Allstate 788.102 Use and care manual

OPERATING INSTRUCTIONS

AND

PARTS LIST FOR

MOTOR SCOOTER

,--------

MODEL NUMBERS

788.102 788.103

788.104

One

of

the

above

numbers

is

the

Model

Number

of

the

Allstate

Motor

Scooter.

It will

be

found

on

a

plate

attached

to

the

outside

of

the

hinged

door

directly

under

the

seat.

Always

mention

the

Model

Number

in

all

correspondence

regarding

the

Scooter

or

when

ordering

repair

parts.

,-----

HOW

TO

ORDER REPAIR PARTS

All

parts

listed

herein

may

be

ordered

through

any

Sears

retail

or

mail

order

store.

In

ordering

parts

bymail

from

the

mail

order

store

which

serves

the

territOly

in

which

you

live,

Selling

Plices

will

be

furnished

on

request

or

parts

will

be

shipped

at

prevailing

prices

and

you

will

be

billed

accordingly.

WHEN ORDERING REPAIR PARTS,

THE FOLLOWING INFORMATION: ALWAYS

GIVE

1.

The

Part

Number

in

this List.

2.

The

Part

Name

in

this List.

3.

The

Model

Number

of

the

item.

being

able

We

sug-

papers.

your

times.

valuable

It will

assure

service

at

all

with

other

is

valuable.

proper

parts

keep

it

This

list

to

obtain

gest

you

SEARS, ROEBUCK

AND

CO.

Scooterworks

USA Inc.

5709 N.

Ravenswood

Chicago,

IL

60660

ph: 773.271.4242

fx:

773.271.5012

Fig.

1 - ALLSTATE

Scooter

WARNING

In

order

to

keep

your

ALLSTATE

Scooter

in

per-

fect

running

condition

and

not

to

void

the

guarantee,

always

have

your

machine

repaired

at

a

Sears,

Roe-

buck

and

Co. Store.

Special

care

should

be

taken

in

regard

to

the

fuel

mixture

which

should

be

regular

gasoline

and

oil

of

the

make,

grade

and

in

the

amount

prescribed

in this booklet.

Ethyl

gasoline

should

never

be

used.

Do

not

use

Allstate

compounded

motor

oil

or

other

premiumsheavy

duty

mo

or

oils

with

de

er-

gents.

The

inexperienced

operator

should

exercise

caution

in

applying

front

wheel

brake,

to

avoid

locking.

In

order

to

allow

a

gradual

running-in

of

all

parts,

particularly

those

of

the

engine,

customers

must

not

use

full throttle

opening

for

the

first 600 miles.

- 2 -

THROTTLE

CONTROL

GRIP

CHOKE

KICKS

TARTER

FUEL

COCK

TTOR

SWITCH,

HORN

BUTTON

EARTH

CONTACT

GEAR

SHIFT-CLUTCH

CONTROL

HORN

R

AR

BRAKE

PEDAL

FRONT

BRAKE

LEVER

Fig.

2 -

Controls

of

Allstate

Scooter

MAIN

SPECIFICATIONS

Fuel

tank. -

Total

capacity:

1.3

gals;

Reserve:

0.17

gals.;

Three-way

cock:

«

open»

-«

closed»

-«

reserve»

Wheels.

-Of

pressed

steel

sheet,

interchangeable

and

easily

removable,

since

they

are

assembled

in

an

automobile-like

system.

Tires:

dia.

3.50 X8in.

Brakes. -

Expanding

type.

Front

brake:

control

lever

on

right

hand

side

of

handlebars

Rear

brake:

control

pedal

on

right

hand

side

of

floorboard.

Frame. -Of

pressed

and

spot-welded

steel

sheet,

with

strem-lined

monocoque-type

structure.

Suspension. -Front

wheel:

coil

springs;

rear

wheel:

coil

spring

and

hydraulic

shock

absorber.

Engine. -Two-stroke, flat

cast

iron

cylinder

and

cast

aluminum

alloy

cylinder

head.

Bore .124.850 cc. (7.63 cu. in.)

Stroke

56.5 mm. (2.22 in.)

Displacement

49.8

mm

..

(1.97 in.)

Effective

power

at

4500

rpm

4.5 HP

Compression

ratio

6.4 : I

Transmission. -Directly from

engine

to

rear

wheel

through

clutch,

cushion

drive

and

gear

box.

Starting. -

By

means

of kickstarter,

right

hand

side

of scooter.

Gear

box. -

3-speed

drive

with

mesh

gears

in

oil

bath.

Its control is

coupled

with

that

of

the

clutch,

on

left

hand

side

of

handlebars.

Clutch. -

Wet

type,

steel

plates

with

cork

inserts.

Two-cable

control.

Ignition. -

By

flywheel

magneto.

Lighting. -

By

flywheel

magneto,

feeding

both

head

lamp

(two-beam)

and

tail

lamp.

Fuel

consumption:

(Gasoline

-oil

mixture)

Max.

speed

Wheel

base.

Max.

width

on

handlebars

Max.

length

of the

scooter

Max.

height

Hgt. of

saddle

above

ground

Ground

clearance

Turning circle .

Weight

IG6-118

miles

per

gal.

43.7

m.p.h.

45.6 in.

31

in.

66 in.

40 in.

31

in.

8.6 in.

59 in.

185 Ibs.

- 3 -

Fig.

3.

-

Steering

lock

Steering

Lock. - A

suitable

security

kck

is

ar-

ranged

on

the

harne,

near

the

handlebars.

Turning

the key

anti

clockwise

and

the

handlebars

to

the

left,

the lock

engages

the

lugs

welded

on

the

st(1.;ring

column,

so

that

the

machine

can

only

turn

around.

Turn the

key

clockwise

and

the

handlebars

back

to

normal

position

for

releasing

the

steering

system

(see

fig.

3). Do

not

attempt

to

ride

the

machine

unless

the key is in,

and

remains

in

the

lock,

and

the

handle-

bars

are

moving

freely.

Do not

lubricate

the

steering

lock.

Central

Stand.

- A

two-leg

stand

is

arranged

under

the floorboard.

Two

strong

return

springs

hold

it

in

contact

with

the

floorboard

and

keep

it from

vibrating

while

the

scooter

is

being

ridden.

Tool Kit. - I

four-end

box

wrench

(11 -

14

-

21

-

:::2

mm.); 3

single

open-end

wrenches

(7

- 8 -

10

mm.);

I

double

open-end

wrench

01

-

14

mm.).

1

screw-

driver.

These

hand

tools

are

contained

in

a

canvas

roll

which

is

placed

in

the

left

wing

with

an

air

pump.

