ALLTEC TerraStreamer TSP-20 Datasheet

TerraStreamer®

Early Streamer Emission Terminals

Installation Instruction Guide

MODELS: TSP-20 | TSP-30 | TSP-40 | TSP-50 | TSP-60 | TPV-60

2 3

TerraStreamer®Early Streamer Emission (ESE) Terminals

Installation Guide

Table of Contents

Warranty............................................................................................... 2

Supplied Items..................................................................................... 3

TerraSteamer®Early Streamer Emission (ESE) Terminals.................. 4

Features..................................................................................................................................4

Protection Performance ...................................................................................................5

Protection Radius - Additional Levels..........................................................................5

Positioning & Height............................................................................ 6

TerraSteamer® ESE Terminal ............................................................................................6

Preferred Installation Points............................................................................................6

Pre-Installation Checklist .................................................................................................7

Important Safety and Other Considerations.............................................................7

Ground System Congurations .....................................................................................8

1. Installation of the Grounding System............................................. 8

Down Conductor Routing Guidelines.........................................................................9

Number of Down Conductors and Grounds.......................................................... 10

Adaptor................................................................................................................................ 10

2. Down Conductor Installation........................................................ 11

3. Termination of the Down Conductor............................................ 12

Lower End........................................................................................................................... 12

Upper End........................................................................................................................... 13

4. TerraStreamer®ESE Terminal Installation .................................... 14

Guyed FRP Masts.............................................................................................................. 14

Metallic Masts.................................................................................................................... 16

5. Lightning Strike Counter Installation............................................ 17

6. TerraStreamer® ESE Post Installation Verication ....................... 18

7. Inspection/Maintenance............................................................... 18

Schedule ............................................................................................................................. 18

Checklist.............................................................................................................................. 18

Disclaimer .......................................................................................... 19

Warranty

The warranty is limited to the cost of replacement of equipment providing it has

been installed and/or certied by Alltec or its authorized distributor. Alltec shall

in no event be responsible for any loss of business or prots, downtime or delay,

labor, repair or material costs or any similar or dissimilar consequential loss or

damage incurred by the buyer. All other costs such as: insurance premiums,

freight charges, loss of prot, and re-installation of equipment are not included.

Also specically excluded from the warranty is any responsibility for other direct

or indirect damages, injuries or death.

NOTE: Alltec shall in no event be responsible if the products have

not been stored or used in accordance with its specications and

recommended procedures.

Do not attempt to install lightning protection components or systems

during periods of lightning activity!

3

Supplied Items

WARNING

THERE IS A SAFETY ADVISORY

AGAINST STANDING WITHIN A

PROXIMITY OF 12 FEET (4 METERS)

OF THIS LIGHTNING PROTECTION

SYSTEM WHILE AN ELECTRIC STORM

TerraStreamer® TSP

ESE Terminal Adaptor

Warning Label (2)

Warranty Card

WARRANTY REGISTRATION AND STATEMENT OF COMPLIANCE

The warranty is limited to the cost of replacement of equipment providing it has been installed and/or certified by ALLTEC or its authorized

distributor. ALLTEC shall in no event be responsible for any loss of business or profits, downtime or delay, labor, repair or material costs or

any similar or dissimilar consequential loss or damage incurred by the buyer. All other costs such as: insurance premiums, freight charges,

loss of profit, and re-installation of equipment are not included. Also specifically excluded from the warranty is any responsibility for other

direct or indirect damages or death. ALLTEC shall in no event be responsible if the products have not been stored or used in accordance with

its specifications and recommended procedures (See complete warranty statement for further details).

TerraStreamer®products require project specific lightning protection design and installation. Inappropriate use of these products, or use

in designs not provided by or approved by ALLTEC will invalidate performance characteristics and all Warranty Provisions.

TerraStreamer®ESE Terminals are guaranteed against defects in workmanship and materials for a period of 5 years from the original date

of sale when purchased from ALLTEC or one of its authorized distributors. TerraStreamer®ESE Terminals shall be installed and used only

as indicated in ALLTEC’s product installation manual and according to UNE 21 186 or NF C 17-102 standards. Improper installation,

mishandling, misapplication or other failure to completely follow ALLTEC’s instructions and warnings may cause product malfunction,

property damage, serious bodily injury or death. TerraStreamer®systems should only be installed during storm free periods.

