer

t

shoulder,

4th

oversize

21

78578

Buffer

43

a)

111596

Mainshaft

22

23

24

25

26

27

90527

Screw,

setting

change

gear

5.1205

Nut

t

setting

change

gear

98787

Bolt

t

securing

stirrup

90306 .

Pivot

pint

for

rear

brake

links

112214

Stirrupt

for

gear

change

(With

parts

Figs.

27

-

28

31 -

33

-

35

-

36).

78945

Slide

t

stirrup,

of

gear

change

44

45

46

47

48

49

50

112378

Gear,

low

speed

112379

Gear

t

2nd

speed

112381

Gear

t

3rd

speed

112380

Gear

t

4th

speed

150110 i

Spring

t

for

balls

5.6379

Ball

5.1108

Nut

t

securing

brake

jaw

sup-

port

disc

23823,

Screw

t

setti

ng

rea

r

bra

ke

5.

1207

Nut

t

setti

ng

rea

r

bra

ke

5.5771 Rivett

for

stirrupt

of

gear

change

S.

3108

Washer

t

spring

link,

brake

link

t

brake

Washer

t

spring

Screw

t

for

L.

T.

socket

l.

T.

socket

g.

a.

(With

parts

Figs.

59

-61 -

62)

.

Bolt

t

for

securing

cable

to

brake

links

70744

85673

42047

94779

5.3109

5. 14402

5.3058

Washer

plain

5.12761

Split

pint

for

arm

axle

5.1426

Nut,

for

securing

bolt

brake

links

53

58

59

52

57

55

54

56

51

60

Cover,

of

the

act.

lever

Union

piece,

for

levers

Packing

Washer

t

spring,

for

cover

Stirrupt

of

gear

change

Washer

t

spring,

for

stirrup

Circlip,

for

stirrup

Pin

78920

78597

78526

110716

5.3105

5.5962

5.6706

5.13010

36

38

30

35

29

32

37

28

34

31

33

~

\

39

40

99462

111589

Screw

t

securing

cover

Selector,

gear

61

62

78598

5.8230

Covert

for

L.

T.

socket

Screw

t

for

L.

T.

socket

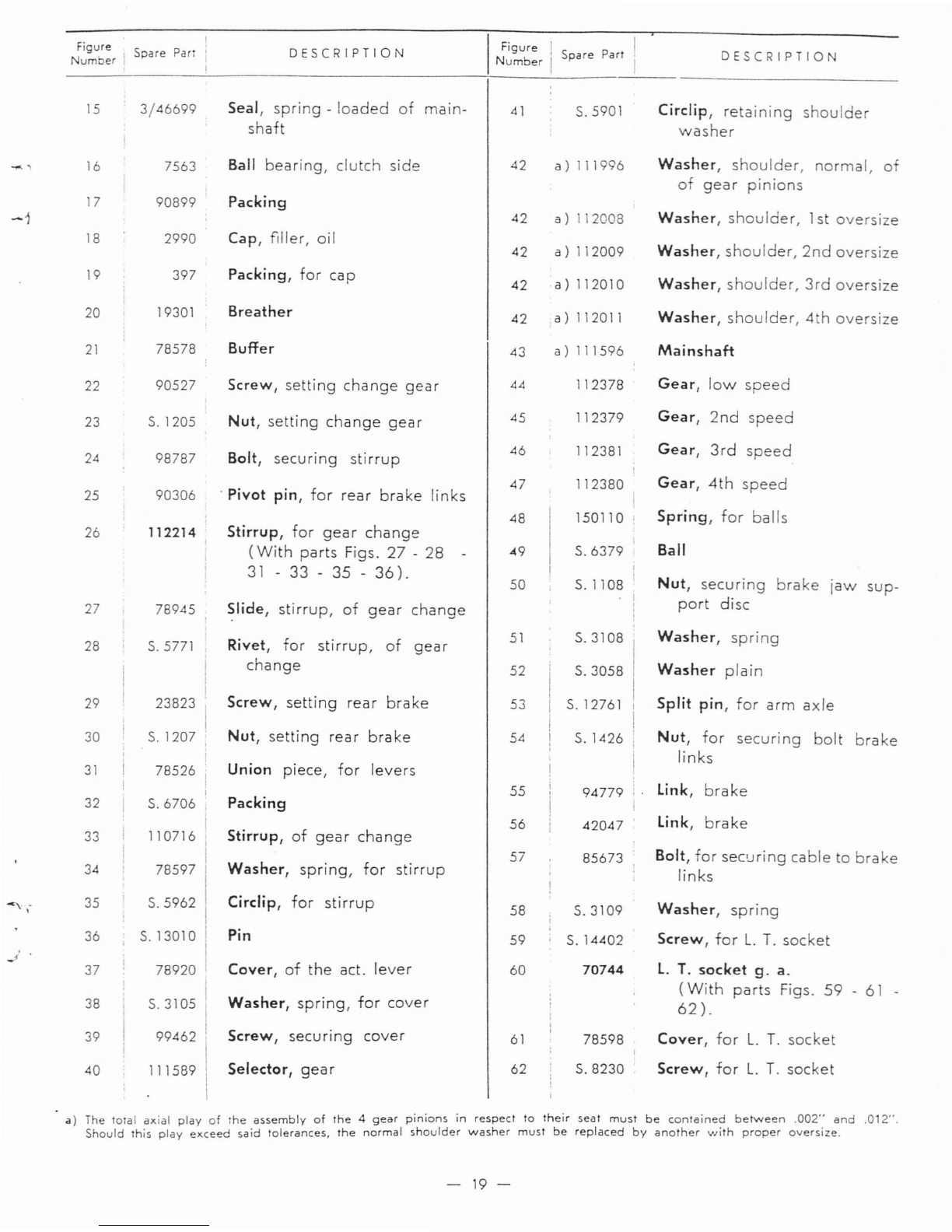

a)

The total axial

play

of

the

assembly

of

the

4

gear

pinions

in

respect

to

their

seat

must

be

contained

between

.002"

and

.012".