Due

to

the

simple

and

conventional

design

of

the

Allstate

scooter,

no

particular

skill is

required

for

its

operation,

nor

skilled

personnel

for its

mainte-

nance.

The

tasks

can

be

quite

well

carried

out

by

any

customer,

even

unexperienced,

by

carefully

follow-

ing

some

general

rules.

- 4 -

OPERATION

Fig.

5

If

the

engine

is

not

flooding,

prime

three

or

four

times

(tickler of float

chamber

cover)

by

pulling

the

chocke

lever

situated

under

the

seat

and

kick

the

starting

lever

again.

LOW

SPEED

NEUTRAL

2ND

SPEED

HIGH

SPEED

Fuel supply. -

Fuel

mixture

should

be

composed

or

regular

gasoline

and

Allstate

Outboard

Motor

Oil,

S.A.E. 30,

or

Allstate

regular

motor

oil S.A.E. 30, in

the

following

proportion:

-0.65

pint

of oil to 1

gallon

of

gasoline

for

run-

ning-in

(900 miles)

-

0.5

pint

of oil to 1

gallon

of

gasoline

afterwards.

Do

not

use

Allstate

compounded

motor

oil

or

other

premium

Heavy

Duty

motor

oils

with

deter-

gents.

Keep

the

breather

of filling

cap

clean.

Oil level. -

Remove

the

level

screw,

on

crank-

case,

marked

«OLIO»

and

indicated

on

pag.

8,

Fig.

11,

to

check

oil

level

in

gear

box

before

starting

the

engine.

The

scooter

standing

upright,

oil

should

just

be

about

to flow

out;

otherwise

top

up

with

ALLST

A

TE

REGULAR S.A.E.

90.

Starting. -

Open

the

fuel

valve,

put

the

gear

shilt in

neutral

and

slightly

open

the

throttle in

slow

running

position, kick

the

starting

lever.

Se

on

Fig. 4

the

three

positions

of

the

fuel

valve:

open,

closed,

reserve.

Caution. -Do

not

open

throttle

wide

when

re-

leasing

clutch.

In

case

of

starting

troubles,

see

that

the

carbu-

retor

is

not.

flooding,

i.

e.

mixture

is

not

dripping

from it.

Engine

flooding

can

be

overcome

by

either

one

of

the

following

methods:

(a)

Push-start

the

scooter:

shift into

second

gear,

declutch

and

push

the

machine;

suddenly

release

the

clutch

lever

and

pull

it

back

as

soon

as

the

engine

starts.

(b)

Remove

the

spark

plug

and

rotate

the

engine

by

means

of

the

kickstarter.

Wipe

the

plug

dry

and

replace.

RESERVE

Fig.

4

CLOSED

Warning. -

112

pint

of oil

should

be

mixed

to

each

gallon

of

gasoline

after

running-in.

Do

not

use

full

throttle

opening

for

at

least

600

miles.

Gear

shift. -

Release

throttle

first,

then

declutch

and

turn

the

gear

shilt

control

grip

until

the

number

corresponding

to

the

required

speed

gear

coincides

with

the

arrow

engraved

on

the

handlebars

(see

Fig. 5).

Release

the

clutch

lever,

slowly

if

a

lower

gear

is

being

shilted

to,

quickly

if

shifting

to a

higher

gear.

5-

"-

,

'"

",

\,

.-l '

EARTH

CONT~cf--~

OFF

TRAFFIC

COUNTRY

BEAM

<DIM>

BEAM

<BRIGHT>

v

AND

TAIL

LAMP

HORN

HORN

GROUND

1

NUMBERS

CORRESPONDING

WITH

THOSE

ON

LOW

TENSION

SOCKET

6V

22

W

HEAD

LAMP

@

LOW

TENSION

SOCKET

Fig.

6 -

Scheme

of

Electric

Wiring

-6-

Tires. -

The

wheels

are

interchangeable,

i.

e.,

they

can

be

assembled

either

in front

or

rear.

Fig.

7

When

aflat tire is to

be

replaced,

unscrew

the

four

nuts

which

secure

the

wheel

to

the

brake

drum,

pull

wheel

sideways

off

the

studs,

repair

it

or

replace

with

spare

wheel

(see

Fig. 7).

For

getting

the

tube

out,

separate

the

felly from

the

ring

by

unscrewing

the

nuts,

which

join

them

(see

Fig.

8)

Tire

pressure

should

be

18

psi

on

rear

wheel.

11

psi

on

front

wheel.

If

the

Allstate

is

ordinarily

Fig.

8

ridden

by

both

driver

and

passenger,

the

pressure

of

the

rear

tire

should

be

28

psi.

Stopping

the

engine.

-

Push

the

switch

lever

all

the

way

to

the

left;

fuel

vapors

remain

in

the

cylinder

in this

way,

and

the

next

start

will

be

much

easier.

Brake

adjustment.

-

The

brakes

are

properly

adjusted

when

the

play

between

linings

and

drums,

as

measured

at

the

end

of

lever

or

pedal,

is

about

5/32".

Set

this

play

by

means

of

suitable

adjuster

screws

(see

Figs. 9

and

10).

Slow

running

adjustment.

-No

hand

tool is

re-

quired

for this

job;

idling

revs

can

be

raised

by

simply

tightening

the

screw

which

presses

on

car-

buretor

cover

and

vice-versa.

Fig. 9

Fig.

10

-"

7-

MAINTENANCE

Fig.

11

Cleaning

the

scooter.

-

Brushing

kerosene

and

wiping

dry

with

clean

rags

is

advisable

or

outside

cleaning

of

engine.

All

painted

surfaces

should

be

washed

with

water.

rinsed

by

means

of a

sponge

and

wiped

dry

with

a

chamois.

Do

not

use

kerosene

on

such

surfaces.

since

i

damages

paint

and

turns

it

dull.

Every

600

miles.

-

Check

oil

level

in

gear

box

by

unscrewing

he

crankcase

plug

marked

«

OLIO"

(see

Fig.

11)

The

scooter

standing

upright,

oil

should

just.

be

about

to

flow

out.

Lubricate

with

oils

indicated

on

table

a

page

9

exclusively.

Clean

the

two

lubricators

on

Iront

wheel

hub

and

relil!

them

by

means

of

a

grease

gun.

Every

1200

miles:

(l)

Remove

silencer,

heat

its

rear

pipe

and

blow

air

through

bigger

pipe.

We

sugges

,

however,

that

decarbonizing

should

be

carried

out

by

your

Sears

sore.