Neither TerraStreamer®ESE systems nor any other lightning protection system can provide 100% protection from lightning. We refer to

the French Standard NF C 17-102: “As in the case with anything related to the natural elements, a lightning protection system designed and

installed in accordance with the standard, cannot guarantee absolute protection to structures, persons or objects: however, applying this

standard will significantly reduce the risk of protected structures being damaged by lightning.”

System Installed - Model Type:

Serial #s:

# of Terminals:

Type, size and length of down conductor:

Protective Radius Obtained:

NF C 17-102

UNE 21 186

Ground Resistance Reading:

Failure to perform installation and maintenance as per Alltec’s recommendations automatically

voids all warranty conditions.

For Warranty registration, please complete the above and mail to ALLT EC within 30 days of installation (see reverse side)

Name of Project:

Address:

Type of Structure:

Installation Date:

Installation Contractor:

Inspected by:

Inspection Date:

Alltec Distributor:

Important Notice:

TerraStreamer®ESE System Project Information

WARNING

WARRANTY

Quality Certificate (Front)

Warranty Statement (Back)

www.alltecglobal.com

ALLTEC - Solution Providers for an EnergizedWorld | 64 Catalyst Drive | Canton, North Carolina 28716 USA | +1.828.646.9290

© 2014 ALLTEC

QUALITY CERTIFICATE

Quality Control Verification Parameters:

TSP-20

Company Stamp:

Signed: Date:

Triggering Time Advance (∆T) = 22µs Accredited High Voltage Testing:

Product Assembly Verification:

Packaging Quality Verification:

Installation Guide Supplied:

Warning Labels (Qty 2) Supplied:

Warranty Certificate Supplied:

Results & Serial Number Archived:

TSP-30

Triggering Time Advance (∆T) = 32µs

TSP-40

Triggering Time Advance (∆T) = 44µs

TSP-50

Triggering Time Advance (∆T) = 55µs

TSP-60

Triggering Time Advance (∆T) = 61µs

Serial No:

Model:

TerraStreamer®

EARLY STREAMER EMISSION TERMINALS

This is to certify the above product is manufactured to a design achieving a triggering time (ΔT) as

stipulated above in accordance with NF C 17-102 and UNE 21 186.

This document further certifies that this unit meets or exceeds all Quality Control parameters as

established by Alltec, and that Electrical Testing according to the above International Standards has

independently verified performance, as documented by a fully Accredited Laboratory.

4 5

TerraStreamer®Early Streamer Emission (ESE) Terminals

The TerraStreamer® ESE Lightning Terminal is an externally mounted, proactive,

structural lightning protection device and is designed to activate itself in the

moments directly preceding an imminent direct strike. The installation of a

TerraStreamer® ESE Terminal combines the best advantages of two systems: the

direct path to ground of a conventional lightning protection system, and state-

of-the-art ESE technology employed in the TerraStreamer®’s internal design.

TerraStreamer®ESE Terminals are designed to react to the rise in the ambient

electrical eld which is present with approaching thunderstorms, and become

active only during storm activity.

• The system operates without the need for external power supply or spare

parts for standard operation.

• To keep the TerraStreamer®ESE Lightning Protection System operating at

optimum levels it needs to be maintained and inspected regularly.

Features & Benets

• Patented Technology

• NF C 17-102 and UNE 21 186 tested and certied

• Lightweight and low wind loading

• Reliable performance in all weather conditions

• Suitable for corrosive environments

• Available in ve models for numerous applications

• Economical and easy to install

• No internal electronics or power supply

TYPICAL APPLICATIONS

• Distribution Warehouses

• Industrial Plants

• Apartment Buildings

• Shopping Malls

• Shipping Terminals

• Other Large Area Structures

5

Protection Radius Additional Levels

Level 1+:

The ESE system at level of protection

1 is additionally connected to the

metal structure or reinforced bars

of the buildings used as natural

downconductors in addition to the

dedicated downconductors included

in the ESE system. Connection to

the natural downconductors shall be

made at roof level and ground level.