Should

this

play

exceed

said

tolerances,

the

normal

shoulder

washer

must

be

replaced

by

another

with

proper

oversize.

-

19-

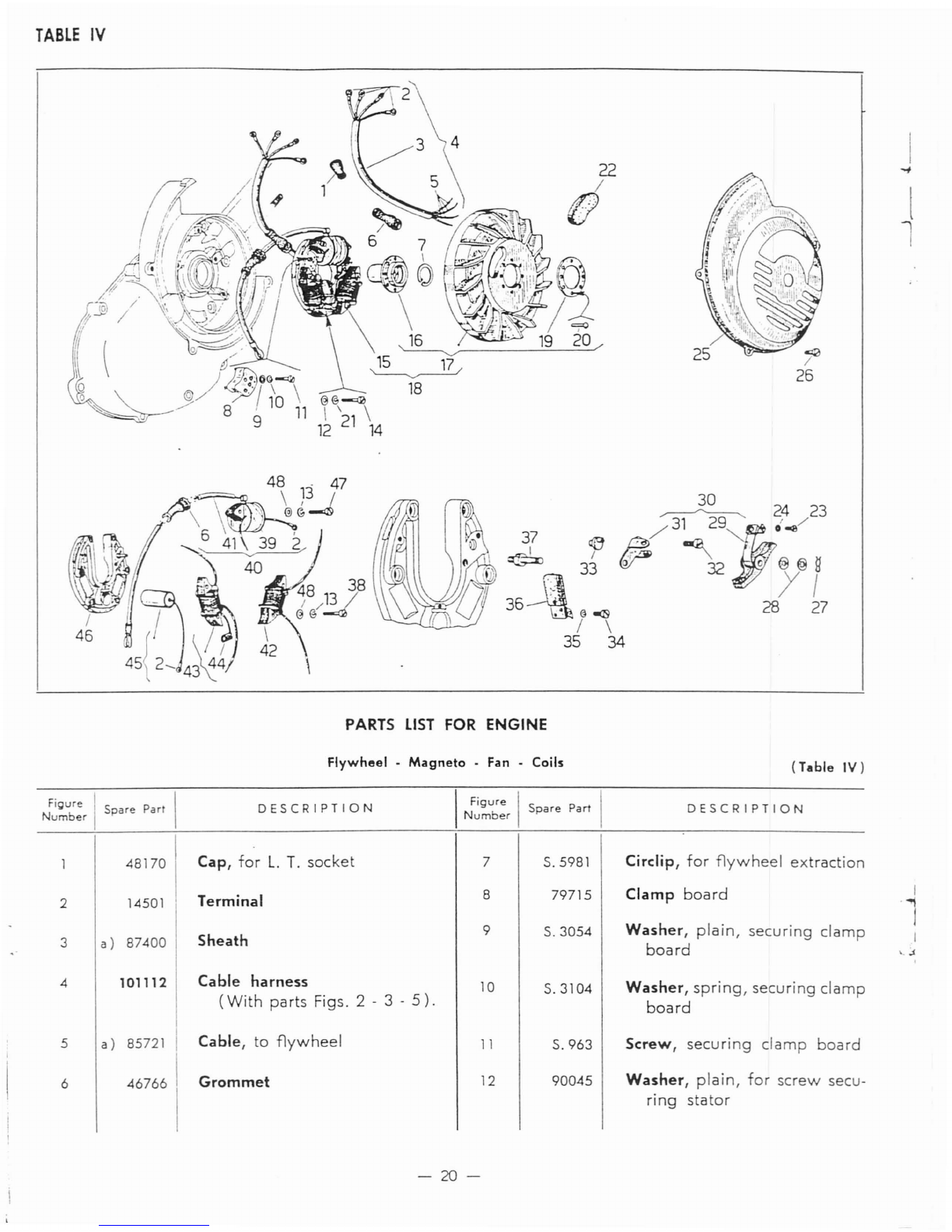

TABLE

IV

I

-#

l

~

2423

37

lIB'

/31

29j'

-a./

~

/

~

~

,-

~

33 W32

.o@@g

36Jl.-S

/

~7

/\

35

34

PARTS

LIST

FOR

ENGINE

Flywheel

.Magneto .

Fan

-Coils

(Table

IV)

FiQure IPI

Number

Spare

art

DESCRIPTION

I

Figure

I

Spare

Part

I

Number

DESCRIPTION

2

3

4

5

6

48170

14501

a)

87400

101112

a)

85721

467661

Cap,

for

L.

T.

socket

Terminal

Sheath

Cable harness

(With

parts

Figs. 2 - 3 -

5).

Cable,

to

flywheel

Grommet

7

8

9

10

11

12

5.5981

79715

5. 3054

5.3104

5.963

90045

Circlip,

for

flywheel

extraction

Clamp

board

Washer,

plain,

securing

clamp

board

Washer,

spring,

securing

clamp

board

Screw,

securing

clamp

board

Washer,

plain,

for

screw

secu-

ring

stator

\.

.1

-20-

Other manuals for 788.94370

1

Table of contents

Other Allstate Scooter manuals