(2)

Remove

the

air

cleaner

from

carburetor

and

shake

it

in

a

30

o~

oil-gasoline

bath.

(3)

Grease

he

felt

which

lubricates

the

cam

of

flywheel

magneto.

Fig.

12

(4)

Check

sparkplug

electrodes

and

breaker

points

for

adjustment

(Breaker

Points

.016 -

Spark-

plug

.C23),

and

clean

them

by

means

of

very

thin

emery

paper

or

suitable

files

(see

Fig.

12).

Inspect

the

insulation

material

of

spark

plug.

Replace

the

spark

plug

if

the

porcelain

is

cracked.

Wash

with

pure

gasoline.

Use

the

spark

plug

type

Allstate

No.

A4 150.

Important:

using

the

proper

type

of

spark

plug

will

eliminate

many

engine

troubles.

(5)

Disassemble

exhaust

pipe,

cylinder

head

and

cylinder;

decarbonize

seeing

that

no

carbon

particle

lalls

into

the

engine.

Assemble

a

new

paper

washer

at

the

cylinder

base

(see

Fig.

13).

(6)

In

case

of

shock-absorber

troubles,

have

the

assembly

overhauled

or

simply

cleaned,

and

oil

changed

by

your

Sears

Store.

Have

gear

shift

control

cables

lubricated

by

your

Sears

Store.

Long

inactivity.

-

In

such

a

case,

cleaning

tlie

scooter

thoroughly

is

advisable.

Pour

some

mineral

oil

into

the

engine

thraugh

the

sparkplug

hole,

and

-8-

@@@

Fig.

13

rotate

the

engine

once

or

twice

in

order

to

smear

all

surfaces

with arust

preventing

oil film.

Place

the

floorboard

on

two

wooden

blocks

in

order

that

the

wheels

don't

touch

the

ground.

TABLE

OF

LUBRICATION

INSTRUCTIONS FOR

ALLSTATE

PARTS

TO

BE

OPERATION

TIM

ETYPE

OF

LUBRICANT

LUBRICATED

Engine

Mix

gasoline

with

the

following a

At

each

refilling of

the

Allstate

Regular

SAE

mount

of

lubricating

oil

(weight

ratio): fuel

tank

30

or

Allstate

Outboard

-0.65

pint

of

oil to 1

gallon

of

gaso-

Motor

Oil

line

for

running-in

(900 miles)

-0.5

pint

of oil to 1

gallon

of

gaso-

line

afterwards.

Gear

Box

Warm

up

the

engine.

Let oil

out

After

the

first 600

miles

Allstate

Regular

SAE

90

from

the

gear

box,

and

thoroughly

»»»

SO

rinse

with

kerosene.

should

be

used

in

zones

Refil

wiih

new

oil to oil

level

hole.

with

mean

temperature

Every

600

miles

below

23"

F.

Front

wheel

Lubricate

with

grease

gun

Every

6CO

miles

High

Pressure

hub

Chassis

Grease

Shock

Change

oil

Only

when

the

shock-

Allstate

Shock

absorber

absorber

is

out

of

order.

Absorber

Fluid

Gear

shift

Clean

and

lubricate

Every

12CO

miles

Allstate

all

purpose

control

cables

GearLubricatorSAE

140

Lubrication felt

Small

spot

of

grease

on

the

felt

Every

l2CO

miles

Esso

Bearing

Grease

I

of

flywheel

cam

I

!

-9-

......

o

"Tl

o!i.

;:

t""

~

go

r;.

!l.

o·

::s

til

n

p-

el>

3

el>

~

~

iii

c.i

;;

REAR

WHEEL

SHOCK-ABSORBER

ALLSTATE

SHOCK

ABSORBER

FLUID

OIL

LEVEL

ALLSTATE

REGULAR

S.A.E.

30

OR

ALLSTATE

OUTBOARO

MOTOR

OIL

BY

MIXTURE

ALLSTATE

REGULAR

S.A.E.

90

HIGH

PRESSURE

CHASSIS

GREASE

GEAR

BOX

LOCATING

TROUBLES AND RUNNING IRREGULARITIES

Carry

out

following

checks

when

the

engine

does

not

start

easily

or

runs

irregularly.

Locating

the

trouble

1

R_e_m_e_d_i_e_s

ill,

L_o_c_a_t_in_g_t_h_e_tr_o_u_b_l_e

_

BAD

S

TAR

TIN

G

Pre-ignition

Replace

both

plates

and

spring:;

Adjust

Adjust

Replace

Release

Replace

Slacken

Adjust

Wash

with

gasoline

or

replace.

Ask

the

sale

agent

about

oil

leakage

Replace

Tighten

Replace

Lubricate

or,

if

necessary,

re-

place

Adjust

Fit

proper

jet

(0.75 mm.)

Re-time

See

No.2

of

this

paragraph

Release

operating

and

lubri-

cating

the

lever

on

he

back

of

the

cleaner

case

Remedies

a)

Fit

on

a

colder

type

spark-

plug

b)

Re-time

the

ignition

}

Address

yourself

to a

sale

agent

See

paragraph

.Bad

starting.,

No. I

Clean

with

pure

gasoline

and

blow

dry.

Dip

the

metal

wadding

into

a30%

gaso-

line-oil

bath

Adjust

Tighten

the

screws

Replace

Replace

Replace

the

selector

Replace

he

pinions

Turn

convex

face

towards

cork-

insert

plate

Top

up

oil

level

Replace

Clean

or

replace

both

needle

and

float

chamber

cover

Excessive

play

8.

-

Steering

column

becomes

stiff

Top

race

of

top

ball

bearing

too

tight

Bottom

races

of

the

two

bea-

rings

pilted

9. -

Excellsive

play

of

steering

column

Top

race

of

top

bearing

loose

10. -

Poor

braking

Stroke

of

pedal

or

lever

too

long

Brake

linings

oily

or

worn

down

IV

-

Diameter

of

main

jet

ori-

fice

wrong

or

increased

V -

Retarded

ignition

VI

-

Poor

compression

7.

-

Controls

not

operating

pro-

perly

Inner

cables

rusted

Brake

drums

and

linings

scrat-

ched

4.

-

Clutch

troubles

a)

Clutch

snatches

Outer

convex

plate

wrongly

assembled

6.