Level 1++:

The roof is protected at level 1+ with

an ESE having a radius of protection

reduced by 40% compared to achieve

a complete protection of equipments

on the roof against direct lightning

strikes.

Protection Performance

Protection Areas

H(m) TSP-20

(Rp)

TSP-30

(Rp)

TSP-40

(Rp)

TSP-50

(Rp)

TSP-60

(Rp)

Level I

2 16 20 25 30 32

3 24 30 37 44 48

4 31 40 50 59 63

5 39 50 62 73 79

6 40 50 62 74 79

8 40 51 63 74 79

10 41 51 63 74 80

Level II

2 18 23 28 32 35

3 27 35 42 48 52

4 36 47 55 64 70

5 45 58 69 80 87

6 47 58 69 80 87

8 47 59 70 81 88

10 48 60 71 81 88

Level III

2 22 27 32 37 39

3 33 40 48 56 59

4 43 53 64 74 78

5 54 66 80 92 97

6 54 66 80 92 98

8 56 68 81 93 99

10 57 69 82 94 99

Level IV

2 25 30 36 41 43

3 37 45 53 61 64

4 49 59 71 81 86

5 61 74 88 101 107

6 62 74 89 102 107

8 63 76 90 103 108

10 65 77 91 104 109

The standard protection radius Rpof the TerraStreamer®is linked (according to

NF C 17-102 standard) to ΔT, to the protection levels I, II, III, or IV and to the

height of the TerraStreamer® above the protected structure (H, dened by NF C

17-102 as a minimum of 2 m). The NF C 17-102 standard includes four levels of

protection.

Upward Streamer

TerraStreamer®

Rp h

6 7

Positioning & Height

TerraSteamer® ESE Terminal

The TerraSteamer® ESE Terminal tip should be at least 2 meters higher than the

area that it protects, including antennae, cooling towers, roofs, tanks, etc.

If the external installation for a given structure comprises several ESE Terminals