-

High

fuel

consumption

I -

Fuel

level

too

high

in

car-

buretlor

a)

Tickler

sticking

in

de-

pressed

posi

tion

b)

Float

perforated

c)

Float

needle

valve

not

properly

fitting

into

its

seating

Condenser

loose

in

its

housing

Tip

of

contact

breaker

loose

ot

enough

mixture

flowing

to

the

carburettor

II

-Air

cleaner

choked

or

dirty

III -

Flap

of

chocke

valve

stick-

ing

in

closed

or

partially

closed

position

Gear

pinions

not

lubricated

properly

b)

Clutch

slips

Springs

feeble

Plates

with

cork

-

inserts

worn

or

burnt

c)

Clutch

does

not

disengage

completely

Excessive

play

on

control

cable

Excessive

convexity

of

outer

steel

plate

5.

-

Gear

pinions

disengage

of

own

accord

Gear

change

control

cables

out

of

adjustment

Gear

shifter

loose

on

crankcase

Spring

of

stirrup

broken,

feeble

or

missing

Excessive

play

between

ac-

tuating

arm

and

gear

shift

flange

Selector

arms

chamfered

Dogs

of

gear

pinions

chipped

or

worn

Replace

or

clean

the

plug

and

correct

the

gap

to 0.6

mm.

Clean

Decarbonize

cylinder,

piston

and

cylinder

head

Replace

Tighten

Set

the

head

properly

anl..

tighten

the

nllts

Replace

Clean

the

rings

and

grooves

Clean

with

tool

provided

Replace

the

packing

between

pipe

and

cylinder.

Tighten

the

nuts

on

cylinder

studs.

Release

by

depressing

the

tickler

Remove

and

wash

in

gasoline

-

Blow

dry

Correct

to 0.4

mm.

with

feeler

gauge

(0.015")

Release

Release

Replace

Clean

Replace

the

plug

Release

the

lever

Turn

to

vertical

pcsition

Disconnect

the

plug

lead.

Check

if

sparking

occurs

between

lead

and

crankcase

when

the

kicks

tarter

is

operated

Clean.

Correct

gap

to 0,6

mm.

(0.023")

Clean

with

suitable

files

or

very

fine

emery

paper

Turn

to •

reserve.

Refill

as

soon

as

possible

a)

Depress

the

tickler

until

some

fuel

drips

out,

or

b)

Unscrew

and

remove

the

main

jet.

If

the

fuel

system

is

efficient,

fuel

will

come

out.

See

pag.

14

Replace

Re-time

ignition

cracked

Replace

INCORRECT

RUNNING

Exhaust

port

partially

closed

by

carbon

deposit

Cylinder

base

gasket

not

tight

2.

-

Poor

compression

Sparking

plug

not

well

screwed

down

in

cylinder

head

Cylinder

head

not

filting

pro-

perly

into

the

spigot

on

top

of

cylinder

Head

gasket

not

tight

Piston

rings

gummed

up

3.

-

Explosions

at

llilencer

or

carburellor

Sparking

plu'"

carbon-coated

or

with

excessive

electrode

gap

Carbon

pearls

on

sparkplug

insulation

1.

-

Lack

of

power

Silencer

outlet

pipe

carbonized

Induction

pipe

to

cylinder

loose

Breaker

points

completely

worn

or

pitted

Timing

wrong

Pick-up

terminal

1.

-

Fuel

system

Fuel

tank

empty

Fuel

does

not

flow to

the

car-

bureltor

although

the

fuel

tap

is

open

or

in

position

c

reserve.

Sparking

plug

dirty

Porcelain

of

sparking

plug

cracked

Switch

lever

jammed

in

•

cut

out.

position

Breaker

points

dirty,

partially

worn

or

pilted

2.

-

Carburation

Engine

flooding

Tickler

sticking

in

depressed

position

Float

perforated

Air

cleaner

choked

or

dirty

Choke

flap

sticking

in

position

•

closed.

Carbureltor

assembly

mounted

at

an

angle

3.

-

Ignition

Gao

between

breaker

points

incorrect

Filter

at

top

of

se-

diment

bowl

Filter

on

carbureltor

Fuel

tap

body

Carbureltor

body

(,

Clogged,

Main

jet

(dirty

Atomizer

Hose

between

sedi-

ment

bowl

and

carbureltor

Float

needle

valve

sticking

on

its

seating

In

order

to

allow

a

gradual

runrung-m

of

all

parts,

parhcularly

those

of

the

engme,

we

recommend

the

customers

not

to

use

full

throltle

opening

for

the

first 600

miles.

PARTS

LIS

T

2287

/

~2189

'.,~~"

31457----

18540

ENGINE

Cranl:case -Crankshaft -Clutch -Cylinder

===1============

Part

Number

DESCRIPTION

Part

Number

DESCRIPTION

97

267

318

675

684

686

2C27

2081

2094

2133

2189

2202

2213

2239

2287

2291

2927

Key. woodruff, for

crankshaft

(clutch

side)

,

Key. woodruff, for

crankshaft

(flywheel :

side)

i

I

Gasket.

cop~er,

of

sparkplug

I

Nut. flywheel

locking

!

Washer, plainl

for

675 nut I

Washer.

shake

proal.

for 675

nut

Roller.

can.

rod

Roller for

clutch

gear

II

Nut.

castle,

clutch

locking

Stud. for

securing

engine

to

bracket

Screw.

clutch

cover

locking

I

Stud.

for

joining

crankc:lse

halves

Washer. shim,

of

clutch

gear

Gasket.

head

Lever.

inner,

clutch

control

Spring.

return,

of

outer

clutch

control

lever

I

Gasket.

cylinder

base

2924

3669

3935

5232

5355

7333

IC012

10099

10874

11406

114C8

11409

11410

11718

11742

11743

Gasket

Packing

between

clutch

cover

and

outer

lever

Cap.

rubber,

for

sparkplug

Circlip for

locking

gudgeon

pin

Bush for

small

end

of

can.

rod

Stud.

cylinder

fastening

Bush for

centering

spring

loaded

seal

of

crankshaft

Ring.

elastic,

for

stopping

clutch

plates

Ring.

piston,

normal

Body.

clutch

Plate.

smooth,

of

clutch

Spring.

clutch

Cup.

clutch

spring

Plate.

spring,

of

clutch

Ring.

piston,

Ist

oversize

Ring. piston,

2nd

oversize

-

12-

Parts List for

Engine

-

Crankcase

0

Crankshaft

'0

Clutch·

Cylinder

0

Continued

14457

Spring

for fixing

16821

plate

Part

Number

11744

11745

11813

12169

12499

12500

12539

12659

13127

13150

13152

13247

13248

13249

13250

13290

13319

13418

13790

13903

14351

14487

14488

14489

14490

14491

14738

DESCRIPTION

Ring, piston, 3rd

oversize

Ring, piston, 4th

oversize

Gasket

between

clutch

cover

and

crank-

case

Gear,

clutch

Plate,

spring,

of

clutch

Ball

Bearing

of

crankshaft

Cylinder

with

dowel

Piston

with

dowels,

normal

Gudgeon

Pin

Plate,

clutch,

with

cork

inserts

Clutch, g.

a.