these are to be interconnected by a suitable conductor, unless it has to be

routed over a structural obstacle (cornice, parapet wall) with a positive or

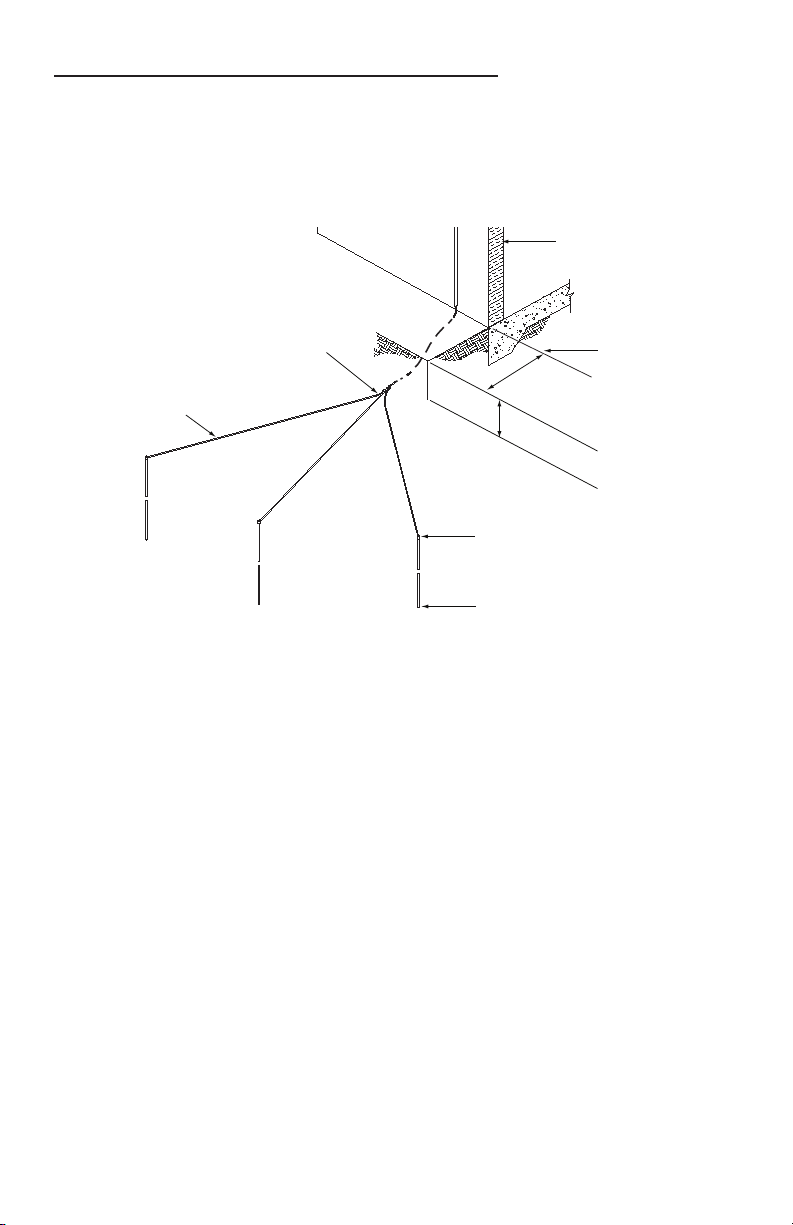

negative level difference in excess of 1.5m (see Fig. A).

When ESE Terminals protect open areas such as playing elds, golf courses,

swimming pools, camping sites, etc., they should be installed on specic

supports such as tower mast, lightning poles, pylons, or any other nearby

structures which enable the ESE Terminal to cover the area to be protected.

The ESE Terminal height may be increased by means of an elevation mast. If the

ESE Terminal is steadied by conductive guy lines, these should be connected

at the bottom attaching points to the down conductors by means of suitable

conductors.

Preferred Installation Points

The architectural features favorable to the ESE Terminal installation should be

taken into account during the lightning protection system design.

Usually, these features are high structural points, such as:

• equipment rooms on at roofs

• gables

• metal or masonry chimneys

< 1.5m < 1.5m

≥2m ≥2m

Fig. A - Positioning & Height

7

Pre-Installation Checklist

Determine the best location for ESE Terminal(s), then the mounting method

(tower, mast, structure, etc.) and the optimum routing of down conductor(s).

Locate area(s) for grounding system installation and determine where the

new system will be connected to any existing grounding system and metal

bodies of conductance, etc.

Verify that all parts and system components are compatible (dissimilar

metals not allowed) and in good condition.

Review installation plans, structural drawings, site drawings and mast

erection instructions.

Read this Installation Guide and familiarize yourself with all of the system

components and functions.

Be sure that all tools and equipment required for system installation are

available and in good working order.

Follow all industry guidelines and local/site requirements for safety and

safety equipment.

Important Safety and Other Considerations

• If the TerraStreamer®ESE Terminal needs to be erected prior to connection

to the grounding system, or immediate connection is not possible, connect

the lower end of the down conductor to structural steel reinforcing or other

suitable grounding point.

• Before installation of the grounding system, consult site drawings of

underground services so that these are not damaged during installation of

the grounding system.

• Where separate grounding systems exist, i.e.: structure, power,

communications and/or lightning protection, they need to be bonded

together to form an equipotential ground plane. This will help prevent

ground potential differences arising under direct/indirect lightning strikes.

• Before service ground bonding takes place make sure proper authorization

is obtained.

• Bonding cable must be 70mm2 (2/0AWG) minimum, depending on local

standards. It may be necessary to use a grounding bus bar which bonds all

grounds to the same potential under transient conditions.

• All local applicable standards, regulations and requirements necessarily

apply.

• It is the responsibility of the customer/installer to label inspection/test wells

or grounding systems to local requirements.

Stay clear of any overhead power lines.

8 9

Ground System Congurations

A ground resistance of less than 10Ωis required for proper operation of the

TerraStreamer® ESE Terminal. If, due to space constraints or high soil resistivity,

it is not possible to readily install a grounding system as recommended,

alternate grounding methods and designs shall be considered.

In order to meet safety and grounding system resistance requirements, Alltec

recommends the installation of a purpose designed and installed grounding

system such as the radial (crow’s foot) design or Delta design. Other

congurations and materials are allowed, and may be required due to local

conditions.