(parts

n. 11406 -11410 -11409

-13150 -11408 -10099 -12499 -11718)

Piston

with

dowels,

1st

oversize

Piston

with

dowels,

2nd

oversize

Piston

with

dowels,

3rd

oversize

Piston

with

dowels,

4th

oversize

Head,

cylinder

Hood,

cooling

Seal,

spring

loaded,

for

crankshaft

Lead,

plug

Sparkplug

with

gasket

Cover, clutch,

with

inserts

Gudgeon

Pin, 1st

oversize

Gudgeon

Pin.

2nd

oversize

Gudgeon

Pin, 3rd

oversize

Gudgeon

Pin, 4th

oversize

Gudgeon

Pin, 5th

oversize

Crankcase

halves,

coupled

with

dowels

and

studs

(parts

n.

7333 -2133 -2202

-

S.

1207

-2924 -2150 -2088 -

S.

3057

-

S.

3107)

Part

Number

15138

15142

15254

16735

16817

16820

16821

18540

19301

31457

S.

1008

S.

1207

S.

1208

S.

3056

S.3057

S.

3058

S.3107

S.3108

S.3108

S.3112

S.

3940

S.11255

13

-

DESCRIPTION

Crankpin,

oversized

Con.

Rod.

oversized,

with

bronze

bush

Washer,

shoulder,

for 2027

rollers

Crankshaft

(Parts

n. 15138 -15254 -15142

-2027

and

webs)

Cover,

clutch,

with

lever

and

thrust

piston

parts

n.

14351

-31457 -3669 -2287 -

S. 3056 -S. 3206 -

105C5

-16820 -

2291)

Piston,

slotted

thrust,

of

clutch

(bronze)

Plate,

clutch

centering

Engine

with

carburetor,

air

cleaner,

nuts

and

washers

for

securing

Breather

Lever,

outer,

clutch

control

Nut

for

locking

cylinder

head

and

securing

engine

to

bracket

Nut

for 2202

stud

Nut

for

securing

cooling

hood

Washer,

plain,

for

inner

clutch

control

lever

Washer,

spring,

for S. 1207

nut

Washer,

plain,

for

cylinder

head

locking

nut

Washer,

plain,

for S. 1207

nut

Washer,

spring,

for S. 1008

nut

Washer,

spring,

for S. 1208

nut

Washer,

spring,

for 2094

castle

nut

Split

Pin

for

lockmg

inner

clutch

control

lever

Stud

for

securing

inlet

pipe

to

cylinder

Stud.

hood

fixing

~

/

mn

zat]

1590Z

ZO~7

67'

~.y~:

~-l'Il--"":~~~']lIl

\~

6J7

IIJ'::

107

\.

627

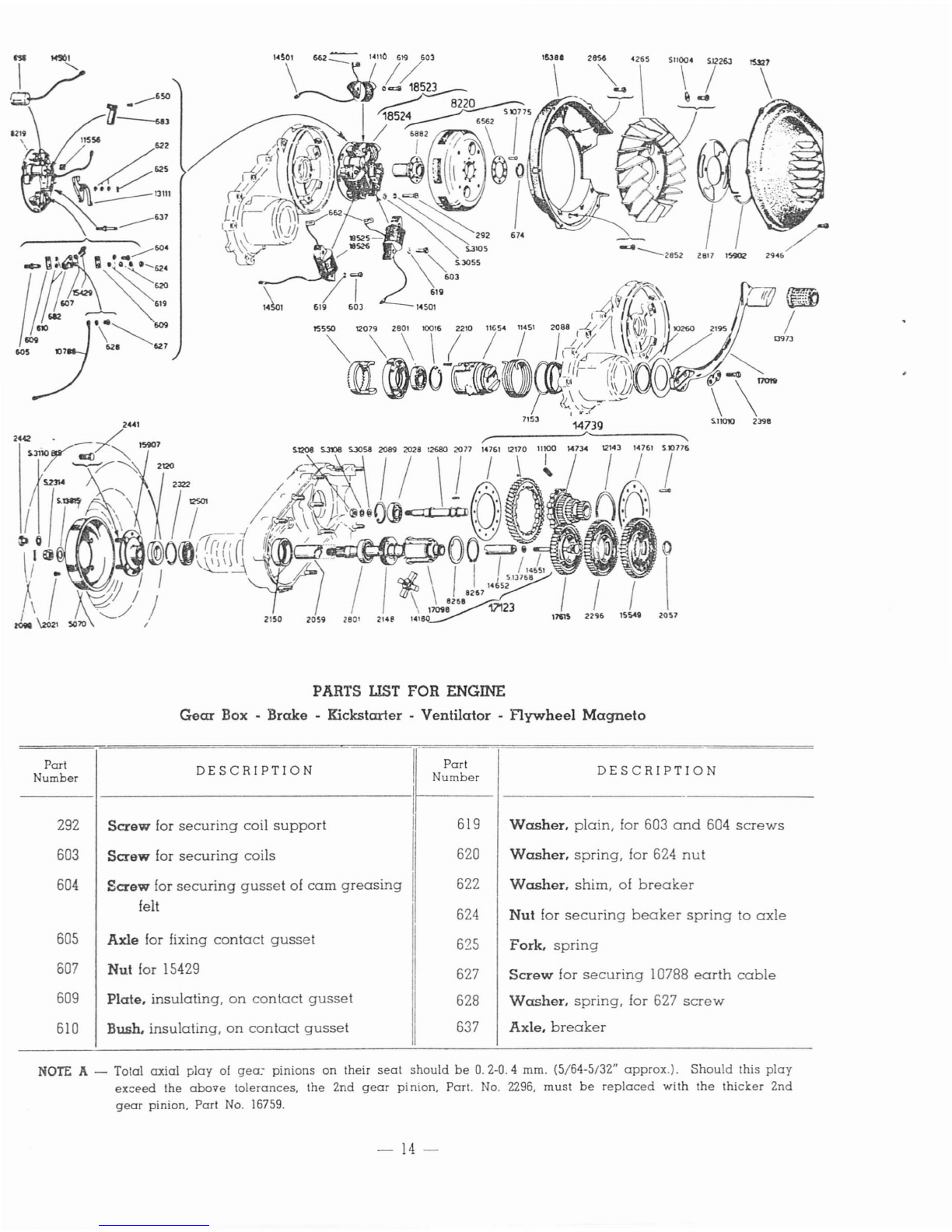

PARTS

UST

FOR

ENGINE

Gear Box -Brake -Kickstarter -Ventilator -

Flywheel

Magneto

Part

DESCRIPTION

I

Part

DESCRIPTION

Number

Number

I

292 Screw for

securing

coil

support

619 Washer.

plain,

for 603

and

604

screws

603

Screw for

securing

coils

620 Washer.

spring,

for 624

nut

604

Screw for

securing

gusset

of

cam

greasing

I622 Washer.