NOTE: Alternate grounding methods and designs are allowed by NF C

17-102, and Alltec is capable of designing a grounding system to meet

specic resistance goal in any type of soil.

DD

P

P

B

B

D: Down-conductor

B: Building foundation loop gr

ound

P: Grounding system

Radial Delta

Fig. B - Recommended Grounding Congurations

1. Installation of the Grounding System

Each radial should consist of a trench (approx. 50cm deep x 20cm wide x

10m length).

A ground rod should be driven at the end of each radial.

The use of copper conductor is recommended, with a cross sectional area

of not less than 50mm². Tin-plated copper is recommended for its corrosion

resistance.

All rods should be interconnected through the use of 1/0-19 strand bare

conductor and ground rod clamps or TerraWeld® exothermic welding. The

use of the TerraWeld® exothermic welding process is a safe and efcient

way of providing a permanent connection between conductors. TerraWeld®

connections will not rust or corrode over time.

ESE Grounding Systems should utilize TerraDyne® Electrolytic Ground

Electrodes and TerraFill® ground enhancement backll to provide the

desired low resistance ground system and stabilize low contact resistance

at locations where the native soil has relatively high resistivity, low ground

9

moisture and/or where installations have limited footprints.

A ground inspection/test well should be installed where the end of the down

conductor terminates to the grounding system. This gives an access point

for disconnection and future testing.

Each down conductor should be provided with a means of disconnect for

testing. These disconnect/test terminals may be located 2m above ground

level and should be marked “Lightning Conductor” and the symbol:

When the building or the protected structure has a foundation earth

termination system for the electrical system, the ESE system earth

termination systems should be connected to it with a standardized

conductor.

The ESE system earth termination components should be at least 2 m

distant away from any buried metal pipe or electrical conduit, in case these

conduits are not electrical connected to the main equipotential bonding of

the structure.

Down Conductor Routing Guidelines

Bare or tin-plated copper conductor is recommended for use as the down

conductor, although building steel and alternate materials are also allowed. NF

C 17-102 requirements should be strictly adhered to as regards materials and

design requirements for number and placement of TerraStreamer®ESE Terminals

and down conductors.

• The route of the down conductor should be as set out in the original design.

Ensure no structural changes such as new antenna, mast installations, air

conditioning towers or ducting has been installed.

• DO NOT double the down conductor back against itself after changes of

direction (i.e. 180° bend).

• The down conductor may be installed internally or externally on the

structure; however internal routing may reduce effectiveness and induce

voltage surges into structures.

• The down conductor should be installed as close (ush) as possible to the

structure.

• Minimize the number of bends and use the most direct route to the ground

possible.

• Ensure recommended bend radius is maintained, never less than 20cm.

• If the down conductor has to cross other services make sure it crosses at

right angles using a conduit that extends at least 1m past either side of the

existing service.

• The down conductor should be protected from damage at the lower end by

installing a protective tube/conduit up to 2m from ground level.

• Provide adequate separation between down conductors, preferably

opposite building corners.

10 11

Number of Down Conductors and Grounds

For a non-isolated ESE system, each terminal should be connected to at

least two (2)down conductors. For a better current distribution, the two paths

to ground should be situated on two different facades. If, due to physical

constraints, it is not possible to route the down conductors on two different

facades, an alternate installation method should be considered.

When many ESE terminals are located on the same building, the down

conductors shall be mutualized on a case by case basis, but a minimum of one

down conductor is mandatory for each ESE terminal.

When a natural component of a structure is utilized as a down conductor,

at least one of them must be a dedicated down conductor complying with

standard requirement.

In case of an isolated ESE system, at least one down conductor is needed for

each ESE terminal.

Adaptor

Down conductors should be attached to the TerraStreamer®ESE Terminal using

the supplied adaptor as per Fig. D , and as recommended in sections following.

Fig. D - Adaptor

11

2. Down Conductor Installation Guidelines

Bare or tin-plated copper conductor is recommended for use as the down

conductor. The route of the down conductor should be as set out in the

original design. Ensure no structural changes have been implemented.

The use of copper conductor is recommended, with a cross sectional

area of not less than 50 mm². Tin-plated copper is recommended for its

corrosion resistance.

The copper should be of a grade normally used for commercial electrical

work. Do not use insulated coaxial cable.

The most direct path to ground is recommended, avoiding sharp bends.

Minimize the number of bends and use the most direct route to the ground

possible.

Ensure recommended bend radius is maintained, never less than 20 cm.

DO NOT double the down conductor back against itself after changes of

direction (i.e. 180° bend).

The down conductor should be installed as close (ush) as possible to the

metal tower.

If the down conductor has to cross other services make sure it crosses at

right angles using a conduit that extends at least 1m past either side of the

existing service.

Suitable fasteners should be installed to secure all down conductors. Down

conductors should be fastened on the basis of one point per meter. Avoid

trip hazards

Each down conductor should be connected to the grounding system.

The Warning Labels supplied with TerraStreamer®ESE Terminals should be

installed in locations where personnel may be in close contact to the down

conductor(s).

Down Conductor

Do not exceed minimum

bend radius.

Mast

Mast Base

Fastener

Roof Edge

Fig. E - Down Conductor Routing Detail

12 13

3. Termination of the Down Conductor

Lower End

Down conductor(s) should be directly connected to the grounding system

through the use of a suitable ground rod clamp or by using TerraWeld®

exothermic welding.

Exterior Wall

1m Minimum

Ground Rod Clamp or

Exothermic Weld

Ground Rod

Minimum 16mm Diameter x 3m length

50cm Min.