shim,

of

breaker

felt 624 Nut for

securing

beaker

spring

to

axle

605

Axle for fixing

contact

gusset

625 Fork.

spring

607

Nut for 15429 627

Screw

for

securing

10788

earth

cable

609 Plate.

insulating,

on

contact

gusset

628 Washer.

spring,

for 627

screw

610

Bush.

insulating,

on

contact

gusset

637 Axle.

breaker

NOTE

A-Total

axial

play

of

gea~

pinions

on

their

seat

should

be

0.2-0.4

mm. (5/64-5/32"

approx.).

Should

this

play

ex::eed the

above

tolerances.

the

2nd

gear

pinion,

Part.

No.

2296,

must

be

replaced

with

the

thicl::.er

2nd

gear

pinion. Part

No.

16759.

-

14-

PARTS LIST -

Continued

ENGINE

Gear

Box -

Brake

-Kickstarter -

Ventilator

-

Flywheel

Magneto

Part

Number

650

655

662

674

682

683

2021

2028

2057

2059

2077

2088

2089

2098

2120

2148

2150

2195

2210

2296

2322

2398

2441

2442

2801

2801

2817

2852

2856

2946

4265

5070

6562

6882

7153

8219

8220

8267

8268

10016

10260

10788

11100

11451

11556

11654

12079

DESCRIPTION

Rivet for

securing

bolt to

683

gusset

Condenser

Tenuinal,

short

cable,

for coils

Circlip for flywheel

extraction

Gusset

contact

Gusset

of

cam

greasing

felt

Screw

for

joining

brake

drum

to

flange

Ball

Bearing

to

support

multiple

gear

Circlip, small, of

gear

shaft

ball

bearing

(selector

side)

Spacer

of

gear

shaft

ball

bearing

Roller for multiple

gear

Bush,

support,

of 11654

Circlip for

locking

multiple

gear

ball

bearing

Split

pin

for locking

S.

2314

castle

nut

Seal,

spring-loaded,

of

gear

shaft

Ring,

threaded,

for locking

gear

shaft

ball

bearing

Bush for

gear

shaft

ball

bearing

Washer,

seal

locking

Spring

for

starter

bush

Gear,

2nd

speed,

See

note

A

Spacer

between

spring

loaded

seal

and

rear

wheel

ball

bearing

Bolt for

securing

kicks

tarter

Bolt for

securing

wheel

Nut for

securing

wheel

to

drum

Ball

Bearing,

inner

gear

shaft

support

Ball

bearing

to

support

gear

shaft

Cover, inspection, of fan

Screw,

long, for

securing

fan

casing

Screw,

short,'

for

securing

fan

casing

Screw

for

securing

fan

casing

cover

Fan

Drum,

rear

brake

Washer

Cam

Seal,

rubber,

for

starter

bush

Disk, coil

supporting

with inserts

Flywheel

with

cam

(Parts n.

S.

10775 -

6882 -6562

and

rotor)

Circlip

Washer,

shoulder

Circlip,

large,

for locking

2801

ball

bearing

on

slotted

housing

Seal,

felt,

of

starter

assembly

Cable,

earth,

with

terminal

Spring

of

cushion

drive

Spring,

return,

of

kicks

tarter

Grummet

for

electric

cables

on

coil

support

Bush,

starter

Housing

slotted

Part

Number

12143

12170

12501

12680

13111

13973

14110

14180

14501

14651

14652

14734

14739

14761

15327

15388

15429

15549

15550

15902

15907

17019

17098

17123

17615

18523

18524

18525

18526

53105

S.

1208

S.2314

S.

3055

S.3058

S.3105

S.3108

S.

3110

bis

S.

10776

S.

10775

S.11004

S.11010

S.

12263

S.

13768

S.13815

DESCRIPTION

Washer,

shoulder,

of

outer

gear

Gear,

outer

Ball

bearing

outer,

of

gear

shaft

Shaft,

intermediate

Breaker

with

platinum

point

Protection,

rubber,

of kicks

tarter

Coil,

ignition

Selector,

gear

Terminal,

long

cable,

for coils

and

con-

denser

Stem,

selector

Bush,

guide,

of

selector

stem

Gear,

multiple

Drive

cushion,

g.

a.

(Parts

n. 11100 -12170

-12143 -14734 -

S.

10776 -14761)

Washer,

plate,

of

cushion

drive

springs

Cover,

fan

casing

Casing,

fan

Screw,

contact,

with

platinum

p0int

Gear,

low

speed

Ratchet

Ring, elastic, for

inspection

cover

Flange,

female

spline,

with

bolt

Kickstarter

Shaft,

gear

Shaft,

gear,

g.

a.

(Parts

n. 17098 -14652 -

S. 13768 -8268 -14651 -14180 -8267)

Gear.

high

speed

Flywheel

Magneto

wits coil

(Parts

n. 18524

-8220)

Coils,

magneto,

with

support

(Parts n.

14110 -

603

-12549 -619 -12553 -

625-

622 -

13111

-

604

-624 -620 -627 -628

-15429 -607 -682 -610 -605 -11556 -

10788 -

S.

3105 -8219 -609)

Coil.

low

tension

CoiL

low

tension,

Washer,

spring

for

securing

coils

Nut for

securing

intermediate

shaft

Nut,

castle,

for

securing

wheelan

gear

shaft

Washer,

plain,

for 292

screw

Washer.

plain,

for

S.

1208

nut

Washer,

spring,

for 292

screw

Washer,

spring,

for S. 1208

nut

Washer,

spring,

for 2442

nut

Rivet for

securing

plate

washers

Rivet for

securing

cam

to

flywheel

Washer,

tab,

for fan

locking

screw

Plate.

tab,

for kicks

tarter

bolts

Screw,

fan

locking

Washer

Washer,

plain,

for S.2 314

nut

-

15-

----14232

----1423S

14237

~

'\

S.12006

"

PARTS

UST

FOR ENGINE

Carburettor

-Air

Cleaner

-

Gear

Shifter

DESCRIPTION

DESCRIPTION

Part

Number

J

Part

Number

-1----

---1--

__

2121

2489

2506

2508

2600

Screw

lor

securing

gear

shifter to

crank-

case

Pivot of roller

carrying

stirrup

Socket.

low

tension, for

earth

and

lighting

cables

Cap,

rubber,

lor low

tension

socket

Cap,

lastening,

olluel

inlet

pipe

2601

2602

2603

2604

2606

2610

2611

Packing

of

inlet

pipe

Pipe,

fuel

inlet

Filter, fuel

Screw

for

securing

float

chamber

cover

Spring

of throttle

slide

Jet.

maximum

Screw,

adj

uster,

for throttle

slide

-16-

PARTS

UST

-

Continued

ENGINE

Carburettor -Air

Cleaner

-

Gear

Shifter

DESCRIPTION

Packing

for

air

cleaner

Packing

between

air

cleaner

case

and

throttle

cable

support

Atomizer

with

idling

jet

Needle,

taper

Clip for

taper

needle

Rod,

hook,

of

throttle

slide

Slitie,

throttle

Plug,

slotted,

for

hook

rod

Slide,

throttle,

with

hook

rod

(Parts

n.

14232

-

14233

-

14234

-

14235

-

14236)

Cover,

mixing

chamber

Terminal.

pick-up

Rocker,

throttle

cable

Support,

throttle

cable

(Parts

n.

13990

-

13991

-

14577

-

S.

12012

-

S.

3104

-

2748

-

2613

-

2612

-

12340)

Carburetor

with

throttle

cable

support

and

rocker

(Parts

n.

13988

-

14579

-

12338)

Plate,

notched,

of

gear

shifter

Shifter,

gear,

g.

a.

(Parts

n.

4475

-

S.

3206

-

S.

3204

-

2489

-

31515

-

13885-

S.

13010

-

31514

-

31512

-

15370-

13883

-3(517)

Flange,

gear

shift

Lever,

gear

shifting

Roller,

control,

gear

shift

Spring

of

roller

carrying

stirrup

Nut for

securing

intake

pipe

Washer,

spring,

for

2748

crew

Washer,

spring,

for S.

1007

nut

Split Pin

on

13885

pin

Split Pin

on

2489

pivot

Split Pin for

gear

shifting

skid

Nut.

jam,

for

12080

screw

Pin,

taper

Nut for

2748

screw

Split Pin for

securing

outer

wall

Packing

between

pick-up

terminal

and

crankcase

14142

14194

14231

14232

14233

14234

14235

14236

14237

14580

14238

14427

14577

14579

15370

15496

31512

31514

31515

31517

S.1007

S.3104

S.3107

S.

3201

S.

32C6

S.

32G6

S.

12CD6

S.13010

::J.120i2

S.12774

S.

14011

II

Part

Number

DESCRIPTION

Screw,

cable

stretcher

Nut,

jam,

of

cable

stretcher

screw

Tickler

Clip, tickler

Spring, tickler

Cover, float

chamber

Packing of float

chamber

cover

Float

Valve,

needle,

of float

Screw,

clamp

Clamp

Body,

carburetor

Screw,

rocker

Cap,

oil filling

Skid,

gear

shifting

Gauze

Cover,

dust.

between

chassis

baffle

and

intake

pipe

Screw,

locking,

for

12079

slotted

housing

Stud for

securing

air

cleaner

to

carburetor

Support.

throttle

cable

Packing

between

cylinder

and

intake

pipe

Air Cleaner, g.

a.

(Parts

n.

13808

-

100

10

-

S.

12774

-

13803

-

14142

-

13809)

Silencer for

air

cleaner

case

Air Cleaner

with

inserts

Cover,

air

cleaner

Nut.

wing

for

12338

stud

Stirrup,

roller

carrying,

of

gear

shifter

Pin, roller

carrying,

of

gear

shifter

Pipe,

intake

Carburetor,

Dell'Orto

TA

17

B

Type

(with-

out

throttle

cable

support)

(Parts

;

n.

26CO

-

2601

-

2602

-

2615

-

2616

-

2617

-

2603

-

2618

-

2619

-

2620

-

2621

-

2622

-

2623

-

2624

-

2610

-

2611

-

14231

-

14237

-

2606

-

2604

-

14238)

Screw,

stop,

of throttle

slide

Spring for

13990

screw

Part

umber

2612

2613

2615

2616

2617

2618

2619

2620

2621

2622

2623

2624

2748

2990

4475

10010

11249

13990

13991

12080

12338

12340

12358

13800

13803

13808

13809

13830

13883

13885

13944

13988

----l------------Ii

I

I

I

I

I

'I

I'

;1

'I

I,

II

II

I

I

I

I

I

I

I

I

i

-17-

19262

C/1f~

~

\

19816

'"

---

.

~~JJ1:

1

19378

"111

117511

17021

PARTS

LIST

FOR CHASSIS

'Fuel Tank -

Saddle

-Tool Box -Bonnet

Part

Number

DESCRIPTION

Part

Number

DESCRIPTION

2319

2383

2917

2939

2940

2941

2944

3142

3221

3663

3979

4433

4435

5082

9433

9640

9641

10055

10984

11032

11128

11166

11177

11242

Packing of filler

cap

Washer, plain, for

S.

1008

nut

(rear)

Pivot, hinge, of

carburetor

side

shutter

Lever, lock,

of

tool

box

shutter

Spring of tool

box

shutter

Pin for 2939 lock

lever

Pivot, hinge,

of

tool

box

shutter

Rivet for

securing

lock

on

engine

bonnet

Strap,

pipe

fastening

Rivet for

securing

12115

basin

Packing

between

chassis

and

fuel

tank

Pivot

Screw, tie, of filler

cap

Rivet for

securing

13481

hinge

Nut for

securing

fuel

tap

Cup, settling, of

gasoline

strainer

Fastener of

settling

cup,

with

inserts

Nut, wing, for filler

cap

Pin, lower, for

securing

front

spring

to

saddle

Rivet for joining

support

gussets

of

saddle

Spring, return, of

carburetor

side

shutter

Lock

of

engine

bonnet

Spring, wire, for 11728 frame

Gusset,

connection

11299

11580

11653

11728

11751

11752

11760

12115

12154

12218

12219

12742

13481

13613

13614

13618

13820

13821

13835

13836

13876

13879

Wire,

connection,

between

lever

and

strangler

Lever,

strangler

control

Hook,

purse

hanging

Frame,

hinge

carrier,

of

engine

bonnet

Strip,

rubber,

for

engine

bonnet

Strip,

rubber,

for tool

box

Buffer,

stop,

of

carburetor

side

shutter

Drip

pan

for

outflowing

fuel

mixture

Washer,

support

of

package

carrier

Spring

for

supporting

canvas

roll

Hook

for

canvas

roll

support

springs

Shutter, tool

box,

with

inserts

Hinge, for

engine

bonnet

Gusset,

saddle

support

Spring,

conical,

rear

left

hand

side

Pivot for

joining

11242

gusset

to

saddle

frame

Gusset,

spring,

for locking fuel

tank

Buffer,

rubber.