Finished grade

Cable Splicers or

Exothermic Welds

Three Radials

2m - 10m long

Fig. F - Down Conductor Lower End

13

Upper End

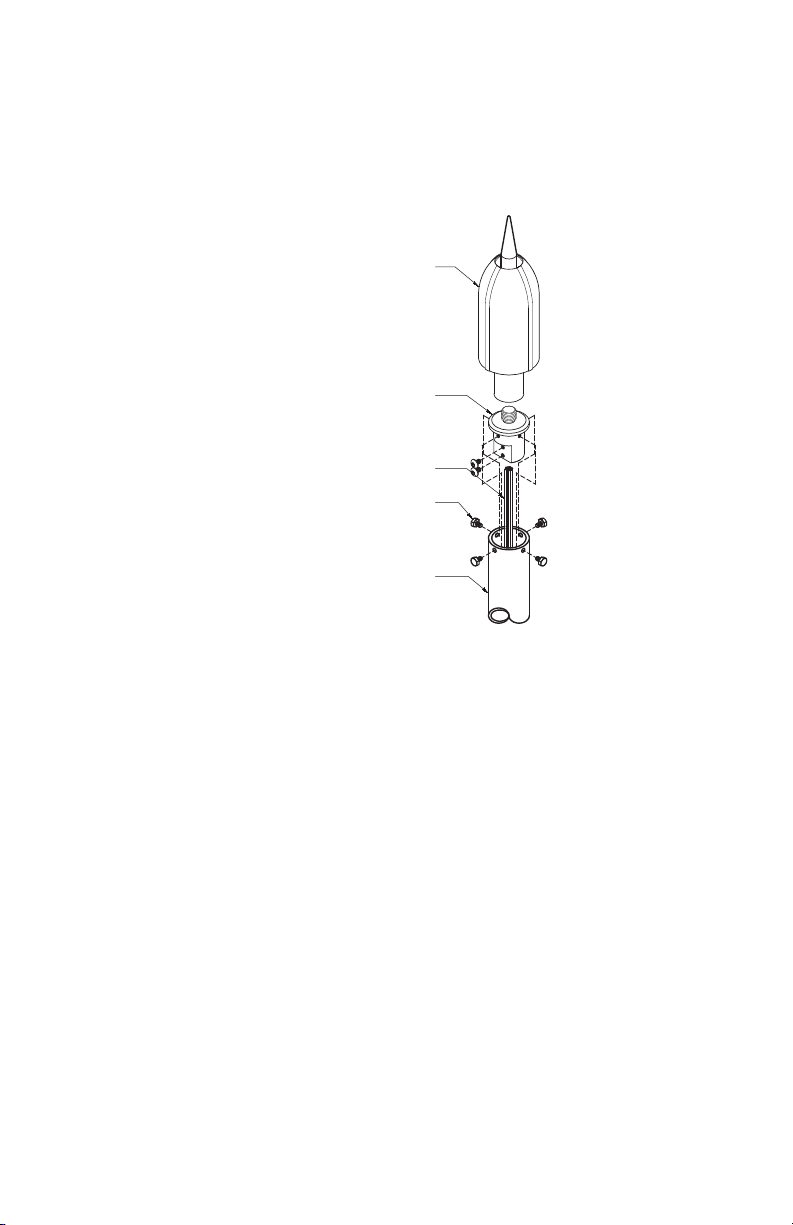

Each TerraStreamer®ESE Terminal comes supplied with the adaptor (Fig. G).

This adaptor accepts either stranded copper wire, or at copper strip.

• Round/stranded copper wire is inserted into the hole in the base of the

adaptor and secured with the two screws provided.

• Flat copper strip attaches to the external “at” side of the adaptor.

TerraStreamer®

ESE Terminal

Stainless Steel TSP to

Mast Adaptor

Down Conductor

Stainless Steel Set Screw-Type

Ø2” Tower Mast

Fig. G - Down Conductor Upper End

14 15

4. TerraStreamer®ESE Terminal Installation

Stay clear of any overhead power lines or electrical sources.

When installing the TerraStreamer® ESE Terminal, Alltec provides for two main

conguration types.

Guyed FRP Masts

When installing the TerraStreamer® ESE Terminal with an Alltec FRP mast,

refer to the supplied FRP Mast Installation Guide for assembly and installation

instructions. Other important items to remember include:

Using a crane or other suitable equipment is recommended for any

installation over 6 meters in height, or for hazardous areas such as unsafe

heights without appropriate safety railings.

It is very important to keep the mast straight during the lift to avoid

damaging the mast.

The TerraStreamer®ESE Terminal must NOT be used as a slinging point.

When lifting masts, ensure that the slings or ropes cannot damage the

TerraStreamer®ESE Terminal.

When lifting the mast, the down conductor must be tied off to the

mast to remove any strain on the down conductor’s termination to the

TerraStreamer®ESE Terminal and/or supplied adaptor.

The TerraStreamer® ESE Terminal tip must be at least 2m above any aerial,

equipment or structure on the roof. Please refer to NF C 17-102 standard or

Alltec design for specic mast/ESE height requirements.

Guy wires must be tight, but also consider roof load limitations (e.g. tighten

guying grips to no more than 7 Nm of torque).

15

Installation Examples Using FRP Masts:

TerraStreamer®

ESE Terminal

Strike Counter

Inspection Well

Grounding System

FRP Mast

Mast Base

Guy Ring

Guy Wire

Fig. H - Mid Roof location

TerraStreamer®

ESE Terminal

Strike Counter

Inspection Well

Grounding System

FRP Mast

Mast Base

Guy Ring

Guy Wire

Fig. I - Edge Location

16 17

Metallic Masts

Following installation of the TerraStreamer® ESE Terminal to a metallic mast,

it will be necessary to connect the metallic mast to a down conductor in

order to convey the lightning energy to the grounding system.

The connection between the metallic mast and the appropriately sized down

conductor should be completed by approved mechanical means or by

exothermically welding (TerraWeld®) the down conductor at a practical point

somewhere along the length of the mast.

Particular care should be taken to ensure that compatible metals are used

when connecting the down conductor to metallic masts (e.g. aluminum to

copper connections require an approved bimetallic connector).

It is important that a minimum of one third of the mast height be securely

xed to the structure to which the mast is mounted.

Installation Examples Using Metallic Masts:

TerraStreamer®

ESE Terminal

Down Conductor

Tower Section 2

Fasten 3’-0” Max. SP.-TYP.

Tower Section 1

System Disconnect

PVC Inspection Well

Copper

Clad Ground

Electrode-

TYP 3X

Tower

Base

Fig. J - ESE - Tower Mast Detail

17

TerraStreamer®

ESE Terminal

Metallic Mast

Stainless Steel Cable Ties or

Mounting Brackets

Strike Counter

Inspection Well

Fig. K - Tower Top Location

5. Lightning Strike Counter Installation

The Lightning Strike Counter should be installed at a position along the

down conductor length where it can be accessed easily for inspection.