for 13820

spring

gusset

Flange

Packing

between

fuel

tap

and

threeway

cover

Filter, fuel,

with

inserts

Clip,

spring,

of fuel filter

-

18-

PARTS LIST -

Continued

CHASSIS

Fuel

Tank -

Saddle

-Tool Box -Bonnet

Part

Number

13963

14162

15011

15012

15098

15123

15464

15466

15467

15900

16724

16764

16779

16994

17021

17170

17337

17338

17402

17532

18474

18946

19262

19268

19269

19271

DESCRIPTION

Spring, conicaL

rear

right

hand

side

Tank, fueL

with

inserts

Tap,

fuel

Washer,

plain,

for

9433

nut

Sheath,

rubber,

for

15464

control

rod

Pipe,

rubber,

from

gasoline

strainer

to

carburetor

Rod, fuel

tap

control

Cover,

three-way

Split Pin for

15464

control

rod

Tap, fueL

with

gasoline

strainer

(Parts

n.

9433

-

15012

-

15013

-

S.

10011

-

13835

-

15011

-

13836

-

9638

-

13876

-

13879

-

9640

-

9641

-

15466

-

15464

-

15467)

Cap,

filler, of fuel tank,

with

inserts

Packing for

gasoline

strainer

Packing

between

fuel

tap

and

tank

Carrier,

package

Tank, fueL

with

tap

and

filler

cap

(Parts

n.

2319

-

4433

-

10053

-

10055

-

4435

-

S.

3212

-

14162

-

15098

-

15900)

Saddle,

complete

Holder,

rear

license

plate

Plate, for

license

plate

holder

Spring, front of

saddle

Plate,

name

«

Allstate»

Transfer,

indicating

gas-oil

ratio

of fuel

Buffer,

rubber,

for

bonnet

lock

Chassis

of

motor-scooter,

with

inserts

Shutter,

carburetor

side

Plate,

number,

on

carburetor

slide

shutter

Washer

under

wire

springs

Part

Number

19378

19816

S.

1004

S.

1006

S.1006

:S.1008

S.II05

I

S.

3058

S.3105

S.3106

S.3106

S.

3204

S.

3208

S.3212

S.IOOII

S.

IOD26

S.

10762

S.

10770

S.10781

S.

12259

S.

12273

S.

13760

S.

13763

S.

13793

S.

13829

DESCRIPTION

Bonnet,

engine,

with

inserts

Box, tooL

with

shutter

(Parts

n.

12742

S.

3204

-

2944

-

2939

-

2941

-

2940)

Nut for

S.

12273

bolt

Nut

on

10984

pin

Nut

for

securing

13481

hinge

to

11728

frame

Nut for

securing

saddle

Nut

Washer,

plain,

for

13618

pivot

Washer, lock

Washer,

spring,

on

10984

pin

Washer,

spring,

for

S.

1006

nut

Split pin,

on

2944

hinge

pin

Split Pin for

13618

pivot

Split Pin for

supporting

tie

screw

Screw

for

securing

13835

flange

Screw,

upper,

for

securing

front

spring

to

saddle

Rivet for fixing

11751

rubber

strip

and

18946

buffer

Rivet for

securing

11728

frame

to

engine

bonnet

Rivet for

19269

name

plate

Bolt, for

license

plate

holder

Bolt~rsecuring~clbox

Washer,

plain

Plate,

strengthening

Washer,

plain,

for S.

1004

nut

Washer,

plain,

for

rivets

securing

name

plate

-

19-

~=

~-'

~--

..

"

0--J:HtO

~----S.Dl'l1

~~=

PARTS

LIST

FOR CHASSIS

Silencer

-

Engine

Bracket -Rear

Suspension

-Strips

Part

Number

61

2035

2036

2040

2083

2444

2957

3135

3197

5943

6281

6285

6290

6291

6293

6294

6295

6297

6359

DESCRIPTION

Clip,

spring,

for

brake

jaws

Link.

rear

brake

Bolt

for

securing

cable

to

Adjusters

of

rear

brake

and

clutch

control

cables

Pin

for

rear

brake

links

Nut.

jam.

for

rear

brake

and

clutch

adju-

sters

Bolt

for

securing

stand

fastener

Rivet

for

securing

brake

lining

Spring,

return,

of

brake

jaws

Plate,

upper.

for

17432

spring

Anchorage,

bottom,

of

rear

suspension

Nut.

spacer

of

shock

absorber

Pin.

anchoring,

for

shock

absorber

Washer,

spacer

Spring,

upper

Circlip

Spring

of

seal

washer

Spacer,

bottom

Bush,

bottom,

rubber,

of

shock

absorber

Part

Number

6360

7881

7884

7886

7888

7890

12403

12404

13406

14836

14850

15008

16852

16995

16996

17012

17013

DESCRIPTION

Bush,

top,

rubber,

of

shock

absorber

Jaw,

brake,

with

lining

Arm,

rear

brake

control

Pad

Axle.

cam,

of

rear

brake

Lining,

brake

Spring,

return,

of

stand

leg

(right

hand

side)

Spring,

return,

of

stand

leg

(left

hand

side)

Tube,

protection,

of

shock

absorber.

with

inserts

Buffer,

stop,

of

engine

bracket

Silencer

Shoe,

rubber,

for

center

stand

Washer,

thrust,

for

32690

packing

Packing

between

16996

anchorage

and

chassis

Anchorage,

top,

of

rear

suspension

Leg

stand,

with

shoes,

g.a.

(Parts

n.

15015

-

17013

-

15008)

Leg,

stand,

with

inserts

-

20-

This manual suits for next models

2

Table of contents

Other Allstate Scooter manuals

Popular Scooter manuals by other brands

Razor

Razor Graffiti owner's manual

Nils Extreme

Nils Extreme Fliker 14619 user manual

Pride Mobility

Pride Mobility Mini Crosser owner's manual

Shoprider

Shoprider mobility scooter user guide

Olsson and Brothers

Olsson and Brothers STROOT BONNEVILLE 5 User guide and guarantee

Helvei

Helvei Smartmove ALLROAD user manual