Typically the strike counter should be installed approximately 2m from

ground level.

The strike counter should be mounted away from areas where damage/loss

may occur due to theft, vandalism or damage from nearby operations.

The strike counter can be enclosed in a security enclosure but the display

should be kept visible to allow for the checking of recorded strikes.

18 19

6. TerraStreamer® ESE Post Installation Verication

The following should be checked for quality of workmanship and compliance to

recommended installation instructions, approved design documents, and NF C

17-102/UNE 21 186 requirements:

Correct TerraStreamer®ESE Terminal model and placement for proper

zone of protection (verify model, height above structures, and radius of

protection).

Correct mast and any associated brackets and fasteners have been used

for installation.

Guying, anchor points and fastenings (if applicable).

Down conductor size, routing, and attachment points

Connection of down conductor to grounding system

Grounding system (3-Point resistance test to verify 10 Ohms or less)

Lightning Strike Counter installation is per recommended guidelines. Record

“strike count” for later comparison.

Safety and product labeling

7. Inspection/Maintenance

Alltec recommends inspection and any required maintenance to be performed

regularly and as listed below:

Schedule

• After each known lightning strike to the terminal.

• Once every twelve months minimum.

• If changes have been made to the protected structure.

Checklist

Check Lightning Strike Counter “strike count”, and compare to previous

display number.

Check Lightning Strike Counter installation for missing/damaged wires and

connections.

Check the strike counter for secure installation and record the number of

strikes, if any.

Check for any damage to the TerraStreamer® ESE down-conductor and

grounding system.

Check TerraStreamer® ESE Terminal body and tip for excessive pitting or

other damage.

Inspect the TerraStreamer® ESE Terminal and ensure that no dirt or

other matter is embedded in the air gap between the center tip and the

surrounding panel edges.

Verify that the structure to be protected has not been modied or expanded

since the last maintenance check.

Make sure that the electrical continuity of all visible conductors is correct,

19

and that no conductors or other parts have been weakened by corrosion.

Check that all rigging, mast mounts, and conductor xings are secure and

tight.

Check that all down conductors and equipotential bonds remain correctly

positioned and that they are securely attached and no damage or theft has

occurred.

All warning labels must still be in place and visible.

Disclaimer

Alltec TerraStreamer®Lightning Protection for Structures and Open Areas

Using Early Streamer Emission (ESE) Technology

“As in the case with anything related to the natural elements, lightning protection

systems, designed and installed in accordance with this standard, cannot

guarantee absolute protection to structures, persons or objects: however,

applying this standard will signicantly reduce the risk of protected structures

being damaged by lightning.” NF C 17-102 (Forward)

Neither the TerraStreamer®ESE Terminal nor any other lightning protection

system to our knowledge can provide 100% protection from lightning.

In order to provide the most effective Early Streamer Emission (ESE) Air

Terminal technology available today, Alltec TerraStreamer®ESE Terminals are

independently tested and certied to meet NF C 17-102 and UNE 21 186

standards. In addition, these modern standards have provided the applicable

information contained in this Installation Guide to correctly implement a proper

ESE system.

The NF C 17-102 and UNE 21 186 standards are “applicable to lightning

protection using early streamer emission lightning conductors of common

structures of less than 60m high and of open areas.” It is recommended that

any ESE installation strictly adhere to the general and detailed contents of

the latest editions of the NF C 17-102 and UNE 21 186 standards.

Alltec has developed the TerraStreamer®product according to

internationally recognized standards. However, Alltec does not make any

specic performance guarantees as no lightning protection system can be

100% eective.

www.alltecglobal.com

WORLD HEADQUARTERS

64 Catalyst Drive, Canton, North Carolina 28716 USA

TEL: +1.828.646.9290 | FAX: +1.828.412.4270

EMAIL: [email protected]

© 2017 ALLTEC | 420-001 | 11/22/2017

This manual suits for next models

5

Table of contents